Endo EWA-15 User manual

INSTRUCTION MANUAL

SPRING BALANCER

EWA-15

ENDO KOGYO CO., LTD.

BM-10097

WARNING

・Read this manual before use.

・Keep this manual available.

Issued on Dec. 2012

Copied digital data

from http://www.endo-kogyo.co.jp/

Copyright and liabilities

The copyright for this manual belongs to Endo Kogyo Co., Ltd.

The manual is provided for the limited purpose of supporting the safe and proper use of

the product. It cannot be used for other purposes.

The customer may not use or make copies of this manual, in whole or in part, outside of

this purpose without receiving prior consent from Endo Kogyo Co., Ltd.

The customer is also prohibited from translating or modifying the content of the manual,

in whole or in part.

The content described in the manual is subject to change without advance notice.

Please note this in advance.

November 2019 ENDO KOGYO CO., LTD.

Copied digital data

from http://www.endo-kogyo.co.jp/

SAFETY ALERT SYMBOL AND ALERT SIGNS SIGNS

Please read this manual carefully and follow its instructions.

The SAFETY ALERT SYMBOL ( ), WARNING, CAUTION, and NOTE carry

special messages.

This SAFETY ALERT SYMBOL is used to call your attention to

items or operations that could be dangerous to you or other persons

using this equipment.

Please read these messages and follow these instructions carefully.

:CAUTION indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury, damage or destruction of the equipment and

others.

:WARNING indicates a hazardous situation which,

if not avoided, could result in death or serious

injury.

NOTE:NOTE indicates a special instruction in operation or maintenance.

Copied digital data

from http://www.endo-kogyo.co.jp/

Scope of warranty and liabilities for the equipment

1. We will repair or replace the product free of charge if a failure due to manufacturing defects

occurs under proper usage during the warranty period.

For details, contact us or your dealer.

2. The warranty will be void in the following cases:

1) Change in ownership.

2) Repair, adjustment, or modification performed by a party other than the manufacturer, agents,

or dealers.

3. Warranty period is 1 year from your purchase.

However, wire rope, wire guide and spring are not covered by warranty.

4. Repairs applicable to any of the following shall be charged even during the warranty period:

1) Failure/damage caused by incorrect use.

2) Failure/damage caused by use of non-genuine parts.

3) Failure/damage caused by fire, earthquake, natural disaster, or other unexpected incident.

4) Incident caused by fall, shock, negligence, or by inadequate storage.

5) Failure/damage caused by use of parts or other equipment that are not included in this product.

6) Replacement of consumables.

7) Usage in violation of dangers or cautions stipulated in this Instruction Manual or the warning

labels.

8) Failure/damage caused by any reason that is not attributable to the manufacturer.

5. Warranty exclusions such as opportunity loss.

Either during or after the warranty period, opportunity loss, damage to anything other than our

product(s), or other duties incurred on you/your customer as a result of the failure of our

product(s) are outside the scope of the warranty.

Copied digital data

from http://www.endo-kogyo.co.jp/

CONTENTS

1. Safety instructions・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・1

2. Description of product・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

2-1. Specifications

2-2. Main features

3. Installation・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

3.1. Balancer installation

3.2. Tool/device attachment and spring tension adjustment

3.3. Working stroke (cable travel) check

4. Use・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・4

4.1. Safety instructions on use

4.2. Drum lock operation

4.3. Tool/device replacement

5. Troubleshooting・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・6

5.1. Common malfunctions and their causes

5.2. Solutions

6. Inspections・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・9

7. Wire rope replacement・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・10

8. Spring replacement・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・10

9. Wire guide replacement・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・12

10. Parts list・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・13

Copied digital data

from http://www.endo-kogyo.co.jp/

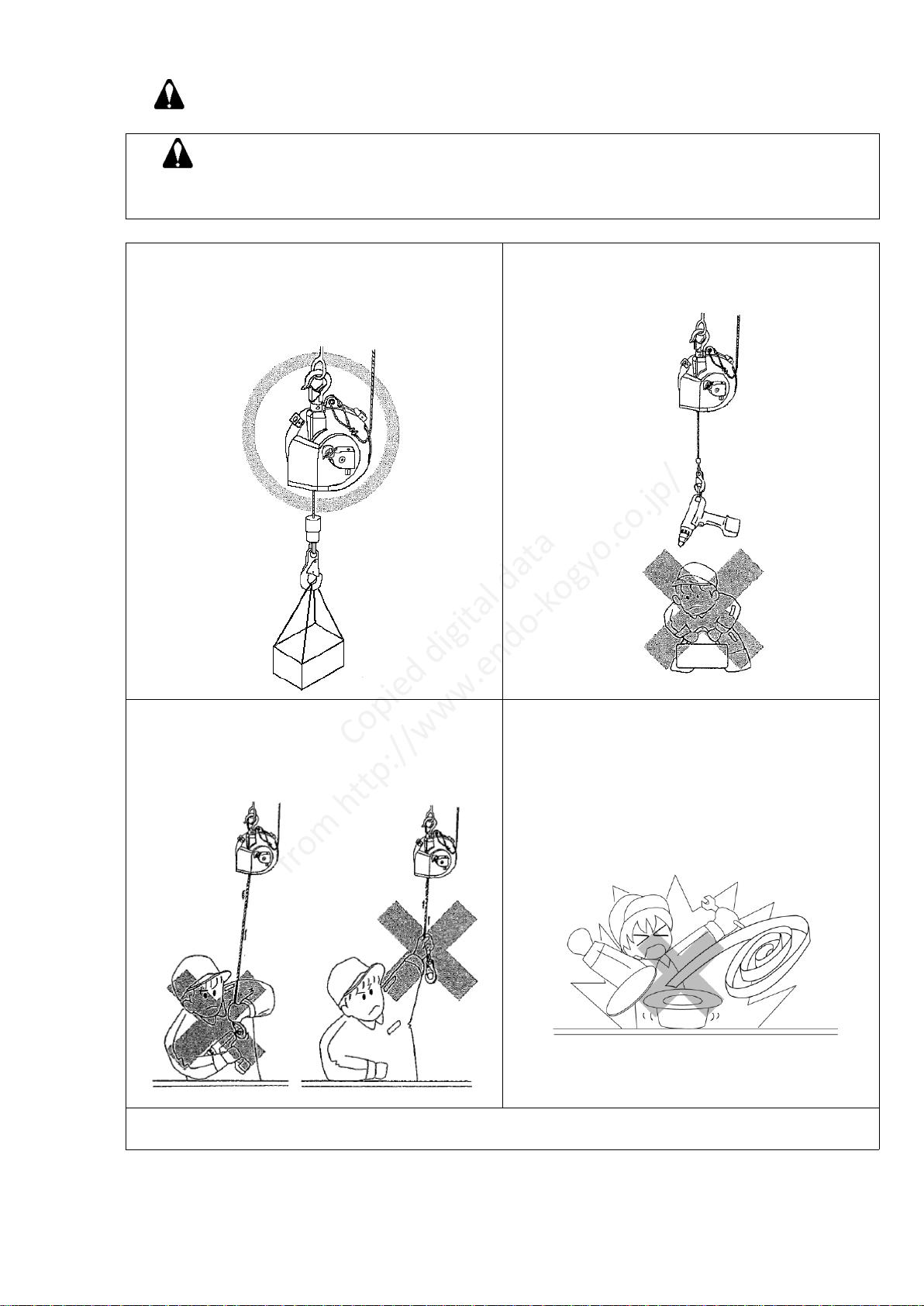

1. Safety Instructions

WARNING

・Incorrect use of the spring balancer could personal injury.

・Observe instructions in the manual and use the balancer correctly.

・Install the balancer correctly. ・Never stand under the suspended

・Always attach a secondary support tool/device.

cable or chain.

