endolite EchelonVAC User manual

EN Instructions for Use 1

FR Instructions D’Utilisation 20

DE Gebrauchsanweisung 39

IT Istruzioni per L’uso 59

ES Instrucciones de Uso 79

NO Bruksanvisning 98

RU Инструкция протезиста 117

TR Kullanım Talimatları 136

EN

1

938367/1-0816

Application:

These instructions are for use by the practitioner.

The EchelonVAC foot is to be used exclusively as part of a lower limb prosthesis.

The EchelonVAC provides limited self-alignment of the prosthesis on varied terrain and following

footwear changes. It is intended to improve on postural sway and symmetry while easing

abnormal pressures at the socket interface. A moderate energy return foot with multi-axial ankle

movement. Independent heel and toe springs provides some axial deection. The split toe

provides good ground compliance.

1 Description and Purpose

This device is recommended for users that have the potential to achieve Activity Level 3 who may

benet from enhanced stability and an increase in condence on uneven surfaces.

Of course there are exceptions and in our recommendation we want to allow for unique,

individual circumstances. There may also be a number of users in the Activity Levels 2 and 4* who

would benet from the enhanced stability oered by the EchelonVAC, but this decision should

be made with sound and thorough justication.

*(maximum user weight 100kg (220lbs) and always use one higher spring rate category than

shown in the Spring Set Selection table).

Contra-indications:

This device may not be suitable for Activity Level 1 individuals or for competitive sports events,

as these types of users will be better served by a specially designed prosthesis optimized for their

needs.

It may not be suitable for use on individuals with poor balance , especially for bilateral use. If

the user has any pertinent circulation condition seek medical advice if there is a possible risk of

adverse reactions.

It is NOT recommended for use for:

• Wearers with poor cognitive function

• Users on dialysis

• Users with neuromas preventing weight bearing

• Use where a large range of heel height is required without re-alignment

EchelonVAC should only be tted by suitably trained practitioners and should only be used with

suitable, well tting total contact sockets. There should be no reliefs or voids into which tissue

may be drawn by the vacuum.

• If multiple walled sockets are used there should be no voids in their construction

• There should be no excessive ares to socket brim or trim lines

Intended for single user.

Ensure that the user has understood all instructions for use, drawing particular attention to the

section regarding Maintenance.

In addition to the visco-elastic, self-aligning hydraulic ankle it generates an elevated vacuum in

the range 12-17in Hg.

2

938367/1-0816

Note:

If in doubt choosing between two categories, choose the higher rate spring set.

Foot Spring set recommendations shown are for transtibial users.

For transfemoral users we suggest selecting a spring set one category lower,

refer to tting advice Section 7 to ensure satisfactory function and range of movement.

Has the ability or potential for ambulation with variable cadence.

Typical of the community ambulator who has the ability to traverse most

environmental barriers and may have vocational, therapeutic, or exercise activity

that demands prosthetic utilization beyond simple locomotion.

Activity Level 3

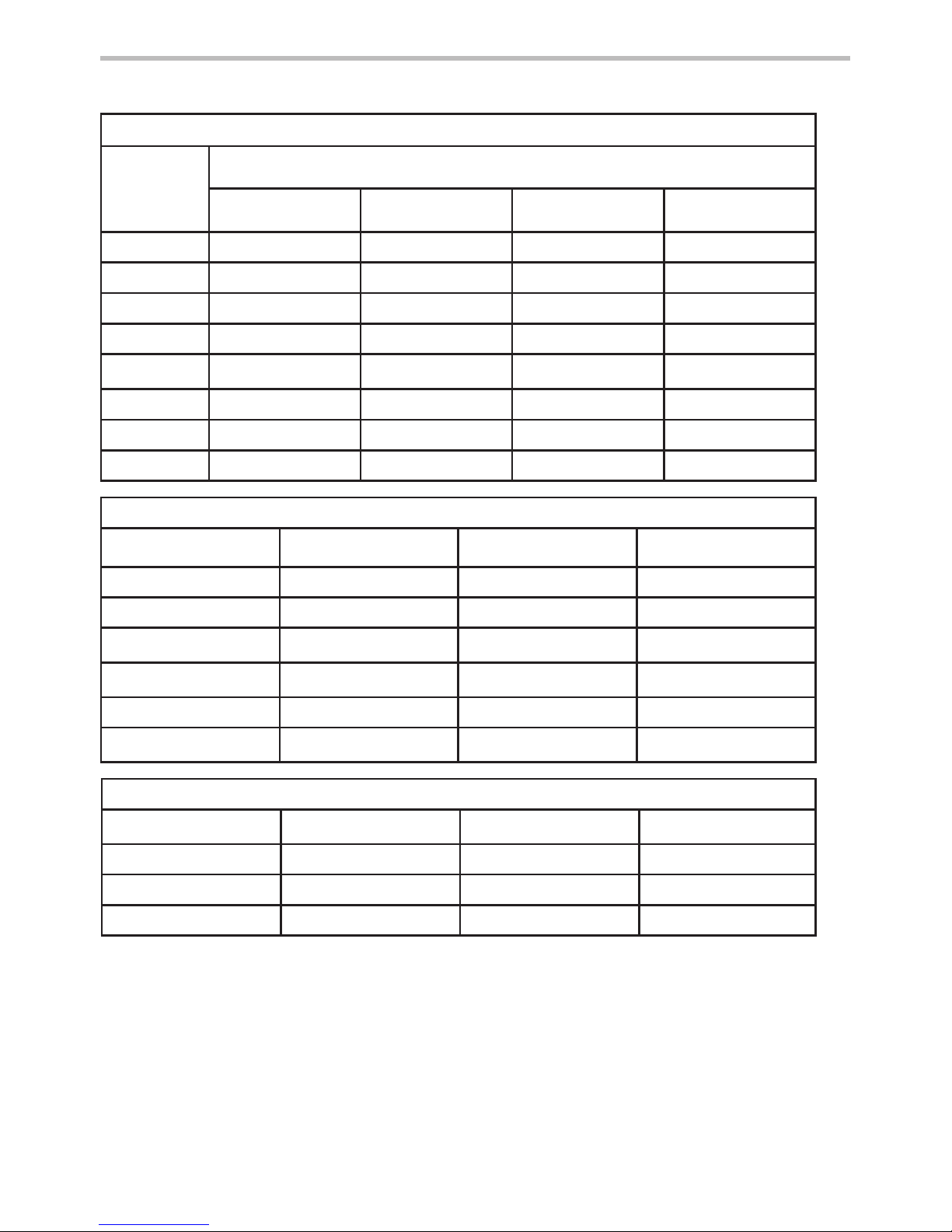

Spring Set Selection

Activity

Foot

Spring Set

44-52 53-59 60-68 69-77 78-88 89-100 101-116 117-125 kg

(100-115) (116-130) (131-150) (151-170) (171-195) (196-220) (221-255) (256-275) (lbs)

1 2 3 4 5 6 7 8

User Weight

3

Available from size 22 to size 30:

EVAC22L1 to EVAC30R8

EVAC22L1D to EVAC30R8D

Size

Side

Spring Set

Category

Order Example:

e.g. EVAC25L3

(add ‘D’ for a dark tone foot shell)

EVAC 25L 3

After continuous use the ankle casing may become hot to the touch.

