027.0008.00 10

- MAIN BURNER

•Unscrew the pipe from the nozzle holder and the gas ramp.

•Remove the pilot burner assembly by undoing the fixing

screws.

•Remove the combustion chamber front panel by undoing the

fixing screws after removing the lower screws and slackening

the upper screws of the side panels of each combustion

chamber.

•Lower the burner / chamber bottom assembly, removing the

side support panels.

- REPLACING VARIOUS COMPONENTS

•Togain accessto the wellwater levelcontrol devices, remove

the side panels and the inspection caps T (fig.14).

•Well water filling solenoid valves accessible from the back of

the unit.

- REPLACING AND CALIBRATING THE HYDRAULIC FLUID

PRESSURE

•The hydraulic fluid is normally long-lasting. However, it ages

with use and should therefore be replaced every 5 years.

Everytwo years, orwhenever necessary, thesupply pressure

must be regulated so that the basket can be raised when

loaded. For this purpose there is a plug on the oil distributor,

under which the adjustment screw P is located (fig. 9) .

Proceed as follows:

- Raise the basket several times without a load to warm the oil

in the hydraulic circuit.

- Load the basket with a weight equal to that of the maximum

quantity of food that can be cooked in the basket.

- Keep the UP selector D (fig.3) turned on and adjust the screw

P so that the basket rises.

The appliance is already set with the hydraulic system supplied

with fluid suitable for use of type ISOVG 46.

Fluid used: REINACH EHT 14 or equivalent.

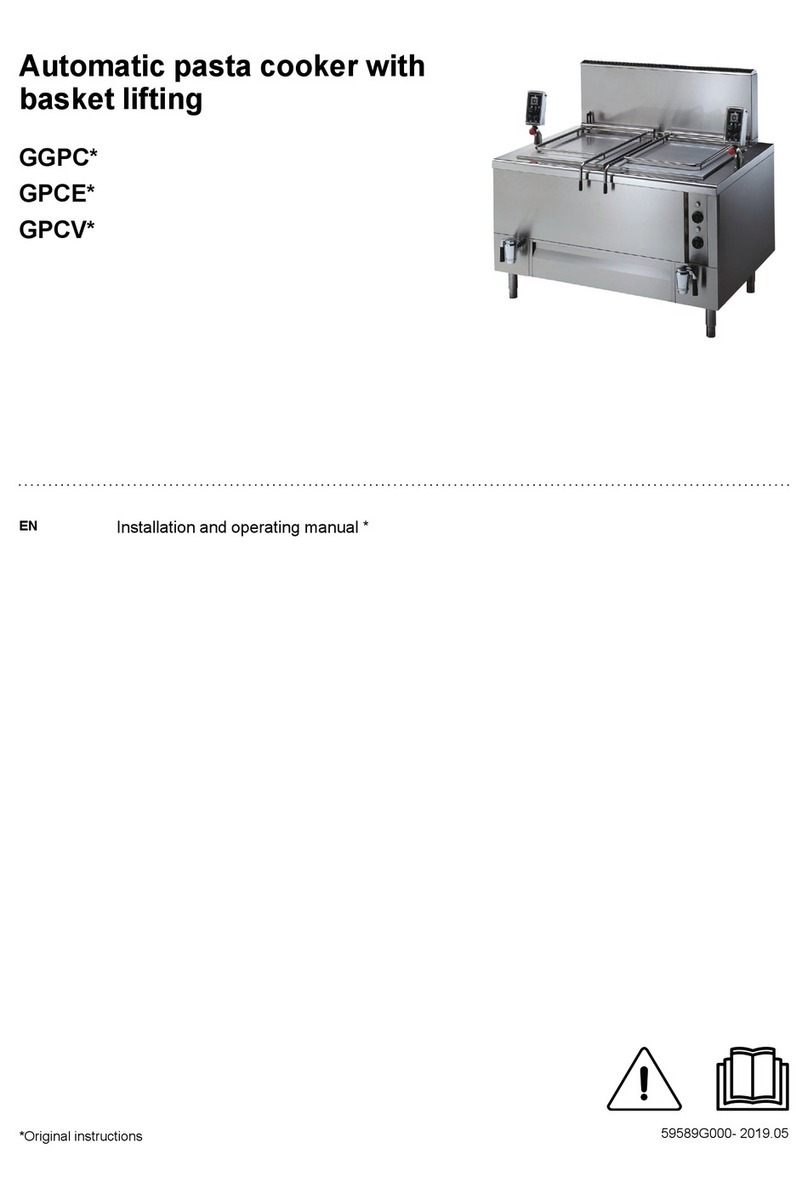

II. OPERATING INSTRUCTIONS

The appliance is intended for professional use and must be

used by trained personnel only.

