ENCAD 215319-1 User manual

CADJET

®

3D

Wide Format Inkjet Printer

User Guide

Text P/N 215319-1 Rev. B

Copyright © ENCAD, Inc. 2000

NOVAJET®, ENCAD®, CADJET®, NovaXsell™, Posterizer™, Extreme Color

Printing™ and Quality Imaging Supplies™ are trademarks of ENCAD, Inc.

Other trademarks are the property of their respective owners.

Except as provided below, no part of this manual may be copied or distributed,

transmitted, transcribed, stored in a retrieval system, or translated in any human

or computing language, in any form or by any means, electronic, mechanical,

magnetic or otherwise, or disclosed to a third party without the express written

permission of ENCAD, Inc., 6059 Cornerstone Court West, San Diego, CA

92121, U.S.A.

Certain manuals are distributed by ENCAD in an electronic format on CD-ROM

or over the internet. The registered user of an ENCAD product whose manuals

is distributed in this fashion may print one copy for their personal use only.

Revision History

Rev.A March 2000

Rev. B April 2000

ii

CADJET®3D User Guide

WARRANTY CLAIMS

United States

ENCAD®, Inc., warrants its printers (“PRODUCT”) to be free from defects in workmanship and

materials for a period of one year from the date of purchase. In order to submit a Warranty claim,

please contact the ENCAD Help Desk at (858) 452-4350.

ENCAD reserves the right to make changes or improvements to Products, without incurring any

obligation to similarly alter Products previously purchased.

Buyer’s sole and exclusive rights pursuant to this Warranty shall be for the repair or replacement

of defective Product. ENCAD specifically disclaims any and all other warranties, expressed or

implied, including but not limited to, implied warranties of merchantability and fitness for a

particular purpose. In no event shall ENCAD be liable for any loss of profit or other commercial

damages, special, incidental or consequential damages, or any other damages or claims, whatso-

ever.

This Warranty gives Buyer specific legal rights, and Buyer may also have other rights that vary

from state to state.

This Warranty applies only to printers purchased from ENCAD, or authorized ENCAD distribu-

tors or dealers. The intent of this Warranty is to repair or replace defective Products subjected to

normal wear and tear, when operated according to ENCAD instructions.

This warranty does not cover damage to the Product resulting from the following:

·Accident or negligence.

·Unauthorized modification of the Product.

·Adverse environmental conditions.

·Service of the Product by other than an ENCAD authorized service provider.

·Unauthorized or improper use, including but not limited to:

-Use in applications for which the Product was not designed.

-Using cartridges, ink, or media other than ENCAD QIS products.

-Lubricating any part of the printer.

Internationally: Contact your reseller for warranty information.

Extended Warranty: An extended warranty is available for your printer. For information in the

U.S., call 1-800-45ENCAD. Internationally, contact your reseller for further information.

iii

CADJET®3D User Guide

FCC Statement (U.S.A.)

The United States Federal Communications Commission has specified that the following notice be

brought to the attention of users of the ENCAD printers.

FEDERAL COMMUNICATIONS COMMISSION RADIO AND TELEVISION INTERFER-

ENCE FOR CLASS A DEVICE

Statement

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy, and if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications.

User Instructions:

If the equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment on and off, the user is encouraged to try to correct the

interference by one of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

•Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by ENCAD, Inc. could void the user’s authority

to operate the equipment.

Note: This product was FCC certified under test conditions that included the use of shielded I/O

cables and connectors between system components. To be in compliance with FCC regulations,

the user must use shielded cables and connectors and install them properly.

iv

CADJET®3D User Guide

VDE statement

Hiermit wird bescheinigt, daß der Drucker in Übereinstimmung mit den Bestimmungen der

BMPT-AmstbIVfg 234/1991 funkentstört ist. Der vorschriftsmäßige Betrieb mancher Geräte

(z.B. Meßsender) kann allerdings gewissen Einschränkungen unterliegen. Beachten Sie deshalb

die Hinweise in der Bedienungsanleitung.