3

938367/1-0816

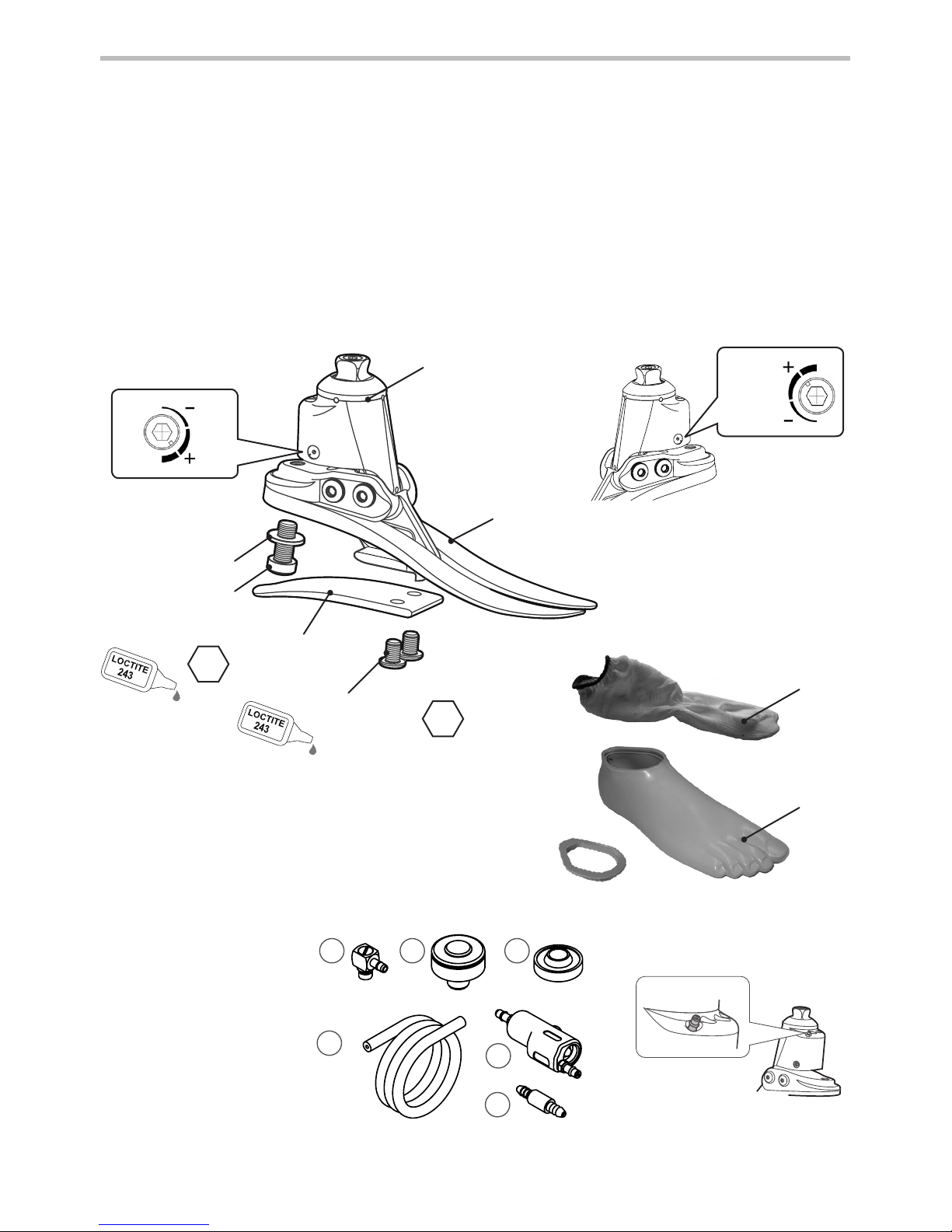

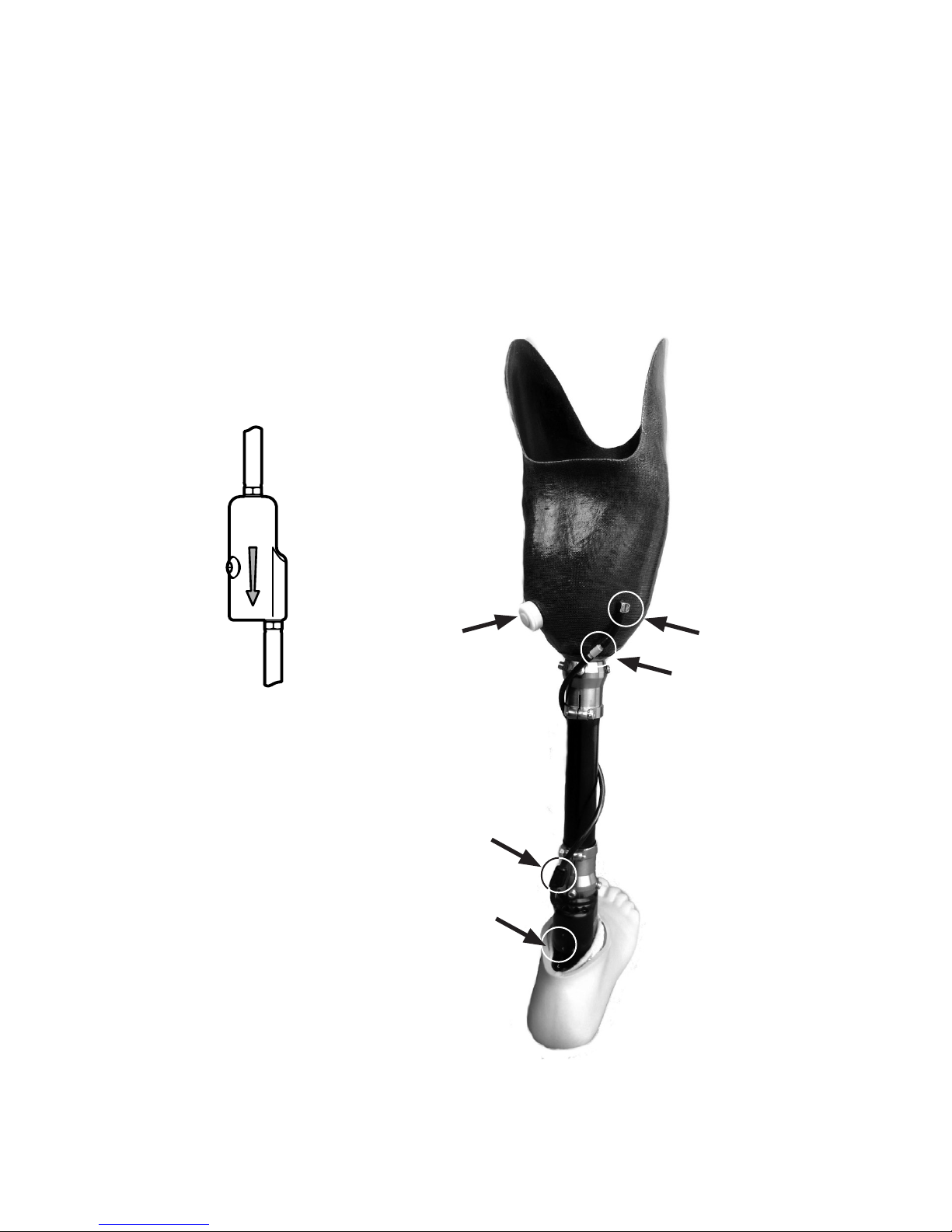

Principal Parts:

• Hydraulic Body Assembly including pyramid (Aluminium/St. Stl./Titanium)

• Carrier Assembly (Aluminium/St. Stl.)

• Heel & Toe Springs (e-Carbon)

• Spring Attachment Screws (Titanium/St.Stl.)

