ENCAD NovaJet PRO 600e User manual

SERVICE MANUAL

60 inch60 inch

60 inch60 inch

60 inch

42 inch42 inch

42 inch42 inch

42 inch

NOVAJET®PRO 600e

COLOR INKJET

PRINTER

SERVICE MANUAL

PartNumber210596

®

iv

NovaJetPRO600eServiceManual

Copyright © 1998ENCAD®, Inc. All rights reserved.

ENCAD®andNovaJet®aretrademarks ofENCAD, Inc.

Othertrademarksand registered trademarksare the

propertyoftheirrespective owners.

Except as provided below, no part of this manual may be

copiedor distributed, transmitted, transcribed, stored in

a retrieval system, or translated in any human or comput-

ing language, in any form or by any means, electronic,

mechanical, magnetic or otherwise, or disclosed to a

third party without the express written permission of

ENCAD, Inc.,6059 Cornerstone CourtWest, San Diego,

CA 92121, U.S.A.

Certainmanualsdeveloped by ENCADarein an elec-

tronicformat tobe distributed on CDs or over the

internet. Theregistered user ofan ENCAD product

whose manual is distributed in this fashion may print one

copy for their personal use only.

Printing history

1st Edition RevA May1998

v

NovaJetPRO600eServiceManual

FCC Statement (U.S.A.)

The United States Federal Communications Commision has specified

that the following notice be brought to the attention of the users of the

NOVAJET PRO 600eprinters.

FEDERAL COMMUNICATIONS COMMISION RADIO AND TELEVI-

SION INTERFERENCE FOR CLASS B DEVICE

This equipment has been tested and found to comply with the limits for a

class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interfer-

ence to radio communications.

User Instructions:

If the equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one of the

following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for

help.

Changes or modifications not expressly approved by ENCAD, Inc. could

void the user’s authority to operate the equipment.

vi

NovaJetPRO600eServiceManual

VDE Statement

Hiermitwird bescheinigt, daß der

NOVAJET PRO 600e

in

Übereinstimmung mit den Bestimmungen der BMPT-AmstbIVfg 234/1991

funkentstörtist. Der vorschriftsmäßigeBetrieb mancher Geräte (z.B.

Meßsender)kannallerdingsgewissen Einschränkungen unterliegen.

BeachtenSiedeshalb die Hinweisein der Bedienungsanleitung.

Dem Zentralamt für Zulassungen im Fernmeldewesen würde dan

Inverkehrbringen dieses Gerätes angezeigt und die Berechtigung zur

Überprüfung der Serie auf die Einhaltung der Bestimmungen

eingeräumt.

ENCAD, Inc.

U.S.A

vii

NovaJetPRO600eServiceManual

Material Safety Data Sheet

ENCAD

QIS(Quality Imaging Supplies)ink is nonhazardous,requiring no

special disposal handling. It can be harmful if swallowed and should be

keptaway from children.

To obtain a Material Safety Data Sheet, contact

ENCAD, Inc.

at:

6059 Cornerstone Court West

San Diego, CA 92121-3734

(619) 452-4350

International users should contact their local dealer or distributor.

viii

NovaJetPRO600eServiceManual

WARRANTY OR DAMAGE CLAIMS

United States

ENCAD®, Inc., warrants its printers ("PRODUCT") to be free from defects in workmanship

and materials for a period of one year from the date of purchase. In order to submit a

Warranty claim, please contact the ENCAD Help Desk at (619) 452-4350.

ENCAD reserves the right to make changes or improvements to Products, without incurring

any obligation to similarly alter Products previously purchased.

Buyer's sole and exclusive rights pursuant to this Warranty shall be for the repair or

replacement of defective Product. ENCAD specifically disclaims any and all other warran-

ties, expressed or implied, including but not limited to, implied warranties of merchantability

and fitness for a particular purpose. In no event shall ENCAD be liable for any loss of

profit or other commercial damages, special, incidental or consequential damages, or any

otherdamagesor claims, whatsoever.

This Warranty gives Buyer specific legal rights, and Buyer may also have other rights that

varyfrom state to state.

This Warranty applies only to printers purchased from ENCAD, or authorized ENCAD

distributors or dealers. The intent of this Warranty is to repair or replace defective Prod-

ucts subjected to normal wear and tear, when operated according to ENCAD instructions.

This Warranty does not cover damage to the Product resulting from the following:

• Accident or negligence.

• Unauthorized modification of the Product.

• Adverse environmental conditions.

