Technical Support Line +44 (0)23 9269 6638 (Option 3) PAK200218 ss 05B Oct 2012 ©2012 ELMDENE NTERNAT ONAL LTD

I

NSTALLATION AND

S

ET

-U

P

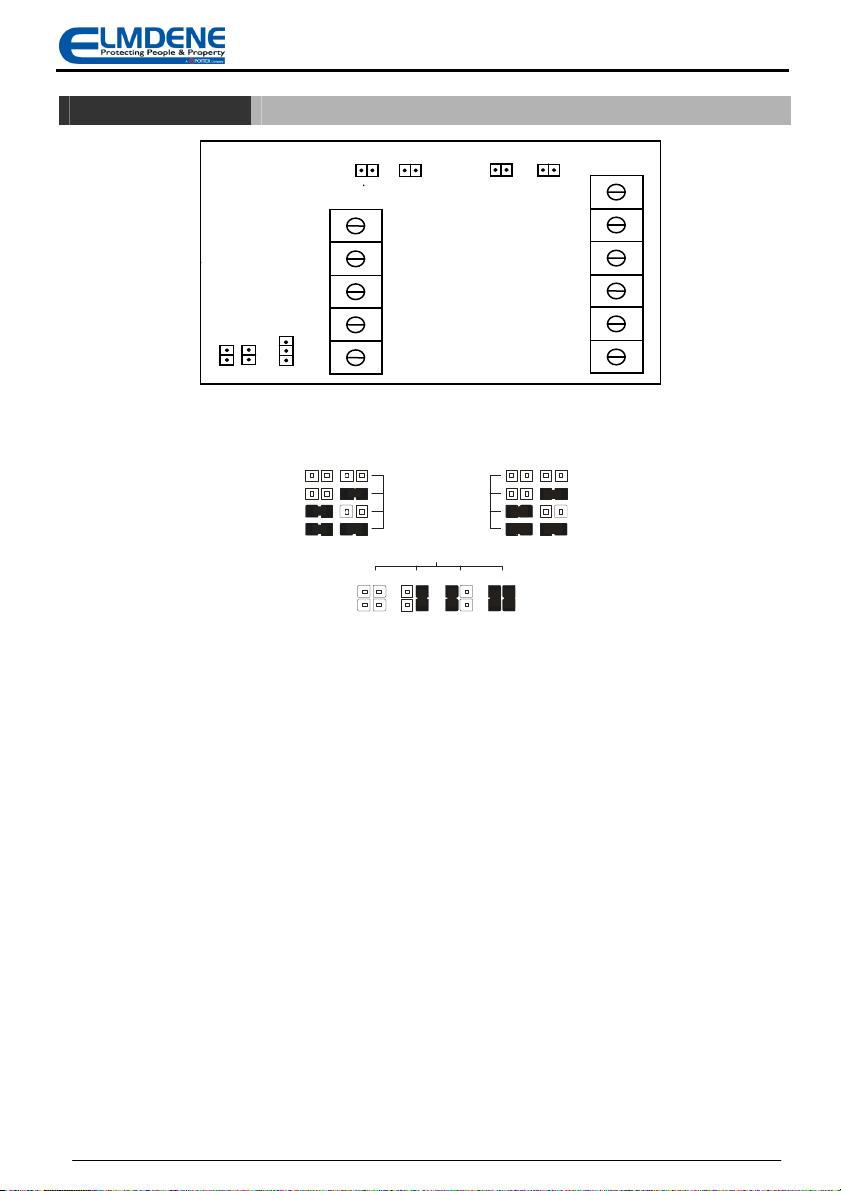

1. Remove cover, undo module fixing screw and swing electronics module away from backplate. Module will self support

when pivots are pushed back in their pivot slots

2. Offer backplate to desired position on mounting surface and drill holes to match chosen fixing centres and rear tamper

insert. A minimum of three fixings should be used.

3. Pierce cable grommet (supplied) to match diameter of control panel cable. Grommet must be used to prevent water

ingress via cable.

4. Fix grommet to backplate and pass control cable through grommet.

5. Fix backplate to mounting surface using appropriate fixings for the mounting

surface.

6.

Fix tamper insert to mounting surface using an appropriate fixing for the

mounting surface

7. Swing electronics module onto backplate and verify that rear tamper pin is

depressed when in contact with the tamper insert.

8. Set the required Cut-off Timer (J1 & J6), LED option (J2 & J7), Tone options

(J4 & J5) and SAB/SCB option (J8).

9. Connect ENG input to H+ or to a switched output of control panel set high.

10. Make remaining connections to control panel in the following order:

sounder activate, strobe activate, tamper return, negative power supply,

positive supply.

11. Connect the black battery lead to BAT-.

12. Disconnect ENG from H+.

13. Lower inner cover and fix using self tapping screw supplied.

14. Replace cover temporarily. Sounder should stop when cover completely replaced.

T

ESTING

1. Activate bell or ring output from control panel. Check sounder activates.

2. Activate strobe output from control panel. Check strobe flashes.

3. Ensure control panel bell and strobe outputs are switched off. Remove cover and check sounder operates due to top

tamper.

4. f a Tamper Return connection is made to the control panel, check that the panel detects a tamper active condition.

5. Temporarily replace cover. Check that sounder switches off. Check that the tamper active condition has cleared at the

control panel.

6. Unfasten inner cover fixing screw so that module sits away from wall mounting and rear tamper is activated. Temporarily

replace cover and check that sounder activates. Check that a tamper active condition is detected at the control panel.

7. Push cover and module into its fully seated position closing the rear tamper pin. Check that sounder switches off and that

the tamper condition is cleared at the control panel.

8. Securely fasten inner cover retaining screw.

9. Remove +ve sounder power supply connection at control panel. Check sounder activates and a tamper active condition is

detected at the control panel.

10. Replace +ve sounder power supply. Check tamper active condition is cleared at control panel.

11. Remove -ve sounder power supply connection at control panel. Check sounder activates and a tamper active condition is

detected at the control panel.

12. Replace -ve sounder power supply. Check tamper active condition is cleared at control panel.

13. Disconnect R- at control panel, check that the siren activates

14. Check correct operation of comfort LEDS.

15. Fasten cover to backplate using two fixing screws supplied. Fit screw covers.

16. Testing complete.

M

AINTENANCE

1. The sounder should be tested for correct operation on a periodic basis. A minimum of one check every 12 months is

recommended. The following features should be verified on each maintenance visit:

2. Correct operation of sounder and strobe from control panel signals

3. Correct operation of cover and rear tampers.

5

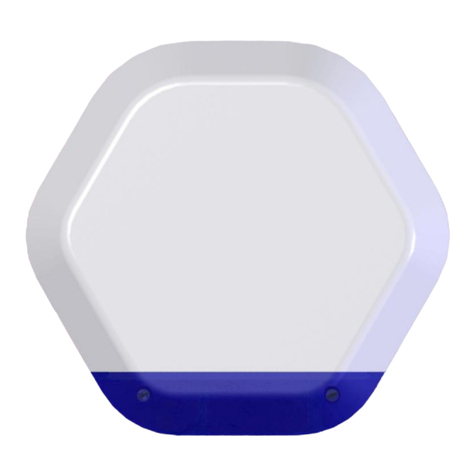

Figure 4: Tamper insert