• Glide Sock (UHM PE)

• Foot Shell (PU)

• Vacuum Parts (PU, Nylon, Aluminium)

2 Construction

Glide

Sock

Foot

Shell

Toe

Spring

Min 1

Dorsiexion

Valve Adjuster

(opposite Plantar

Flexion adjuster)

DF

Heel Spring

Screws

(Loctite 243)

Plantar Flexion

Valve Adjuster

Toe Spring

Washer

Toe Spring

Screw

(Loctite 243)

PF

Heel

Spring

4

15Nm

8

35Nm

Attachment

Plate

Min

Max

Min

Max

Carrier, Hydraulic

Body and Vacuum

Assembly

Vacuum System Parts

1 Vac Barb 90deg

2a Auto-Expulsion Valve

2b Threaded Housing

3 Check Valve

4 In-line Filter

5 Vacuum Tubing

Vacuum Connector

1

3

5

2a

4

2b

4

938367/1-0816

3 Function

The EchelonVAC comprises a hydraulic body assembly containing adjustable hydraulic valves.

The valves can be independently adjusted to increase and reduce hydraulic resistance of plantar

exion and dorsiexion.

4 Maintenance

The hydraulic body assembly is connected to a carrier assembly via two pivot pins. Heel and toe

springs are attached to the carrier assembly using titanium and stainless steel screws. The foot is

wrapped in a UHM PE sock which is in turn surrounded by a PU foot shell.

Maintenance must be carried out by competent personnel.

It is recommended that the following maintenance is carried out annually:

• Remove the foot shell and glide sock, check for damage or wear and replace if necessary.

• Check all screws for tightness, clean and reassemble as necessary.

• Visually check the heel and toe springs for signs of delamination or wear and replace if

necessary. Some surface damage may occur after a period of use, this does not aect the

function or strength of the foot.

The wearer should be advised:

Any changes in performance of this device must be reported to the practitioner.

Changes in performance may include:

• Increase in ankle stiness

• Reduced ankle support (free movement)

• Any unusual noise

• Lack of vacuum

Cleaning:

Use a damp cloth and mild soap to clean outside surfaces, do not use aggressive cleansers.

The practitioner must also be informed of:

• Any changes in body weight and/or activity level.

• Discoloration of the residual limb.

The hydraulic body also houses a pneumatic chamber and piston which, via one-way valves

and a lter, creates a vacuum that can be passed via tubing to a prosthetic socket. For maximum

vacuum eect the check valve should be positioned close to the ankle. The number of steps

necessary to create an elevated vacuum will vary depending on the free space/air in the system.

The use of multiple socks may require an increased number of steps to reach an elevated

vacuum.

NB. if high hydraulic resistances are used such that they restrict ankle movement, the ability to

generate vacuum may be compromised.

5

938367/1-0816

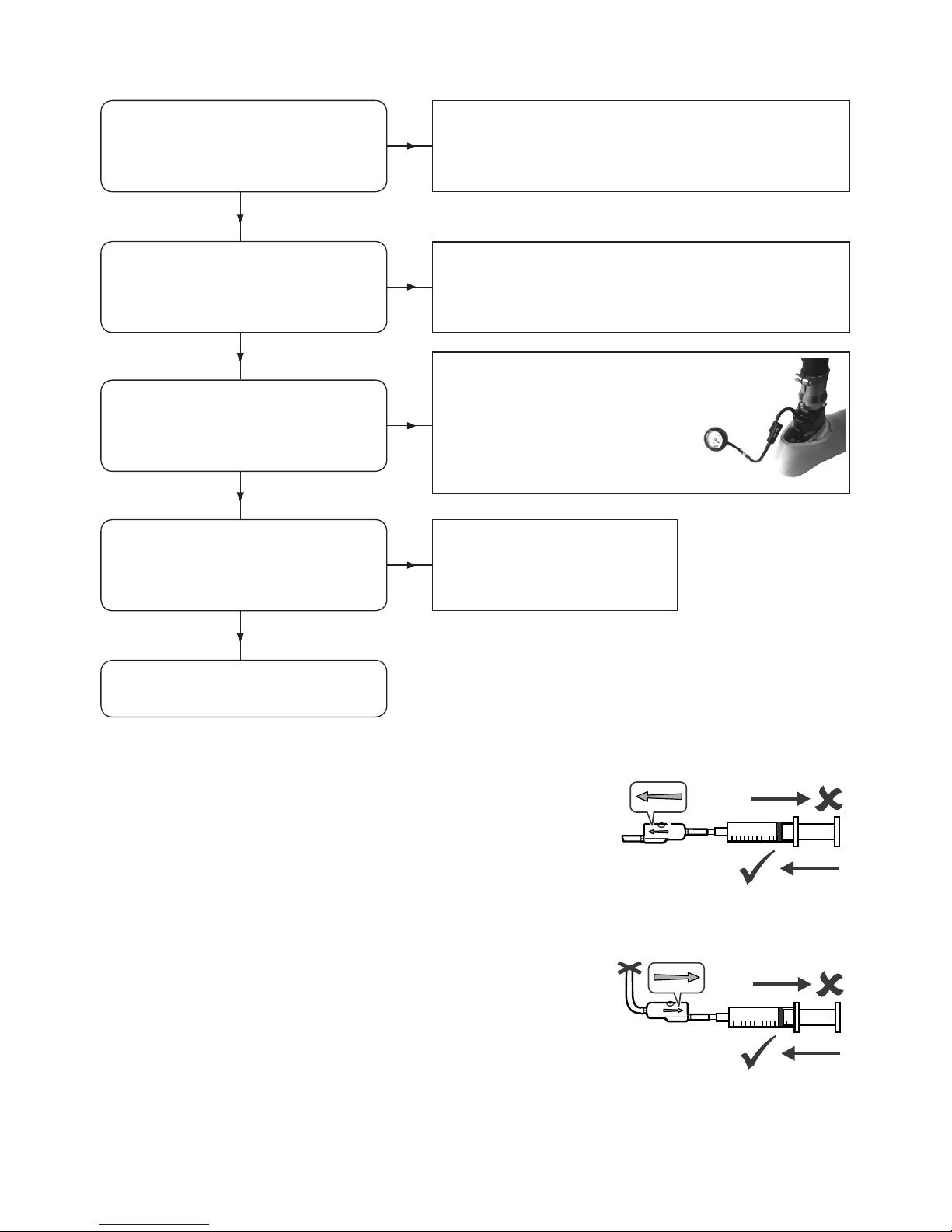

4.1 Vacuum System Maintenance Guide

1 Visual Inspection

Make a visual inspection of the system parts paying attention to connections, these must be air

tight to ensure integrity of the vacuum. Inspect the tubes and ensure they are rmly connected

and are not kinked or split. The socket arrangement should also be inspected to check the

integrity of the vacuum seals.

Auto-Expulsion

Valve In-line Filter

Check Valve

Vac Barb

90deg

distal

tube

2 Check Valve

The check valve retains the vacuum created

in the socket. It must be connected with

the direction arrow pointing towards the

EchelonVAC ankle.

proximal

tube

Connector

6

938367/1-0816

Check the Auto-Expulsion Valve

in the socket

The valve should be silent after the user takes some steps.

Check that the seal is not compromised, clean it or replace

it if required.

1 Cleaning the Check Valve, vacuum inlet

Disconnect the check valve and connect a syringe to the proximal

tube with the ow direction arrow pointing away from the syringe.

If the valve is working correctly the syringe should only push

inwards. If the valve is blocked use the syringe to clear the valve

with a‘blast of air’ (Do not use compressed air). If it is still blocked

clean it with distilled water using the syringe. If the valve is still not

working replace it (409663 or 409863).

2 Cleaning the Check Valve, exhaust port

Check the exhaust valve is working correctly by connecting a

syringe to the distal tube and clamp the proximal tube. Use a

‘blast of air’ to clear it through (Do not use compressed air). If

the exhaust valve is working correctly and retaining the vacuum

it should not be possible to draw the syringe plunger back out

again.

4.2 Vacuum System Checklist

Inspect the tubing and connections Ensure the tubes are rmly connected and are not

kinked or split, replace if required.

