ENCAD NovaJet 800 Series User manual

NovaJet®8-Head Family

Service Manual

NovaJet

800 Series

NOVAJET®

800 Series

Color Inkjet Printer

Service Manual

PartNumber216520-01

®

iii

NovaJet800SeriesServiceManual

Copyright Eastman Kodak Company, 2002

KODAK, ENCAD®, VinylJet®, VinylJet®, CADJET®,

ExtremeColorPrinting™,andGraphicOutdoorMatched

System™ (GO) are trademarks ofEastman Kodak

Company.

Othertrademarksandregisteredtrademarksarethe

propertyoftheirrespectiveowners.

No part of this manual may be copied or distributed,

transmitted, transcribed, stored in a retrieval system, or

translated in any human or computing language, in any

formor by anymeans, electronic, mechanical,magnetic

or otherwise, or disclosed to a third party without the

express written permission of:

Encad, Inc., 6059 Cornerstone Court West, San Diego,

CA92121,U.S.A.

CertainmanualsdevelopedbyENCADareinanelec-

tronic format to be distributed on CDs or over the

internet. The registered user of an ENCAD product

whose manual is distributed in this fashion may print one

copy for their personal use only.

Printing history

1st Edition RevADecember2000

2ndEdition RevB June 2002

iv

NovaJet800 Series ServiceManual

FCC Statement (U.S.A.)

TheUnited States Federal Communications Commision

has specified that the following notice be brought to the

attention of the users of theNOVAJET 800 series printers.

FEDERALCOMMUNICATIONSCOMMISIONRADIOAND

TELEVISIONINTERFERENCE FORCLASSBDEVICE

This equipment has been tested and found to comply with

the limits for a class A digital device, pursuant to part 15

ofthe FCC Rules. These limits are designed to provide

reasonableprotection against harmful interference in a

residentialinstallation. This equipment generates, uses,

andcanradiateradiofrequencyenergyand,if not in-

stalled and used in accordance with the instructions, may

causeharmful interference to radio communications.

v

NovaJet800 Series ServiceManual

User Instructions:

Iftheequipmentdoes cause harmful interference to radio

ortelevision reception, whichcan be determinedby

turning the equipment off and on, the user is encouraged

to try to correct the interference by one of the following

measures:

−Reorientorrelocatethe receiving antenna.

−Increasetheseparation between the equipmentand

receiver.

−Connect the equipment into an outlet on a circuit

differentfrom that to which the receiver is connected.

−Consultthedealer or an experienced radio/TV

technicianforhelp.

Changesormodifications not expressly approved by

ENCAD, Inc. could void the user’s authority to operate the

equipment.

vi

NovaJet800 Series ServiceManual

VDE Statement

Hiermit wird bescheinigt, daß dieNOVAJET 800 Serie

vonDruckerinÜbereinstimmungmitdenBestimmungen

der BMPT-AmstbIVfg 234/1991 funkentstört ist. Der

vorschriftsmäßigeBetrieb mancher Geräte (z.B.

Meßsender)kannallerdingsgewissenEinschränkungen

unterliegen. BeachtenSie deshalb die Hinweise in der

Bedienungsanleitung.

DemZentralamtfürZulassungenim Fernmeldewesen

würdedanInverkehrbringen dieses Gerätes angezeigt und

dieBerechtigungzurÜberprüfungder Serie auf die

Einhaltung der Bestimmungen eingeräumt.

ENCAD, Inc. U.S.A

vii

NovaJet800 Series ServiceManual

Material Safety Data Sheet

ENCAD QIS(QualityImaging Supplies) ink isnonhazard-

ous, requiring no special disposal handling. It can be

harmful if swallowed and should be kept away from

children.

To obtain a Material Safety Data Sheet, contactENCAD,

Inc. at:

6059CornerstoneCourt West

SanDiego, CA 92121-3734

(619)452-4350

Internationalusers should contacttheir local dealeror

distributor.

viii

NovaJet800 Series ServiceManual

Warranty or Damage Claims

United States

ENCAD®, Inc., warrants itsprinters ("PRODUCT") to be free from defects in

workmanshipand materials for a period of one year from the date of

purchase. In order to submit a Warranty claim, please contact the

ENCADHelp Desk at (858) 452-4350.

ENCADreserves the right to make changes or improvementsto Products,

without incurring any obligation to similarly alter Products previously

purchased.

Buyer's sole and exclusive rights pursuant to this Warranty shall be for the

repairor replacement of defective Product. ENCAD specifically disclaims

any and all other warranties, expressed or implied, including but not limited

to,implied warranties of merchantability and fitness for a particular pur-

pose. In no event shall ENCAD be liable for any loss of profit or other

commercialdamages, special, incidentalor consequential damages,or

anyotherdamagesorclaims, whatsoever.

