Electronic Ovens rev. 0 _________________________________________________________________EKF 523 E UD

_________________________________________________________________________________________ page 7

2

22

2.

..

.

Instructions for the installer

Instructions for the installerInstructions for the installer

Instructions for the installer

The following instructions are aimed at the qualified installer to ensure that he carries out the

installation adjustment and maintenance operations as correctly as possible and according to

current legal regulations. Any operation must be performed with electrical power cut to the

appliance.

Before using the appliance carefully remove the special adhesive film protecting the parts in

stainless steel. Do not leave any glue residues on the surfaces. If necessary remove them at

once with an appropriate solvent.

Fitting the feet

Fitting the feetFitting the feet

Fitting the feet - The feet are inside the appliance and must be secured on the four threaded

holes on the base. If necessary the height of the feet can be adjusted by screwing or

unscrewing.

Positioning

PositioningPositioning

Positioning - Position the appliance perfectly horizontally on a table or similar support (the table

or support must be at least 85 cm above the floor). Position it at a distance of not less than 10

cm from the side and rear walls to enable natural ventilating air to circulate freely around it.

The appliance is ventilated through specific openings on the metal walls of the outer housing

and ensures efficiency and long-life. For this reason it is strictly forbidden to obstruct these

ventilation openings even partially or for short periods. Failure to observe this specific

Failure to observe this specific Failure to observe this specific

Failure to observe this specific

prohibition releases the man

prohibition releases the manprohibition releases the man

prohibition releases the manufacturer of the appliance from all responsibility and immediately

ufacturer of the appliance from all responsibility and immediately ufacturer of the appliance from all responsibility and immediately

ufacturer of the appliance from all responsibility and immediately

voids any guarantee rights for the said appliance

voids any guarantee rights for the said appliance voids any guarantee rights for the said appliance

voids any guarantee rights for the said appliance because its constructive conformity has been

voluntarily compromised. Furthermore the appliance is not suitable for embedding and for

grouped positioning with other identical appliances.

Electrical connection

Electrical connectionElectrical connection

Electrical connection - The appliance must be connected to the electrical mains according to

current legal regulations. Before making the connection make sure of the following:

-the voltage and frequency values of the power supply system match the values on the

"technical data" plate affixed on the appliance;

-the limiting valve and the system are able to support the appliance's load (see the

"technical data" plate);

-the power supply system has an adequate ea

the power supply system has an adequate eathe power supply system has an adequate ea

the power supply system has an adequate earth connection according to current legal

rth connection according to current legal rth connection according to current legal

rth connection according to current legal

regulations;

regulations;regulations;

regulations;

-a omnipolar switch with minimum between-contacts aperture of the overvoltage

category III (4000 V) sized to the load and conforming to current legal regulations is

fitted between the appliance and the mains in the direct connection to the mains;

-the omnipolar switch used for connection is easy to reach when the appliance is

installed;

-the yellow/green earth wire is not interrupted by the switch;

the yellow/green earth wire is not interrupted by the switch;the yellow/green earth wire is not interrupted by the switch;

the yellow/green earth wire is not interrupted by the switch;

-the power supply when the appliance is operating must not deviate from the rated

voltage value by ±10%;

-make sure that after inserting the power supply cord into the terminal block it does not

come into contact with any of the cooking range's hot parts;

-if the supply cable is damaged then it must be replaced

if the supply cable is damaged then it must be replaced if the supply cable is damaged then it must be replaced

if the supply cable is damaged then it must be replaced by the manufacturer or by your

by the manufacturer or by your by the manufacturer or by your

by the manufacturer or by your

technical support or by a qualified person to avoid any risk.

technical support or by a qualified person to avoid any risk.technical support or by a qualified person to avoid any risk.

technical support or by a qualified person to avoid any risk.

