ENCAD CADJET User manual

CADJET®3D

COLOR INKJET

PRINTER

SERVICE MANUAL

PartNumber215508-00

®

iv

CadJet3DServiceManual

Copyright © 1999 ENCAD®, Inc. All rights reserved.

ENCAD®andCadJet®are trademarksofENCAD, Inc.

Othertrademarks andregisteredtrademarks arethe

propertyoftheir respectiveowners.

Except as provided below, no part of this manual may be

copiedor distributed, transmitted,transcribed, stored in

a retrieval system, or translated in any human or comput-

ing language, in any form or by any means, electronic,

mechanical, magnetic or otherwise, or disclosed to a

third party without the express written permission of

ENCAD, Inc.,6059 CornerstoneCourt West,San Diego,

CA 92121, U.S.A.

Certainmanuals developed byENCAD areinan elec-

tronicformat tobe distributed onCDs orover the

internet. Theregistered userof anENCAD product

whose manual is distributed in this fashion may print one

copy for their personal use only.

Printing history

1st Edition RevA Feburary2000

v

CadJet3DServiceManual

FCC Statement (U.S.A.)

TheUnited StatesFederal CommunicationsCommision hasspecified that

thefollowing noticebe brought to the attentionof theusers ofthe CADJET

3D printer.

FEDERALCOMMUNICATIONSCOMMISIONRADIOANDTELEVISION

INTERFERENCEFORCLASS BDEVICE

This equipment has been tested and found to comply with the limits for a

class B digital device, pursuant to part 15 of the FCC Rules. These limits

aredesignedto provide reasonableprotectionagainstharmful interference

in a residential installation. This equipment generates, uses, and can

radiateradio frequencyenergy and,if notinstalled andused inaccordance

withthe instructions,may cause harmful interference toradio communica-

tions.

User Instructions:

Ifthe equipment doescause harmfulinterference to radioor television

reception,which canbe determinedby turningthe equipmentoff andon,

the user is encouraged to try to correct the interference by one of the

followingmeasures:

•Reorientorrelocate thereceivingantenna.

•Increasetheseparation betweentheequipmentand receiver.

•Connectthe equipmentinto an outlet on acircuit differentfrom

that to which the receiver is connected.

•Consultthe dealeroran experiencedradio/TV technicianfor

help.

Changesor modificationsnotexpressly approvedby ENCAD, Inc. could

voidthe user’sauthority tooperate theequipment.

vi

CadJet3DServiceManual

VDE Statement

Hiermit wirdbescheinigt, daßder CADJET 3D in Übereinstimmungmit

denBestimmungen derBMPT-AmstbIVfg 234/1991funkentstört ist. Der

vorschriftsmäßigeBetrieb mancherGeräte(z.B. Meßsender)kann

allerdingsgewissen Einschränkungenunterliegen. BeachtenSie deshalb

dieHinweisein derBedienungsanleitung.

DemZentralamtfürZulassungen im Fernmeldewesenwürdedan

InverkehrbringendiesesGerätes angezeigt unddieBerechtigung zur

ÜberprüfungderSerie auf dieEinhaltungder Bestimmungeneingeräumt.

ENCAD, Inc. U.S.A

vii

CadJet3DServiceManual

Material Safety Data Sheet

ENCAD QIS(Quality ImagingSupplies) inkisnonhazardous, requiringno

special disposal handling. It can be harmful if swallowed and should be

keptaway fromchildren.

To obtain a Material Safety Data Sheet, contact ENCAD, Inc. at:

6059 Cornerstone Court West

San Diego, CA 92121-3734

(619) 452-4350

International users should contact their local dealer or distributor.

viii

CadJet3DServiceManual

WARRANTY OR DAMAGE CLAIMS

United States

ENCAD®, Inc., warrants its printers ("PRODUCT") to be free from defects in workmanship

and materials for a period of one year from the date of purchase. In order to submit a

Warranty claim, please contact the ENCAD Help Desk at (619) 452-4350.

ENCAD reserves the right to make changes or improvements to Products, without incurring

any obligation to similarly alter Products previously purchased.

Buyer's sole and exclusive rights pursuant to this Warranty shall be for the repair or

replacement of defective Product. ENCAD specifically disclaims any and all other warran-

ties, expressed or implied, including but not limited to, implied warranties of merchantability

and fitness for a particular purpose. In no event shall ENCAD be liable for any loss of

profit or other commercial damages, special, incidental or consequential damages, or any

otherdamages orclaims, whatsoever.

