D103075X012

Installation Sheet Type HSR

www.emersonprocess.com/regulators

June 2006

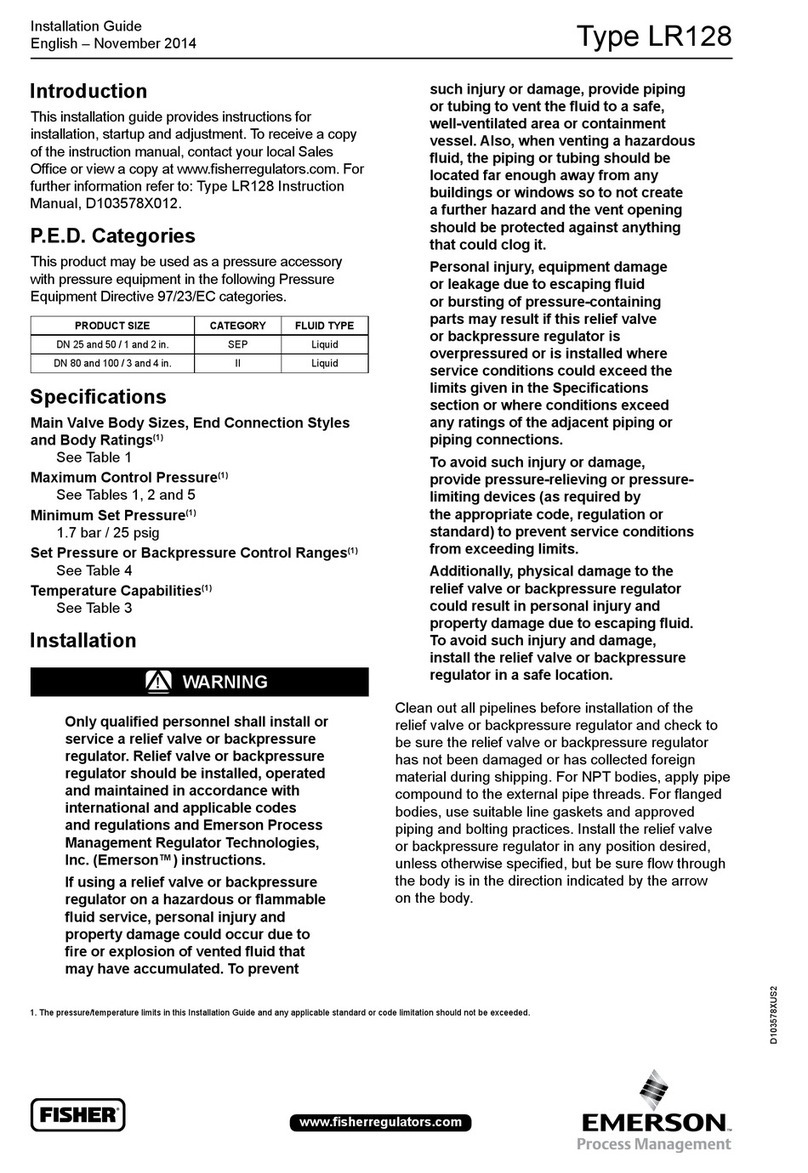

Introduction

This manual provides instructions for the installation,

startup, and adjustment of the Type HSR pressure

regulator. If maintenance is required, refer to the Type

HSR Instruction Manual, form 5753. To receive a copy of

the instruction manual, contact your Fisher Sales Ofce or

Sales Representative.

Specications

Maximum Emergency Inlet Pressures(1)

150 psi (10,3 bar)

Maximum Emergency Outlet (Casing) Pressures(1)

25 psig (1,72 bar)

Outlet Pressure Ranges

4 to 6-inches w.c. (10 to 15 mbar),

6 to 8-inches w.c. (15 to 20 mbar),

8 to 10-inches w.c. (20 to 25 mbar),

10 to 12.5-inches w.c. (25 to 31 mbar),

12.5 to 20-inches w.c. (31 to 50 mbar),

20 to 35-inches w.c. (50 to 87 mbar),

1.25 to 2.2 psig (0,09 to 0,15 bar)

Temperature Capabilities(2)

-20° to 160°F (-29° to 71°C)

Installation

!

WARNING

Personal injury, equipment damage, or

leakage due to escaping gas or bursting

of pressure-containing parts might result

if these regulators are overpressured or

installed where service conditions could

exceed the limits for which the regulators

were designed, or where conditions exceed

any ratings of the adjacent piping or

piping connections. To avoid such injury

or damage, provide pressure-relieving

or pressure-limiting devices (as required

by the appropriate code, regulation or

standard) to prevent service conditions

from exceeding those limits.

Additionally, physical damage to a

regulator could cause personal injury and

property damage due to escaping gas. To

avoid such injury and damage, install the

regulator in a safe location.

A regulator may vent some gas to the

atmosphere in hazardous or ammable gas

service, vented gas might accumulate and

cause personal injury, death or property

damage due to re or explosion. Vent

a regulator in hazardous gas service to

a remote, safe location away from air

intakes or any hazardous location. The

vent line must be protected against

condensation or clogging.

Before installing the regulator, check for damage which

might have occurred in shipment. Also check for dirt

or foreign matter which may have accumulated in the

regulator body or in the pipeline. Apply pipe compound to

the male threads of the pipeline and install the regulator

so that the ow is in the direction of the arrow cast on

the side of the body. The diaphragm actuator assembly

can be rotated to any position relative to the body, in 90°

increments. Remove the two cap screws that hold the

body to the actuator in order to rotate the diaphragm

actuator assembly.

Do not install the regulator in a location where there can

be excessive water accumulation, such as directly beneath

a downspout or in an undrained pit.

To obtain the maximum ow capacities or other

performance characteristics, the length of pipe from the

regulator outlet to the meter should have no bends and

should be the same size as the regulator outlet. Replace

the regulator if water gets into the spring case or the lower

casing of the regulator.

CAUTION

You are advised to use new vent piping

because defective threads on the relief

vent piping may interfere with the venting

assembly if the piping obstructs the

movement of the vent apper.

On indoor installations, the vent should be piped outside

the building. Remove the screen from the regulator vent

connection and connect vent piping from that connection

to the outdoors. Install a weather and insect resistant

vent assembly on the outside end of the pipe. Inspect

the vent opening regularly. On some installations, it may

be necessary to install the regulator beneath a protective

hood. The vent should be pointing or sloping down

sufciently to allow any condensate to drain. Also check

the regulator periodically for external or internal corrosion.

Overpressure Protection

!

WARNING

Some type of overpressure protection is

needed if actual inlet pressure can exceed

the outlet pressure rating. Overpressuring

any portion of this equipment may cause

damage to regulator parts, leaks in

the regulator, or personal injury due to

bursting of pressure-containing parts or

explosion of accumulated gas.