1. INSTRUCTIONS FOR THE USER

Warnings:

•Read this manual carefully as it provides information on how

to install, operate and service the appliance safely.

•This manual must be looked after carefully for future

consultation by operators.

•The appliance must be installed and adapted to different

types of gas by trained personnel only. If any fluid (even a

small quantity) leaks from the hydraulic system, call the

technical service centre to remedy the problem. This

fluid must be collected and not allowed to escape into the

environment.

•For repairs call a technical service centre that has been

authorised by the manufacturer and ask for original spare

parts to be used. Failure to follow these instructions may

affect the safety of the appliance.

2. OPERATION

•This appliance must be used solely for the purpose for which

it was designed, i.e for cooking foods such as pasta and rice

in water. All other uses are to be considered inappropriate.

•The appliance must not be used as a fryer.

•Fill the well with water.

•Do not turn the appliance on without water.

•Before using the appliance for the first time, clean industrial

grease from the wells and baskets as follows:

- Fillthewellwithwater,addwashing-upliquidandboilforafew

minutes.

- Drain the water out through the tap and rinse the well

thoroughly.

2.1 FILLING EACH WELL WITH WATER (fig.3)

Check that both the well drain taps are closed.

Open the gas and water taps.

Turn on the electric circuit-breaker installed up-line of the

appliance.

•Turn switch E on the control panel to the (I) position.

•For automatic water filling and level control, turn selector F to

the Aut position and leave it there.

•For manual level control, turn selector F to the Man position.

N.B.: as level reference choose a position at least 10 cm from

the lower edge of the well. When the water has reached the

desired level, return the selector to the intermediate position.

2.2 HEATING BOTH WELLS (fig.4)

Both gas control knobs G1 and G2 have the following positions:

OFF position

"Pilot ignition" position

"High flame" position (to raise temperature or

return to the boil)

"Low flame" position (to maintain the water

temperature during pauses between cooking).

2.2.1Lighting pilot burners

After filling the wells with water, light the corresponding

pilot burners.

•Press knob G1 (fig.4) and turn it to position .

•Press the knob down fully and at the same time press the

electric igniter button P1 until the burner has lit. The pilot

burner flame can be seen through the inspection window

under the door T or through the hole F (fig.13).

•Holddown knob G1 for about 20 seconds. When it is released

the pilot burner should remain lit. It not, repeat the operation.

The pilot burner can be lit manually by introducing a flame

through hole F (fig.13).

Carry out the same procedure for controls "G2" and P2".

2.2.2Lighting main burner (fig.4)

Important:Donotlight the main burner orleave it onif thewater

level is lower than the minimum line (see section 2.1).

Failure to follow this instruction can cause serious damage to

the cooking well and the functional parts of the appliance.

With pilot burner on:

•Turn knobs G1 and G2 to the high flame position or the low

flame position (position for maintaining the temperature of

the water in the well while waiting for a subsequent cooking

cycle), regulating water heating according to the quantity and

type of food to be cooked.

2.3 COOKING (fig.3)

When the water in both wells has come to the boil:

•Add salt (to prevent corrosive deposits from forming on the

bottom of the well, it is important to use refined salt; if this is

not possible, dissolve it in water in a separate container).

•For both wells: remove the plastic cover from timer A, then

turn the pointer to the required cooking time (between 0 and

30 minutes).

•Put the food to be cooked in the basket, which should be

raised by turning selector D to the left (icon showing raised

basket) for the entire time it takes the basket to rise out of the

well.

•Turn selector D to the right (icon showing immersed basket)

until the basket stops.