Endo BS3W User manual

INSTRUCTION MANUAL

SQUARE BALANCER

BS3W/BS3N

BS5W/BS5N

BS7W/BS7N

ENDO KOGYO CO., LTD.

BM-10121c

WARNING

・Read this manual before use.

・Keep this manual available.

Issued on April 2016

Copied digital data

from http://www.endo-kogyo.co.jp/

Copyright and liabilities

The copyright for this manual belongs to Endo Kogyo Co., Ltd.

The manual is provided for the limited purpose of supporting the safe and proper use of

the product. It cannot be used for other purposes.

The customer may not use or make copies of this manual, in whole or in part, outside of

this purpose without receiving prior consent from Endo Kogyo Co., Ltd.

The customer is also prohibited from translating or modifying the content of the manual,

in whole or in part.

The content described in the manual is subject to change without advance notice.

Please note this in advance.

November 2019 ENDO KOGYO CO., LTD.

Copied digital data

from http://www.endo-kogyo.co.jp/

SAFETY ALERT SYMBOL AND ALERT SIGNS SIGNS

Please read this manual carefully and follow its instructions.

The SAFETY ALERT SYMBOL ( ), WARNING, CAUTION, and NOTE carry

special messages.

This SAFETY ALERT SYMBOL is used to call your attention to

items or operations that could be dangerous to you or other persons

using this equipment.

Please read these messages and follow these instructions carefully.

:CAUTION indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury, damage or destruction of the equipment and

others.

:WARNING indicates a hazardous situation which,

if not avoided, could result in death or serious

injury.

NOTE:NOTE indicates a special instruction in operation or maintenance.

Copied digital data

from http://www.endo-kogyo.co.jp/

Scope of warranty and liabilities for the equipment

1. We will repair or replace the product free of charge if a failure due to manufacturing defects

occurs under proper usage during the warranty period.

For details, contact us or your dealer.

2. The warranty will be void in the following cases:

1) Change in ownership.

2) Repair, adjustment, or modification performed by a party other than the manufacturer, agents,

or dealers.

3. Warranty period is 1 year from your purchase.

However, wire rope, wire guide and spring are not covered by warranty.

4. Repairs applicable to any of the following shall be charged even during the warranty period:

1) Failure/damage caused by incorrect use.

2) Failure/damage caused by use of non-genuine parts.

3) Failure/damage caused by fire, earthquake, natural disaster, or other unexpected incident.

4) Incident caused by fall, shock, negligence, or by inadequate storage.

5) Failure/damage caused by use of parts or other equipment that are not included in this product.

6) Replacement of consumables.

7) Usage in violation of dangers or cautions stipulated in this Instruction Manual or the warning

labels.

8) Failure/damage caused by any reason that is not attributable to the manufacturer.

5. Warranty exclusions such as opportunity loss.

Either during or after the warranty period, opporunity loss, damage to anything other than our

product(s), or other duties incurred on you/your customer as a result of the failure of our

product(s) are outside the scope of the warranty.

Copied digital data

from http://www.endo-kogyo.co.jp/

CONTENTS

1. Safety instructions ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

2. Specifications ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

3. Drawing ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

4. Spring tension attachment ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

5. Safety instructions on use ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

6. Inspections ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4

7. Rope replacement ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

8. Spring replacement ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

9. Spring disposal ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・6

10. Parts list ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・7

Copied digital data

from http://www.endo-kogyo.co.jp/

1. Safety Instructions

WARNING

・Incorrect use of the balancer could cause personal injury.

・Observe instructions in the manual and use the spring rod correctly.

・Install the balancer correctly.

・Never use overhead or at the place where may cause an accident in case of suspended load

falling.

・Never place hands, feet, etc., under suspended loads or movable range of rope.

・Never alter the balancer.

・Periodically inspect the balancer.