Check that a vacuum is being

created at the ankle using a vacuum

gauge or syringe

Fully plantar ex and dorsiex the

foot several times.

If the vacuum is working and there is

no vacuum at the socket, the In-line

Filter or the Check Valve may need

replacing.

Check the Check Valve See Cleaning the Check Valve

Contact your practitioner or

Endolite representative

7

938367/1-0816

5 Limitations on Use

Intended life:

A local risk assessment should be carried out based upon activity and usage.

Lifting loads:

User weight and activity is governed by the stated limits.

Load carrying by the user should be based on a local risk assessment.

Environment:

Avoid exposing the EchelonVAC to corrosive elements such as water, acids and other liquids. Also

avoid abrasive environments such as those containing sand for example as these may promote

premature wear.

Exclusively for use between -15˚C and 50˚C (5˚F to 122˚F).

It is recommended that only Endolite products be used in conjunction with the EchelonVAC.

For use only by appropriately trained practitioners.

Should only be used with well tting total surface bearing sockets with no reliefs or voids, which

have been constructed with air tight sockets and a suspension sleeve to create an air tight seal

proximally.

8

938367/1-0816

½½

0-10mm

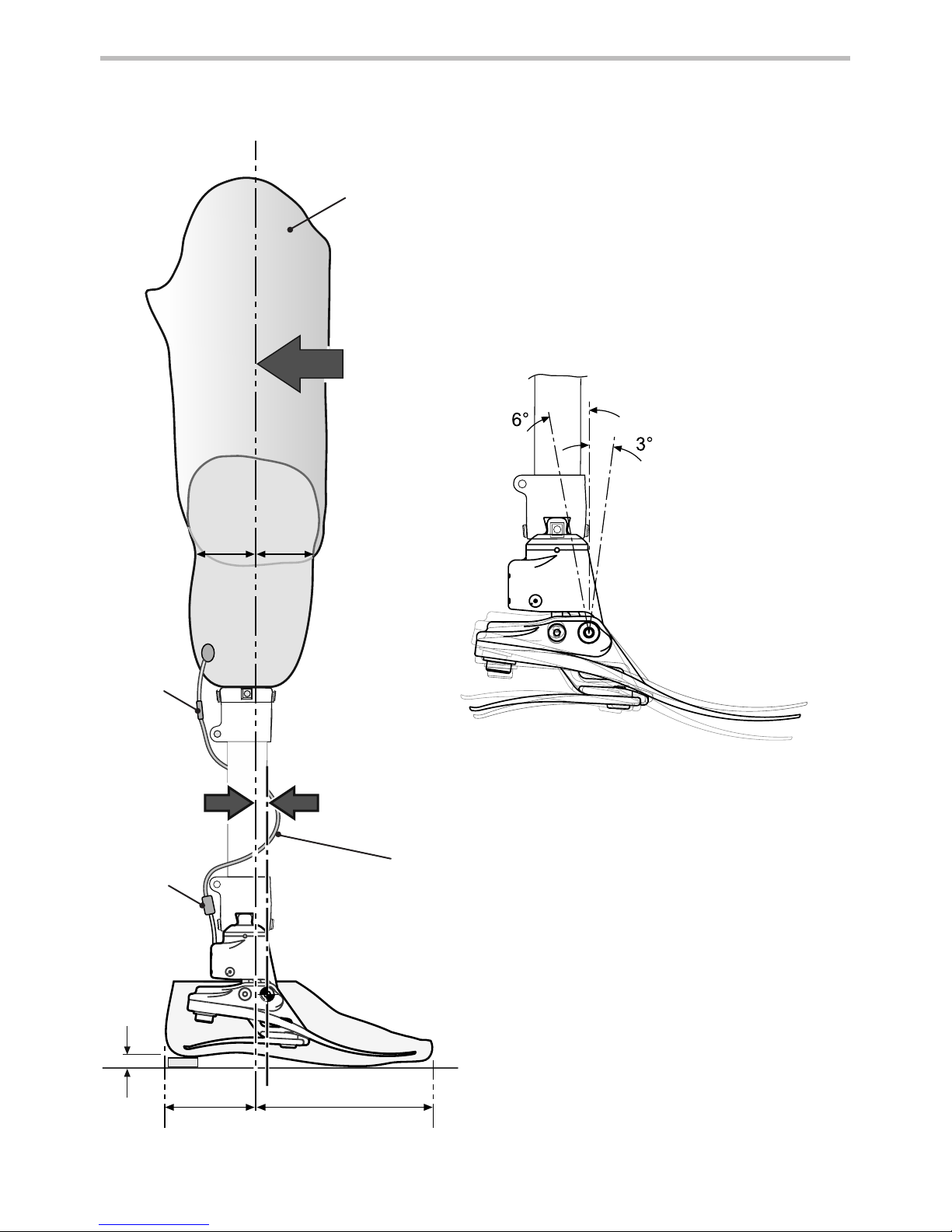

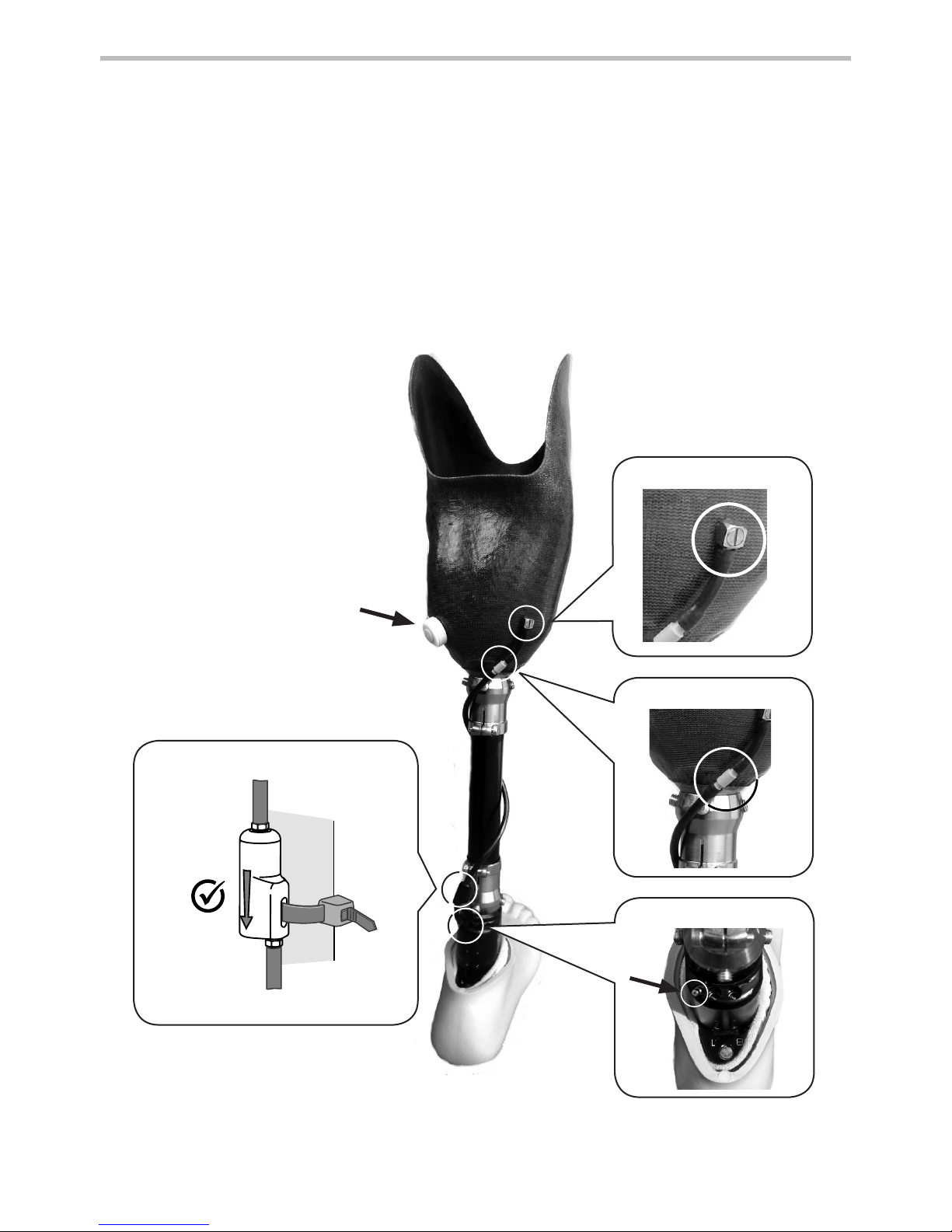

6 Bench Alignment

6.1 Static Alignment

Align limb to

achieve range of

motion shown.