This Warranty gives Buyer specific legal rights, and Buyer may also have other rights that

varyfrom state tostate.

This Warranty applies only to printers purchased from ENCAD, or authorized ENCAD

distributors or dealers. The intent of this Warranty is to repair or replace defective Prod-

ucts subjected to normal wear and tear, when operated according to ENCAD instructions.

This Warranty does not cover damage to the Product resulting from the following:

• Accident or negligence.

• Unauthorized modification of the Product.

• Adverse environmental conditions.

• Service of the Product by other than an ENCAD authorized service provider.

• Unauthorized or improper use, including but not limited to:

– Use in applications for which the Product was not designed.

– Using cartridges or ink other than those supplied by ENCAD or authorized

ENCAD resellers.

– Using media other than that supplied by ENCAD or authorized ENCAD

resellers.

– Lubricating any part of the printer.

Internationally: Contact your dealer or distributor for warranty information.

ix

CadJet3DServiceManual

Table of Contents

Chapter 1 General Description ............................................................ 1-1

Introduction...............................................................................................................1-1

Overview ...................................................................................................................1-3

RelatedPublications ..........................................................................................1-3

ElectrostaticDischarge (ESD)Sensitivity .................................................................1-3

Warnings,Cautions andNotes .................................................................................1-4

PrinterSpecifications................................................................................................1-5

Contentsof thisService Manual................................................................................1-6

TechnicalSupport .....................................................................................................1-8

Chapter 2 Theory of Operation............................................................ 2-1

Introduction...............................................................................................................2-1

CadJet3DPrinter General BlockDiagram ................................................................2-1

Paper(Media)Axis Drive ..........................................................................................2-3

TheCarriageAxisDrive.............................................................................................2-4

MainPrinted CircuitBoard (MPCB)...........................................................................2-5

Microprocessor ..................................................................................................2-6

GateArray .........................................................................................................2-6

MemoryCircuits.................................................................................................2-7

Flash EEPROM ...........................................................................................2-7

DRAM..........................................................................................................2-8

SerialEEPROM...........................................................................................2-9

StepperMotorController.....................................................................................2-9

ServoMotorController ...................................................................................... 2-11

Interface Circuits:Serial& Parallel ................................................................... 2-13

Carriage AssemblyCircuits .................................................................................... 2-14

ControlPanel.......................................................................................................... 2-15

PowerSupply .........................................................................................................2-16

BeeperandFans .................................................................................................... 2-16

Chapter 3 Maintenance ........................................................................ 3-1

Introduction...............................................................................................................3-1

ScheduledMaintenance ...........................................................................................3-1

CleaningProcedures ..........................................................................................3-2

ExternalCleaning.........................................................................................3-2

SlideShaftCleaning.....................................................................................3-2

x

CadJet3DServiceManual

ServiceStationCleaning ..............................................................................3-3

LinearEncoderStrip Cleaning......................................................................3-4

CartridgeDimplesCleaning..........................................................................3-5

FlexCable Contact Cleaning........................................................................3-6

Cleanand InspectStepperMotor Gears.......................................................3-7

Cleanand InspectMPCB.............................................................................3-7

Cleanand Inspect CarriageAssembly .........................................................3-8

ReseatConnectorson MPCBandCarriage Board..............................................3-8

ReplaceCarriageBushings .............................................................................. 3-10

ServoMotor WindingResistanceCheck ................................................................. 3-11

Stepper Motor WindingResistance Check.............................................................. 3-12

Banding:HardwarevsSoftware............................................................................... 3-13

CommonBandingCauses ......................................................................... 3-14

Alignments/Adjustments.........................................................................................3-16

Slide Shaft ProfileAdjustment .......................................................................... 3-16

HeadHeightAlignment Procedure.................................................................... 3-19

ColorCalibration............................................................................................... 3-23

DeadbandAlignments ......................................................................................3-26

ColorDeadbandAlignment......................................................................... 3-30

Paper Axis Calibration...................................................................................... 3-32

Diagnostics Menu................................................................................................... 3-34

Limited Access Menu .............................................................................................3-37

FirmwareDownload/UpgradingforthePC ...............................................................3-38

