EC1-233_65150_EN_R02.doc Replacement for R01 2 / 2 Part No. 864 908 07.07.2008

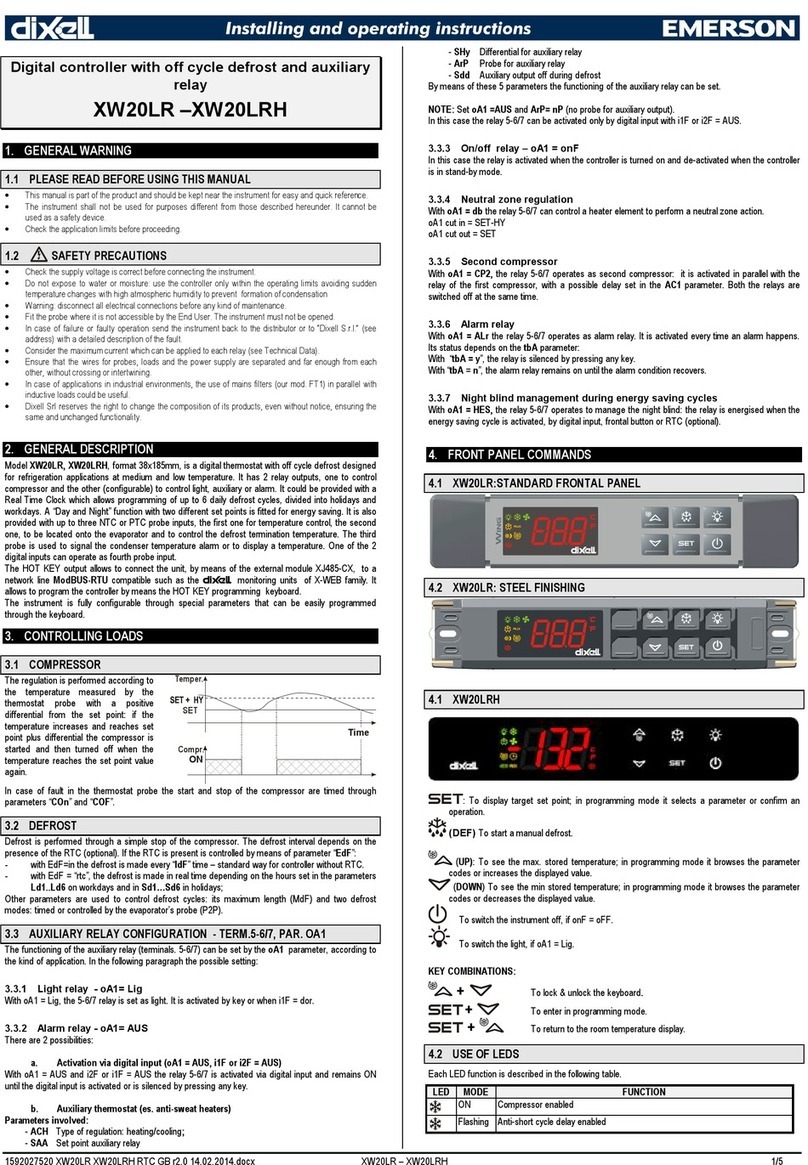

EC1-233 Display Case and Coldroom Controller

Operating Instructions GB

Parameter Modification: Procedure

•When the Prg LED is illuminated the parameters may be modified and the first

parameter “St” will be displayed.

•Press the Prg button again to display the current value associated with the

parameter.

•Press or to increase or decrease the value. Pressing either button for 3

seconds will increase the speed of value change.

•Press the Prg button again to display the current parameter; “St”

•Press repeatedly to show the next parameter code to be changed;

•Press the Prg button again to display the current value associated with the

parameter and the or to increase or decrease the value.

•Repeat the procedure from the beginning "press repeatedly to show..."

To exit and save the new settings:

•Press Prg for 3 seconds to confirm the new values and exit the parameters

modification procedure. The Prg LED will be turned off.