Dem Zentralamt für Zulassungen im Fernmeldewesen würde den Inverkehrbringen dieses Gerätes

angezeigt und die Berechtigung zur Überprüfung der Serie auf die Einhaltung der Bestimmungen

eingeräumt.

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet apparell numérique de la classe A respecte toutes les exigences du Réglement sur le matériel

brouilleur du Canada.

Material safety data sheet

To obtain information on the proper use, handling, and disposal of any ENCAD QIS ink,

consult the material safety data sheet included in the ink kit or obtain a copy from

ENCAD, Inc. at:

6059 Cornerstone Court West

San Diego, California 92121-3734

(858) 452-4350

International users should contact their local reseller.

v

CADJET®3D User Guide

General operating safety

The use of a <HAR> cord set (rated 10A, 250VAC) with the proper plug configuration

for the country where the device will be used, is required for continued safety compli-

ance.

Ein harmonisiertes (<HAR>) Netzkabel (min. 10A, 250V~) mit dem vorgeschriebenen

Netzstecker für das entsprechende Land in dem das Gerät installiert wird, ist unbedingt

notwendig für die elektrische Sicherheit.

El uso de cable poder <marcado HAR> (capacidad de 10A, 250V~), con el enchufe

apropiado para el país donde se use el producto, es requerido para acatamiento de

seguridad eléctrica.

L' emploi d' un cordon surmoulé <HAR> (estimé 10A, 250V CA) avec la configuration

de la fiche convenable pour le pays où l' appareil sera utilisé, est exigé pour la

conformité à la sécurité continuée.

Manual conventions

➪Indicates a procedure for you to follow in order to perform a specific function.

Read the accompanying explanatory text before following the step-by-step

procedure.

!Indicates a warning. Ignoring the warning can damage the printer or result in an

unsatisfactorily printed image.

✓Indicates a tip or suggestion that can make using the printer easier or improve

your printed images.

vi

CADJET®3D User Guide

Other reference materials

In addition to this guide, the following additional documentation is included with your

printer:

Quick Start Guide - Tells you how to assemble and install the printer's hardware.

TwoCD-ROMs

One CD-ROM contains sample images.

The other CD-ROM contains:

•this guide;

•Maintenance Guide, instructions for maintaining your printer;

•V/R Xpress driver;

•Heidi driver;

•ADI driver; and

•print server software.

vii

CADJET®3D User Guide

Contents

Introduction ............................................................ 1-1

Printing .....................................................................................1-1

Obtaining quality results .............................................................1-2

Caring for your ink and cartridges ................................................1-3

Nine Factors that Affect Print Quality ...........................................1-4

Printer options ........................................................ 2-1

Returning to the default settings ..................................................2-1

Printing the settings ...................................................................2-1

Choosing print mode options .......................................................2-1

Important notes about image size vs. dpi......................................2-2

Color mode................................................................................2-3

Quality modes ...........................................................................2-3

Choosing feed media options ......................................................2-4

End of media .............................................................................2-4

Media counter............................................................................2-5

Choosing paper options ..............................................................2-6

Supply Type ..............................................................................2-6

Media standard ..........................................................................2-7

Margins ................................................................................... 2-10

Auto-Load Delay ...................................................................... 2-11

Auto-Cut ................................................................................. 2-11

Save Media ............................................................................. 2-11

Auto-Wipe ............................................................................... 2-12

Defining user setup .................................................................. 2-12

Choosing a language ................................................................ 2-13

Choosing ink options ................................................................ 2-13

Printer Default Settings ............................................................. 2-16

Printing ................................................................... 3-1

ENCAD V/R Xpress driver ...........................................................3-1

Heidi driver ................................................................................3-8

ADI driver ................................................................................ 3-12

viii

CADJET®3D User Guide

HPGL/2.................................................................... 4-1

CAD printing modes ...................................................................4-1

Printing vector data ....................................................................4-1