• Service of the Product by other than an ENCAD authorized service provider.

• Unauthorized or improper use, including but not limited to:

– Use in applications for which the Product was not designed.

– Using cartridges or ink other than those supplied by ENCAD or authorized

ENCAD resellers.

– Using media other than that supplied by ENCAD or authorized ENCAD

resellers.

– Lubricating any part of the printer.

Internationally: Contact your dealer or distributor for warranty information.

ix

NovaJetPRO600eServiceManual

Table of Contents

Chapter 1 General Description ........................................................... 1-1

Introduction...............................................................................................................1-1

Overview ...................................................................................................................1-3

RelatedPublications ..........................................................................................1-3

ElectrostaticDischarge (ESD)Sensitivity .................................................................1-3

Warnings,Cautions and Notes .................................................................................1-4

PrinterSpecifications................................................................................................1-5

Contentsof this ServiceManual................................................................................1-6

TechnicalSupport .....................................................................................................1-8

Chapter 2 Theory of Operation........................................................... 2-1

Introduction...............................................................................................................2-1

NovaJetPRO600ePrinter General Block Diagram ...................................................2-1

Paper(Media)AxisDrive ..........................................................................................2-3

TheCarriageAxisDrive.............................................................................................2-4

MediaFeed and Take-UpSystem.............................................................................2-5

MainPrinted Circuit Board(MPCB)...........................................................................2-6

Microprocessor ..................................................................................................2-7

GateArray .........................................................................................................2-7

MemoryCircuits................................................................................................. 2-8

FlashEEPROM...........................................................................................2-8

DRAM..........................................................................................................2-9

SerialEEPROM......................................................................................... 2-10

StepperMotorController...................................................................................2-10

ServoMotorController ......................................................................................2-12

InterfaceCircuits: Serial &Parallel ................................................................... 2-14

CarriageAssembly Circuits .................................................................................... 2-15

Keypad ................................................................................................................... 2-16

PowerSupply ......................................................................................................... 2-17

BeeperandFans .................................................................................................... 2-17

Chapter 3 Maintenance ....................................................................... 3-1

Introduction...............................................................................................................3-1

ScheduledMaintenance ...........................................................................................3-1

x

NovaJetPRO600eServiceManual

CleaningProcedures ..........................................................................................3-2

ExternalCleaning.........................................................................................3-2

SlideShaftCleaning.....................................................................................3-2

ServiceStationCleaning ..............................................................................3-3

LinearEncoderStripCleaning ......................................................................3-4

CartridgeDimplesCleaning.......................................................................... 3-5

FlexCableContact Cleaning........................................................................3-6

Cleanand Inspect StepperMotorGears.......................................................3-7

Cleanand Inspect MPCB.............................................................................3-7

CleanandInspect Carriage Assembly .........................................................3-8

ReseatConnectorson MPCB and CarriageBoard..............................................3-8

ReplaceCarriageBushings ..............................................................................3-10

ServoMotorWinding Resistance Check ................................................................. 3-11

StepperMotor Winding Resistance Check..............................................................3-12

PowerFeed and Take-UpMotor Winding ResistanceCheck................................... 3-13

Banding:HardwarevsSoftware...............................................................................3-14

CommonBandingCauses................................................................................ 3-15

Alignments/Adjustments.........................................................................................3-17

SlideShaft Profile Adjustment..........................................................................3-17

HeadHeightAlignmentProcedure ....................................................................3-20

ColorCalibration............................................................................................... 3-24

DeadbandAlignment ........................................................................................3-27

PaperAxis Calibration......................................................................................3-30

DiagnosticsMenu...................................................................................................3-32

Limited Access Menu .............................................................................................3-34

FirmwareDownload/UpgradingforthePC ...............................................................3-36

FirmwareDownload/UpgradingfortheMAC ............................................................3-37

InternalCablingandSignalFlow Diagrams .............................................................3-38

Chapter 4 Troubleshooting................................................................. 4-1

Introduction...............................................................................................................4-1

NoPower ...........................................................................................................4-1

MediaDoesNotMove ........................................................................................4-2

Table of Contents (cont)

Chapter 3 Maintenance (cont)

xi

NovaJetPRO600eServiceManual

InternalERROR“CarriageAxisFailure” .............................................................. 4-3

InternalERROR“EncoderSensorFailure” ..........................................................4-4

InternalERROR“PaperSensorFailure”.............................................................. 4-4

InternalERROR“Auto-SensorFailure”................................................................4-4