•Alternatively avoid pressing any button for at least 15 seconds and the controller

will automatically revert to the operation mode; controller “times out”.

•If any parameter is modified and the controller then times out, the new setting

will be automatically saved.

Copy Key Procedure

Upload procedure:

•With the controller powered, plug the copy key into the mini USB.

•Press the button and the controller will display “UPL”.

•Press the PRG button to start the upload process to the copy key.

•Turn 230V power off before removing the copy key from the controller.

Download procedure:

•Turn 230V power off before inserting the copy key into the controller.

•Turn 230V power on. The controller will automatically detect the copy key is

present and start downloading the stored parameters into the controller. “DOW”

will be displayed on the controller during downloading process.

•Turn 230V power off before removing the copy key from the controller or the

data will be corrupted.

•Turn 230V power on and check the parameter values following the parameter

modification procedure above.

Caution:

DO NOT turn the controller off during this process. The control temperature will

be displayed when the process has been completed. ”Err” will be displayed if there

is an error during the upload/download procedure.

Any attempt to download a second set of parameter into the copy key will

automatically overwrite the original set.

Defrost Activation:

A defrost cycle can be activated locally from the keypad:

•Press the button for more than 3 seconds, the defrost cycle is activated and

the defrost LED will be illuminated (only if S5< value of parameter dt).

Continuous Cooling Demand Activation:

The controller can be set to continuous cooling:

•Press the button for more than 3 seconds, the controller will be forced into the

cooling mode and the cooling LED will be illuminated.

•Press the button for more than 3 seconds again to stop the continuous cooling

process.

Display of Data:

During normal operation, the display will show the temperature measured by the

S1 air sensor.

Press to display the current value associated with the defrost termination sensor.