FirmwareDownload/UpgradingfortheMAC ............................................................ 3-39

InternalCablingand SignalFlowDiagrams ............................................................. 3-41

Chapter 4 Troubleshooting.................................................................. 4-1

Introduction...............................................................................................................4-1

NoPower ...........................................................................................................4-1

InitializationFailure.............................................................................................4-2

MediaDoesNot Move ........................................................................................4-2

InternalERROR“CarriageAxis Failure” ..............................................................4-3

InternalERROR“EncoderSensor Failure” ..........................................................4-5

Table of Contents (cont)

Chapter 3 Maintenance (cont)

xi

CadJet3DServiceManual

InternalERROR“PaperSensorFailure”..............................................................4-5

InternalERROR“Auto-SensorFailure”................................................................4-6

InternalERROR“MPCBFailure”.........................................................................4-6

UnrecognizedCartridgesError............................................................................4-6

ImageSkewsor Moves ......................................................................................4-7

Does Not Print....................................................................................................4-7

InkCartridgeMisfiring .........................................................................................4-7

PaperSkewing ...................................................................................................4-9

PrinterOutput isBanding(Horizontal) ................................................................4-9

PrinterOutput isBanding (Vertical) .................................................................. 4-11

PrinterOutput isBanding (Horizontallyand Vertically)...................................... 4-11

KeypadLocked-Up or NotFunctioning Properly ............................................... 4-11

NoisyOperation ...............................................................................................4-12

LineQualityDegraded ......................................................................................4-13

FanDoes NotPower Up................................................................................... 4-14

InitializationTroubleshooting ...................................................................................4-16

Chapter 5 Assembly\Disassembly ...................................................... 5-1

Introduction...............................................................................................................5-1

RemovetheLeft,Top, and RightCovers ....................................................................5-2

Installthe Left,Top,and Right Covers .......................................................................5-5

RemovetheKeypad, Display,andDisplayPowerConverter......................................5-6

Installthe Keypad,Display,and DisplayPower Converter.........................................5-8

RemoveMemory(SIMM) ..........................................................................................5-9

Install Memory (SIMM)............................................................................................ 5-10

Remove theMPCB(Main PrintedCircuitBoard) ..................................................... 5-10

Install the MPCB ....................................................................................................5-13

Remove PowerSupply, CoolingFan, andACEntry Module .................................... 5-14

Install the Power Supply, Cooling Fan, and AC Entry Module ................................. 5-16

RemoveServoMotor ...............................................................................................5-17

InstallServoMotor ..................................................................................................5-19

RemovetheInk DeliverySystem............................................................................. 5-20

Installthe Ink DeliverySystem................................................................................ 5-23

Table of Contents (cont)

Chapter 4 Troubleshooting (cont)

xii

CadJet3DServiceManual

Remove theCarriageAssembly,Carriage Belt,andthe FrameTensioner................ 5-23

Installthe CarriageAssembly, CarriageBelt, and theFrame Tensioner..................5-26

RemovetheCarriagePCB ......................................................................................5-28

Install theCarriagePCB ......................................................................................... 5-30

Removethe PaperSensororthe EncoderSensor .................................................. 5-31

Install the PaperSensor or the EncoderSensor...................................................... 5-32

ReplacingtheCarriage Bushings ............................................................................ 5-34

RemovetheServiceStation .................................................................................... 5-35

Install the ServiceStation ....................................................................................... 5-36

Removethe TrailingCableAssembly ...................................................................... 5-36

Install theTrailingCable Assembly ......................................................................... 5-37

Remove the StabilizerBracket andEncoder Strip ................................................... 5-38

Install the Stabilizer Bracket and Encoder Strip ......................................................5-39

Removethe Y-ArmAssembly, PinchRollers, SlideShaft, and Auto-Load Sensor... 5-40

Install the Y-Arm Assembly, Pinch Rollers, Slide Shaft, and Auto-Load Sensor ......5-42

Remove theLower RollerAssembly, StepperMotor andVacuumFan..................... 5-44

Installthe Lower RollerAssembly, StepperMotor and Vacuum Fan........................ 5-47

Chapter 6 Parts List.............................................................................. 6-1

Index...............................................................................................Index-1

Table of Contents (cont)

Chapter 5 Assembly/Disassembly (cont)

xiii

CadJet3DServiceManual

List of Illustrations

Figure Page

Chapter 1 General Description

1-1. CadJet3D Inkjet Printer ..................................................................................1-1