Accessing HPGL/2 features ........................................................4-2

Palette select ............................................................................4-2

Control ......................................................................................4-3

Rotation ....................................................................................4-4

Reprints ....................................................................................4-4

Nesting .....................................................................................4-5

Nest wait time ...........................................................................4-6

Ink limit .....................................................................................4-7

HPGL/2 Test File .......................................................................4-7

Installing additional memory ..................................A-1

Acceptable SIMM sizes ............................................................. A-1

SIMM installation ...................................................................... A-1

Serial Communications and Cabling.......................B-1

RS-422 cable requirements ........................................................ B-1

Setting serial communications parameters .................................. B-2

Setting the baud rate................................................................. B-2

Setting the parity bit .................................................................. B-2

Menu tree ................................................................C-1

Main menu at a glance .............................................................. C-1

Main menu ............................................................................... C-2

Feed media menu ..................................................................... C-3

Setup menu at a glance............................................................. C-4

Setup menu.............................................................................. C-5

Utility menu at a glance............................................................C-10

Utility menu .............................................................................C-11

Calibration Menu ......................................................................C-12

Service Menu...........................................................................C-13

Technical information .............................................D-1

Error messages....................................................... E-1

Error Messages ........................................................................ E-1

Cartridge Errors ........................................................................ E-1

ix

CADJET®3D User Guide

Troubleshooting ...................................................... F-1

Troubleshooting quick list ...........................................................F-1

Isolating problems ......................................................................F-1

Printer Health ............................................................................F-2

Data Transfer ...........................................................................F-12

Application Software.................................................................F-15

Calling for Help ........................................................................F-17

Customer Technical Support .....................................................F-17

Introduction 1

This User Guide provides complete information on the CADJET®3D printer.

The printer is a wide-format color inkjet printer that gives you professional-quality output

with all the brilliance and gloss of liquid ink. For CAD, engineering, architectural, creative

and business professionals, this printer lets you experience the value of exceptional

graphics quality and cut hours of production time, while giving you the dramatic impact of

high fidelity images.

Printing

Wide format inkjet printers let you create printed pieces the length of a roll of media (up to

300'). Only Extreme Color Printing™ combines the technical sophistication of the

CADJET printer with the unique qualities of ENCAD CIS ink and media.

Your printer features a continuous-feeding ink system which uses 500ml reservoirs for

each color, so you never have to worry about running out of ink halfway through a big

print job. Before starting a print job, just look at the transparent plastic reservoirs to

check the ink supply. When the ink supply is low, just open the cap and refill.

Introduction 1-2

CADJET®3D User Guide

The printers accept raster-oriented data in the form of HP RTL format. In this mode,

printing begins immediately after the first complete line of HP RTL data is received.

Depending on the software used, millions of colors are possible, yielding superb results.

If your applications do not support HP RTL, there are several software utilities available

to convert various raster file formats (TIFF, GIF, BMP, etc.) into HP RTL. There are also

more than 50 Raster Image Processors (RIPs) which convert Postscript or CGM to HP

RTL. When choosing a RIP or a file format converter for output to the printer, make sure

it has the features you need. (Contact your ENCAD distributor or dealer for an up-to-date

listing.)

Obtaining quality results

You have probably seen a demonstration of your printer's capabilities or sample output. If

so, you are aware of the superb color graphics which can be obtained, and the variety of

papers and films you can use. Note, however, that to obtain high-quality results, you must

consider several factors. Follow the simple guidelines in the sections that follow to obtain

excellent results.

Use the right inks and media

ENCAD’s commitment to Extreme Color encompasses media, ink, and cartridges. A

team of color scientists and media specialists work with world class ink and media

manufacturers to develop supplies that are scientifically matched to ENCAD printers.

Used together, ENCAD inks and media provide the widest color gamut available, making

our Quality Imaging Supplies ideal for applications from proofs to presentations.

ENCAD inks and media give you optimal image quality through:

•Scientifically matched ink and media

•Ultra-wide color gamut or process standard

•Media: bond paper, photogloss, vellum, and clear film.