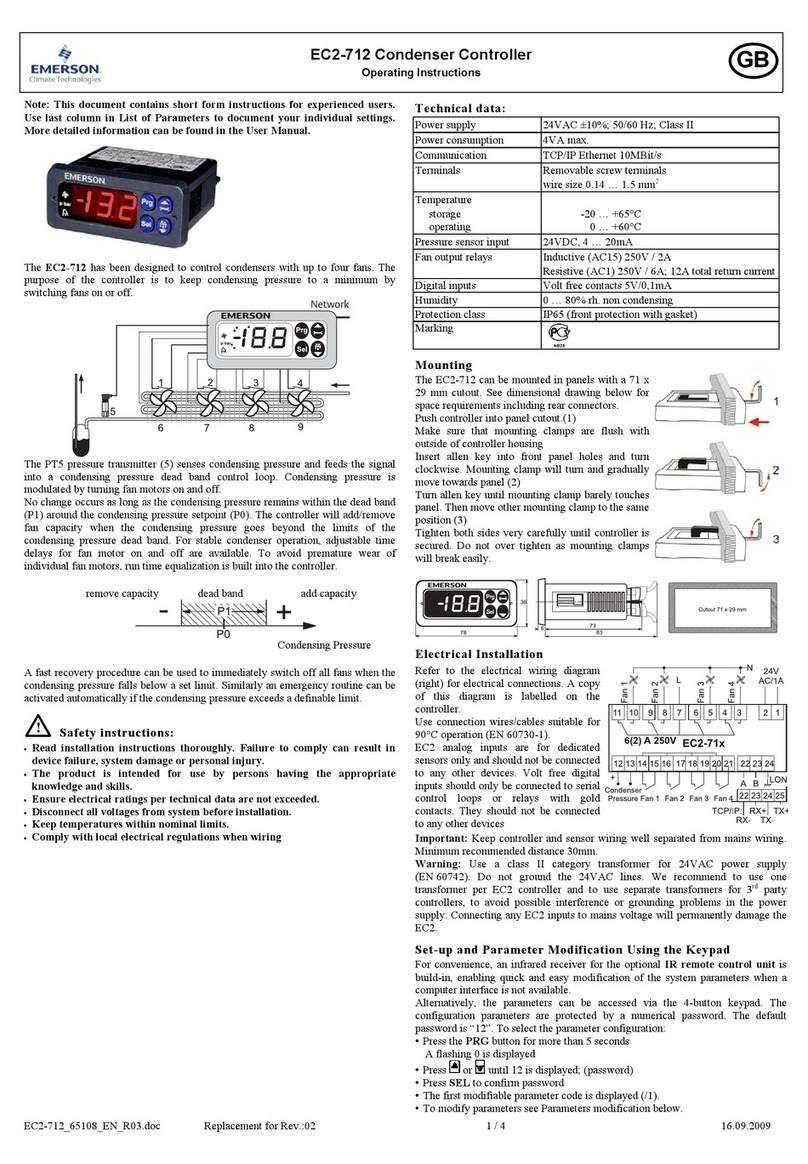

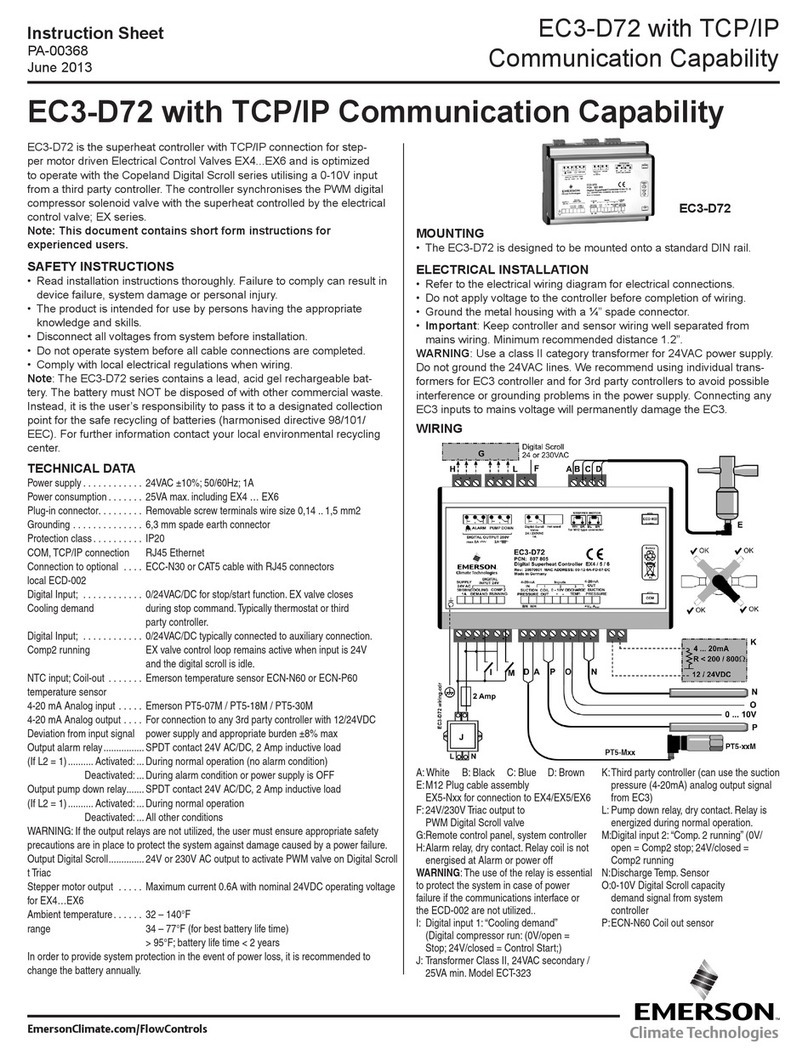

LED displayed when:

Parameter alteration mode is active.

