TECNOEKA Srl _____________________________________________________________ use and instruction manual

page. 6 __________________________________________________________________________________________

1. Description and general warnings

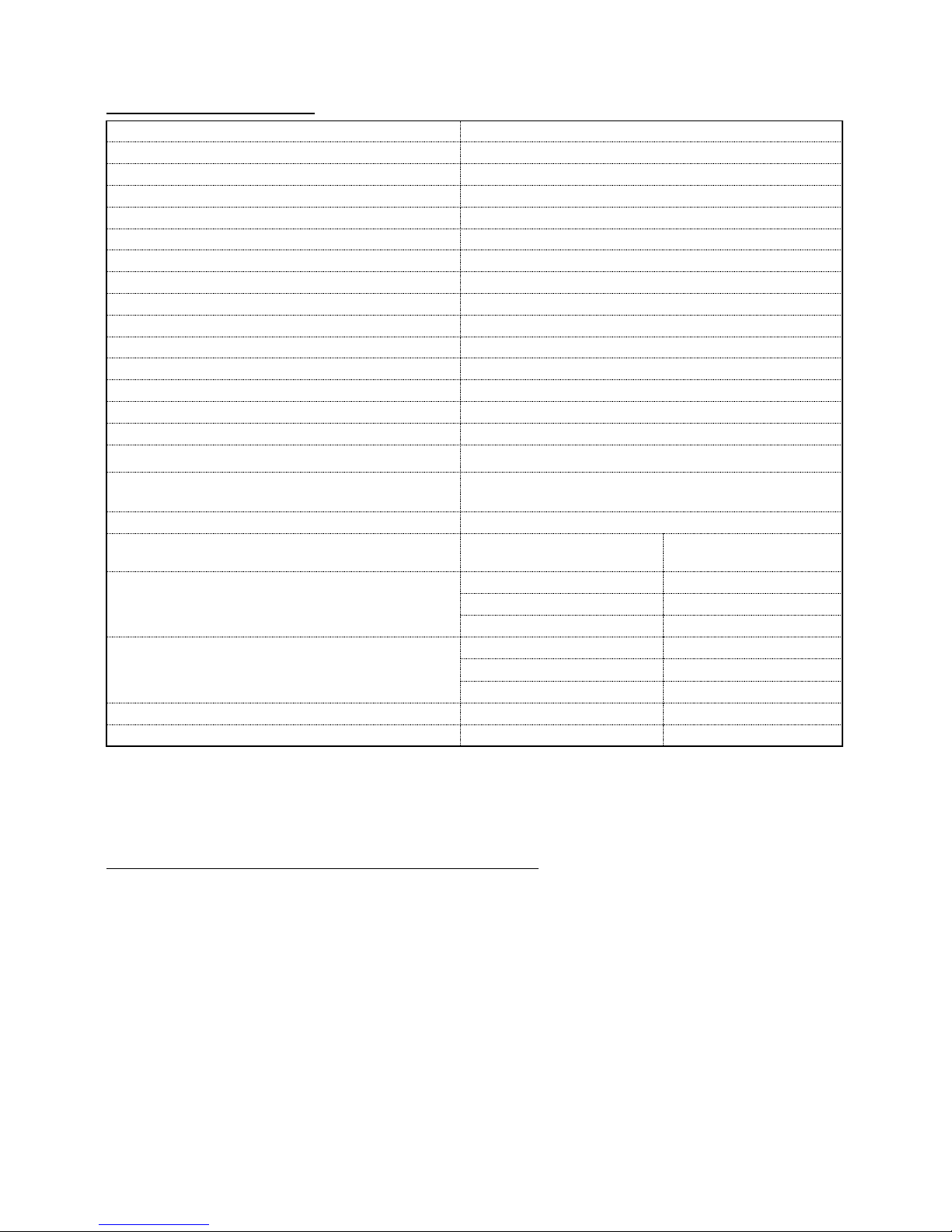

The model convector oven bears (EKF616GUD - EKF664GUD - EKF711GUD) an official CE mark,

issued by a Notified Body, entrusted with and responsible for evaluating the observance of the

essential requirements specified by Gas Directive 2009/142/EC. The oven and the quality of the

production system are subjected to regular surveillance by means of inspection checks in order

to ascertain their conformity to the type certificate specified by the above mentioned Directive.

This appliance may be marketed in all the European countries whose abbreviated reference is

present on the technical data-plate. The appliance must be installed to conform with the local

laws on the installation of electrical-gas appliance for collective use, and shall include the

accessories and functional adaptations required in the destination countries, which are

described in the original language in the use and maintenance handbook.

The oven has an atmospheric burner and a heat exchanger for heating the cooking

compartment. Heat is diffused by an internal two-way fan. The parameters relative to cooking

(times, temperatures and climate) you set electronically and appear on the digital display.

It is possible to get steam inside the oven chamber. If the burner doesn’t switch on, a red block

light: it is possible to restart safely the ingnition of burner through the reset button. If the oven

chamber overheats, a safety thermostat blocks the gas delivery and the power to the oven is cut

off; it will be possible to switch it on again only manually. The device is located on the rear of

the unit.

1.1 General warnings

-If, on receipt of the goods, the packaging is damaged, write the following on the delivery note: “I

REVERSE THE RIGHT TO CONTROL THE GOODS”, specify the damage and get the driver to sign in

acceptance; send a claim in writing to the seller within 4 calendar days from the date of receipt. No

claim shall be accepted after such period.

-Read this handbook carefully: it supplies information on safe use, installation and maintenance. The

purpose of this manual is to provide information to operators on the essential prescriptions and

criteria to ensure their own safety and prolong the oven’s operating life. This manual must be read

by all personnel authorised to work on the machine before it is started up. It must be stored

together with the machine for all future consultation. If the manual becomes worn or is mislaid, ask

for another copy directly from the manufacturer. These instructions are valid only for countries

whose abbreviated reference appears on the cover of this manual and on the data-plate. In

European countries where marketing is possible, manuals in the official language shall be provided

with specific references to gas, pressures, categories and conditions for the connection. In European

countries where marketing is possible, manuals in the official language shall be provided with

specific references to gas, pressures, categories and conditions for the connection.

-Maintenance, adaptation to another type of gas, installation, and the functional check must be

performed only by qualified personnel authorised by the manufacturer. Install the appliance in a

suitable ventilated room and put it into operation while observing the laws in force. Insist on original

spare parts and, after replacing and/or adjusting a part, such as primary air, make sure that it is

sealed with paint to prevent any tampering. We advise you to take out a maintenance contract.

-This appliance is designed for cooking or heating foods. Do not use it for other purposes; all other

uses are considered improper. The appliance is intended for collective and professional use and must

be utilised by personnel trained to use it.

-Before every oven cleaning or maintenance job, switch off electrical power, and shut off gas and

water supplies.

-This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be

made by children without supervision.

N.B.: Improper or incorrect use and failure to observe the installation instructions shall release the

manufacturer from all responsibility.