Introduction 1-3

CADJET®3D User Guide

Caring for your ink and cartridges

!Handle cartridges only on the plastic areas. Touching the copper electrical interconnect

or the inkjets can damage the cartridge.

•Be sure the ink in the cartridges matches the ink in the reservoirs.

•Do not mix inks.

•Do not shake ink refill containers.

•Store ink and cartridges in the same environment as the printer whenever possible.

•Removing cartridges may result in loss of negative pressure and cause the cartridge to

leak through the jet plate. If you remove a cartridge from the printer, do not leave it

exposed to the air for an extended period because the jets may clog. Replace the

original tape on the jet plate. Place the cartridge in a cartridge garage or sealed plastic

bag and store it in a closed area at room temperature. Keep it out of direct sunlight.

•Open new cartridges only when you are ready to install them.

•Use only ENCAD-brand ink refills and cartridges.

•Drawings containing both black and color elements require alignment of the cartridges

to each other. See the Quick Start Guide for details.

Choose the right media

You can rely on ENCAD media for rich, vivid images across the entire color spectrum.

ENCAD media is specially formulated to demanding specifications, strict performance

criteria, and uncompromising quality controls. This assures superb interaction with CIS Ink

and flawless performance with the printer.

Caring for your media

Store media in its original packaging in a cool, dry area until you are ready to use it. The

environment should be stable; i.e., no extremes of heat and cold, and non-condensing

humidity. If conditions are outside the operating ranges recommended for the printer,

allow the media to acclimate in the operating environment for at least 48 hours before

using it.

If you remove a roll of media from the printer, be sure to store it in a manner which keeps

it clean and dust-free. Ideally, you should return it to its original packaging for storage.

Introduction 1-4

CADJET®3D User Guide

Print on the correct side! Roll media is wound with the coated side out. Cut sheet

media has an ink-receptive and a non-ink-receptive side. The sheets are notched to help

you orient them correctly. To assure that you print on the correct side, be sure that the

notch is in the upper right corner when you feed the sheet into the printer.

Handle with care! Handle your media carefully to avoid creases, scrapes, and tears.

Avoid crushing or damaging roll media edges.

Wear cotton gloves! Film-based and photographic paper-based media are sus-

ceptible to absorbing skin oils. Fingerprints on the media prior to printing may

result in visible fingerprints after ink is applied.

Choose the correct printing mode

There are four pre-defined printing modes, giving you freedom to tradeoff drawing quality

and speed. When printing heavier renderings, maps, or art graphics, choose one of the

enhanced printing modes (Normal or Best).

Use the right software

The quality of the software driver or the RIP can be very important, especially when

printing continuous tone images or 3D renderings. Error diffusion or stochastic screening

algorithms can yield photo-like images, even when these images are scaled to full size.

Software without advanced imaging features may produce images which are grainy when

enlarged.

Nine Factors that Affect Print Quality

Understanding all the factors that contribute to print quality is the only way to ensure

perfect printing each and every time. This section details nine important factors; by

controlling them, you can achieve the very best print quality possible.

1. Use the highest quality type of image possible.

2. Check to make sure the image is in focus and exposed properly.

3. Scan it with the best scanner possible.

4. Scan it at the proper resolution.

5. Color correct and sharpen the image with software.

6. Ensure your color profile accurately reflects the exact ink and media you are using.

7. Use the best diffusion pattern available in your RIP.

8. Use only the best possible ink and media combinations.

9. Make sure your cartridges are aligned and firing properly.

Introduction 1-5

CADJET®3D User Guide

1. Original Image Type

The type of original image will determine the quality of your final inkjet print. The best

image type is an original transparency (not a duplicate). They are extremely crisp with

superb edge definition. Print film photos are not as good as they are already one genera-

tion removed from the original film. Also, because of the emulsion process of photo

prints, edge definitions tend to be lost. Color prints can be used, but they have to be of

very good quality to produce acceptable scaled prints. Digital photo files are newest

image type. Many are unacceptable for large-format printing as they contain only a

small fraction of the information contained in a film transparency.