2. Specifications

Model

Capacity

range(kg)

Stroke(m)

Type of rope

Mass(kg)

BS3W

1.5~3.0

1.3

Wire rope

With thimble

Approx.2.3

BS5W

3.0~5.0

Approx.2.5

BS7W

5.0~7.0

Approx.2.5

BS3N

1.5~3.0

Nylon rope

Without thimble

Approx.2.3

BS5N

3.0~5.0

Approx.2.5

BS7N

5.0~7.0

Approx.2.5

■Working conditions Application area : Indoor and normal atmospheric conditions

Temperature range: -10 ゚C to +50 ゚C

3. Drawing

Copied digital data

from http://www.endo-kogyo.co.jp/

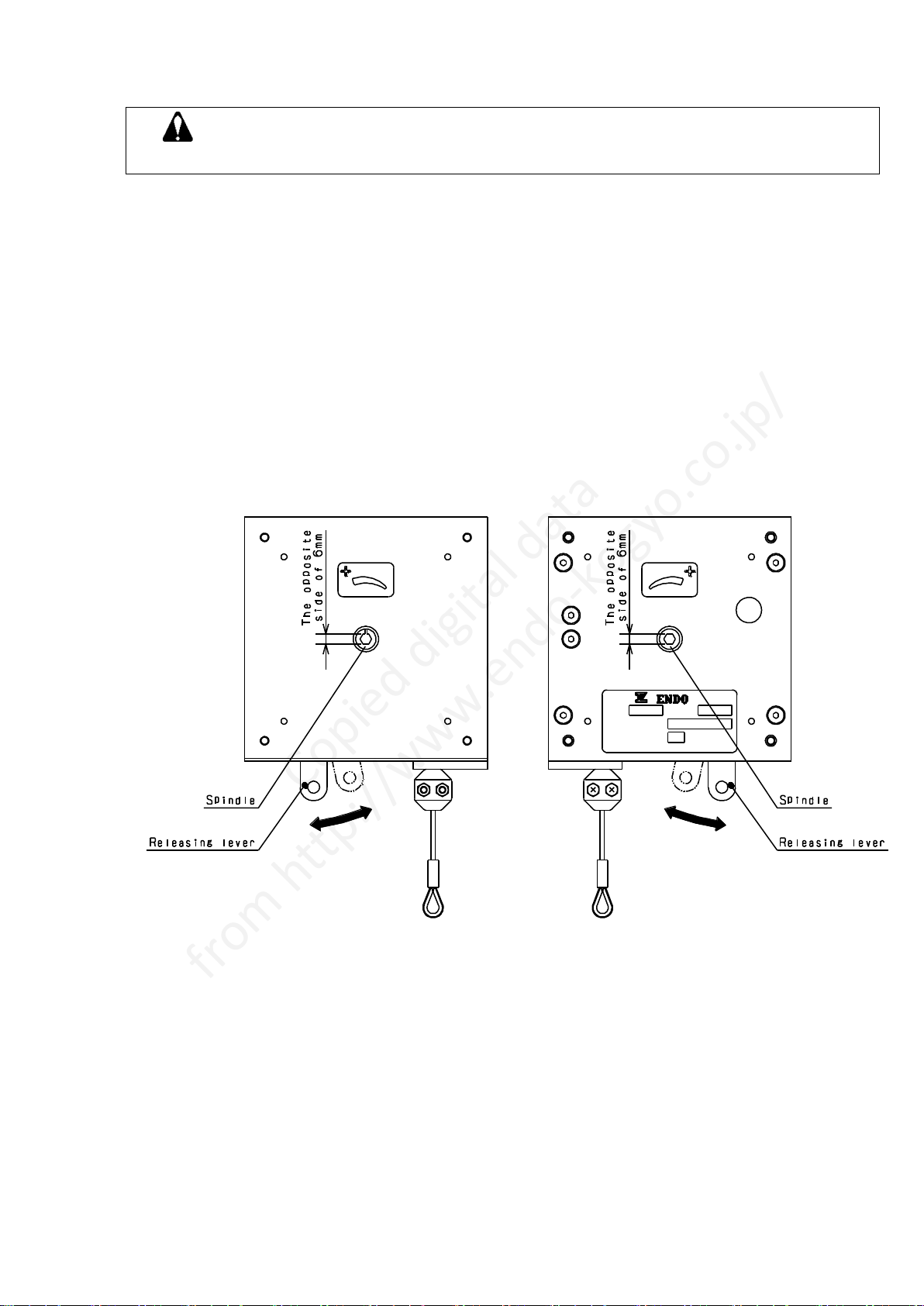

4. Spring tension attachment

CAUTION

・Never move releasing lever with inserting hexagon socket screw key(adjustment tool).