・Never remove tool/device while the wire ・Be careful when handling the spring.

rope is extended.

・Never pull the wire rope when unloaded.

・Never release the drum lock when unloaded.

・Never alter the balancer.

・Periodically inspect the balancer.

Copied digital data

from http://www.endo-kogyo.co.jp/

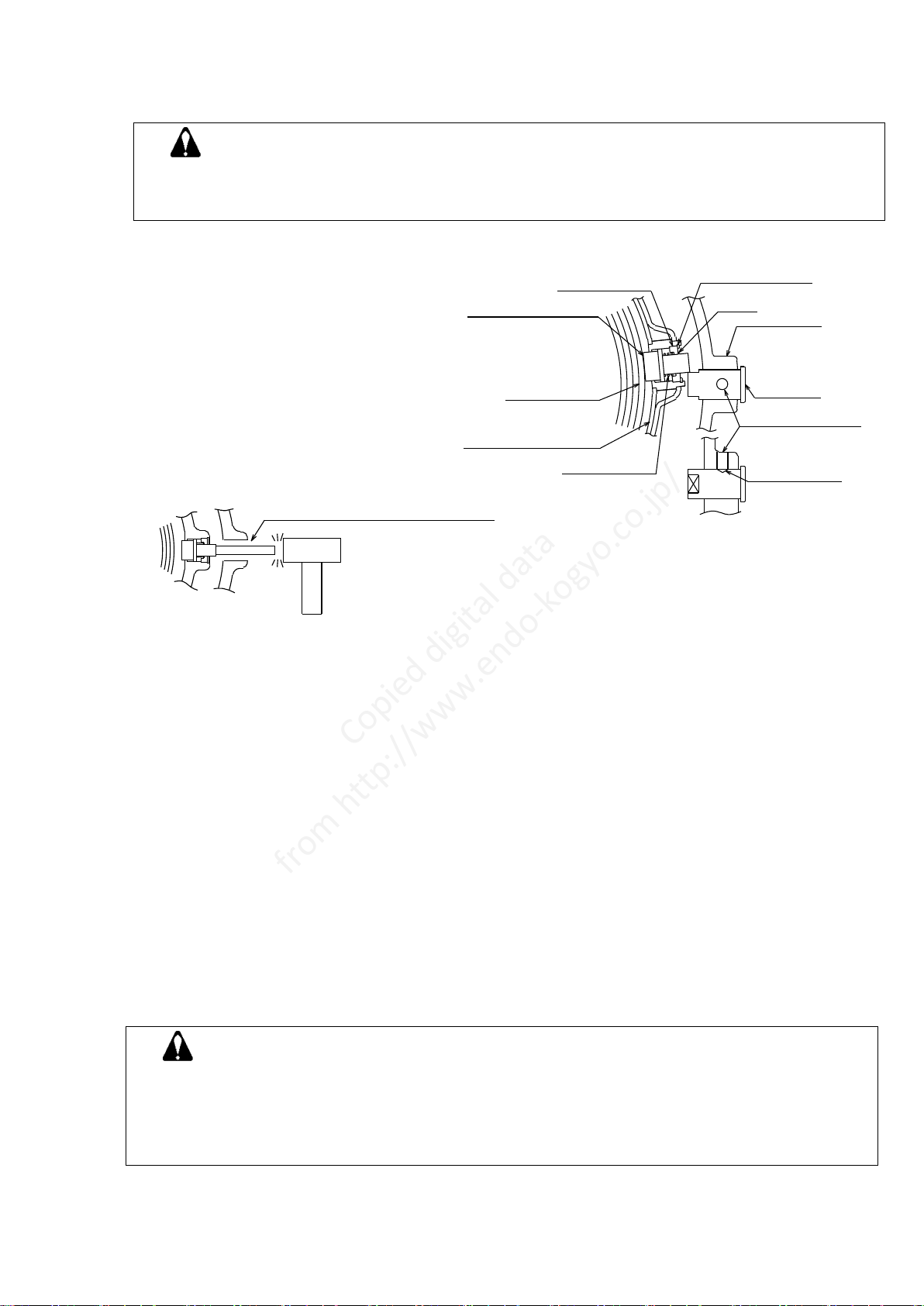

YBM000255

W i t h i n 1 0 0 m m

No opening

Fitting

Top hook

Bottom hook

Secondary

support cable

2. Description of product

2-1. Specifications

Model

Capacity range(kg)

Cable travel(m)

Mass(kg)

EWA-15

9~15

1.3

Approx.4.7

■Working conditions Application area : Indoor and normal atmospheric conditions

Temperature range: -10 ゚C to +50 ゚C

2-2. Main features

■Fall prevention device

A mechanism to prevent the suspended tool/device from falling to the maximum cable

travel in case of spring breakage.

This mechanism can not prevent the tool/device from falling at all when the spring

breaks.

■Drum lock (See Chapter 4-2 "Drum lock operation")

A mechanism to lock the drum at every 1/6 turn.

This mechanism is used when removing the suspended tool/device (see Chapter 4-3) or

replacing the wire rope (see Chapter 7).

■A snap back arrest device

This device is provided to arrest Wire rope snap back in case that Wire rope is cut or

suspended tool is disengaged. As soon as Wire rope is cut, drum revolves rapidly

winding Wire rope up. The centrifugal force makes Ratchet on a spring case pushed out

and the ratchet sticks in wheel fixed on a cover, stopping the revolution of the drum.

This is not engineered to keep the machine away from Wire rope snap back in advance.

Snap back arrest device works when the length of pulled wire is between 300mm and

1300mm. Between 100m and 200m of Wire rope must be wound very fast until Snap back

arrest device works in case of the cutting.

The device is only for emergency.