Approx. 1/3 2/3

Build

Line

Allow for users

own footwear

*

Align trans-femoral devices according to tting

instructions supplied with the knee.

Keep the build line between foot pivots as shown,

using shift and/or tilt devices as necessary.

In-Line

Filter

*

For the Vacuum System

Assembly see section 8.0

Wrap the vacuum tubing

around the pylon as shown and

position the Check Valve close

to the ankle for the best vacuum

performance.

Check

Valve

9

938367/1-0816

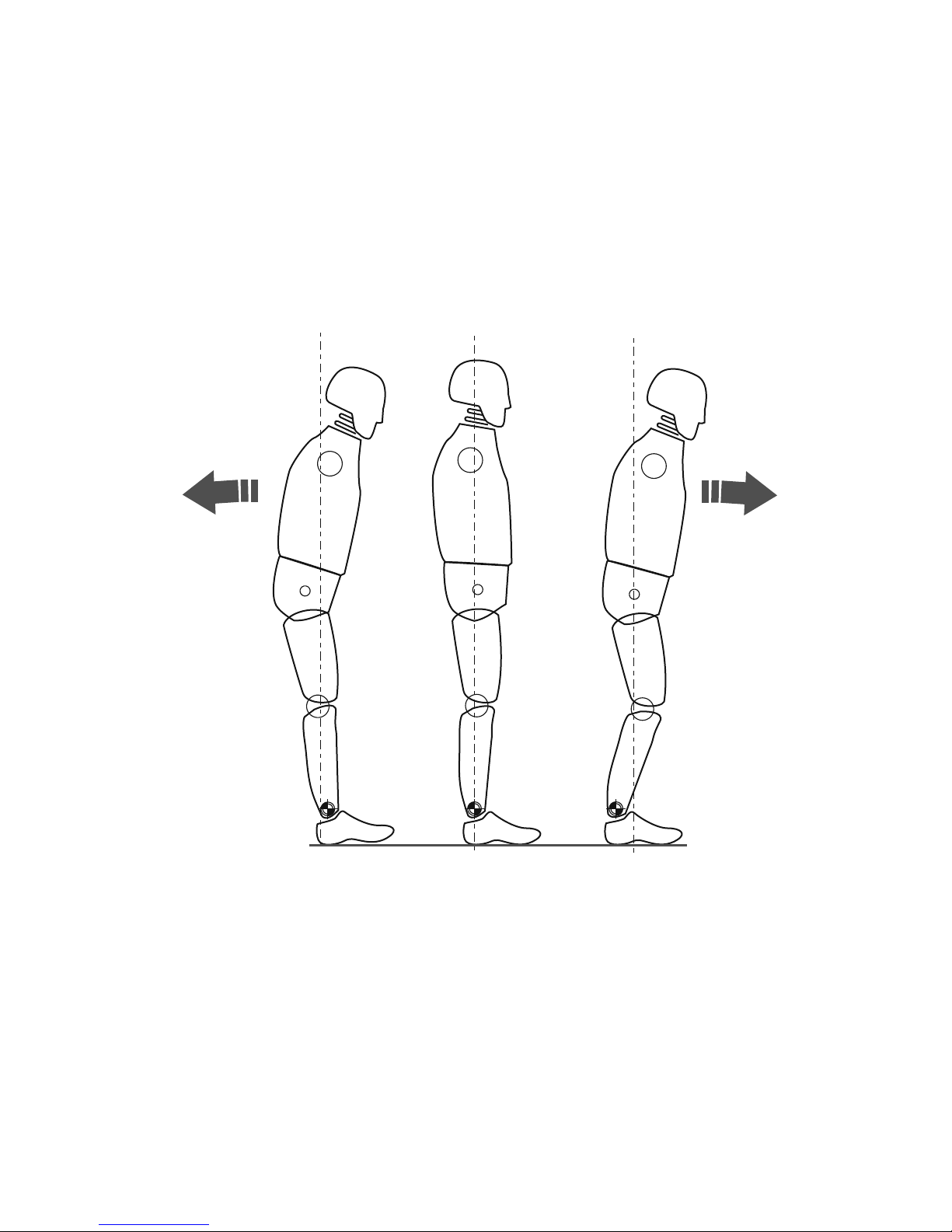

6.2 Biomimetic Alignment

The aim of alignment is to achieve a“balance point” while standing and set the hydraulically

damped range of motion. The aim of damping adjustment is to ne tune the ankle-foot roll-

over stiness characteristics until a comfortable gait is achieved. Due to the increased range of

motion provided by the ankle the user may experience the need for more voluntary control and

initially nd the ankle disconcerting during setup. This should quickly pass upon completion of

satisfactory setup.

Ensure that the user is relaxed and not resting on the dorsiexion limit.

Falling backwards =

[Hyper-extension]

A-P shift too far forward

Falling forwards =

[Hyper-exion]