This Warranty gives Buyer specific legal rights, and Buyer may also have

other rights that vary from state to state.

ThisWarranty applies only to printers purchased from ENCAD, or autho-

rized ENCAD distributors or dealers. The intent of this Warranty is to

repairor replace defective Products subjected to normal wearand tear,

when operated according to ENCAD instructions.

ix

NovaJet800 Series ServiceManual

Table of Contents

Chapter 1 General Description .......................................1-1

Introduction .................................................................................. 1-1

Overview ....................................................................................... 1-3

Related Publications ..................................................................... 1-3

Electrostatic Discharge (ESD) Sensitivity ...................................... 1-3

Warnings,Cautionsand Notes...................................................... 1-4

PrinterSpecifications .................................................................... 1-5

Contentsof this Service Manual .................................................... 1-6

Technical Support ......................................................................... 1-8

Chapter 2 Theory of Operation.......................................2-1

Introduction .................................................................................. 2-1

NovaJet800Series Printers General Block Diagram ...................... 2-2

Paper(Media)AxisDrive............................................................... 2-4

TheCarriageAxisDrive ................................................................. 2-5

MediaFeedand Take-Up System.................................................. 2-6

MainPWA(PrintedWiringAssembly) ........................................... 2-7

Main PWA LED Status Indicators............................................ 2-8

Microprocessor (CPU) ............................................................ 2-8

GateArray ............................................................................. 2-9

DigitalSignalProcessor (DSP) ............................................... 2-9

Memory Circuits ................................................................... 2-10

Flash EEPROM ............................................................. 2-10

SDRAM ......................................................................... 2-11

Serial EEPROM ............................................................. 2-11

StepperMotorController ....................................................... 2-11

ServoMotorController .......................................................... 2-13

InterfaceCircuits:Serial&Parallel ........................................ 2-15

x

NovaJet800 Series ServiceManual

Table of Contents (cont)

Chapter 3 Maintenance ...................................................3-1

Introduction .................................................................................. 3-1

ScheduledMaintenance................................................................ 3-1

CleaningProcedures .............................................................. 3-2

External Cleaning ............................................................. 3-2

Slide Shaft Cleaning ......................................................... 3-2

Service Station Cleaning ................................................... 3-3

Linear EncoderStripCleaning ........................................... 3-4

TrailingCablesCleaning ................................................... 3-5

Platen/VacuumHoleCleaning........................................... 3-5

CartridgeDimplesCleaning .............................................. 3-6

Flex Cable Contact Cleaning ............................................ 3-7

Clean and Inspect Stepper Motor Gears ............................ 3-8

Clean and Inspect Main PWA........................................... 3-8

CleanandInspectCarriageAssembly............................... 3-8

DryerCleaning ................................................................. 3-9

Reseat Connectors on Main PWA and Carriage Boards ........... 3-9

ReplaceTrailingCables ........................................................ 3-12

ReplaceCarriageCover/CarriageBushings............................ 3-13

ServoMotor WindingResistance Check ...................................... 3-14

Stepper Motor WindingResistance Check ................................... 3-15

PowerFeedand Take-Up Motor Winding Resistance Check......... 3-16

Banding:Hardwarevs Software ................................................... 3-16

BandingDifferences.............................................................. 3-17

Banding Causes & Quick Analysis........................................ 3-19

HorizontalBandingProblems.......................................... 3-19

Vertical Banding Problems.............................................. 3-22

Line Quality Problems (Overspray) .................................. 3-23

Alignments/Adjustments............................................................. 3-24

Slide ShaftProfile Adjustment ............................................... 3-24

HeadHeightAlignmentProcedure ......................................... 3-27

ColorCalibration ................................................................... 3-31

DeadbandAlignments ........................................................... 3-34

ColorDeadbandAlignment.............................................. 3-37

PaperAxisCalibration .......................................................... 3-39

Diagnostics Menu ....................................................................... 3-40

FirmwareDownload/UpgradingforthePC .................................... 3-43

FirmwareDownload/Upgrading for theMAC ................................. 3-44

InternalCablingandSignalFlow Diagrams .................................. 3-45

xi

NovaJet800 Series ServiceManual

Table of Contents (cont)

Chapter 4 Troubleshooting.............................................4-1

Introduction .................................................................................. 4-1

NoPower ............................................................................... 4-1

NoPower ............................................................................... 4-2

Initialization Failure ................................................................. 4-2

MediaDoesNot Move............................................................. 4-3

InternalERROR“CarriageAxisFailure” ................................... 4-4

InternalERROR “Encoder SensorFailure” ............................... 4-5

Internal ERROR “Paper Sensor Failure” ................................... 4-6

InternalERROR...................................................................... 4-6