1) Confirm that the weight of suspended load is within the capacity range of the balancer when

you suspend tool/device or when you pull rope sideways.

2) Increase the spring tension by turning the spindle to the + side with a hexagon socket screw

key.(see Fig.1)

CAUTION: turn it to the opposite direction, the spring will break.

Please confirm indication of main body, the direction of two sides is not same.

Decrease the spring tension by moving releasing lever in right and left.

NOTE:Factory setting of spring tension

・BS3W/BS3N.…Approx.2.3kg

・BS5W/BS5N…Approx.4.0kg

・BS7W/BS7N…Approx.6.0kg

Refer to graph and adjust tension that load is balanced. (see Fig.2)

(“0”indicates the condition that wire rope is fully retracted into drum and all

spring tension is released.)

■Back side ■Front side

Fig.1

Copied digital data

from http://www.endo-kogyo.co.jp/

Model BS3W/BS3N Model BS5W/BS5N Model BS7W/BS7N

Fig.2

CAUTION: Initial tension indicates the number of revolutions of the spindle when rope is fully

retracted into drum.

Use in the range of dotted line will lose balance.

E.g. When setting BS5W in 4kgf

Turning the spindle 5 times from the condition that rope is fully retracted into drum and spring

tension is released.

※The graph shows a reference level.

5. Safety instructions on use

WARNING

・Never use overhead or at the place might lead to injury accident when load dropped.

・Never place hands, feet, etc., under suspended loads or movable range of rope.

・Never alter the balancer.

CAUTION

・Always use within maximum spring tension.

・Always adjust the spring tension before use.

・Do not extend the rope past the maximum cable travel.

・Do not pull the rope at an angle. Fix main body so that rope does not touch to plate.

It will cause recovery problem resulting in uneven winding.

・Nylon rope type: attach surely so that wire does not come loose with the tension of the balancer.

・Fix the main body in two M5 bolts or more.

The bolt length

6-10mm: cover and case (front and back side)

8-10mm: side of case (see fig.3)

Clamping torque: 3N・m

Fig.3

Copied digital data

from http://www.endo-kogyo.co.jp/

6. Inspections

WARNING

Periodically inspect the balancer, and replace any worn or damaged parts.

CAUTION

Always use genuine parts for replacement.

■Inspect the balancer at least once a month.

Correct and repair any problems which are detected.

Make the inspection interval shorter when operating frequently or under hostile environments.

■Items to be inspected

●Wire rope type

・Is there any broken wire, deformation or kink in wire?

Allowable number of broken

wires in 1 pitch 13.

・Is there any part of wire rope worn beyond service limit?

・Is there any remarkable wear of thimble?

●Nylon rope type

・Is there any broken fiber or damage (kink, fuzzing)?

・Is there any loosen on the rope attaching device?

・Is there any melting by heat?

●Is there any loosen screws?