Chapter 2 Theory of Operation

2-1. GeneralBlockDiagram ...................................................................................2-2

2-2. Paper(Media)Axis Drive.................................................................................2-3

2-3. CarriageAxisDrive..........................................................................................2-4

2-4. MainPrinted CircuitBoard ..............................................................................2-5

2-5. GateArray ......................................................................................................2-6

2-6. StepperMotorController .................................................................................2-9

2-7. ServoMotorController................................................................................... 2-11

2-8. QuadratureSignalGeneration .......................................................................2-12

2-9. InterfaceCircuits ........................................................................................... 2-13

2-10. Carrier AssemblyCircuits ............................................................................. 2-14

2-11. MainMenu .................................................................................................... 2-15

Chapter 3 Maintenance

3-1. EncoderStripCleaning ...................................................................................3-5

3-2. CartridgeDimpleRegion..................................................................................3-5

3-3. FlexCable Contacts .......................................................................................3-6

3-4. MainPCB ConnectionLocations.....................................................................3-9

3-5. CarriagePCBConnection Locations ...............................................................3-9

3-6. RibbonConnector LockingMechanism ......................................................... 3-10

3-7. ServoMotor................................................................................................... 3-11

3-8. StepperMotor ...............................................................................................3-12

3-9. Examples ofBanding .................................................................................... 3-13

3-10. Dial Gauge Micrometer Assembly................................................................. 3-17

3-11. Measurement PositionsforSlide Shaft.......................................................... 3-18

3-12. SlideShaft ProfileAdjustment....................................................................... 3-19

3-13. CarrierHeadHeightTolerance ....................................................................... 3-20

3-14. Setting UpTools fromHeight GaugeKit ........................................................ 3-20

3-15. Zeroing theMicrometerGauge ...................................................................... 3-21

xiv

CadJet3DServiceManual

List of Illustrations (cont)

Figure Page

Chapter 3 Maintenance (cont)

3-16. TestCartridgeInstalled.................................................................................. 3-21

3-17. ColorCalibration............................................................................................3-24

3-18. Utility Menu................................................................................................... 3-25

3-19. ColorCalibMenu........................................................................................... 3-25

3-20. CyanVertical OptionsMenu.......................................................................... 3-26

3-21. DeadbandSlow/Fast ..................................................................................... 3-27

3-22. ServiceMenu ................................................................................................3-28

3-23. Calibration(Deadband)Menu ........................................................................3-29

3-24. CalibrationMenu ........................................................................................... 3-30

3-25. ColorDbMenu .............................................................................................. 3-31

3-26. Paper Axis Test ............................................................................................ 3-33

3-27. Diagnostics Menu .........................................................................................3-34

3-28. Accessory Menu........................................................................................... 3-35

3-29. NVRAM Clear and ClockReset Menu ........................................................... 3-37

3-30. MPCBConnectionsDiagram......................................................................... 3-42

3-31. CarriagePCBConnectionsDiagram.............................................................. 3-43

Chapter 4 Troubleshooting

4-1. CarriageBoard LEDD2andD5 Locations..................................................... 4-17

Chapter 5 Assembly/Disassembly

5-1. Right Cover Assembly Removal/Installation .....................................................5-3

5-2. LeftCoverAssemblyRemoval/Installation .......................................................5-4

5-3. KeypadandDisplay Removal/Installation ........................................................5-7

5-4. KeypadGroundingConnection ........................................................................5-8

5-5. Memory(SIMM)Removal/Installation ..............................................................5-9

5-6. MPCBRemoval............................................................................................. 5-12

xv

CadJet3DServiceManual

List of Illustrations (cont)

Figure Page

Chapter 5 Assembly/Disassembly (cont)

5-7. PowerSupplyRemoval .................................................................................5-15

5-8. CoolingFan/ACEntry Module Removal......................................................... 5-16

5-9. Slacken CarriageBelt ................................................................................... 5-18

5-10. ElectronicsCover Removal ............................................................................ 5-21

5-11. DisconnectInk Delivery SystemLink ............................................................ 5-22

5-12. StrainReliefRemoval/Installation .................................................................. 5-24

5-13. Frame Tensioner ........................................................................................... 5-25

5-14. CarriageBelt Clamp ......................................................................................5-25