Internal ERROR“Trailing CableFailure” ..............................................................4-5

InternalERROR“MPCBFailure”.........................................................................4-5

Does Not Print....................................................................................................4-5

InkCartridgeMisfiring.........................................................................................4-5

PaperSkewing...................................................................................................4-7

PrinterOutput is Banding ...................................................................................4-7

KeypadLocked-Upor Not FunctioningProperly .................................................4-8

NoisyOperation .................................................................................................4-9

LineQualityDegraded ......................................................................................4-10

FanDoes Not PowerUp................................................................................... 4-11

MediaTake-UpMotor Not Operating, Sensor Works ........................................ 4-11

MediaFeed Motor NotOperating,SensorWorks ............................................. 4-12

MediaFeed and Take-UpMotors Not Operating,Both SensorsWorking .......... 4-12

MediaFeedor Take-UpSensor(s) Not Operating..............................................4-13

InitializationTroubleshooting ...................................................................................4-14

Chapter 5 Assembly\Disassembly ..................................................... 5-1

Introduction...............................................................................................................5-1

RemovetheLeft,Top,andRightCovers ....................................................................5-2

Installthe Left, Top,andRightCovers .......................................................................5-5

RemovetheKeypad,Display, and DisplayPowerConverter......................................5-6

Installthe Keypad, Display,and Display PowerConverter .........................................5-8

RemoveExtraMemory(SIMM) .................................................................................5-9

InstallExtra Memory (SIMM) .................................................................................. 5-10

RemovetheMPCB (Main PrintedCircuit Board) ..................................................... 5-10

Install the MPCB .................................................................................................... 5-13

RemovePowerSupply, CoolingFan,and AC EntryModule .................................... 5-14

Install the Power Supply, Cooling Fan, and AC Entry Module ................................. 5-16

RemoveServoMotor............................................................................................... 5-17

Table of Contents (cont)

Chapter 4 Troubleshooting (cont)

xii

NovaJetPRO600eServiceManual

InstallServoMotor ..................................................................................................5-19

RemovetheInk Delivery System.............................................................................5-20

Installthe Ink Delivery System................................................................................ 5-23

RemovetheCarriage Assembly, CarriageBelt,and the FrameTensioner................5-23

Installthe Carriage Assembly, Carriage Belt,and the FrameTensioner..................5-26

RemovetheCarriagePCB ......................................................................................5-28

Installthe Carriage PCB .........................................................................................5-30

RemovethePaper Sensor orthe Encoder Sensor ..................................................5-30

Installthe Paper Sensor or the Encoder Sensor......................................................5-32

ReplacingtheCarriageBushings ............................................................................5-33

RemovetheServiceStation ....................................................................................5-35

Installthe Service Station .......................................................................................5-35

RemovetheTrailingCableAssembly ......................................................................5-36

Installthe Trailing CableAssembly .........................................................................5-36

Removethe Stabilizer Bracket and EncoderStrip...................................................5-37

Install the Stabilizer Bracket and Encoder Strip ...................................................... 5-39

Removethe Y-ArmAssembly, Pinch Rollers, Slide Shaft, and Auto-LoadSensor...5-39

Install the Y-Arm Assembly, Pinch Rollers, Slide Shaft, and Auto-Load Sensor......5-41

Removethe Lower RollerAssembly, Stepper Motorand Vacuum Fan.....................5-43

Installthe LowerRoller Assembly, Stepper Motor and Vacuum Fan ........................5-46

RemovetheMedia Take-Upand Feed SensorBracketsand Sensors .....................5-49

Installthe Media Take-Up and Feed Sensor Brackets and Sensors ........................5-51

RemovetheMediaTake-UpandFeed Motors ......................................................... 5-51

Installthe Media Take-Upand Feed Motors ............................................................5-52

RemovetheMediaDrying Fans ..............................................................................5-54

Installthe Media Drying Fans .................................................................................5-54

Chapter 6 Parts List............................................................................. 6-1

Index...............................................................................................Index-1

Table of Contents (cont)