For example, most digital cameras can only create a 1 MB file. This is not enough

information for large inkjet prints. A file must be at least 10 - 12 MB for a fair print and

30 - 50 MB for a good E-size print (see scanning section). Only the best commercial

digital cameras can achieve these files sizes. Digital files from other sources such as

CD stock photography are usually created from scanned transparencies, so may be

suitable for inkjet printing. Check with the manufacturer to ensure that the images are at

least 10 - 12 MB and were created from drum-scanned transparencies.

The better CDs have images of 28MB or more stored in a TIFF format. These are

preferable for great quality prints. If you use a file stored in PhotoCD format, make sure

you use the highest resolution available. Images stored in compressed files such as

JPEG, LZW, GIF, etc. can lose valuable data during the compression process. Avoid

images stored this way if possible. If you have to use a compression file format for

whatever reason, use JPEG. It is closer to a “lossless” compression.

2. Original Image Clarity and Color

The quality of the original photograph, transparency, or digital file plays a key role in

final print quality as this is where the clarity and color of the image is created. If the

original photographer took a picture that was not in focus, or was fuzzy for any reason,

sharpening or after-effects cannot correct it and a poor inkjet print will result. Differ-

ences in film, speed, grain, or developing process can also affect quality of prints. If the

image was too dark or too light, color correction cannot correct it and a poor inkjet print

will result. The axiom of “garbage in, garbage out” applies to all printing, including

inkjet printing. Companies that utilize a lot of photography for large-format inkjet

printing should check for focus by using a loupe. If you have a good, in-focus original,

you can maintain the image quality throughout the entire process.

Introduction 1-6

CADJET®3D User Guide

3. Scanner Type

How you get the original image into the computer is important to the overall printing

process as scanner quality varies greatly. Using a scanner that meets the requirement of

the overall print quality is essential to have enough color fidelity and edge clarity. An

image scanned with a low end scanner will lose detail, clarity, and color. It is important

that you understand what type of image quality is required for your print and use the right

scanner to achieve it.

Traditionally, drum scanners are ideal for retaining the best edge definition and color

depth. If the original image is poor, an expensive drum scan may be a waste of money.

Almost all service bureaus use drum scanners.

Flatbed scanners require an optional transparency adapter to scan transparencies.

4. Scan Resolution

Scanning the original at low resolution will degrade the large-format inkjet print quality.

Scanning at resolution which is too high slows down the RIP and adds no quality to the

image. Consequently, choosing the right resolution for the output print size (and thus, the

amount of scaling needed after scanning) will determine what the optimum resolution is

for each image.

The quality of the image you would like to produce is determined by the final output size

and the file size. For example, if you want output a 36" x 36" image, the file size will be

approximately 24MB for a fair-good quality image (75dpi), 43MB for a good-very good

quality (100 dpi) and 97MB for an excellent quality (150 dpi) print.

Your service bureau can help you determine the optimum resolution to scan your image

based on the size and quality of the image you would like to print.

DONOTUSEINTERPOLATEDRESOLUTIONOFYOURSCANNERTOCOM-

PUTE IMAGE SIZE

Most 300 dpi scanners can interpolate or “imitate” 600 dpi scanning. This is really not

really scanning at 600 dpi and will degrade the image quality. When scanning, ensure that

you are using the scanner's true optical resolution, not its interpolated resolution. Scan-

ning at the highest optical resolution (300 dpi) is better than scanning at the scanner's

highest interpolated resolution (600 dpi).

Introduction 1-7

CADJET®3D User Guide

5. Post Scanning Color Correction and Sharpening

All scanned images, even those scanned on expensive drum scanners, must be color

corrected and sharpened before using them for a large-format inkjet print. If you are

using a service bureau for scanning images, their scanner operator will usually do this as

part of the scanning fee. However, you should always check the image before using it.