3. Installation

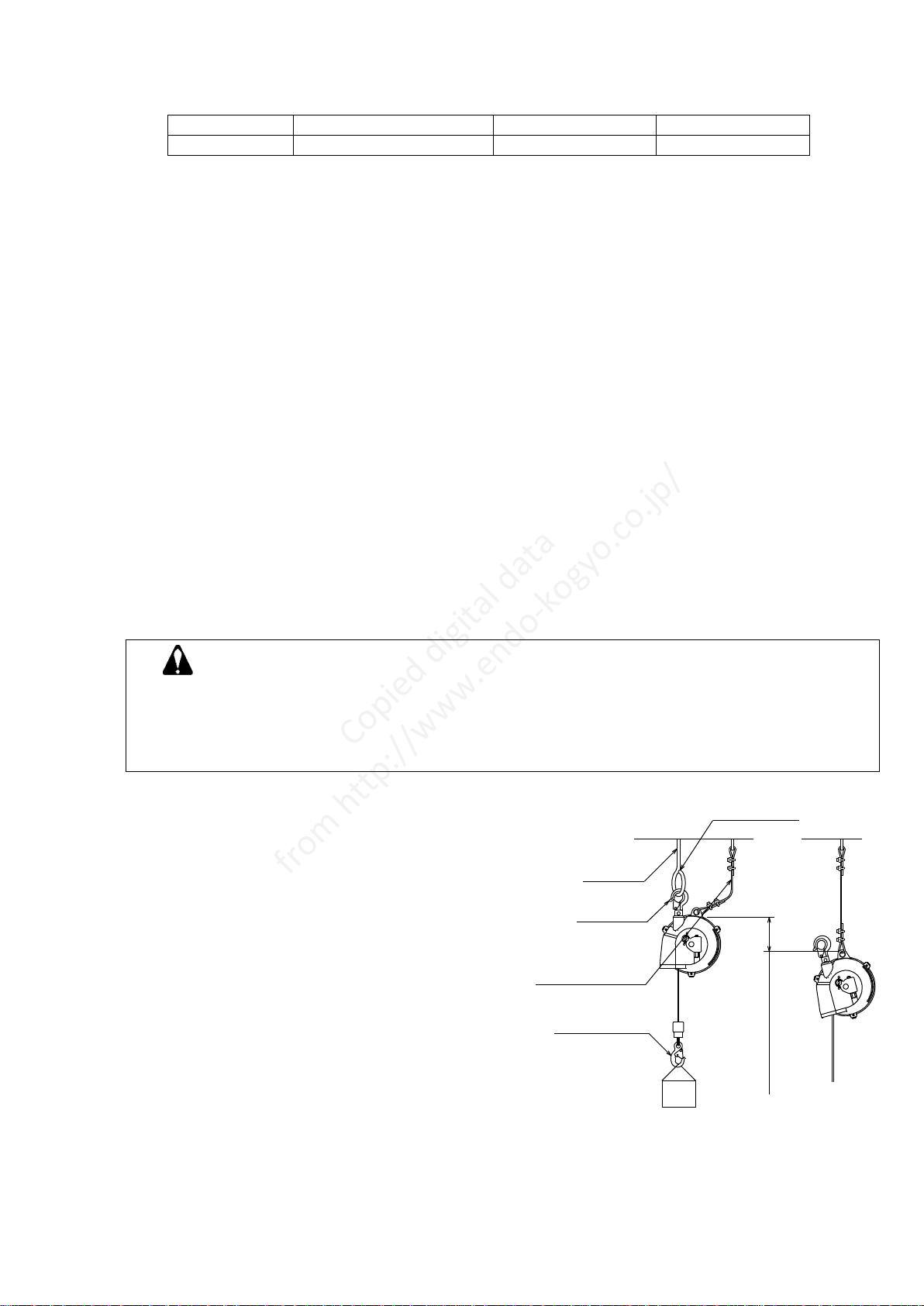

3-1. Balancer installation

WARNING

・Install the balancer correctly.

Incorrect installation could cause personal injury or damage to the balancer or other equipment.

・Always attach a secondary support cable or chain.

It is required to protect personnel in case of failure of the top hook or the fitting.

1) Prepare a fitting that can support at least 10 times . Fig.1

the maximum capacity of the balancer .

NOTE: The fitting must have no opening as

shown in Fig. 1 to prevent the balancer

from disengaging when it swings.

2) Attach the top hook of the balancer directly to

the fitting. Check the latch is closed.

NOTE: Take care the balancer does not hit

surrounding objects.

Make the mounting height different for

each balancer to avoid collision.

3) Check the top hook can swivel freely.

NOTE: Do not fasten the top hook to the balancer

body.

4) Prepare a secondary support cable or chain that

can support at least 10 times

the maximum capacity of the balancer .

5) As shown in Fig. 1, attach an end of the secondary

support cable or chain to the balancer body,

and attach the other end to a separate fitting which does not support the balancer.

NOTE: Leave some slack in the secondary support cable or chain to allow the balancer

to rotate freely. The slack must be a suitable length so that the balancer will stop

within 100 mm when falling in case of failure of the top hook or the fitting (See Fig. 1).

Copied digital data

from http://www.endo-kogyo.co.jp/

Pin(8)

Release

position

Lock

position

4. Use

4-1. Safety instructions on use

WARNING

・Never remove tool/device from the bottom hook while the wire rope is extended.

・Never stand under the suspended tool/device.

・Never alter the balancer.

CAUTION

・Always use within the capacity range of the balancer.

・Always adjust the spring tension before use.

・Do not extend the wire rope past the maximum cable travel.

・Do not pull the wire rope at an angle.

Fig.3

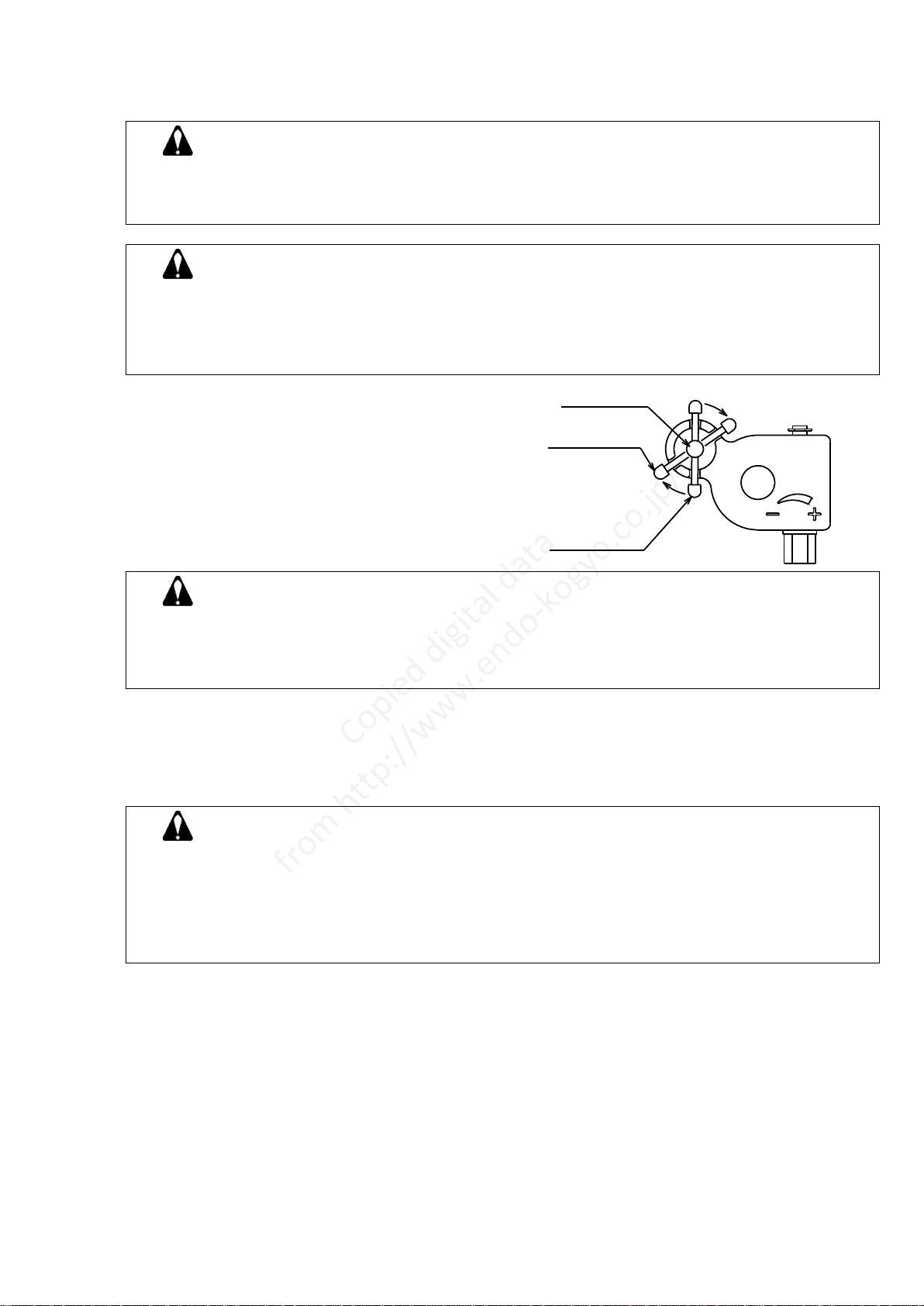

4-2. Drum Lock operation

1) Pull Pin (8) out and turn it clockwise to place

in the lock position (See Fig. 3).

2) Move the suspended tool/device upward or

downward until Pin (8) enters the slot/ hole in

the drum and the drum becomes locked.

3) Move the tool/device again to check the drum is

locked securely.

4) Remove the tool/device from the bottom hook.

WARNING

Never remove the suspended tool/device before checking the drum is locked securely.