5-15. CarriagePCBRemoval/Installation ................................................................ 5-29

5-16. Paper andEncoderSensorRemoval ............................................................. 5-31

5-17. PaperandEncoder SensorInstallation.......................................................... 5-32

5-18. CarriageBushingRemoval ............................................................................ 5-34

5-19. Carriage Bushing Installation ......................................................................... 5-34

5-20. ServiceStationRemoval................................................................................5-35

5-21. StabilizerBracket Installation/Removal.......................................................... 5-38

5-22. Y-ArmInstallation/Removal ........................................................................... 5-41

5-23. Pinch Roller .................................................................................................. 5-41

5-24. Inner Platen Assembly/Disassembly............................................................. 5-45

5-25. StepperMotorRemoval/Installation ............................................................... 5-47

5-26. Inside Platen, RightSide............................................................................... 5-49

Chapter 6 Parts List

6-1. LeftSide PartsBreakdown..............................................................................6-3

6-2. PlatenandAbove PartsBreakdown ................................................................6-5

6-3. RightSide PartsBreakdown ...........................................................................6-7

6-4. InnerPlatenParts Breakdown .........................................................................6-9

6-5. CarriageAssembly Parts Breakdown ............................................................ 6-11

xvi

CadJet3DServiceManual

List of Tables

Table Page

Chapter 1 General Description

Chapter 2 Theory of Operation

Chapter 3 Maintenance

Chapter 4 Troubleshooting

4-1. TroubleshootingTable......................................................................................4-1

Chapter 5 Assembly/Disassembly

Chapter 6 Parts List

1

1-1

GENERAL

DESCRIPTION

GeneralDescription

Figure 1-1. CadJet 3D Inkjet Printer.

Introduction

Thismanual providesservice informationfor the ENCAD®, Inc. 36

inchCadJet 3D Color InkjetPrinters.

Itiswritten forservicepersonnel whopossessanalog anddigital

circuitryexperience. Chapter 2,Theory of Operation,should be read

andthoroughlyunderstoodbeforetroubleshooting/calibratingthe

printers.

Theprinters supportbothpre-cut androll media. Mediasize is auto-

maticallydetermined andhardcliplimits areset accordingly. Pre-cut

1-2 GeneralDescription

CadJet3DServiceManual

mediauses differentmaximum plotting areasthan rollmedia. See the

PrinterSpecifications intheUser Guidefor moredetailson themedia

sizeprintablearea.

BothRS-422serialand Centronics parallelconnectionsareprovidedto

interfacewith thehostcomputer. Network connectionsare made

possiblethrough the installedXCD printserver. Commands sent from

thehost computercan be inseveral formsincluding HP-GL/2, HP-RTL

andEN-RTL formats.

Driversaresupplied tosupportWindows-basedPC’s (3.XX,95/98,and

NT)as wellas Macintoshand PowerPC computers.

Theseprintersexpand uponENCAD’s traditionof deliveringfast, high-

qualitycolor or monochromegraphics foravariety ofapplications.

ENCAD hasmade significantadvancesin designingthese printersto

respondto and anticipateour customers’needs. Principalfeatures are

summarizedbelow.

LocallyorRemotelyConfigured viaHostComputer

Take-UpBasket

Self-AligningPinchRollers

PowerPC33MHzMicroprocessor

8UserConfigurableSettings

208JetInk Cartridges

Ink Priming System

BulkInk DeliverySystem with 250mlInk Reservoirs

orRefillableFoamCartridges

SmartCartridges

OdometerFunction

GeneralDescription 1-3

CadJet3DServiceManual

GENERAL

DESCRIPTION

Overview

Printersdraw accordingto instructions issuedfrom a“host” computer.

Everyprinteris engineeredtounderstand aspecificset ofinstructions

andto executeeach instructionin aprecise manner. Inaddition, most

printersaredesignedtoexecute predetermined charactersautomati-

callywithout a specificline-by-line instructionfromthe program.

Thesecharacters arepart of theprinter’s permanentmemory.

Related Publications

Thefollowingpublication contains additionalinformationwhichmay

beuseful inservicing the ENCAD, Inc. CadJet 3D ColorInkjet

Printers:

•ENCAD ReadmeFirst forthe CadJet 3D,

P/N 215057-00

•ENCAD CadJet 3D QuickStart Guide,

P/N 215058-00

•ENCADCadJet 3D CD-ROM Set,

P/N 215059-00

Copiesofthese andotherENCAD, Inc. publications maybeobtained

bycontacting yournearestauthorized ENCAD, Inc. dealer orby

contactingENCAD’s TechnicalSupport and ServiceDepartment.