Although the process of color correction and sharpening are more detailed than can be

explained within this document, the following outline will give you a good grasp of

what is required:

Color Correction - all scanners give the image a slight color cast during the scanning

process. This happens because all light sensing devices have a slight bias. The easiest

way to correct most of this color cast is to use a function such as Auto Levels in

PhotoShop. This function finds the whitest pixel and the darkest pixel in an image and

distributes all colors in-between. This works well on 75% of all images that are properly

exposed. In very dark night scenes or in very white snow background scenes, Auto

Levels does not work properly and the correction must be made manually using histo-

gram adjustments.

Sharpening using UnSharp Mask - all scanned images, even images scanned on the

most expensive drum scanners, need to be sharpened. The best digital tool to do this

with is a function called an unsharp mask (available in programs such as PhotoShop).

An unsharp mask basically redefines the edges of images by adding a mask. Most

unsharp mask tools allow you to set the pixel width of the mask and the amount of

sharpening. A good start is to use a pixel width of 3 - 5, with an amount of 75%. Too

much unsharp mask will give the whole image a hard, pixelated look. A little more

unsharp mask can be used with inkjet images as they are somewhat diffused in the

printing process, hiding any small amounts of oversharpening.

6. RIP Color Profile

The engine that converts your image into a series of C, M, Y, K dots is called the Raster

Image Processor or RIP. Before it can actually create these dot patterns, it must first

adjust for the colors of the inks, color of the media, dot volume of the cartridges on a

particular machine, and the humidity/temperature of the environment on the day of

printing (as this affects how far the ink will spread or dot gain). Most RIPs include what

is commonly referred to as a color profile or color link. This profile is automatically used

when you choose the media and ink within the software.

Introduction 1-8

CADJET®3D User Guide

7. RIP Diffusion/Dither Patterns

Images that are going to be printed on an inkjet printer are eventually divided into C, M, Y,

K and rasterized into dots using patterns that cause the eye to see a continuous tone

image. These patterns are called many things, such as frequency modulated screening,

diffusion patterns, dither patterns, screen patterns, etc. There are various types of screen-

ing that are better for photographic images. Stochastic screening was developed specifi-

cally for the CMYK process to avoid the problem of visually perceptible banding that

occurs with other pattern types. It does this by pseudo-random placement of dots. Varia-

tions of the stochastic strategy have evolved into even better patterns. Each RIP manufac-

turer uses different names to describe its particular variation on the stochastic theme. To

get the best print quality, make sure you are using the best possible diffusion pattern

available from the RIP software you are using. Also remember that a different diffusion

pattern should be used for spot color objects (such as filled vector objects). If you are

printing an image that contains both photographs and spot color objects, use the diffusion

pattern designed for photos.

8. Ink and Media

Using the right ink and media is a much bigger factor in print quality than most inkjet

users realize. It takes many months of using a printer before a user begins to understand

what an exceptional print looks like. Then and only then can they fully appreciate what

quality materials and inks can do. Inks must be developed specifically for a particular

head, otherwise, cartridge reliability will be severely reduced. ENCAD inks are specifi-

cally developed for ENCAD cartridges, printers, and media. These inks create the perfect

ink drop shape, trajectory, and landing shape when used with ENCAD cartridges. The

media controls the color, dot gain, and durability of the final print. As the ink must

chemically interact with the media, only medias developed specifically for a particular

ink can achieve the perfect dot shape that leads to improved image quality. Additionally,

the chemical bond created through co-developed inks and medias is much better than

independently developed inks and medias. Although many people will not be able to

visually perceive differences in quality inks and medias initially (poor inks and medias

show more pronounced visual defects), a less-than-optimal image quality, image color, or

image durability will likely develop over time. Chemical compatibility between inks

(made for a specific head technology) and medias is a key, and often overlooked ingredi-

ent to print quality.