If the drum is not locked securely, the drum lock could be released allowing the wire rope to snap

back, possibly causing personal injury.

Drum lock check is very important factor for safety . Never fail to verify the sufficient drum lock .

5) Before releasing the drum lock, attach a new tool/device if the old one has been removed.

The new tool/device must have almost the same mass (weight) as the old one.

6) Release the drum lock by pulling Pin (8) out.

Turn Pin (8) counterclockwise and place it in the release position.

WARNING

Never release the drum lock when the balancer is unloaded or the new tool/device has a different

mass (weight) to the old one.

If released, the wire rope will snap back or the tool/device could drop down respectively, possibly

causing personal injury.

Always release the drum lock after arranging the tension of spring suspending a tool.

This is important factor for safety. Never fail to abide by procedure instructed in the manual.

Copied digital data

from http://www.endo-kogyo.co.jp/

4-3. Tool/device replacement

■Method 1 - With drum lock

1) Lock the drum according to Chapter 4-2 "Drum lock operation" Remove the suspended

tool/device.

WARNING

Move the tool/device upward and downward to check the drum is locked securely.

Never remove the tool/device before checking this.

If the drum is not locked securely, the drum lock could be released allowing the wire rope to snap

back, possibly causing personal injury.

Drum lock check is very important factor for safety. Never fail to verify the sufficient drum lock.

2) Before attaching, check the mass (weight) of the new complete tool/device, including all

accessories, is within the capacity range of the balancer.

3) While watching the gauge, pre-adjust the spring tension to the mass of the new complete

tool/device by turning the worm with a wrench etc.

Turn clockwise for increasing the spring tension, turn counterclockwise for reducing.

The gauge shows the approximate spring tension (see Fig.2).

4) Attach the new complete tool/device to the bottom hook. Releasing the drum lock

WARNING

Never release the drum lock when the balancer is unloaded.

If released, the wire rope will snap back, possibly causing personal injury.

Always hold the suspended new tool/device by hand when releasing the drum lock, if the new

tool/device has a different mass (weight) to the old one.

Otherwise, the tool/device could rise up or drop down suddenly, possibly causing personal injury.

5) After attaching the new complete tool/device and releasing the drum lock, adjust the spring

tension again and check the tool/device is balanced.

NOTE: Over-tensioning could cause damage to the balancer body or the wire rope.

■Method 2 - Without drum lock

WARNING

Never remove the suspended tool/device while the wire rope is extended.

If removed, the wire rope will snap back and could cause personal injury.

1) Lift then remove the suspended tool/device when the wire rope is fully retracted.

2) Attach a new tool/device according to Chapter 3-2

"Tool/device attachment and spring tension adjustment".

Copied digital data

from http://www.endo-kogyo.co.jp/

5. Troubleshooting

WARNING

If a malfunction occurs during operation, stop operation immediately and take the necessary steps

to rectify the problem.

Never remove the suspended tool/device before identifying causes of the malfunction.

If removed, the wire rope will snap back and could cause personal injury.

Never take off a tool suspend to make the work safe. Wire rope snap back protection is for only

emergency.

5-1. Common malfunctions and their causes

Malfunction

Cause

Solution

・Wire rope cannot be pulled

out and retracted.

・Drum lock is engaged.

・Fall prevention device is

engaged because the spring

tension is set under the

maximum capacity .

・Wire rope has slipped

off from the drum groove and

is caught between drum and

casing.

・Spring has broken.

・Release drum lock

See Chapter 4-2 .

・Release fall prevention device

See Chapter 5-2 .

・Return wire rope

to the drum groove.

See Chapter 5-2.

・Replace spring.

See Chapter 8.

・Wire rope can not be

retrieved.

・Wire rope snap back

protection actuated

・Wire rope has slipped off from

the drum groove and is

caught between drum and

casing .

・Release the wire rope snap

back protection See Chapter

5-2 .

・Return wire rope to the drum

groove . See Chapter 5-2.

Contact your dealer or us if a malfunction not listed above occurs.

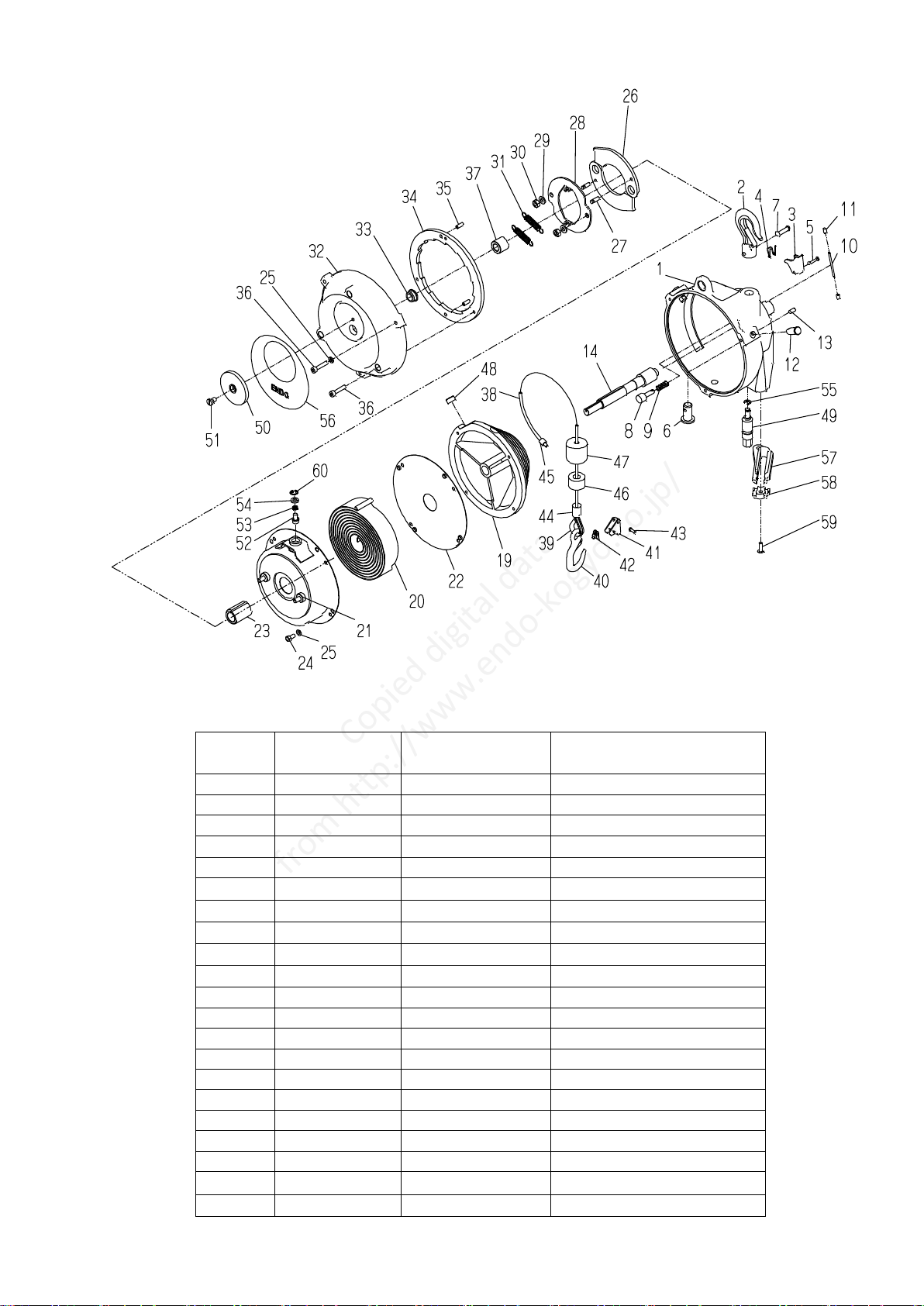

5-2. Solutions (Refer to the disassembly drawings on page 13)

CAUTION

Careless repairs can cause personal injury or damage to the balancer.