Chapter 5 Assembly/Disassembly (cont)

xiii

NovaJetPRO600eServiceManual

List of Illustrations

Figure Page

Chapter 1 General Description

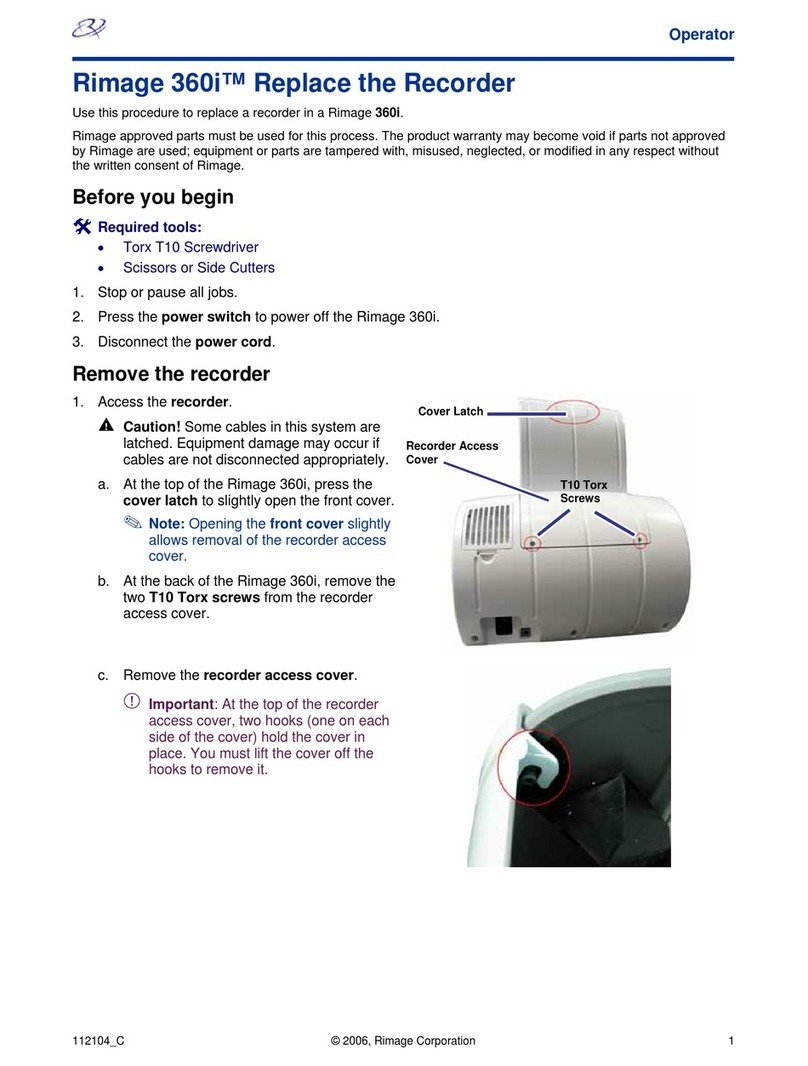

1-1. NovaJetPRO600eInkjet Printers ................................................................... 1-1

Chapter 2 Theory of Operation

2-1. GeneralBlockDiagram ...................................................................................2-2

2-2. Paper(Media)AxisDrive.................................................................................2-3

2-3. CarriageAxisDrive..........................................................................................2-4

2-4. PowerFeedand Take-Up System ...................................................................2-5

2-5. MainPrinted Circuit Board ..............................................................................2-6

2-6. GateArray ......................................................................................................2-7

2-7. Stepper Motor Controller ............................................................................... 2-10

2-8. ServoMotorController ...................................................................................2-12

2-9. QuadratureSignalGeneration .......................................................................2-13

2-10. InterfaceCircuits ...........................................................................................2-14

2-11. CarrierAssemblyCircuits ............................................................................. 2-15

2-12. MainMenu.................................................................................................... 2-16

Chapter 3 Maintenance

3-1. EncoderStripCleaning ...................................................................................3-5

3-2. Cartridge Dimple Region.................................................................................. 3-5

3-3. FlexCable Contacts ....................................................................................... 3-6

3-4. MPCBConnectionLocations .......................................................................... 3-9

3-5. CarriageConnectionLocations........................................................................3-9

3-6. Ribbon Connector LockingMechanism ......................................................... 3-10

3-7. ServoMotor................................................................................................... 3-11

3-8. StepperMotor ............................................................................................... 3-12

3-9. PowerFeedandTake-UpMotor ....................................................................3-13

3-10. Examplesof Banding .................................................................................... 3-14

3-11. DialGaugeMicrometer Assembly................................................................. 3-18

3-12. Measurement Positionsfor Slide Shaft.......................................................... 3-19

3-13. SlideShaft Profile Adjustment....................................................................... 3-20

3-14. Carrier HeadHeightTolerance ....................................................................... 3-21

3-15. SettingUp Tools from Height GaugeKit ........................................................3-21

