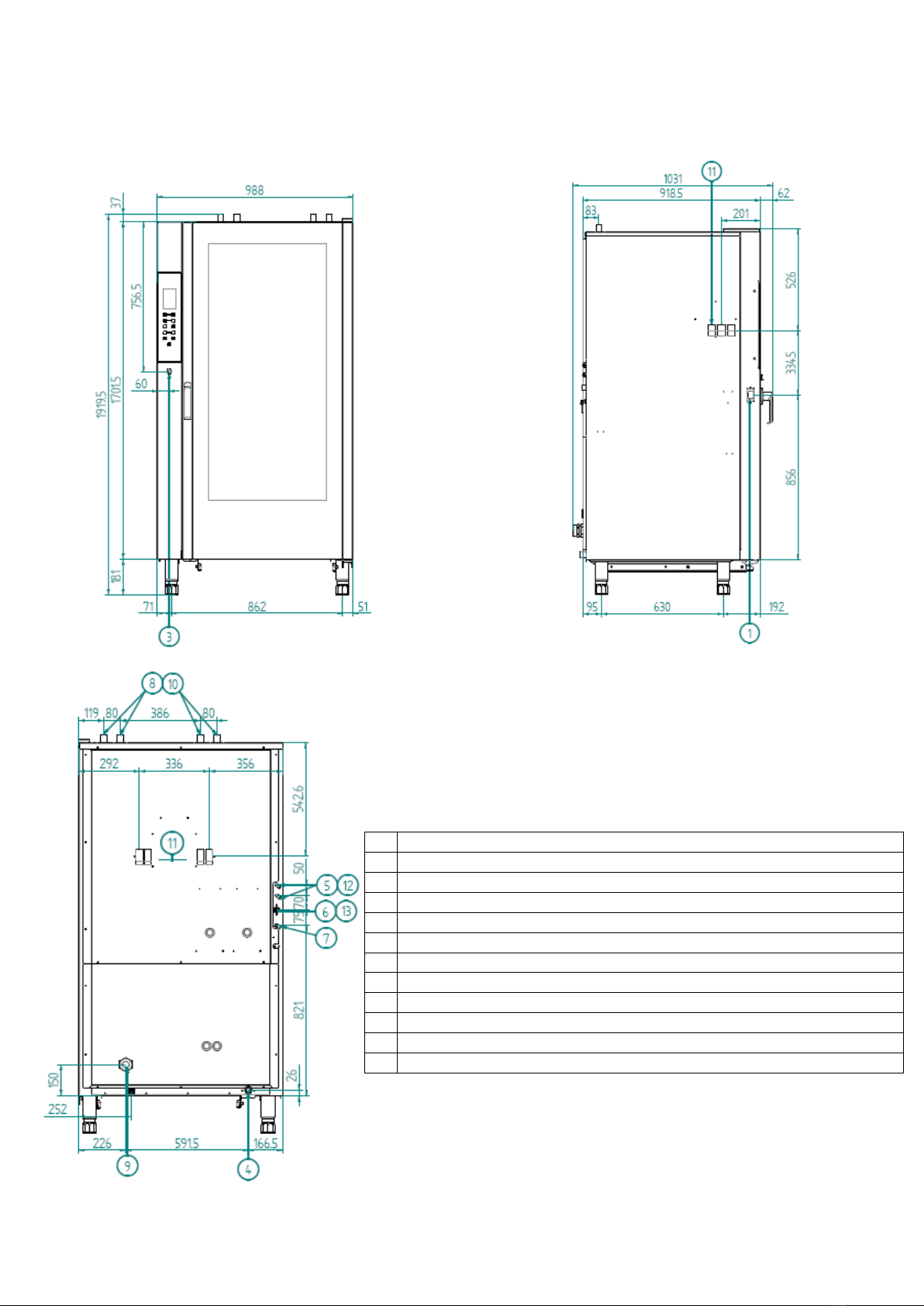

Electronic convection oven rev. 11 ________________MODD. EKF 616 TC –EKF 664 TC –EKF 711 TC –EKF 1016 TC

EKF 1064 TC –EKF 1111 TC –EKF 1664 TC –EKF 2011 TC

_________________________________________________________________________________________ page 7

3.6.1 Table top oven placement

The appliance must be placed in a perfectly horizontal position on a table or similar support; never

on the floor.

For safety reasons it is recommended to use the support produced by the manufacturer; otherwise

the weight of the appliance must be taken into account. The appliance is unsuitable for recessing.

Warning

In the event the appliance is positioned on a wheeled table/support, ensure the permissible

movement does not damage electrical wires, water pipes, drain pipes or anything else.

3.6.2 Placement of wheeled ovens

The appliance must be positioned on a flat and level floor. After placement, ensure the appliance

is horizontally aligned. This check may be carried out by placing a "bubble level" on the 4 top

sides of its casing. Ensure the tray trolley is able to go in and out of the cooking chamber easily,

without rubbing against the lower surface, even when it is "fully loaded". In the event this

operation should not be possible, the appliance feet must be adjusted to lower it so that the tray

trolley may be moved properly. In any case, upon completing adjustment, ensure the wheels of

the tray trolley, inserted in the cooking chamber, are raised from the floor (not more than 5 mm),

and that the trolley is supported by the suitable guides at the bottom of the appliance.

The tray trolley must be moved using the handgrip supplied. The handgrip must be inserted into

the suitable seats at the front of the trolley up to the "stopping point".

The tray trolley must be inserted inside the cooking chamber, freely sliding on the suitable guides

in the lower portion of the appliance.

Warning

Appliance malfunctioning may occur unless the tray trolley is correctly positioned.

3.7 Electrical connection

Connection to the power mains must be performed according to regulations in force. Before

performing the connection ensure that:

-the voltage and frequency of the power supply system match with

the specifications on the "technical data" plate affixed on the side of the appliance;

-the limiting valve and the system are able to withstand the appliance's load (see "technical data"

plate);

-the power supply system is fitted with effective earthing connection according to the regulations

in force;

-In the permanent connection to the mains, a protective pole switch must be provided between

the appliance and the mains with minimum opening between the contacts of overvoltage

category III (4000V), sized for the load and complying with applicable regulations (e.g. automatic

magnetic circuit breaker);

-the pole switch used for the connection is easily accessible with installed appliance;

-the yellow/green earthing cable is not interrupted by the switch;

-The appliance must be connected to an equipotential system the effectiveness of which must be

suitably assessed according to applicable regulations. This connection must be performed with

the suitable terminal located on the rear and marked with the symbol . The equipotential

conductor must have minimum section 2.5mm².

-when the appliance is operating, the power supply voltage does not deviate from the nominal

voltage value by ±10%;

-ensure the power supply cable does not enter in contact with the appliance's hot parts after

inserting it in the terminal board.

-if the power supply cable is damaged it must be replaced by the manufacturer or their technical

support service, or in any case by a person with similar qualifications, to prevent any risk.