Therefore, be careful but thorough when making repairs.

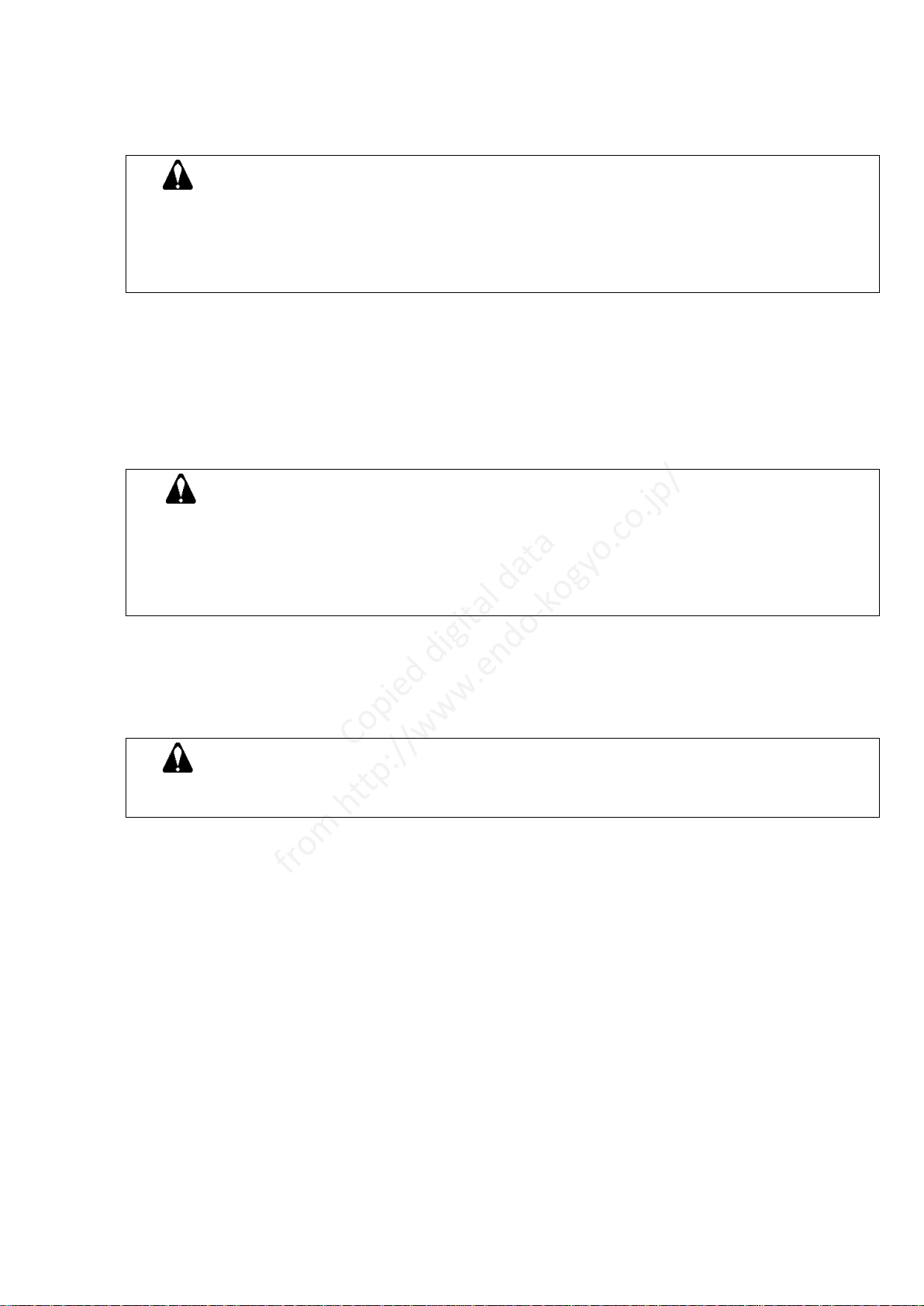

■When the fall prevention device has engaged because the spring tension is set under the

minimum capacity

1) Move the suspended tool/device upward and downward by hand.

The tool/device can be moved about 70 to 140 mm.

If the tool/device raises after being lowered and then released, turn Worm (49)

counterclockwise until the toll/device starts dropping down. If the tool/device drops down

after being lifted and then released, turn Worm clockwise until the tool/device starts rising.

2) Loosen Set screws (13), and remove all pins (12) while holding the tool/device by hand.

NOTE: For safety reasons, perform this work with two persons.

3) Lift then remove the tool/device from bottom Hook (40) when check the mass (weight) of

removed tool/device is within the capacity range of the balancer.

4) Attach a weight, which has been measured to be within the capacity range, to bottom Hook

(40) and adjust the spring tension.

5) Move the tool/device upward or downward so that Safety pin (52) appears at the opening (cut

off portion) of Causing (1).

6) Check safety pin (52) does not project out from the surface of Spacer (54).If protruding, lightly

tap the top of safety pin with a plastic hammer etc.

7) If safety pin does not return, it has burrs or spring (53) is broken. Remove Spacer (54) and

check Safety pin. Spring (53) pops out when Spacer (54) is removed, therefore be careful not

to lose it.

Copied digital data

from http://www.endo-kogyo.co.jp/

8) Attach Pins (12) to Casing (1).

Fasten depressions in pins (12) with set screws (13).

Fig. 4

■When the wire rope is caught between drum and casing

1) Release Wire rope (38) by jerking it strongly while the tool/device is suspended.

NOTE: After jerking, check Wire rope and replace if damaged.

2) If Wire rope can not be released by jerking, disassembly is required.

Remove Retaining ring (55) from Worm (49).

3) Release all spring tension by turning Worm (49) counterclockwise, and remove the balancer

from the fitting. .

4) Remove the tool/device from bottom Hook (40), and remove the balancer from the fitting.

5) Loosen Set Screws (13) and remove all pins (12).

6) Remove Gauge (50).

7) Loosen Cap screw (36), and remove Cover (32).

8) Return wire rope (38) to the groove of Drum (19).

NOTE: Check wire rope (38) and replace if damaged.

9) Install Cover (32)

10) Install Worm (49), and attach Retaining ring (55) .

11) Adjust the spring tension, and install Gage (50) and Pins (12) .

See Chapter 8 “Spring replacement”

■In case that the Wire rope snap back protection has actuated by sudden retrieve.

1) Pull out Wire rope (38) and release Ratchet (26), suspending a tool.

WARNING

Never remove the suspended tool when Wire rope snap back protection has actuated.

Release of Wire rope snap back protection may cause a serious danger, retrieving cable rapidly if

has performed without a tool suspended.

Wire rope pilling out one recovery work will release Wire rope snap back protection, causing

personal injury. Wire rope will be retrieved about 100mm-200mm rapidly.

2) If Ratchet is not released despite cable pulls out enough, Lock the drum according to Chapter

4-2 Drum lock operation.

3) Remove Retaining ring (55) from Worm (49) after checking the sure lock of drum.

WARNING

If installation of Safety pin (52) or pins (12) is incorrect or missed, the fall prevention device will

not operate in case of spring breakage, causing personal injury or damage to equipment.

Spr ing case(21)

Depress ion

Casing(1)

Burr

Pin(12)

Set screw(13)

Spring(53)

Spring(20)

Sefety pin(52)

Spacer(54) Snapring(60)

Lightly hit the safety pin

through the installation

hole of pin using a plastic

hammer.

Copied digital data

from http://www.endo-kogyo.co.jp/

4) Release all spring tension by turning Worm (49) counterclockwise, and remove Worm.

5) Remove the tool/device from bottom (40), and remove the balancer from the fitting.