3-16. ZeroingtheMicrometerGauge ...................................................................... 3-22

xiv

NovaJetPRO600eServiceManual

List of Illustrations (cont)

Figure Page

Chapter 3 Maintenance (cont)

3-17. Test CartridgeInstalled.................................................................................. 3-22

3-18. ColorCalibration............................................................................................3-25

3-19. Utility Menu...................................................................................................3-26

3-20. ColorCalibMenu...........................................................................................3-26

3-21. Cyan VerticalOptions Menu..........................................................................3-27

3-22. Deadband Slow/Fast .....................................................................................3-27

3-23. ServiceMenu ................................................................................................3-28

3-24. Calibration (Deadband)Menu ........................................................................3-29

3-25. CalibrationMenu ...........................................................................................3-31

3-26. Paper Axis Test ............................................................................................ 3-31

3-27. DiagnosticsMenu .........................................................................................3-32

3-28. Accessory Menu ...........................................................................................3-33

3-29. NVRAM Clear and ClockReset Menu...........................................................3-35

3-30. MPCBConnections Diagram.........................................................................3-39

3-31. CarriagePCBConnections Diagram..............................................................3-40

3-32. LegHarnessConnectionsDiagram ...............................................................3-41

Chapter 4 Troubleshooting

4-1. CarriageBoardLEDD2Location...................................................................4-15

Chapter 5 Assembly/Disassembly

5-1. RightCoverAssemblyRemoval/Installation .....................................................5-3

5-2. LeftCoverAssemblyRemoval/Installation .......................................................5-4

5-3. KeypadandDisplayRemoval/Installation ........................................................5-7

5-4. KeypadGroundingConnection ........................................................................5-8

5-5. ExtraMemory(SIMM)Removal/Installation .....................................................5-9

5-6. MPCBRemoval.............................................................................................5-12

5-7. PowerSupplyRemoval .................................................................................5-15

5-8. Cooling Fan/AC EntryModuleRemoval......................................................... 5-16

5-9. SlackenCarriageBelt ...................................................................................5-18

5-10. Electronics Cover Removal ............................................................................5-21

5-11. DisconnectInk DeliverySystem Link ............................................................5-22

xv

NovaJetPRO600eServiceManual

List of Illustrations (cont)

Figure Page

Chapter 5 Assembly/Disassembly (cont)

5-12. Strain Relief Removal/Installation .................................................................. 5-24

5-13. FrameTensioner ...........................................................................................5-25

5-14. CarriageBeltClamp ......................................................................................5-25

5-15. Carriage PCBRemoval/Installation ................................................................ 5-29

5-16. Paper and Encoder Sensor Removal ............................................................. 5-31

5-17. PaperandEncoder Sensor Installation..........................................................5-32

5-18. CarriageBushingRemoval ............................................................................5-34

5-19. CarriageBushingInstallation ......................................................................... 5-34

5-20. ServiceStationRemoval................................................................................ 5-35

5-21. StabilizerBracketInstallation/Removal.......................................................... 5-38

5-22. Y-Arm Installation/Removal ........................................................................... 5-40

5-23. PinchRoller ..................................................................................................5-41

5-24. InnerPlaten Assembly/Disassembly ............................................................. 5-44

5-25. Stepper Motor Removal/Installation ............................................................... 5-46

5-26. InsidePlaten, RightSide............................................................................... 5-48

5-27. MediaTake-UpandFeedSensorRemoval .................................................... 5-50

5-28. MediaTake-UpandFeedMotorRemoval ...................................................... 5-53

Chapter 6 Parts List

6-1. LeftSide Parts Breakdown..............................................................................6-3

6-2. Platen andAbovePartsBreakdown ................................................................ 6-5

6-3. RightSide Parts Breakdown ...........................................................................6-7

6-4. InnerPlatenPartsBreakdown .........................................................................6-9

6-5. CarriageAssemblyParts Breakdown ............................................................ 6-11

6-6. PowerFeedandTake-Up PartsBreakdown................................................... 6-13

xvi

NovaJetPRO600eServiceManual

List of Tables

Table Page

Chapter 1 General Description

Chapter 2 Theory of Operation

Chapter 3 Maintenance

Chapter 4 Troubleshooting

4-1. TroubleshootingTable......................................................................................4-1

Chapter 5 Assembly/Disassembly

Chapter 6 Parts List

1

GENERAL

DESCRIPTION

1-1

GeneralDescription

Figure 1-1. NovaJet PRO 600e Inkjet Printers.