A-P shift too far back

10

938367/1-0816

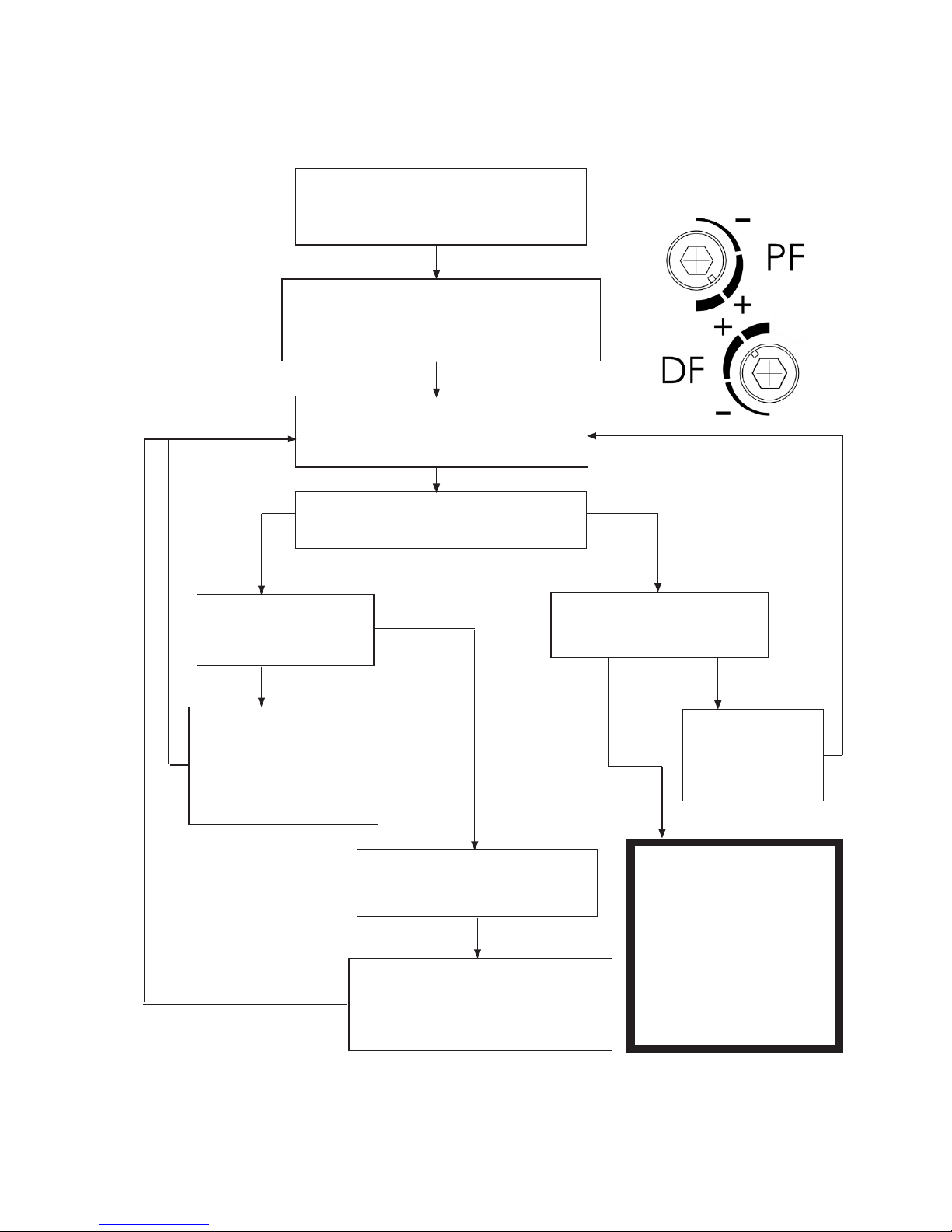

6.3 Biomimetic Adjustment

NB: Carry out static alignment while ensuring the user has some means of support such as

parallel bars. This is standing alignment only.

Check bench alignment taking

heel height into account

Ensure PF and DF valves are set as shown.

(the user must feel some movement in

the ankle)

Ask the user to stand with weight

evenly distributed between each foot

Does the user feel sufficiently stable

using minimal muscle control?

No Yes

Does the user report

a feeling of falling

forwards?

Shift the foot forwards

slightly relative to the

socket (e.g. tilt using

proximal & distal

interfaces)

Yes

No

Yes

Yes

Can the user dorsiflex the

ankle by approx. 3°?

Adjust the angle

of the foot at the

distal pyramid

interface

Does the user report a

feeling of falling backwards?

Shift the foot backwards slightly

relative to the socket (e.g. tilt

using proximal & distal interfaces)

Proceed to

Dynamic

Adjustment

Allow user to become

accustomed to the ankle for

10 mins before carrying

out any DF/PF valve

adjustments

Use shift for static alignment and standing.

The device should encourage some degree of self adjustment to achieve a sense of balance for

the user during standing.

No

}

11

938367/1-0816

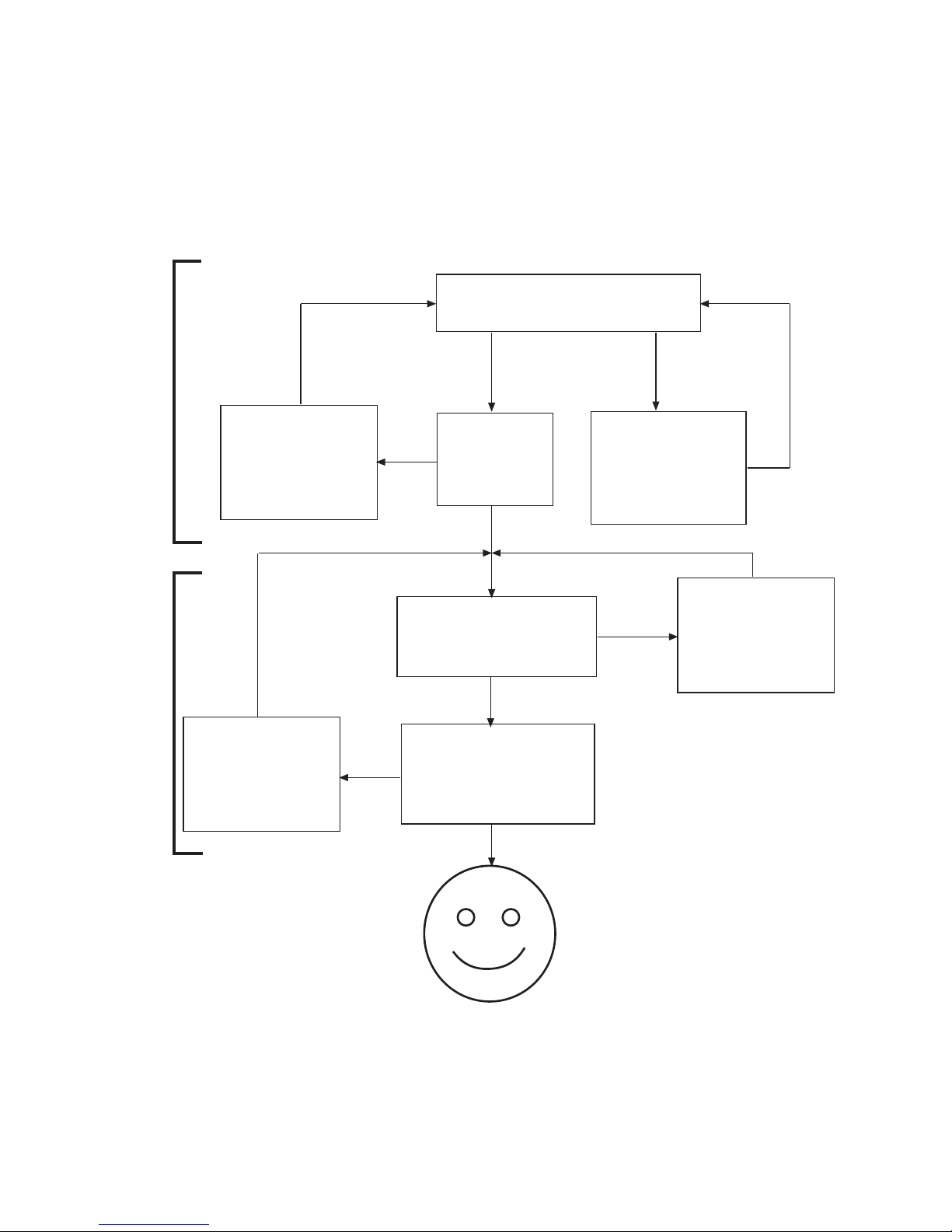

Upon walking, does the user

experience foot slap?

No Yes

Adjust the Plantar

flexion valve to

reduce resistance

(counterclockwise)

No

Yes

Yes

Yes

No

No

Adjust the Plantar

Flexion valve to

increase resistance

(clockwise)

Adjust the

Dorsiflexion

valve to

reduce resistance

(counterclockwise)

Does the

user find the

heel too

hard?

Transfer should be smooth.

Does the user feel as if they

are walking uphill?

Does the user feel as

if they are being

thrown forwards

through stance?

Adjust the

Dorsiflexion

valve to

increase resistance

(clockwise)

PF

1st

6.4 Dynamic Adjustment

Adjustment of the hydraulic valves.

The user should experience the ankle moving smoothly with the body through the gait cycle

with no additional eort required by the user to overcome the hydraulic resistance of the ankle.

During this procedure the user should walk at normal speed, in a straight line on a level surface.