Copied digital data

from http://www.endo-kogyo.co.jp/

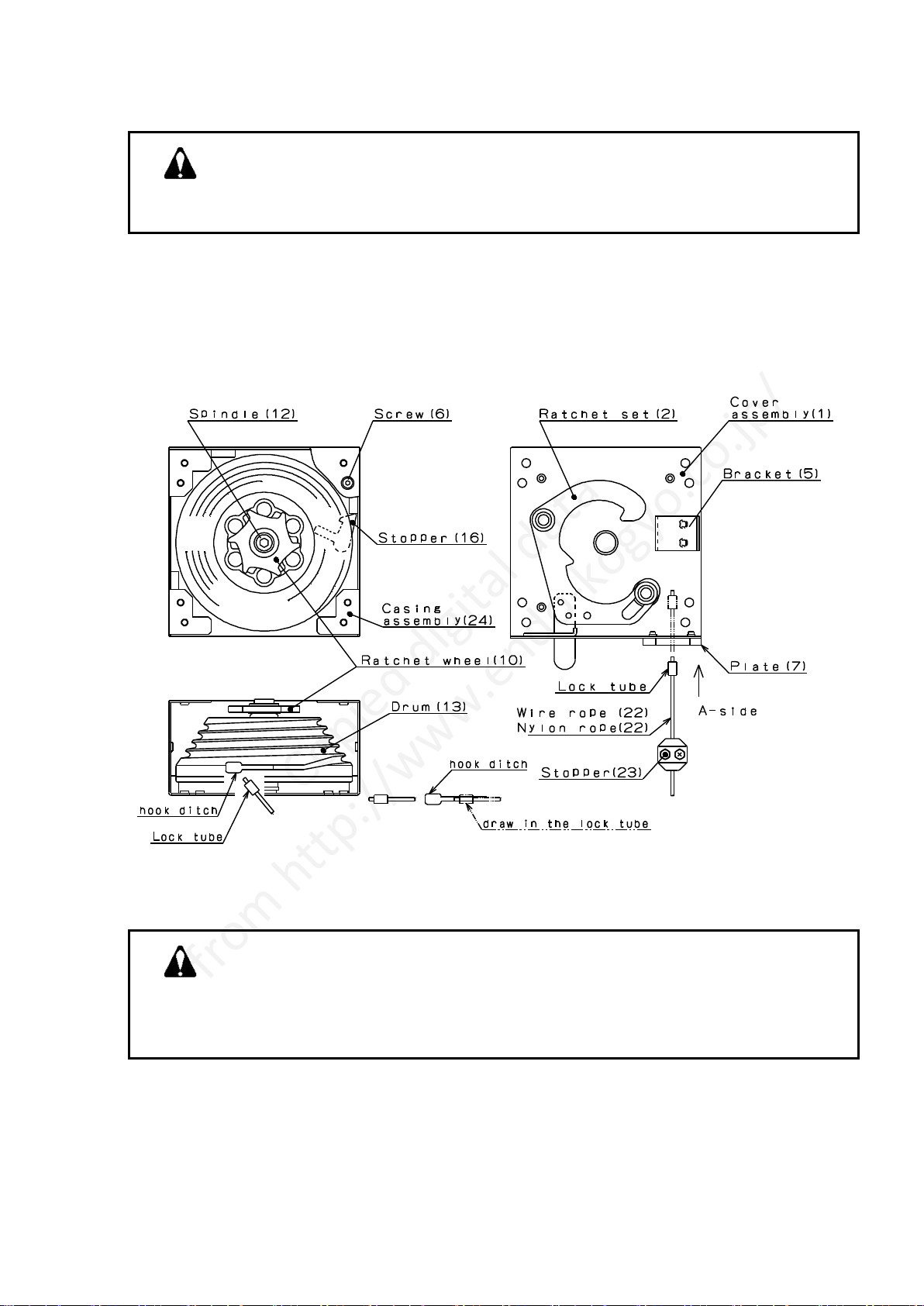

7. Rope replacement

1) Get rid of the spring tension by moving releasing lever in right and left.

See Chapter 4 ‘’Spring tension attachment‘’.

2) Remove Hex. Head screw (6) then remove cover (1).

3) Remove old rope from the drum.

4) Insert the lock tube of the new rope from the A side of the plate (1).

Then install lock tube to the hook ditch of the drum (13).(see Fig.4)

5) Reassemble in reverse order.

6) Turn spindle (13) and wind the rope.

Be careful that a rope does not come off from the ditch of the drum.

Fig.4

8. Spring replacement

Never remove the spring from the drum unless the replacement is required.

Referring to the disassembly drawing (on page 7),

1) Remove the balancer when in the state that rope rolled up.

2) Check the spring tension by pulling rope.

If the tension is left, of the tension by moving ratchet set lever (2) in right and left.

Tension should not be left. See clause 4 ‘’spring tension attachment’’

3) Remove Hex. Head screw (6) then remove cover (1).

WARNING

Do not take the body apart before tensility of the spring disappears.

It take it apart, the rope will snap back and could cause personal injury.

WARNING

・The spring is extremely dangerous. Be careful when handling the spring.

・Never pull the center of the spring when removing the spring from the drum.

If pulled, the spring will expand explosively and cause personal injury.