Introduction

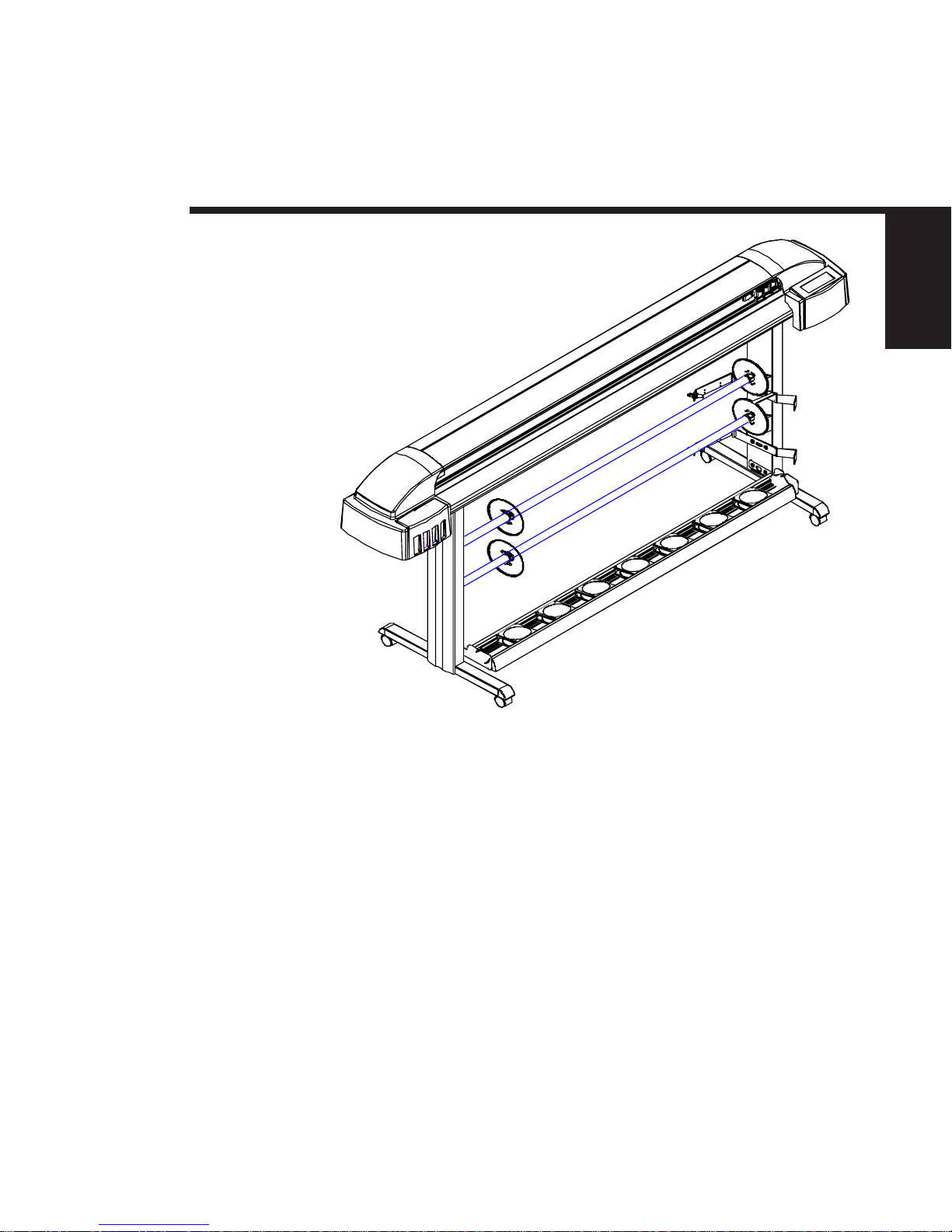

Thismanual provides serviceinformation for theENCAD®, Inc.

NovaJet®PRO 600e Color InkjetPrinter. TheNovaJet®PRO 600e

printer comes in two sizes: a 42 inch model and a 60 inch model.

It is written for service personnel who possess analog and digital

circuitry experience. Chapter 2, Theory of Operation, should be read

and thoroughly understood before troubleshooting/calibrating the

printers.

1-2 GeneralDescription

NovaJetPRO600eServiceManual

Theprinterssupport pre-cut androll media. Media sizeisautomati-

callydetermined and hardcliplimits are setaccordingly. Pre-cut media

usesdifferent maximum plottingareas than rollmedia. See thePrinter

Specificationsformoredetails.