Guidance:

Following dynamic adjustment, trial the foot/ankle on ramps and stairs. Ensure the user is

comfortable with the kind of terrain he/she may normally be expected to encounter. If the user

reports any issues with comfort, usability or range of movement of the ankle, adjust accordingly.

DF

2nd

12

938367/1-0816

7 Fitting Advice

The springs for the EchelonVAC foot will be supplied assembled with heel and toe springs of the

same category. If after following the instructions below you still have problems with the function

please contact the sales team in your area for advice.

Any of the following:

• Incorrect spring selection

• Incorrect A-P shift alignment

• Incorrect distribution of plantar exion and dorsiexion range

will have a negative eect on function and stability.

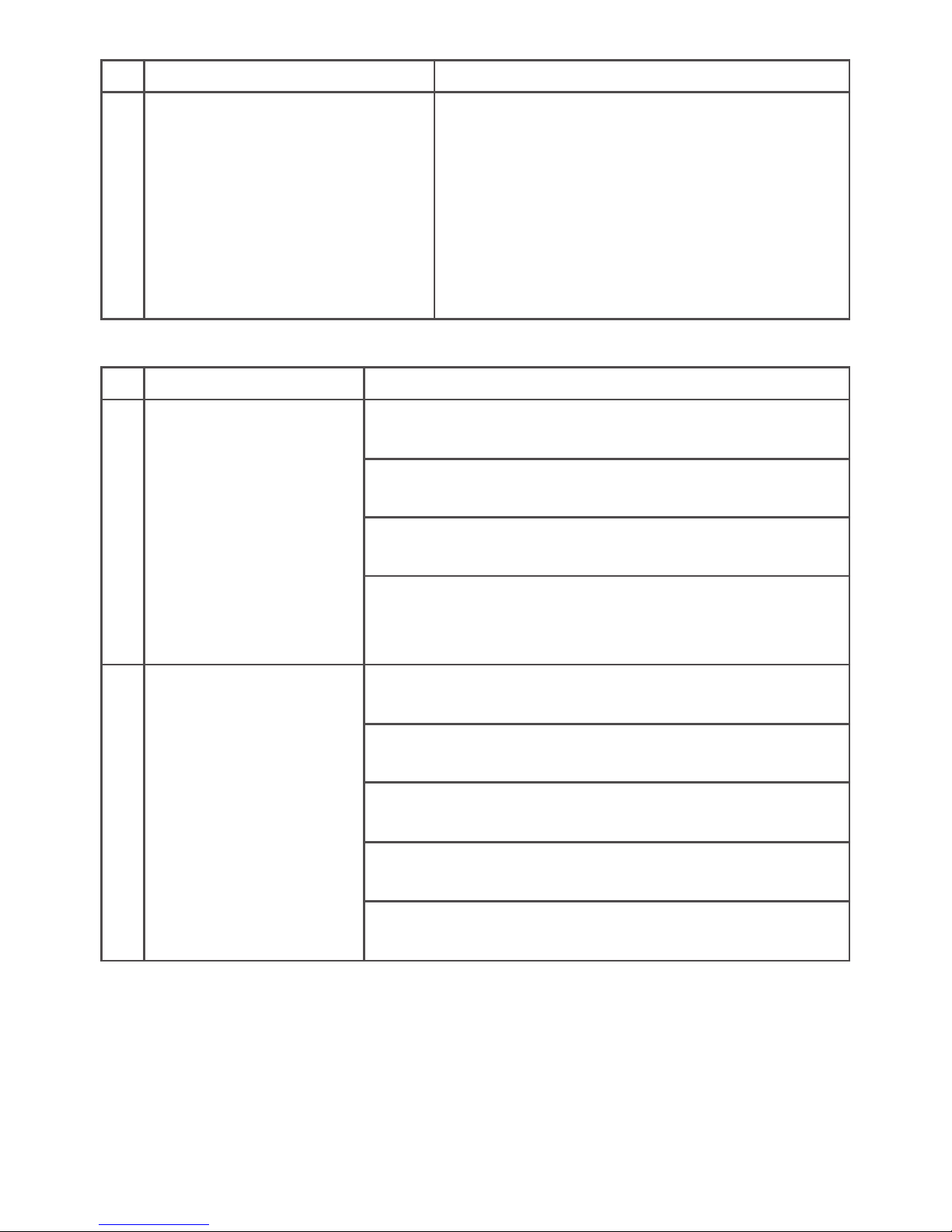

Symptoms: Remedy

1. Sinking at heel strike

Diculty in achieving a smooth

progression to mid stance

User feels they are walking up hill

or forefoot feels excessively long

1. Increase plantar exion resistance

2. Check A-P shift alignment; ensure foot is not too

anteriorly positioned

3. Check distribution of plantar exion and

dorsiexion movement; ensure that the plantar

exion range is not excessive

4. Check spring category is not too soft,

if so t a higher rate spring

2. Progression from heel strike to mid

stance is too rapid

Diculty in controlling the energy

return from the foot at the heel

strike (reduced knee stability)

User feels heel is too hard, fore foot

is too short

1. Reduce plantar exion resistance

2. Check A-P shift alignment; ensure foot is not too

posteriorly positioned

3. Check distribution of plantar exion and

dorsiexion movement; ensure that there is

adequate plantarexion range

4. Check the spring category is not too high for the

weight and activity of the patient, if so t lower

rate spring

3. Heel contact and progression feel

OK but:

Forefoot feels too soft

Forefoot feels too short

User feels they are walking down

hill, possibly with reduced knee

stability

Lack of energy return

1. Increase dorsiexion resistance

2. Check A-P shift alignment;

ensure foot is not too posteriorly positioned

3. Check distribution of plantar exion and

dorsiexion movement; ensure that there is not

excessive dorsiexion range

4. Check the spring category is not too soft for the

weight and activity of the patient, if so t higher

rate spring

The correct alignment (A-P position), range of motion (distribution of plantar exion to

dorsiexion) and adjustment of the hydraulic settings are critical in achieving a smooth roll over

and correct slope adaptation (see 6.3).

The user should feel the vacuum eect after taking approximately 15-20 steps depending on the

initial socket t.