Copied digital data

from http://www.endo-kogyo.co.jp/

4) Remove the set of drum (15) and plate (15) from casing

assembly (24). Fig.5

5) Remove rope (22) from drum.

6) Loosen Screws (21) and remove Plate (15) from Drum (13).

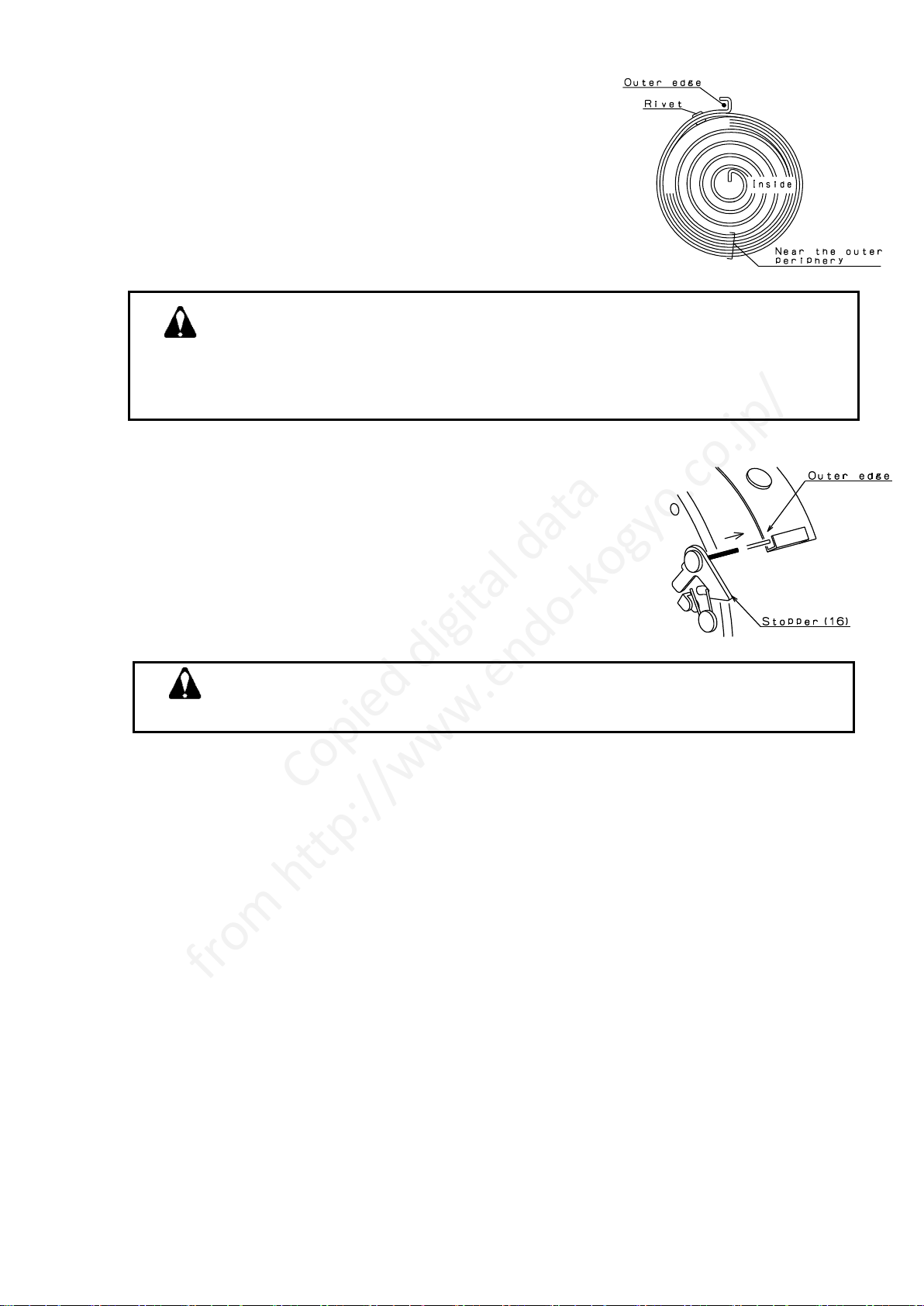

7) Check spring (14) fracture point and rivet condition.

If fracture caused in the inside, remove spring.