Auto-Load Paper Sensor Failure” ............................................ 4-6

InternalERROR“MPCBFailure” ............................................. 4-7

UnrecognizedCartridgesError ................................................ 4-7

MediaSen Ref. PtsNot Initialized (NJ880only) ....................... 4-8

ImageSkewsor Moves........................................................... 4-8

Does Not Print ....................................................................... 4-8

Ink Cartridge Misfiring ............................................................. 4-9

PaperSkewing ..................................................................... 4-10

PrinterOutput is Banding (Horizontal) ................................... 4-10

Printer Output is Banding (Vertical) ....................................... 4-12

Printer Output is Banding (Horizontally and Vertically) ........... 4-12

KeypadLocked-UporNot Functioning Properly..................... 4-13

NoisyOperation ................................................................... 4-13

LineQualityDegraded .......................................................... 4-14

Fan Does Not Power Up ....................................................... 4-16

MediaTake-UpMotor Not Operating, Sensor Works ............... 4-16

Media Feed Motor Not Operating, Sensor Works................... 4-17

MediaFeedand Take-Up Motors NotOperating,

BothSensorsWorking.......................................................... 4-17

MediaFeedor Take-Up Sensor(s) NotOperating ................... 4-17

Print Quality Issues .............................................................. 4-19

CartridgeMisfires(Intermittent Banding) ................................ 4-19

Failure Analysis - Print Misfires............................................ 4-20

CommonMisfireProblems.............................................. 4-25

ClearingCartridgeMisfires.............................................. 4-26

MultipleCartridgeFailures .............................................. 4-26

xii

NovaJet800 Series ServiceManual

Table of Contents (cont)

Chapter 4 Troubleshooting (cont)

Microbanding............................................................. 4-28

BandingDifferences................................................... 4-30

Horizontal Banding .................................................... 4-31

Vertical Banding ........................................................ 4-43

LineQualityProblems (Overspray) ............................. 4-46

CartridgeWarranty .................................................... 4-47

CartridgeMaintenance& Testing................................ 4-48

InkStarvation............................................................. 4-52

InkDropout ............................................................... 4-57

ColorTest Problems .................................................. 4-60

“UnrecognizedCartridge”Error Message .................... 4-63

PaperSensorError.................................................... 4-65

EncoderSensorError ................................................ 4-68

AutoLoadPaperSensor Error .................................... 4-69

CarriageAxisError .................................................... 4-70

Initialization Failure ................................................ 4-75

MediaSensorReference Points Not Initialized........... 4-79

HardwareFailures/DiagnosticTests............................ 4-79

DryerFailure/SensorError ......................................... 4-81

IntermittentProblems/Continuity ................................ 4-86

ReinitializingthePrinter ............................................. 4-95

Printer Hesitation/Networking Problems...................... 4-96

ParallelPortTest ..................................................... 4-100

FirmwareDownloadingProcedures........................... 4-101

NJ850Printer .......................................................... 4-101

NJ880Printer .......................................................... 4-102

Media Handling System Failure................................ 4-104

xiii

NovaJet800 Series ServiceManual

Table of Contents (cont)

Chapter 5 Assembly\Disassembly................................5-1

Introduction .................................................................................. 5-1

RemovetheLeft,Top,andRightCovers......................................... 5-2

Removethe E-ConnectNetworkAssembly .................................... 5-6

InstalltheE-ConnectNetworkAssembly ....................................... 5-7

Remove the Keypadand Display ................................................... 5-8

Install the Keypad and Display ...................................................... 5-9

RemoveMemoryModule............................................................. 5-10

Install Memory Module................................................................ 5-11

RemovetheMainPrintedWiringAssembly(PWA) ...................... 5-11

InstalltheMain Printed Wiring Assembly (PWA) ......................... 5-14

RemovePower Supply, Cooling Fan, and AC Entry Module .......... 5-15

InstallthePower Supply, Cooling Fan, and ACEntry Module........ 5-17

RemoveServoMotor ................................................................... 5-18

Install Servo Motor ...................................................................... 5-20

RemovetheInkDeliverySystem ................................................. 5-21

Install the Ink Delivery System .................................................... 5-23

RemovetheCarriage Assembly, Carriage Belt, and theFrame

Tensioner.................................................................................... 5-23

Installthe Carriage Assembly, Carriage Belt, and the

FrameTensioner ......................................................................... 5-28

RemovetheCarriage PWA.......................................................... 5-31

Install the Carriage PWA............................................................. 5-33

Remove the Paper Sensor or the Encoder Sensor........................ 5-34

Install the Paper Sensor or the Encoder Sensor ........................... 5-36

Replacingthe Floating Carriage Cover Bushings .......................... 5-37

ReplacingtheCarriage Bushings................................................. 5-39