6) Loosen Set screw (13), and remove all pins (12).

7) Remove Gauge (50).

8) Remove Cap screw (36).

9) Remove Cover (32).

NOTE: Replace Wheel (34), Ratchet (26),Spring (31) etc. if they has damaged.

10) Install Cover (32).

11) Mount Cap screw (36).

12) Install Worm (49), and attach Retaining ring (55).

13) Adjust the spring tension, and install Gauge (50) and Pins (12).

See chapter 8 “Spring replacement”, 10-11)

■In case that Snap back protection has actuated due to wire rope cut etc.

WARNING

If snap back protection has actuated due to Wire rope cut etc, Stop operation at once and

perform proper solution. Wire rope will be retrieved suddenly, causing injury of personal in

case that the damaged Wire rope is pulled out or machine receives excessive shock.

Wire rope pulling out or excessive shock to the Balancer will release Wire rope snap back

protection, causing personnel injury. Wire rope will be retrieved about 100mm -200mm

rapidly.

1) Lock Drum according to Chapter 4-2 [Drum lock operation]

2) Remove retaining ring (55) from Worm (49) after checking the sure lock of drum.

3) Release all spring tension by turning Worm (49) counterclockwise, and remove Worm.

4) Take off a Spring balancer from the support.

5) Loosen Set screw (13), and remove all pins (12).

6) Remove Gauge (50).

7) Remove Cap screw (36).

8) Remove Cover (32).

NOTE: Replace Wheel (34), Ratchet (26), Spring (31) etc. if they has been damaged.

9) Install Cover (32).

10) Mount Cap screw (36)

11) Install Worm (49), and attach Retaining ring (55).

12) Equip Wire rope (38) to Drum (19) after passing Wire rope through the Wire rope entrance

on Casing (1) and then fix wire rope with Plug (48).

13) Adjust the spring tension, and install Gauge (50) and Pins (12).

See Chapter 8 “Spring replacement”

Copied digital data

from http://www.endo-kogyo.co.jp/

B

D

A

C

Is a retaining ring

taken off?

Are any pins or

safety pin missing?

Is there any

wear or damage?

Top hook

Latch

Is there any

deformation?

swivel smoothly?

Can hook

Casing,Drum

Is there any

wear or damage?

Wire guide

Are there any wear

or cracks?

Are screws loose?

Latch

Is there any

deformation?

Secondary support

cable(chain)

Is there any damage?

Are bolts loose?

Is there any wear or damage?

Are screws loose?

Wire rope

Is there any damage?

Check for wire

near the lock tube.

breakage or damage

Buffer

Is there any wear

or cracks?

Collar

Move upward during

inspection.

Is there any wear

or damage?

Thimble,Bottom hook

Bottom hook

Fitting

1 Pitch

There must be no kinks.

H

8.0mm

Y B M 0 0 0 2 1 1

16.5mm

41.0mm

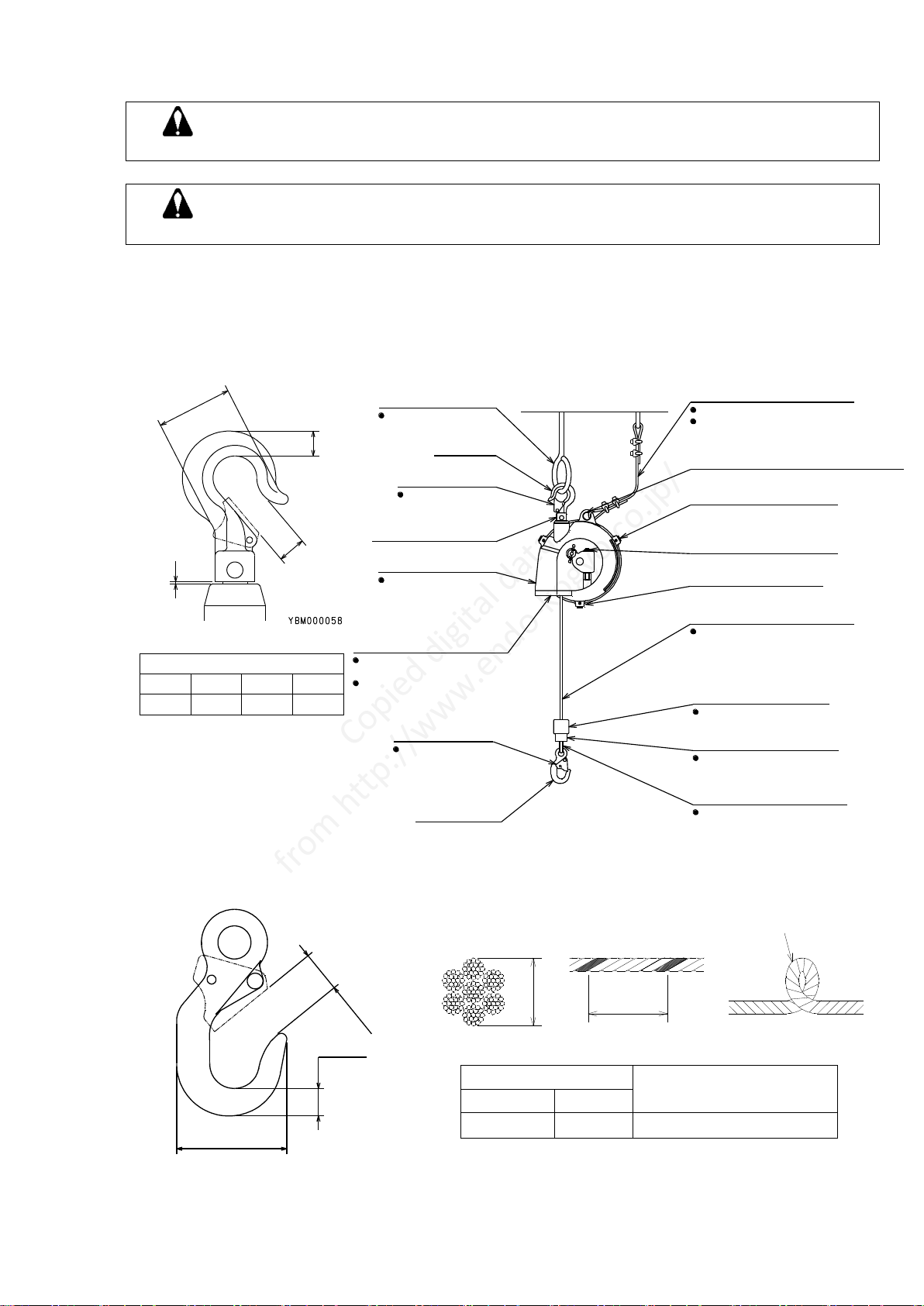

6. Inspections

WARNING

Periodically inspect the balancer, and replace any worn or damaged parts.

CAUTION

Always use genuine parts for replacement.

■Inspect the balancer at least once a month.

Correct and repair any problems which are detected.

Make the inspection interval shorter when operating frequently or under hostile environments.