Both RS-422 serial and Centronics parallel connections are provided

to interface with the host computer. Commands sent from the host

computercan be inseveral forms includingHP-RTLandEncad RTL

formats.

Drivers are supplied to support Windows-based PC’s (3.XX, 95, and

NT) as well as Macintosh and Power PC computers.

These printers expand upon ENCAD’s tradition of delivering fast,

high-quality color or monochrome graphics for a variety of applica-

tions. ENCAD has made significant advances in designing these

printers to respond to and anticipate our customers’ needs. Princi-

pal features are summarized below.

Locally or Remotely Configured via Host Computer

Powered Media Take-Up and Feed System

Media Drying System

Quick Ink Changeover

Self-Aligning Pinch Rollers

PowerPC 33 MHz Microprocessor

8UserConfigurableSettings

208JetInkCartridges

Ink Priming System

500ml Ink Reservoirs

Smart Cartridges

GeneralDescription 1-3

GENERAL

DESCRIPTION

NovaJetPRO600eServiceManual

Overview

Printers draw according to instructions issued from a “host” com-

puter. Every printer is engineered to understand a specific set of

instructions and to execute each instruction in a precise manner.

In addition, most printers are designed to execute predetermined

characters automatically without a specific line-by-line instruction

from the program. These characters are part of the printer’s

permanent memory.

Related Publications

The following publication contains additional information which may

beuseful in servicing theENCAD, Inc. NovaJet PRO 600e Color

InkjetPrinters:

•ENCAD NovaJet PRO 600e UserGuide,

P/N 210131

•ENCAD NovaJet PRO 600e QuickStart Guide,

P/N 210058

•ENCAD NovaJet PRO 600eConnectivity Guide,

P/N 210611-1

Copiesofthese andotherENCAD, Inc.publications may beobtained

bycontacting your nearestauthorizedENCAD, Inc. dealerorby

contactingENCAD’s Technical Support andServiceDepartment.

Electrostatic Discharge (ESD) Sensitivity

AllPCBs(Printed Circuit Boards)associated with theNovaJet PRO

600e printershavecomponentssensitivetoESD(electrostaticdis-

charge). Caremust be takento avoiddamage to anyof the components

byfollowingcurrentESD handling procedures andpractices.

Always use an approved ESD grounding strap when handling or

working with PCBs.

1-4 GeneralDescription

NovaJetPRO600eServiceManual

Warnings, Cautions and Notes

Warnings,cautionsandnotes are used whenadditionalinformation,

instructionsor care should be observed. Inthis manual warnings,

cautionsandnotes precede thetextto which eachapplies. The defini-

tionofeachis provided below.

WARNINGS -Warningsare used tostress thatthe following stepsor

procedureshas the potentialtocause serious harmor death to service

personnel. Extremecareshouldbeobserved when following theproce-

duresandtoexercise standard safety procedures. Theyareindicated

by:

Followedbyaparagraph describing theconcern.

CAUTION - Cautionsdepictthatthefollowingstepsorprocedurescan

causedamageto the equipment ifnotproperly followed. Extreme care

shouldbeobservedwhenfollowingtheproceduresandtoexercise

standardsafetyprocedures. They are indicated by:

Followedbyaparagraph describing theconcern.

NOTE - Notes areplacedbeforeaprocedureto inform the service

personnelofspecificdetails to improve quality,togivereminders of

interrelatedpartsandto provide other helpfulinformation. Theyare

indicatedby: NOTE

Followed by a paragraph describing the concern.

GeneralDescription 1-5

GENERAL

DESCRIPTION

NovaJetPRO600eServiceManual

Printer Specifications

Thespecificationsand performance characteristics oftheNovaJet

PRO 600e ColorInkjet Printers areas follows:

Max Printing Area:

42inch 60 inch

Norm 40.8” 58.8”

1.04m 1.49m

Extend 41.61” 59.61”

1.06m 1.51m

Language Emulation:

HP-RTL

ENCADRTL

Buffer:

32MBinstalled

upgradeableto64MB

Power Requirements:

InputVoltage:

90-246VAC

47-63Hz

OutputPower:

20W idle

140Wtypical

215 W maximum

Baud Rates:

9600,19200,38400

Resolution:

600x600dpior

300x300dpi,addressable

Weight:

60” 88 lbs 135lbs(boxed)

42” 72 lbs 117lbs(boxed)

Accuracy:

+/- 0.2% line length using

ROLLfeed and4 mil

draftingmattefilm

Interface:

Centronicsparallel

(IEEE1284)

RS-422serial

NetworkOption:via

10BaseT,10Base2

PrintServer

Environment:

Operating:

59° to 95° F

(15° to 35° C)

10% to 70% RH

non-condensing

Storage:

-5° to 140° F

(-21° to 60° C)

5% to 80% RH

non-condensing

Dimensions:

Height 44” (1.12m)

Width 77” (1.96m)

42inch

95” (2.41m)

60inch

Depth 28” (0.71m)

Other manuals for NovaJet PRO 600e

1

Table of contents

Other ENCAD Printer manuals

ENCAD

ENCAD VinylJet 36 User manual

ENCAD

ENCAD CADJET 2 User manual

ENCAD

ENCAD 215319-1 User manual

ENCAD

ENCAD NovaJet 4 User manual

ENCAD

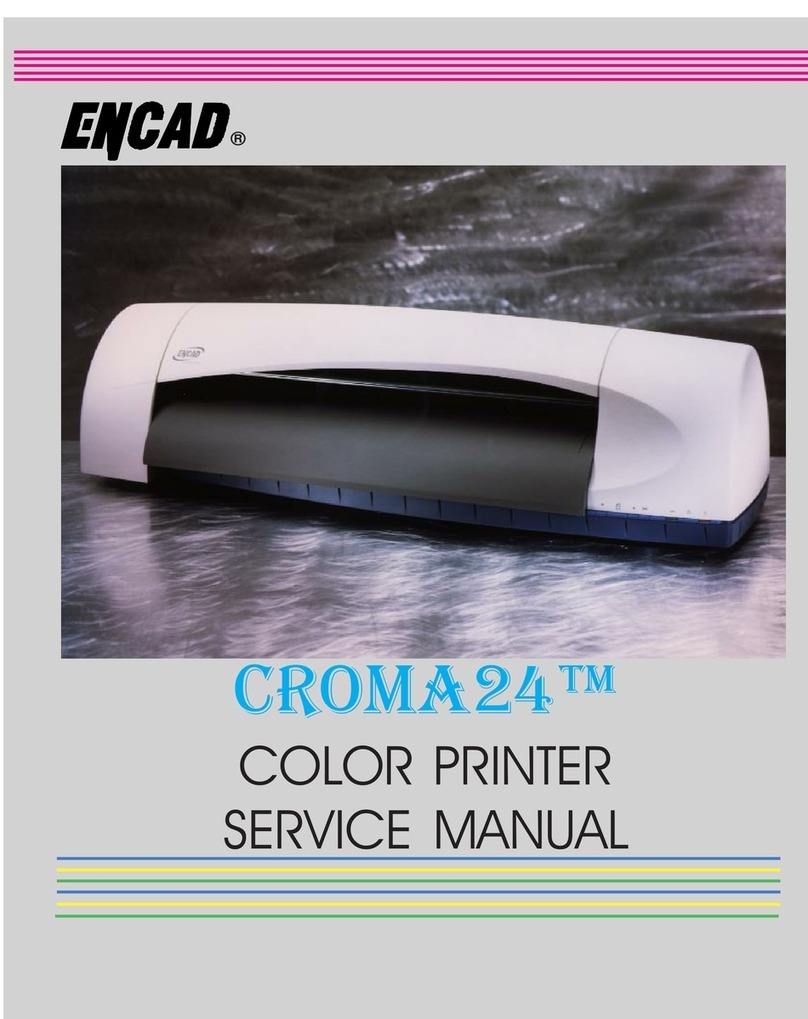

ENCAD CROMA24 User manual

ENCAD

ENCAD NovaJet 880 User manual

ENCAD

ENCAD ENCAD T200+ User manual

ENCAD

ENCAD 60e User manual

ENCAD

ENCAD VinylJet 36 User manual

ENCAD

ENCAD CADJET User manual

ENCAD

ENCAD NovaJet 630 User manual

ENCAD

ENCAD NovaJet PRO 600e User manual

ENCAD

ENCAD Encad NovaJet 1000i User manual

ENCAD

ENCAD CADJET 3D User manual

ENCAD

ENCAD Croma 24 User manual

ENCAD

ENCAD CROMA24 User manual

ENCAD

ENCAD NovaJet 500 Manual

ENCAD

ENCAD CADJET 3D User manual

ENCAD

ENCAD NovaCut 24 User manual

ENCAD

ENCAD NovaJet 800 Series User manual