Remove the Service Station ......................................................... 5-40

Install the Service Station ............................................................ 5-41

RemovetheTrailingCableAssembly ........................................... 5-41

Installthe TrailingCableAssembly .............................................. 5-42

RemovetheStabilizer Bracket and Encoder Strip......................... 5-43

Installthe Stabilizer Bracket and Encoder Strip............................ 5-44

RemovetheY-ArmAssembly,PinchRollers,SlideShaft,and

AutoLoad Sensor ........................................................................ 5-44

Install the Y-Arm Assembly, Pinch Rollers, Slide Shaft,

andAutoLoadSensor.................................................................. 5-47

RemovetheGap Sensor (NovaJet 880only)................................. 5-48

xiv

NovaJet800 Series ServiceManual

Table of Contents (cont)

Chapter 5 Assembly\Disassembly (cont)

RemovetheLowerRollerAssembly, Stepper Motor and

VacuumFan(NovaJet 850).......................................................... 5-48

Installthe Lower Roller Assembly, StepperMotor and

VacuumFan(NovaJet 850).......................................................... 5-51

RemovetheLowerRollerAssembly, Stepper Motor and

VacuumFan(NovaJet 880).......................................................... 5-54

LowerRollerInstallationTip(NovaJet880) ................................... 5-57

Y-ArmAssemblyInstallationTip(NovaJet880)............................. 5-57

RemovetheMediaTake-UpandFeedSensorBracketsand

Sensors ..................................................................................... 5-58

InstalltheMedia Take-Up and Feed Sensor Brackets and

Sensors ..................................................................................... 5-59

RemovetheMediaTake-UpandFeedMotors .............................. 5-60

InstalltheMedia Take-Up and Feed Motors ................................. 5-60

RemovetheThermalDryerAssembly .......................................... 5-61

InstalltheThermalDryerAssembly ............................................. 5-62

Removethe ThermalDryerRightEndcap Assembly..................... 5-62

InstalltheThermalDryerRightEndcapAssembly............................5-

64Assembly\Disassembly............................................................. 5-1

Introduction .................................................................................. 5-1

RemovetheLeft,Top,andRightCovers......................................... 5-2

Removethe E-ConnectNetworkAssembly .................................... 5-6

InstalltheE-ConnectNetworkAssembly ....................................... 5-7

Remove the Keypadand Display ................................................... 5-8

Install the Keypad and Display ...................................................... 5-9

RemoveMemoryModule............................................................. 5-10

Install Memory Module................................................................ 5-11

RemovetheMainPrintedWiringAssembly(PWA) ...................... 5-11

InstalltheMain Printed Wiring Assembly (PWA) ......................... 5-14

RemovePower Supply, Cooling Fan, and AC Entry Module .......... 5-15

InstallthePower Supply, Cooling Fan, and ACEntry Module........ 5-17

RemoveServoMotor ................................................................... 5-18

Install Servo Motor ...................................................................... 5-20

RemovetheInkDeliverySystem ................................................. 5-21

Install the Ink Delivery System .................................................... 5-23

xv

NovaJet800 Series ServiceManual

Chapter 5 Assembly\Disassembly (cont)

RemovetheCarriage Assembly, Carriage Belt, and theFrame

Tensioner.................................................................................... 5-23

Installthe Carriage Assembly, Carriage Belt, and the

FrameTensioner ......................................................................... 5-28

RemovetheCarriage PWA.......................................................... 5-31

Install the Carriage PWA............................................................. 5-33

Remove the Paper Sensor or the Encoder Sensor........................ 5-34

Install the Paper Sensor or the Encoder Sensor ........................... 5-36

Replacingthe Floating Carriage Cover Bushings .......................... 5-37

ReplacingtheCarriage Bushings................................................. 5-39

Remove the Service Station ......................................................... 5-40

Install the Service Station ............................................................ 5-41

RemovetheTrailingCableAssembly ........................................... 5-41

Installthe TrailingCableAssembly .............................................. 5-42

RemovetheStabilizer Bracket and Encoder Strip......................... 5-43

Installthe Stabilizer Bracket and Encoder Strip............................ 5-44

RemovetheY-ArmAssembly,PinchRollers,SlideShaft,and

AutoLoad Sensor ........................................................................ 5-44

Install the Y-Arm Assembly, Pinch Rollers, Slide Shaft, and

AutoLoad Sensor ........................................................................ 5-47

RemovetheGap Sensor (NovaJet 880only)................................. 5-48

RemovetheLowerRollerAssembly, Stepper Motor and

VacuumFan(NovaJet 850).......................................................... 5-48

Installthe Lower Roller Assembly, Stepper Motor and Vacuum

Fan (NovaJet850) ....................................................................... 5-51