Introduction 1-9

CADJET®3D User Guide

9. Cartridge Preparation and Alignment

The single most overlooked factor in image color accuracy and quality is cartridge align-

ment. Even if you carefully control factors 1 though 8, a printer with poor cartridge

alignment or unmaintained heads can severely deteriorate image quality. Cartridge

maintenance and alignment are key to producing images that exhibit the best of what a

printer is capable of. Printer wiping stations must be kept clean so that heads stay clean.

Cartridges need to be aligned and checked to be sure that all nozzles are working prop-

erly. Use a loupe to evaluate the registration of test patterns to achieve the best possible

accuracy. Whenever you adjust, move, or replace a cartridge, take the time to realign the

cartridges. Alignment errors of a single pixel (or single digit in the alignment process)

will affect both color and image quality.

Printer options 2

You can define printer options through your application software or by choosing settings

from the printer's control panel. The following printer options are described in this

chapter:

•Initialize (return to printer default settings)

•Print Mode

•Paper Options

•User Setup

Returning to the default settings

Pressing the Setup/User Setup/Init Settings buttons returns all printer options to the

factory defaults. All saved user settings are lost. The table at the end of this chapter

shows the printer defaults.

Printing the settings

Pressing the Setup/User Setup/Print Settings buttons causes the printer to print a

listing of its current settings. Be sure to have paper loaded before you start.

Choosing print mode options

Your printer offers several print modes which let you make tradeoffs between speed and

quality.

The print mode you use depends on various factors, such as your software application,

whether you’re printing in color or monochrome, and the type of media you’re using.

Each print mode directly affects the printing speed and quality of the image you print, so

you should understand the differences.

Each of the print modes attempts to strike a balance between speed and quality, with the

quality mode providing quality images at a reasonable printing speed for most users.

Whenever you choose a print mode other than Normal, you will choose to emphasize

either speed or quality.

Printer Options 2-2

CADJET®3D User Guide

Print mode options include color mode and print quality.