(See Fig. 5)

■Service limit of top hook Fig.5

Limit dimension (mm)

A

B

C

D

11.7

15.5

44.0

1.5

■Service limit of bottom hook ■Service limit of wire rope

H dimension (mm)

Allowable number of

broken wires in 1 pitch

Standard

Limit

4

3.7

11

Copied digital data

from http://www.endo-kogyo.co.jp/

W i n d o w

W i r e r o p e

P l u g ( 4 8 )

P i n ( 8 )

H o o k ( 4 0 )

Collar(46)

B u f f e r ( 4 7 )

W i r e r o p e ( 3 8 )

Drum(19)

W i r e r o p e

e n t r a n c e h o l e

A

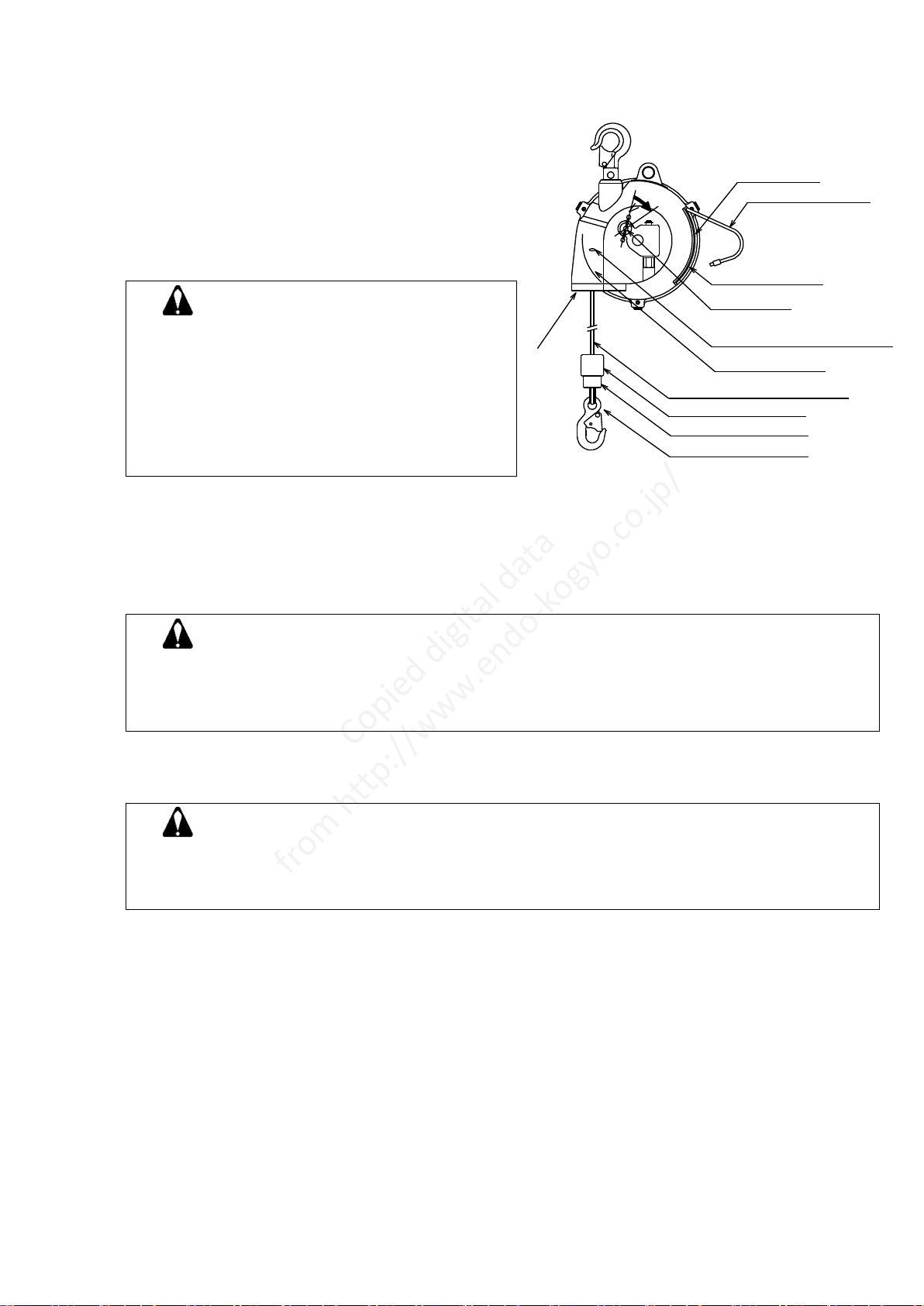

7. Wire rope replacement Fig.6

1) Lower the tool/device, extending Wire rope to

the maximum cable travel.

2) Position Plug (48) at the casing opening as

shown in Fig. 6, and engage the drum lock.

See Chapter 4-2 "Drum lock operation".

3) Move the tool/device upward and downward to

check Drum is locked securely. Remove the

tool/device from bottom Hook (40).

4) Remove the balancer from the fitting and place on the floor.

5) Remove Plug (48), and remove old Wire rope from drum.

6) Insert new Wire rope from A-side, pass it through Drum.

7) Attach the end of Wire rope to Drum and fasten with plug (48).

8) Install the balancer on the fitting.

See Chapter 3-1 “Balancer installation”

9) Attach the tool/device to bottom Hook, and release the drum lock.

WARNING

Never release the drum lock before attaching the tool/device.

If released, Wire rope (38) will snap back and could cause personal injury.

Always release the drum lock after arranging the tension of spring suspending a tool. This is

important factor for safety. Never fail to abide by the procedure instructed in the manual.

8. Spring replacement

WARNING

Never remove the spring from the spring case. If removed, the spring will expand explosively and

cause personal injury.

Replace the spring assembly as a whole.

Referring to the disassembly drawing (on page13), disassemble the balancer using the following

procedure.

1) A. When the spring has broken;

Remove the tool/device from bottom Hook (40).

B. When the spring has not broken;

Lift then remove the tool/device from bottom Hook (40) when Wire rope (38) is fully

retracted into Drum (19).

2) Remove the balancer from the fitting and place on the floor.

3) Remove Gauge (50)

4) Remove Retaining ring (55) from Worm (49). Release all spring tension by turning

worm (49) counterclockwise until Worm can almost be removed. If the drum lock is engaged,

check there is no spring tension remaining, and then release the drum lock.

NOTE: Check the spring tension by pulling Wire rope.

5) Turn Worm (49) further and remove it.

6) Loosen Set screws (13), and remove all Pins (12).

WARNING

Never remove the suspended tool/device before

checking Drum (19) is locked securely.

If Drum (19) is not locked securely, the drum lock

could be released allowing Wire rope to snap back

or Drum to rotate suddenly, possibly causing

personal injury.

Drum lock check is very important for safety.

Never fail to verify the sufficient in the manual.