RemovetheLowerRollerAssembly, Stepper Motor and

VacuumFan(NovaJet 880).......................................................... 5-54

LowerRollerInstallationTip(NovaJet880) ................................... 5-57

Y-ArmAssemblyInstallationTip(NovaJet880)............................. 5-57

RemovetheMediaTake-UpandFeedSensorBracketsand

Sensors ..................................................................................... 5-58

InstalltheMedia Take-Up and Feed Sensor Brackets and

Sensors ..................................................................................... 5-59

RemovetheMediaTake-UpandFeedMotors .............................. 5-60

InstalltheMedia Take-Up and Feed Motors ................................. 5-60

RemovetheThermalDryerAssembly .......................................... 5-61

InstalltheThermalDryerAssembly ............................................. 5-62

Removethe ThermalDryerRightEndcap Assembly..................... 5-62

InstalltheThermalDryerRightEndcapAssembly........................ 5-64

Table of Contents (cont)

xvi

NovaJet800 Series ServiceManual

Chapter 6 Parts List........................................................6-1

Table of Contents (cont)

xvii

NovaJet800 Series ServiceManual

List of Illustrations

Figure Page

Chapter 1 General Description

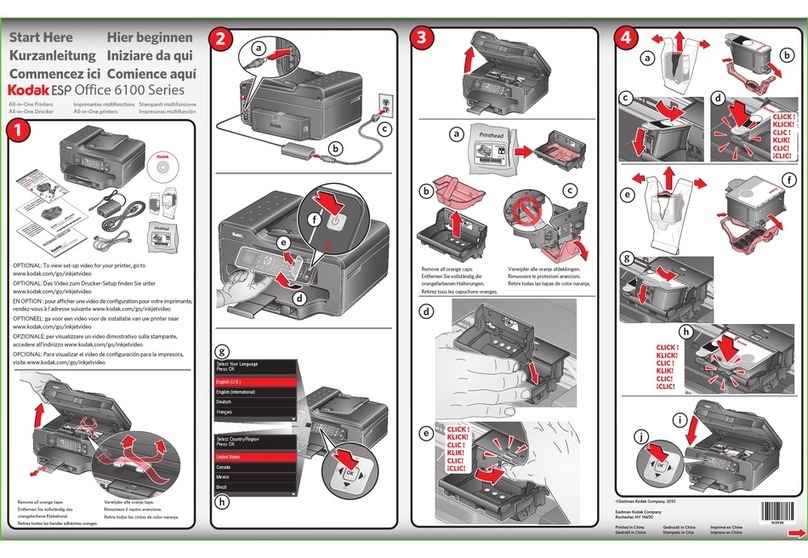

1-1. NovaJet800 Series InkjetPrinter ................................................. 1-1

Chapter 2 Theory of Operation

2-1. General Block Diagram. .............................................................. 2-3

2-2. Paper(Media) AxisDrive. ............................................................ 2-4

2-3. CarriageAxisDrive. ..................................................................... 2-5

2-4. PowerFeed and Take-Up System................................................ 2-6

2-5. MainPWA(Printed Wiring Assembly).......................................... 2-7

2-6. GateArray. ................................................................................. 2-9

2-7. StepperMotorController. ........................................................... 2-11

2-8. Servo Motor Controller. .............................................................. 2-13

2-9. QuadratureSignal Generation.................................................... 2-14

2-10. InterfaceCircuits. .................................................................... 2-15

2-11. Carriage AssemblyCircuits. ..................................................... 2-16

2-12. Main Menu. ............................................................................. 2-18

Chapter 3 Maintenance

3-1. Encoder Strip Cleaning. ............................................................... 3-4

3-2. Cartridge Dimple Region. ............................................................. 3-6

3-3. Flex Cable Contacts.................................................................... 3-7

3-4. MainPWA Connection Locations............................................... 3-10

3-5. Carriage PWA Connection Locations. ........................................ 3-11

3-6. Ribbon Connector Locking Mechanism. ..................................... 3-12

3-7. ServoMotor............................................................................... 3-14

3-8. Stepper Motor. .......................................................................... 3-15

3-9. PowerFeed and Take-Up Motor. ................................................ 3-16

3-10. Examples of Horizontal Banding. ............................................. 3-17

3-11. DialGaugeMicrometerAssembly. ........................................... 3-25

3-12. MeasurementPositionsfor Slide Shaft..................................... 3-26

3-13. SlideShaftProfileAdjustment.................................................. 3-27

3-14. CarriageHeadHeightTolerance. .............................................. 3-28

3-15. SettingUp Tools from Height Gauge Kit. ................................. 3-28

3-16. Zeroing theMicrometer Gauge. ................................................ 3-29

3-17. TestCartridgeInstalled. ........................................................... 3-29

3-18. Vert. andHoriz.Color Calibration. ............................................ 3-32

3-19. Utility Menu. ........................................................................... 3-33

xviii

NovaJet800 Series ServiceManual

List of Illustrations (cont)

Figure Page

Chapter 3 Maintenance (cont.)