Electrostatic Discharge (ESD) Sensitivity

AllPCBs(Printed CircuitBoards)associated withtheCadJet 3D

printershavecomponentssensitive toESD(electrostaticdischarge).

Caremust betaken toavoid damage toany ofthe componentsby

followingcurrentESD handling proceduresandpractices.

Alwaysusean approvedESDgrounding strapwhenhandling or

workingwith PCBs.

1-4 GeneralDescription

CadJet3DServiceManual

Warnings, Cautions and Notes

Warnings,cautionsand notesareused when additionalinformation,

instructionsor careshould beobserved. In thismanual warnings,

cautionsand notes precedethe texttowhich eachapplies. The defini-

tionofeach isprovidedbelow.

WARNINGS - Warnings areused tostress thatthe followingsteps or

procedureshas thepotential to causeserious harmor deathto service

personnel. Extremecareshould be observedwhenfollowing the proce-

duresandto exercisestandardsafety procedures. Theyareindicated

by:

Followedbya paragraphdescribingthe concern.

CAUTIONS - Cautionsdepictthat the followingstepsorprocedures can

causedamageto theequipmentif notproperlyfollowed. Extreme care

shouldbeobservedwhen followingtheproceduresandto exercise

standardsafetyprocedures. They areindicatedby:

Followedbya paragraphdescribingthe concern.

NOTES - Notesare placedbeforeaprocedure toinformtheservice

personnelofspecific detailstoimprove quality,togive reminders of

interrelatedpartsand toprovideother helpfulinformation. Theyare

indicatedby: NOTE

Followedbya paragraphdescribingthe concern.

GeneralDescription 1-5

CadJet3DServiceManual

GENERAL

DESCRIPTION

Printer Specifications

Thespecificationsand performancecharacteristicsof the CadJet 3D

ColorInkjet Printers areas follows:

Max Printing Area:

Norm 40.8”

1.04m

Extend 41.61”

1.06m

Language Emulation:

HP-RTL

EN-RTL

HP GL/2

Buffer:

64MBinstalled

upgradeableto128MB

Power Requirements:

InputVoltage:

90-246VAC

47-63Hz

OutputPower:

20W idle

140W typical

215 W maximum

Resolution:

600x600dpior

300x600dpiin monofast

draftmode

Baud Rates:

9600,19200,38400

Accuracy:

greaterof +/-0.2% line

length or +/- 0.015 in. (0.38

mm)in vectormode with

Calibration“on”and using

4mil draftingmatte film

Interface:

Centronicsparallel

(IEEE1284)

RS-422serial

Network:via 100Base T

PrintServer

Certifications:

Safety

CSA,CSE/NRTL

(equivalenttoUL1950)

EN50082-1

EN60 950

UL1950

NOM-019-SCFI-1993

IEC950

AS/NZS3260

IRAM

EMIFCCClassB

CSAC108.8

EN55 022 ClassB

GB9254-98

CISPR22-Class B

AS/NZS3548

1-6 GeneralDescription

CadJet3DServiceManual

Contents of this Service Manual

Figuresare used inthis manualto clarify procedures. Theyare for

illustrativepurposes only andmay notnecessarilybe drawnto scale.

Materialin thismanual maybe repeated invarious chaptersso that

eachchapter can“standalone”. This allowsinformation tobelocated

withouthaving to referback andforthbetween chapters.

Figuresandtables areeasilylocatedand cross-referenced,andare listed

inthe frontof themanual under List of Illustrationsand Listof Tables.

Thismanual isdivided intosix chaptersas:

Chapter1 GENERAL DESCRIPTION -Contains ageneral

descriptionof the ENCAD CadJet 3D printer. This

includesprinterspecifications,and relatedmaterials.Also

includedis adescriptionof theuse of Warnings,Cautions

andNotes asused inthis manualand chaptercontents.

Chapter2 THEORY OFOPERATION -Functional

descriptionsofthe overallprinterand major assembliesare

containedinthis chapter.