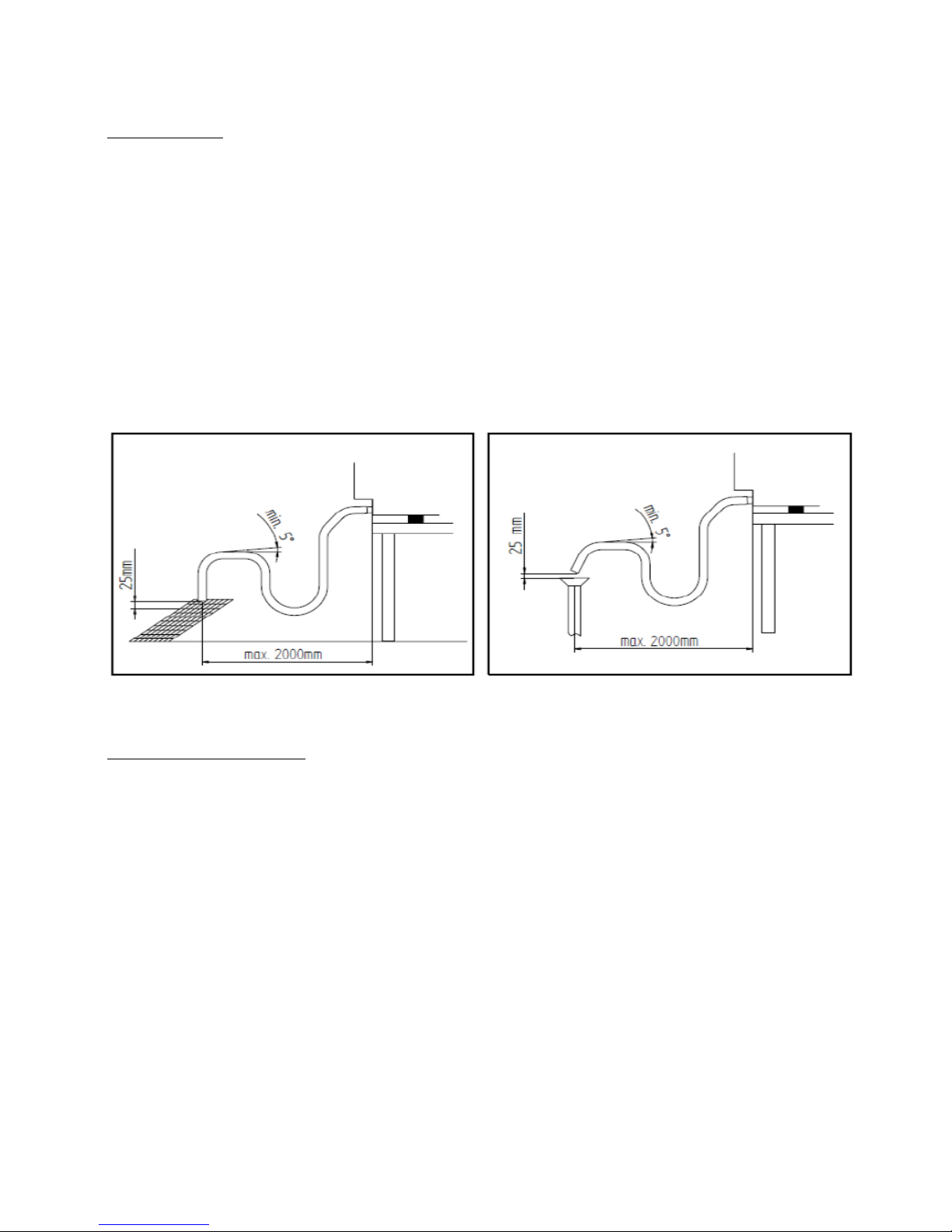

Connection to water mains

Connection to water mainsConnection to water mains

Connection to water mains - The oven must be supplied with softened drinking water with a

hardness value of 0.5 to 3°F (it is obligatory to use water softener to reduce the formation of

scaling inside the cooking chamber). The water pressure must be in the range of 100 to 200 kPa

(1.0 – 2.0 bar). If the water pressure exceeds 2.0 bar install a pressure reducer device upstream.

If the pressure is below 1.0 bar use a pressure pump to increase the level.