3-20. ColorCalib Menu..................................................................... 3-33

3-21. VerticalOptions Menu. ............................................................ 3-34

3-22. Slow Deadband. ...................................................................... 3-35

3-23. Service Menu. ......................................................................... 3-36

3-24. Calibration (Deadband) Menu. .................................................. 3-36

3-25. Calibration Menu. .................................................................... 3-37

3-26. Color Db Menu. ....................................................................... 3-38

3-27. Paper Axis Test....................................................................... 3-40

3-28. Diagnostics Menu. .................................................................. 3-41

3-29. Accessory Menu. .................................................................... 3-41

3-31. CarriagePWAConnectionsDiagram........................................ 3-46

3-32. LegHarnessConnections Diagram. ......................................... 3-47

Chapter 4 Troubleshooting

4-1. CartridgeMisfire. ..................................................................... 4-19

4-2. Excessive Ink Pressure. .......................................................... 4-20

4-3. DirtyServiceStation. ............................................................... 4-21

4-4. SeptumandValves. ................................................................. 4-21

4-5. UnseatedFlexDriver Cable. ..................................................... 4-22

4-6. SeptumConnector. .................................................................. 4-22

4-7. DamagedFlexDriverCable. ..................................................... 4-23

4-8. DefectiveTrailingCable. ........................................................... 4-23

4-9. Unseatedor Defective Trailing Cable......................................... 4-24

4-10. DefectiveCarriage PWA. ......................................................... 4-24

4-11. StallConfiguration.................................................................... 4-25

4-12. MagentaCartridge Misfires. ..................................................... 4-25

4-13. AdjacentJetMisfire(Cyan). ..................................................... 4-26

4-14. Service Station. ....................................................................... 4-27

4-15. DefectiveCartridgePowerLines. .............................................. 4-27

4-16. Catastrophic Jet Failure. ........................................................... 4-28

4-17. PowerLineFailure. .................................................................. 4-28

4-18. Address Line Failure. ............................................................... 4-28

4-19. MultipleAddressLineFailure. .................................................. 4-28

4-20. Microbanding. .......................................................................... 4-29

4-21. Quality Print Modes. ................................................................ 4-29

4-22. InkCartridgeConfigurations. .................................................... 4-30

4-23. DefectiveMagentaCartridge..................................................... 4-31

4-24. AutoWipeInterference. ............................................................ 4-32

4-25. ImproperGrounding. ................................................................ 4-32

xix

NovaJet800 Series ServiceManual

List of Illustrations (cont)

Figure Page

Chapter 4 Troubleshooting (cont)

4-26. Unseated orDefective TrailingCables. ...................................... 4-33

4-27. ESD Problems. ........................................................................ 4-34

4-28. DefectiveCarriagePWAs......................................................... 4-34

4-29.CarriageHead Strike. ............................................................... 4-35

4-31. LowDataTransfer Problem. ..................................................... 4-35

4-32.Test Print. ................................................................................ 4-36

4-33.MisfiringJet.............................................................................. 4-36

4-34.DefectiveCarriagePWA (Color Test). ........................................ 4-37

4-35.DefectiveStepperMotor. ........................................................... 4-37

4-36.DefectiveStepperMotor. ........................................................... 4-38

4-37.ServoSystemSynchronizationFailure. ..................................... 4-39

4-38.RIPError. ................................................................................. 4-39

4-39.ConnectivityProblem . .............................................................. 4-40

4-40. Dirty orDefective EncoderStrip. ............................................... 4-40

4-41.MainPWA Failures. ................................................................. 4-41

4-42.RIPProblem. ........................................................................... 4-42

4-4. BentServoMotor Pulley........................................................... 4-42

4-44. Dirty or Worn Carriage Bushings. ............................................. 4-43

4-45. Worn Bushings or Bushing Pads. ............................................ 4-43

4-46. DefectiveTrailingCable Examples............................................ 4-44

4-47. Dirty Encoder Strip. ................................................................. 4-45

4-48. DefectiveTeflonStrip. .............................................................. 4-45

4-49. RIP Error (Page Layout Violation)............................................. 4-46

4-50. ESDProblem. ......................................................................... 4-47

4-51. Jet Out Detection. ................................................................... 4-48

4-52. CartridgeCleaning. .................................................................. 4-50

4-53. ServiceStationCleaning. ......................................................... 4-51

4-54. Magenta Ink Pressure Failure. ................................................. 4-52

4-55. Ghosting. ................................................................................ 4-53

4-56. CartridgeTubing Needle andSeptum. ...................................... 4-54