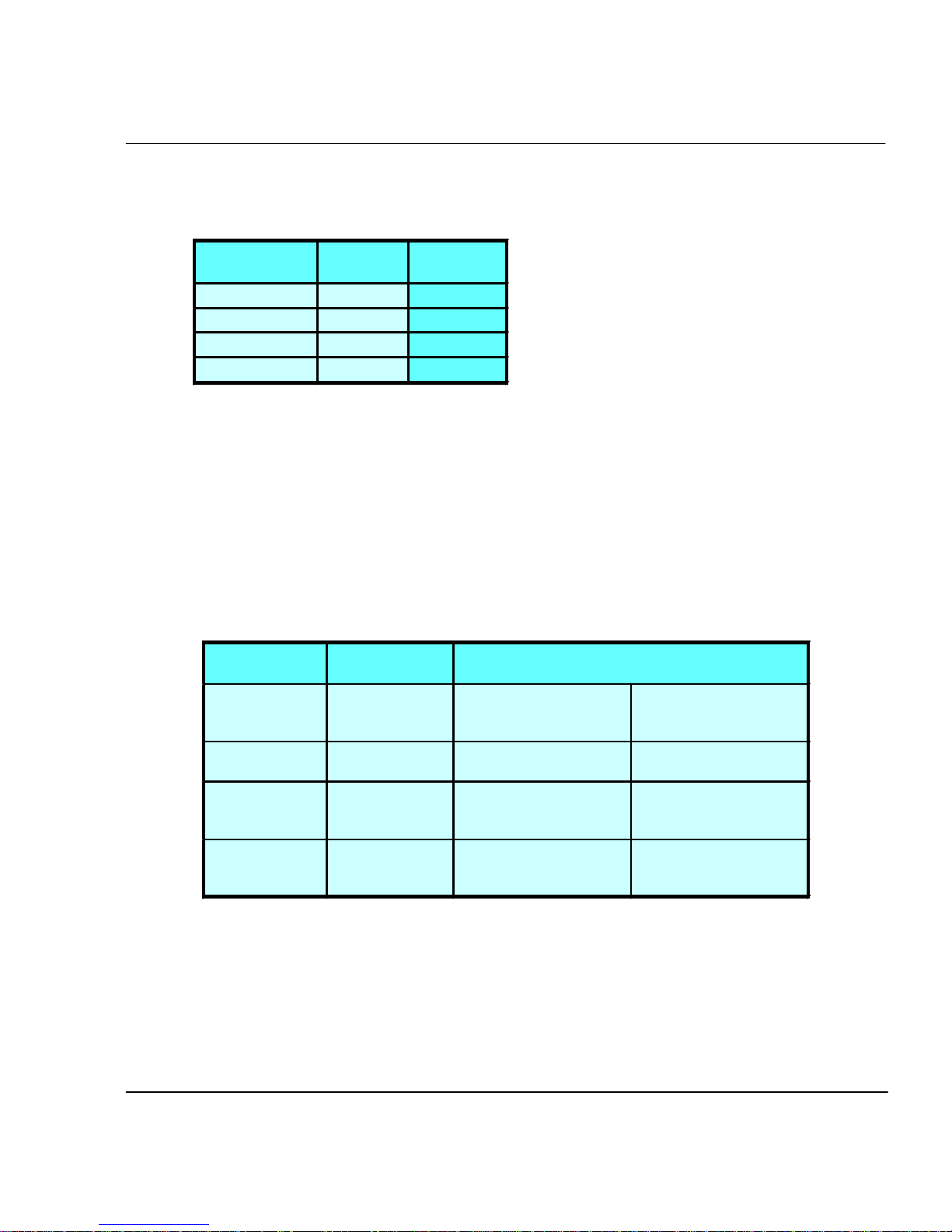

Default print mode settings are summarized in the table which follows.

MODE DPI # OF

PASSES

DRAFT 600X600 1

SUPER DRAFT 600X300 1

NORMAL 600X600 3

BEST 600X600 4

Important notes about image size vs. dpi

For best results, be sure the printer dpi setting matches the image resolution in the

file you are printing.

The printer always prints at 600 dpi, even when the dpi setting in the Print Mode

menu is set to 300 dpi. The dpi setting refers to the resolution at which your image is

created, not the resolution at which it is printed.

Image (file)

resolution

Printer dpi

setting

Effect on printed output

300 dpi 300 dpi 1 input pixel prints as 4

output pixels. The printed image is the

same size as the

original.

300 dpi 600 dpi 1 input pixel prints as 1

output pixel. The printed image is 1/4

the size of the original.

600 dpi 300 dpi 1 input pixel prints as 1

output pixel. The printed image is four

times the size of the

original.

600 dpi 600 dpi 1 input pixel prints as 1

output pixel. The printed image is the

same size as the

original.

This manual suits for next models

1

Table of contents

Other ENCAD Printer manuals

ENCAD

ENCAD ENCAD T200+ User manual

ENCAD

ENCAD NovaJet PRO 600e User manual

ENCAD

ENCAD NovaJet 630 User manual

ENCAD

ENCAD 60e User manual

ENCAD

ENCAD CADJET User manual

ENCAD

ENCAD NovaJet 4 User manual

ENCAD

ENCAD NovaJet 500 Manual

ENCAD

ENCAD Croma 24 User manual

ENCAD

ENCAD CADJET 3D User manual

ENCAD

ENCAD VinylJet 36 User manual

ENCAD

ENCAD Encad NovaJet 1000i User manual

ENCAD

ENCAD VinylJet 36 User manual

ENCAD

ENCAD CADJET 2 User manual

ENCAD

ENCAD CROMA24 User manual

ENCAD

ENCAD NovaJet 800 Series User manual

ENCAD

ENCAD NovaCut 24 User manual

ENCAD

ENCAD CADJET 3D User manual

ENCAD

ENCAD NovaJet 880 User manual

ENCAD

ENCAD CROMA24 User manual

ENCAD

ENCAD NovaJet PRO 600e User manual