Compressor / Cooling relay active

Defrost heater relay active

Fan relay active

Note: A blinking LED indicates the respective relay is inhibited from becoming

active due to a time delay or an active alarm condition

LED Indication

Indicator Status Function

OFF Cooling relay inactive: cooling off

Blinking Compressor start delay

ON Cooling relay active: cooling on

Cooling

Blinking: fast Cooling relay active: continuous cooling

OFF Defrost relay inactive: defrost off

ON Defrost relay active: defrost on

Blinking Defrost relay inactive: drain down

Defrost

Blinking: fast Defrost relay active: forced defrost

OFF Fan relay inactive: fan off

Blinking Fan start delay

Fan

ON Fan relay active: fan on

OFF Normal working mode

Prg ON Controller in programming mode

List of Parameters

USER Min Max Unit Def. Custom

St Temperature control setpoint r1 r2 °C -5.0

cut in = set-point + difference; cut out = set-point

rd Control deadband differential 1.0 +25.0 K 2.0

dP Max defrost duration 0 255 min 30

dI Defrost interval (0.1 h = 6 min.) 0.0 99.9 h 6.0

Factory default settings are all in °C. Refer to parameter /5 for °F settings

ADMINISTRATOR Min Max Unit Def. Custom

r1 Minimum setpoint -45.5 St °C -20.0

r2 Maximum setpoint St 110 °C 20.0

/C Air temperature alignment for S1 -10.0 +10.1 K 0.0

/d Defrost temperature alignment for S5 -10.0 +10.1 K 0.0

C2 Compressor start delay time 0 50 min 3

C3 Minimum emergency RUN time 0 255 min 45

C4 Maximum emergency OFF time 0 255 min 15

/5 Temperature Unit °C °F - °C

Note: When /5=°F all temperature parameters must be entered in °F or Rankin

d0 Defrost type: EL = electric; HtG = off cycle EL

dt Defrost termination temperature -45.5 +49.9 °C 10

/7 Display during defrost rt

rt: Air temperature (S1)

lt: Defrost start-up temperature

SEt: Air setpoint temperature

dEF: “dEF” displayed

A3 Display delay after defrost 0 255 min 30

d7 Drain down time: cooling restart delay 0 255 min 2

d4 Defrost at start-up y = yes, n = no n

d5 Defrost delay after start-up 0.0 24.0 h 0.0

F1 Fan mode:

C-n: start/stop with cooling, Off during defrost

O-n: continuously on, Off during defrost

C-Y: start/stop with cooling, ON during defrost

O-Y: continuously on, ON during defrost

C-n

Fd Fan delay after defrost 0 255 min 10

Ft On temp differential after defrost

Diff: Air temp. (S1) – Defrost temp. (S5)

0.0 +50.0 °C 10.0

AH High temp alarm limit AL 110 °C 110

AL Low temp alarm limit -45.5 AH °C -45.5

A1 Air temp alarm delay 0 255 min 15

A2 Air temp. alarm delay after start-up 0 255 min 60

Ert Temperature sensor failure delay 0 255 min 0

FSt Fan stop temperature setpoint -45.5 +49.9 °C 10.0

Alarm Codes

AH High temperature alarm

Upper control temp alarm limit (AH) exceeded beyond delay time (A1)

AL Low temperature alarm

Lower control temperature alarm limit (AL) exceeded beyond delay time

(A1)

Er Sensor error

Air or defrost sensor open circuit

Compressor run & off times are set by parameters C3 and C4

Emerson Electric GmbH & Co OHG is not to be held responsible for erroneous

literature regarding capacities, dimensions, applications, etc. stated herein.

Products, specifications and data in this literature are subject to change without

notice. The information given herein is based on technical data and tests which

ALCO CONTROLS believes to be reliable and which are in compliance with

technical knowledge of today. It is intended only for use by persons having the

appropriate technical knowledge and skills, at their own discretion and risk. Since

conditions of use are outside of ALCO'S control we cannot assume any liability for

results obtained or damages occurred due to improper application.

This document replaces all former versions

Emerson Electric GmbH & Co OHG - Postfach 1251 - Heerstraße 111 - 71332 Waiblingen - Germany - Phone +49 7151 509 0 - Fax +49 7151 509 200

www.emersonclimate.eu