4-57. 208Jet Cartridge. .................................................................... 4-55

4-58. EasyPrime Operation. ............................................................. 4-55

4-59. Reservoirsand Ink DeliverySystem.......................................... 4-56

4-60. Excessive Ink Pressure. .......................................................... 4-57

4-61. Excessive Ink PreHeat Settings. .............................................. 4-58

4-62. DirtyServiceStation Problem................................................... 4-60

xx

NovaJet800 Series ServiceManual

List of Illustrations (cont)

Figure Page

Chapter 4 Troubleshooting (cont)

4-63. Normal Color Test (3 Pass)...................................................... 4-61

4-64. AbnormalTest Examples. ........................................................ 4-61

4-65. Cartridge Tubing Needle and Septum. ...................................... 4-62

4-66. Ink Starvation. ......................................................................... 4-63

4-67. CartridgeIdentification Chip. .................................................... 4-64

4-68. Flex Driver Cable. .................................................................... 4-65

4-69. Paper Sensor. ......................................................................... 4-66

4-70. PaperSensor Location. ........................................................... 4-68

4-71. EncoderSensor. ..................................................................... 4-68

4-72. AutoLoadPaperSensor. .......................................................... 4-70

4-73. CarriageHeadAssembly. ......................................................... 4-71

4-74. ServoCycle/PWMMenu. ......................................................... 4-71

4-75. Dirty or Defective Encoder Strip................................................ 4-72

4-76. Main PWATrailingCable Connection. ...................................... 4-74

4-77. Boot ROM Access Function. ................................................... 4-75

4-78. Main PWA LED Operation. ...................................................... 4-76

4-79. Memory Module. ..................................................................... 4-76

4-80. Paper Sensor. ......................................................................... 4-78

4-81. Main PWA LED Operation. ...................................................... 4-79

4-82. FunctionalProblem................................................................. 4-80

4-83. ConnectivityProblem............................................................... 4-80

4-84. ESD Problem. ......................................................................... 4-81

4-85. Main PWA Humidity Sensor..................................................... 4-82

4-86. Dryer LEDs. ............................................................................ 4-85

4-87. DryerConnectivity. .................................................................. 4-85

4-88. InternalTest Print. ................................................................... 4-86

4-89. SEHActivated Test Pattern...................................................... 4-87

4-90. E-Connect LEDs. .................................................................... 4-87

4-91. Driver/RIPProblem. ................................................................. 4-88

4-92. InadaquateNetworkDataTransferRate................................... 4-88

4-93. ESD Problems. ....................................................................... 4-89

4-94. Servo Cycle/PWM Menu. ........................................................ 4-90

4-95. Carriage Bushings. ................................................................. 4-90

4-96. ServoSystem Synchronization Error. ...................................... 4-91

4-97. ProbableDefective Main PWA. ............................................... 4-91