Copied digital data

from http://www.endo-kogyo.co.jp/

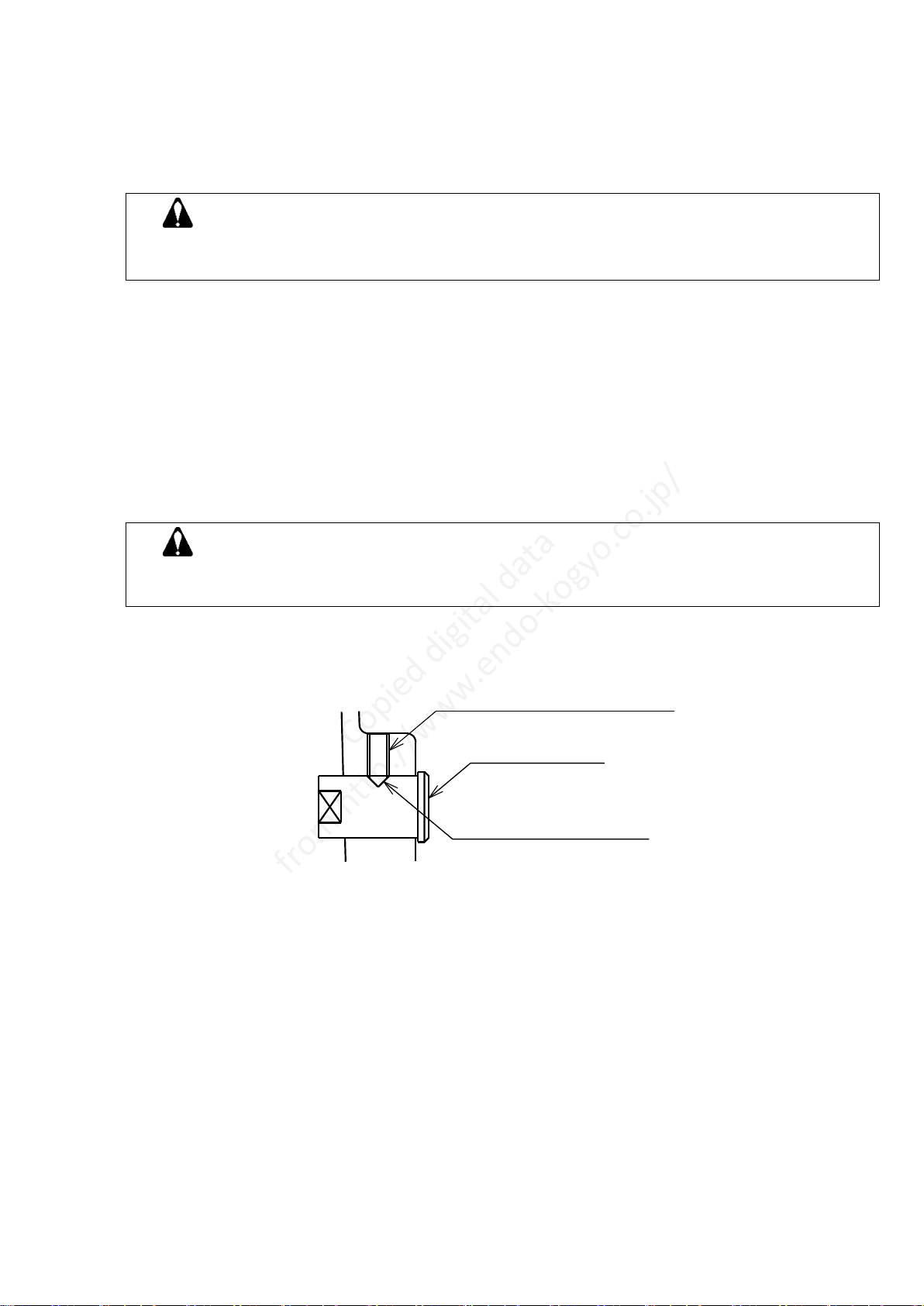

Set screw(13)

Pin(12)

Depression

7) Remove Plug (48), and remove Wire rope (38) from Drum (19).

8) Remove Cover (32), and remove Spring case (21), Drum (19), and Spindle (15), together from

the Casing(1).

9) Remove Spindle (14).

10) Remove Hex. head bolt (24), and remove Spring case (21) from Drum (19).

11) Remove Bushing (23) from Spring case (21) .

WARNING

Never remove cover (22) from Spring case(21).

If removed, the internal spring could pop out and cause personal injury.

12) Reassemble in reverse order.

Pins (12) should be installed after adjusting the spring tension as instructed below.

13) Wind the spring by turning worm (49) clockwise.

NOTE: While turning Worm, Wire rope (38) will be retracted into drum (19). Pay attention

Wire rope does not slip out from the drum groove. After Wire rope is fully retracted,

turn worm 50 times.

14) Attach a weight, which has been measured to be within the capacity range,

to bottom Hook (40) and adjust the spring tension.

15) Attach and adjust Gauge (50).

16) Attach Pins (13) to Casing (1) ( See Fig.7)

fasten depressions in Pins (12) with set screws (13).

Fig.7

WARNING

If installation of Pins (12) is incorrect or missed, the fall prevention device will not

operate in case of spring breakage, causing personal injury or damage to equipment.

Copied digital data

from http://www.endo-kogyo.co.jp/

Hex. socket

button bolt(59)

Pin(8)

Wire guide(57)

(58)

9. Wire guide replacement

1) Pull out the wire rope (57), (58) to the position Fig. 8

which wire guide replacement is available

and lock drum with drum lock device(refer to Fig-8).

Refer to Chapter 4-2 ”Drum lock operation”.

2) After confirming that drum lock is surely

on work, moving a suspended tool up and down,

take off a suspended tool.

3) Remove the balancer from a fitting and place on the floor.

4) Remove Hex. Socket button bolts (59) are old wire guide from casing.

5) Fix new wire guide (57) (58)

NOTE: Hex. Socket button bolts (59) are sealed against looseness

Always replace old ones with new ones when they are remove.

Tighten the hex. Socket bolts with torque of 2.8~3.0N・m{0.28~0.3kgf・m}.

6) Mount the balancer on a fitting.

Refer to Chapter 3-1 “Balancer Installation”.

7) Attach the tool/device to bottom Hook, and release the drum lock.

WARNING

Never release the drum lock before attaching the tool/device.

If released, Wire rope will snap back and could cause personal injury.

WARNING

Never remove the suspended tool/device before

checking Drum (19) is locked securely. If Drum (19) is

not locked securely, the drum lock could be released

allowing Wire rope (38) to snap back or Drum to

rotate suddenly, possibly causing personal injury.

Copied digital data

from http://www.endo-kogyo.co.jp/

10. PARTS LIST EWA-15

Ref. No.

Part No.

Quantity

Description

-

LBP001097

1

Casing assembly

1

P2B100131

1

-Casing

-

LBP000262

1

-Hook complete

2

-

1

--Hook

-

LBP000263

1

--Latch set

3

-

1

---Latch

4

-

1

---Spring

5

-

1

---Rivet

6

-

1

--Shaft

7

-

1

--Rivet

8

P2B400347

1

-Pin

9

P2B400081

1

-Spring

10

P2B400224

1

-Spring pin

11

P2B400348

2

-Cap

12

P2B400044

3

-Pin

13

P2B400041

3

-Set screw

14

P2B301252

1

Spindle

19

P2B100045

1

Drum

-

LBP001661

1

Spring assembly

20

-

1

-Spring

21

-

1

-Spring case

Copied digital data

from http://www.endo-kogyo.co.jp/

Ref. No.

Part No.

Quantity

Description

-

LBP001822

1

-Safety pin set

52

-

1

--Safety pin

53

-

1

--Spring

54

-

1

--Spacer

60

-

1

--Retaining ring

22

-

1

-Cover

23

P2B300163

1

Bushing

24

KA00120510

4

Hex. head bolt

25

KA31120500

7

Spring washer

-

LBP001662

2

Ratchet set

26

-

2

-Ratchet

27

-

2

-Pin

28

P2B301254

1

Plate

29

KA31120600

2

Spring washer

30

KA20320600

2

Hex. nut

31

P2B401895

2

Spring

-

LBP001663

1

Cover complete

32

-

1

-Cover

33

-

1

-Bushing

34

P2B301255

1

Wheel

35

KA42410512

2

Spring pin

36

KA00910525

6

Cap screw

37

P2B401896

1

Collar

-

LBP000136

1

Wire rope assembly

38

-

1

-Wire rope

39

-

1

-Thimble

-

LBP001505

1

-Hook complete

40

-

1

--Hook

-

LBP001524

1

--Latch set

41

-

1

---Latch

42

-

1

---Spring

43

-

1

---Rivet

44

-

1

-Lock tube

45

-

1

-Lock tube

46

P2B400150

1

-Collar

47

P2B400147

1

-Buffer

48

P2B400007

1

Plug

49

P2B300062

1

Worm

50

P2B300166

1

Gauge

51

P2B400165

1

Screw

55

KA40310050

1

Retaining ring

56

P2B301256

1

Name plate

-

LBP001096

1

Wire guide set

57

-

1

-Wire guide

58

-

1

-Wire guide

59

P2B401213c

2

-Hex. socket button bolt

NOTE) When placing an order, clearly specify the product model, part number and description.

Parts without a part number cannot be supplied individually.

Please purchase a set or complete unit.

Copied digital data

from http://www.endo-kogyo.co.jp/

Table of contents

Other Endo Wheel Balancer manuals