If fracture caused near outer periphery or rivet of

spring is broken. do not remove spring.

Reassemble the plate (15) to drum (13), then contact

to the store.(see Fig.5)

8) Remove spring (14) from drum (13).

9) Reassemble in reverse order.

・After drum (13) assembling, install spring (14). Fig.6

・After assembling new Spring (14), lubricate Spring with grease.

・When installing Plate (15) on Drum (13), place Stopper (16)

in the outer edge Spring (14). (see Fig.6)

Check Stopper can move smoothly after installing Plate.

NOTE:Turn spindle (13) and wind rope (22).

Be careful that a rope does not come off from

the ditch of the drum.

9. Spring disposal

Give a warning to disposal companies that the spring will expand explosively and cause

danger if the spring is treated roughly or the center of the spring is pulled.

WARNING

Never remove Spring (14) from Drum (13) when Spring is broken near the outer

periphery or the rivet of Spring is broken (see Fig.5).

If removed, Spring will expand explosively and cause personal injury.

WARNING

The spring is dangerous due to remaining tension even if it is broken.

Copied digital data

from http://www.endo-kogyo.co.jp/

10. PARTS LIST

Ref.No.

Part No.

Description

Quantity

BS3W

BS3N

BS5W

BS5N

BS7W

BS7N

1

LBP001776

Cover assembly

1

1

1

1

1

1

2

LBP001777

Ratchet set

1

1

1

1

1

1

3

KA30220800

Plain washer

2

2

2

2

2

2

4

KA40310060

Retaining ring

2

2

2

2

2

2

5

P2B301333

Bracket

1

1

1

1

1

1

6

P2B402102

Hex.socket button bolt

6

6

6

6

6

6

7

P2B402092

Plate

1

1

1

1

1

1

8

KA10220410

Screw

2

2

2

2

2

2

9

P2B402093

Bushing

2

2

2

2

2

2

10

P2B301336

Ratchet wheel

1

1

1

1

1

1

11

P2B402034

Washer

1

1

1

1

1

1

12

P2B301337

Spindle

1

1

1

1

1

1

13

P2B100163

Drum

1

1

1

1

1

1

14

P2B300089

Spring

1

1

-

-

-

-

14

P2B300507

Spring

-

-

1

1

-

-

14

P2B300508

Spring

-

-

-

-

1

1

-

LBP000750

Plate assembly

1

1

1

1

1

1

15

-

-Plate

1

1

1

1

1

1

16

-

-Stopper

1

1

1

1

1

1

17

-

-Rivet

1

1

1

1

1

1

Copied digital data

from http://www.endo-kogyo.co.jp/

Ref.No.

Part No.

Description

Quantity

BS3W

BS3N

BS5W

BS5N

BS7W

BS7N

18

-

-Spring

1

1

1

1

1

1

19

-

-Rivet

1

1

1

1

1

1

21

KA10220512

Screw

3

3

3

3

3

3

-

LBP001668

Wire rope assembly

1

-

1

-

1

-

-

LBP001868

Nylon rope assembly

-

1

-

1

-

1

22

-

-Wire rope

1

-

1

-

1

-

22

-

-Nylon rope

-

1

-

1

-

1

23

LBP000924

-Stopper

1

1

1

1

1

1

24

LBP001778

Casing assembly

1

1

1

1

1

1

25

KA31120500

Spring washer

6

6

6

6

6

6

26

P2B301342

Name plate

1

-

-

-

-

-

26

P2B301418

Name plate

-

1

-

-

-

-

26

P2B301343

Name plate

-

-

1

-

-

-

26

P2B301419

Name plate

-

-

-

1

-

-

26

P2B301344

Name plate

-

-

-

-

1

-

26

P2B301420

Name plate

-

-

-

-

-

1

27

P2B301347

Label

1

1

1

1

1

1

28

P2B301348

Label

1

1

1

1

1

1

NOTE) When placing an order, clearly specify the product model, part number and description.

Parts without a part number cannot be supplied individually.

Please purchase a set or complete unit.

Copied digital data

from http://www.endo-kogyo.co.jp/

This manual suits for next models

5

Table of contents

Other Endo Wheel Balancer manuals