Environment:

Operating:

41° to 95° F

(5° to 35° C)

20%to 80% RH

non-condensing

Storage:

-5° to 140° F

(-21° to 60° C)

5% to 80% RH

non-condensing

Weight:

head 58 lbs 60 lbs(boxed)

stand 37 lbs 40 lbs(boxed)

Dimensions:

Height 48” (1.21m)

Width 55” (1.40m)

Depth 30” (0.77m)

Table of contents

Other ENCAD Printer manuals

ENCAD

ENCAD 60e User manual

ENCAD

ENCAD NovaJet PRO 600e User manual

ENCAD

ENCAD NovaJet PRO 600e User manual

ENCAD

ENCAD NovaJet 4 User manual

ENCAD

ENCAD NovaJet 800 Series User manual

ENCAD

ENCAD 215319-1 User manual

ENCAD

ENCAD Croma 24 User manual

ENCAD

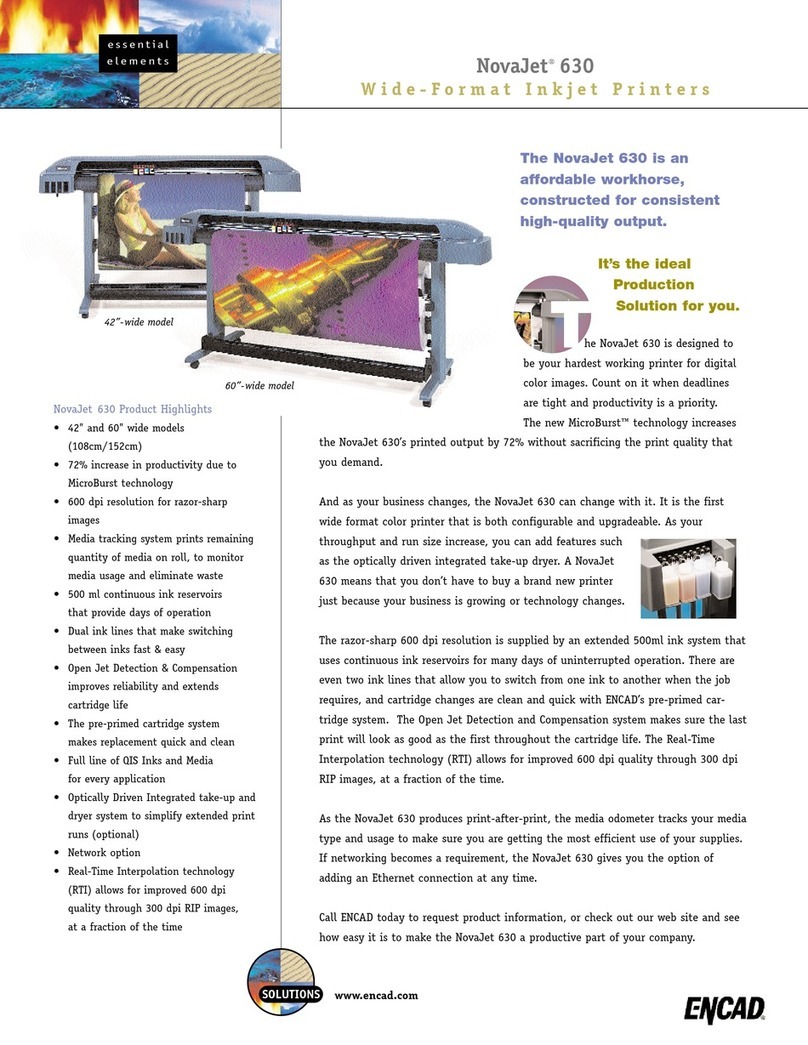

ENCAD NovaJet 630 User manual

ENCAD

ENCAD VinylJet 36 User manual

ENCAD

ENCAD Encad NovaJet 1000i User manual

ENCAD

ENCAD CADJET 3D User manual

ENCAD

ENCAD ENCAD T200+ User manual

ENCAD

ENCAD NovaCut 24 User manual

ENCAD

ENCAD NovaJet 880 User manual

ENCAD

ENCAD CADJET 3D User manual

ENCAD

ENCAD CROMA24 User manual

ENCAD

ENCAD NovaJet 500 Manual

ENCAD

ENCAD CADJET 2 User manual

ENCAD

ENCAD CROMA24 User manual

ENCAD

ENCAD VinylJet 36 User manual