Table of contents

Other ENCAD Printer manuals

ENCAD

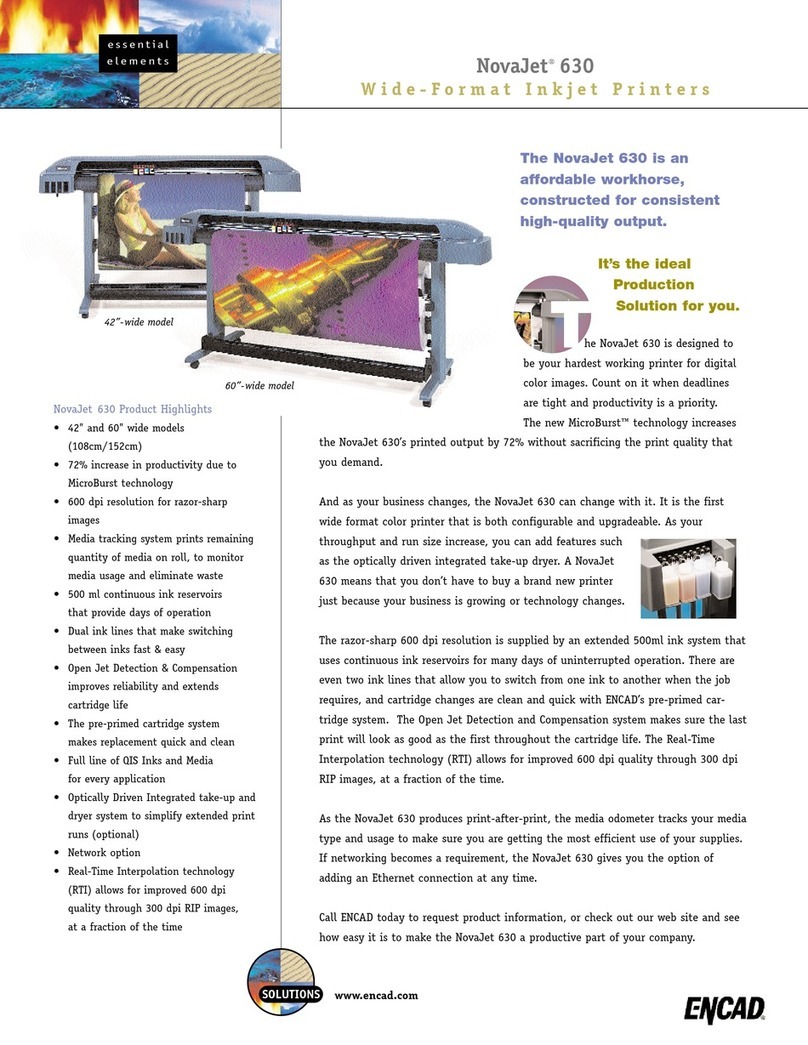

ENCAD NovaJet 630 User manual

ENCAD

ENCAD CADJET 2 User manual

ENCAD

ENCAD NovaJet PRO 600e User manual

ENCAD

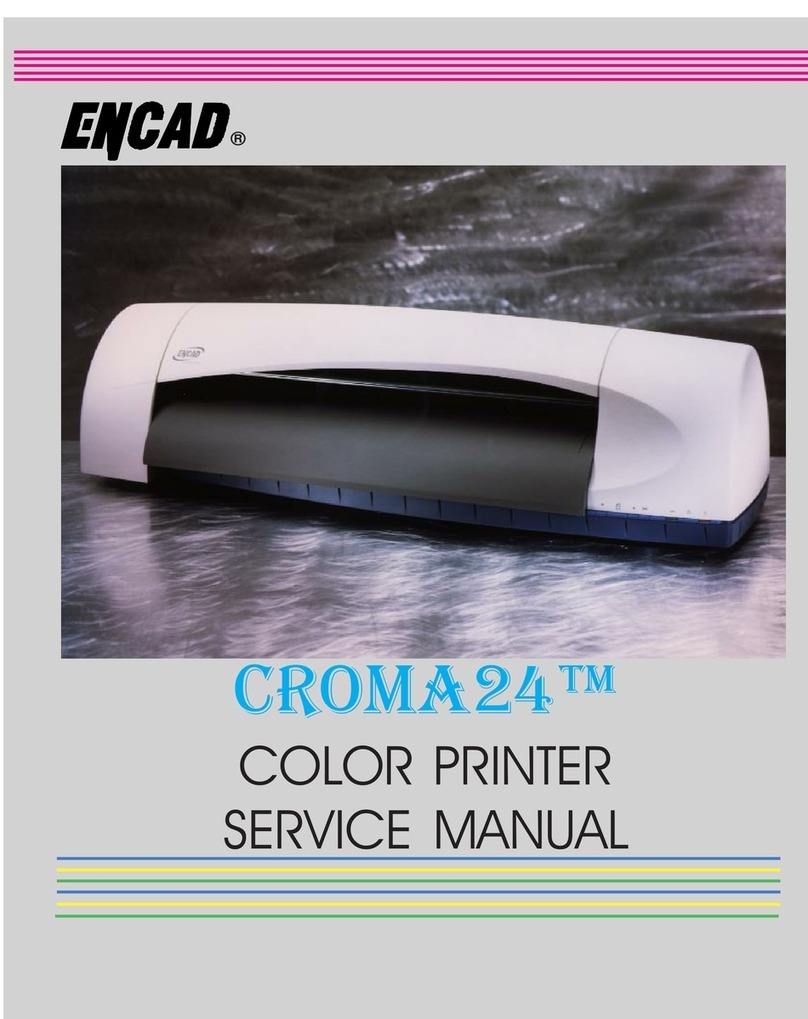

ENCAD CROMA24 User manual

ENCAD

ENCAD CADJET 3D User manual

ENCAD

ENCAD Encad NovaJet 1000i User manual

ENCAD

ENCAD NovaJet PRO 600e User manual

ENCAD

ENCAD CADJET User manual

ENCAD

ENCAD CADJET 3D User manual

ENCAD

ENCAD NovaJet 880 User manual

ENCAD

ENCAD 60e User manual

ENCAD

ENCAD NovaJet 4 User manual

ENCAD

ENCAD NovaJet 500 Manual

ENCAD

ENCAD ENCAD T200+ User manual

ENCAD

ENCAD VinylJet 36 User manual

ENCAD

ENCAD Croma 24 User manual

ENCAD

ENCAD CROMA24 User manual

ENCAD

ENCAD VinylJet 36 User manual

ENCAD

ENCAD NovaCut 24 User manual

ENCAD

ENCAD 215319-1 User manual