13

938367/1-0816

Symptoms: Remedy

4. Forefoot feels too rigid

Forefoot feels too long

Feels like walking up hill

1. Reduce dorsiexion resistance

2. Check A-P shift alignment;

ensure foot is not too anteriorly positioned

3. Check distribution of plantar exion and

dorsiexion movement; ensure that there is

sucient dorsiexion range

4. Check the spring category is not too rigid for the

weight and activity of the user, if so t a lower

rate spring

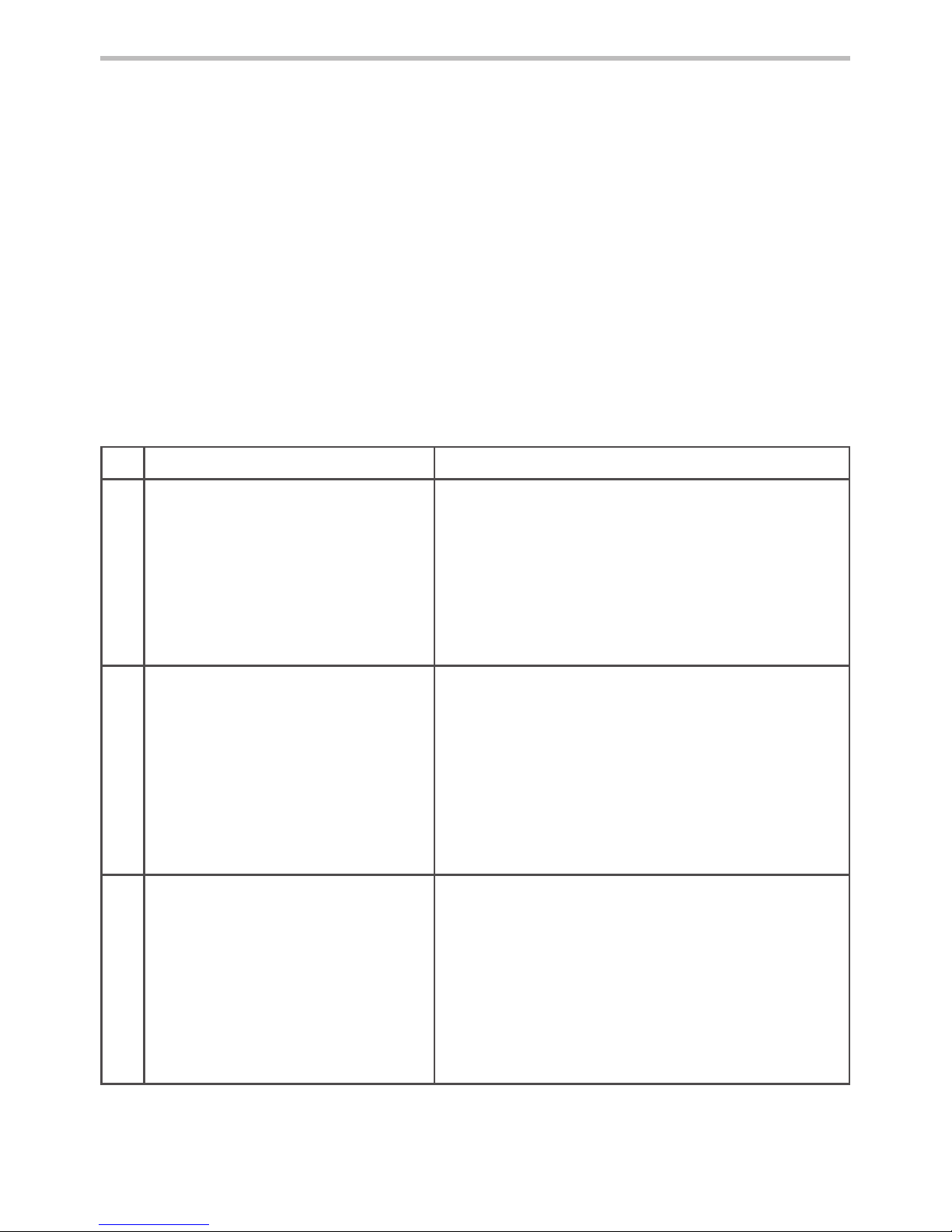

Symptoms: Cause/Remedy

1. Unable to generate a

vacuum

Vacuum tube(s) split or disconnected

Inspect and repair/replace as necessary

Check and clean/replace the check valve

Filter blocked, replace Filter

Limited ankle movement creating insucient vacuum due to:

1. Excessive PF/DF setting

2. Footwear

2. Unable to maintain a

vacuum

Vacuum tube(s) split or disconnected

Inspect and repair/replace as necessary

Check and clean/replace the check valve

Leakage at socket valve/barbs

Reseal valve/barb

Porous socket

Seal with lacquer/re-make

Check the integrity of the vacuum seal at the socket/

residuum interface

Vacuum System

2

3

1

4

5 6

14

938367/1-0816

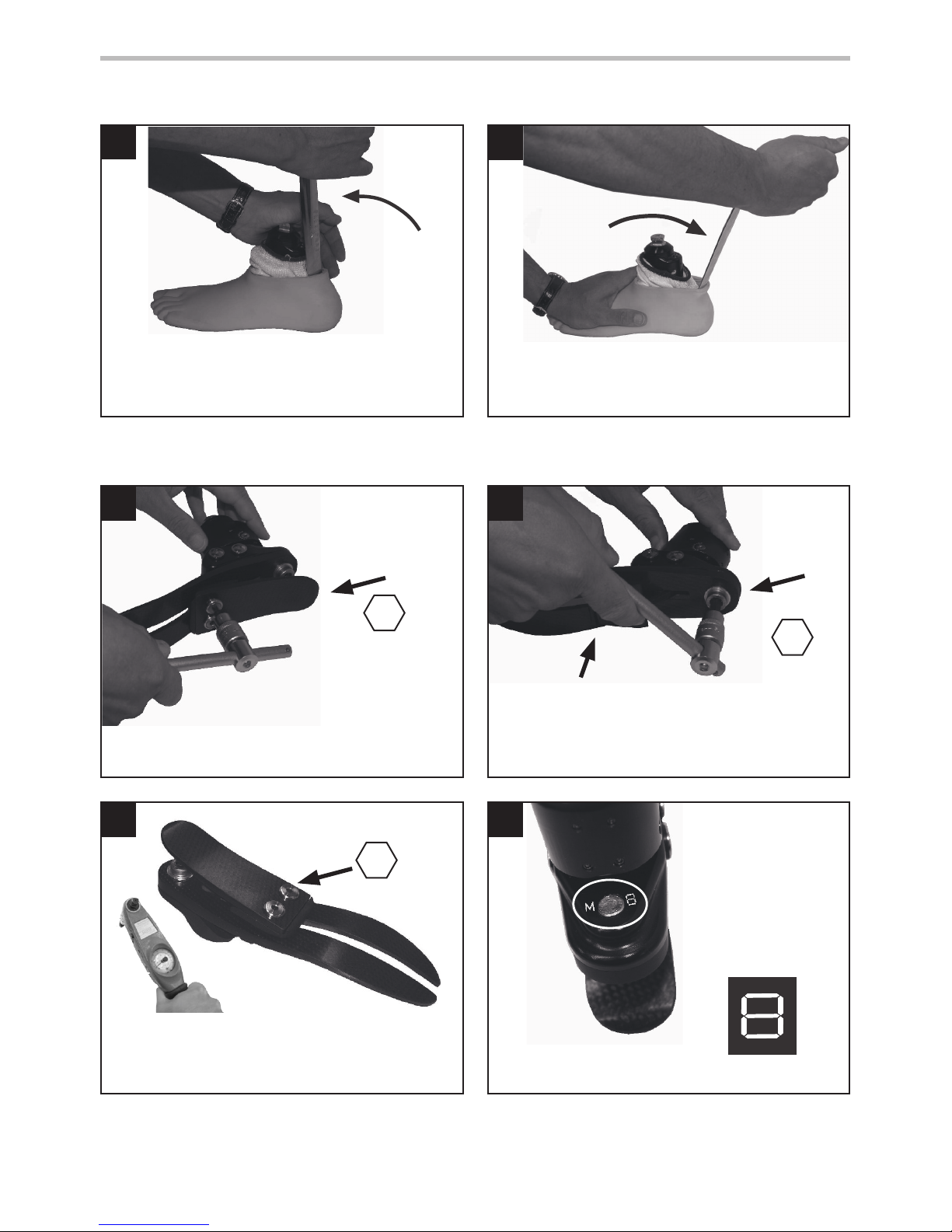

Insert shoe horn behind Heel Spring

Carrier

Assembly

Rotate shoe horn as shown to remove shell

heel Spring

Re-assemble with replacement heel spring. Use

Loctite 243 (926012) and torque to 15Nm.

Cover appropriate

lines on the carrier

with permanent

black marker to

leave the spring set

number showing.

Remove Heel Spring and screws.

Remove toe spring screw, replace toe. Upon

reassembly, use Loctite 243 (926012) and torque

to 35Nm. Ensure toe spring is central to the

carrier.

35Nm

4

8

4

15Nm

Spring Replacement

8 Assembly Instructions: Footshell Removal

Toe Spring

8

10

12

9

7

11

15

938367/1-0816

If a cosmetic nish is required please contact a member of the Endolite Sales Team.

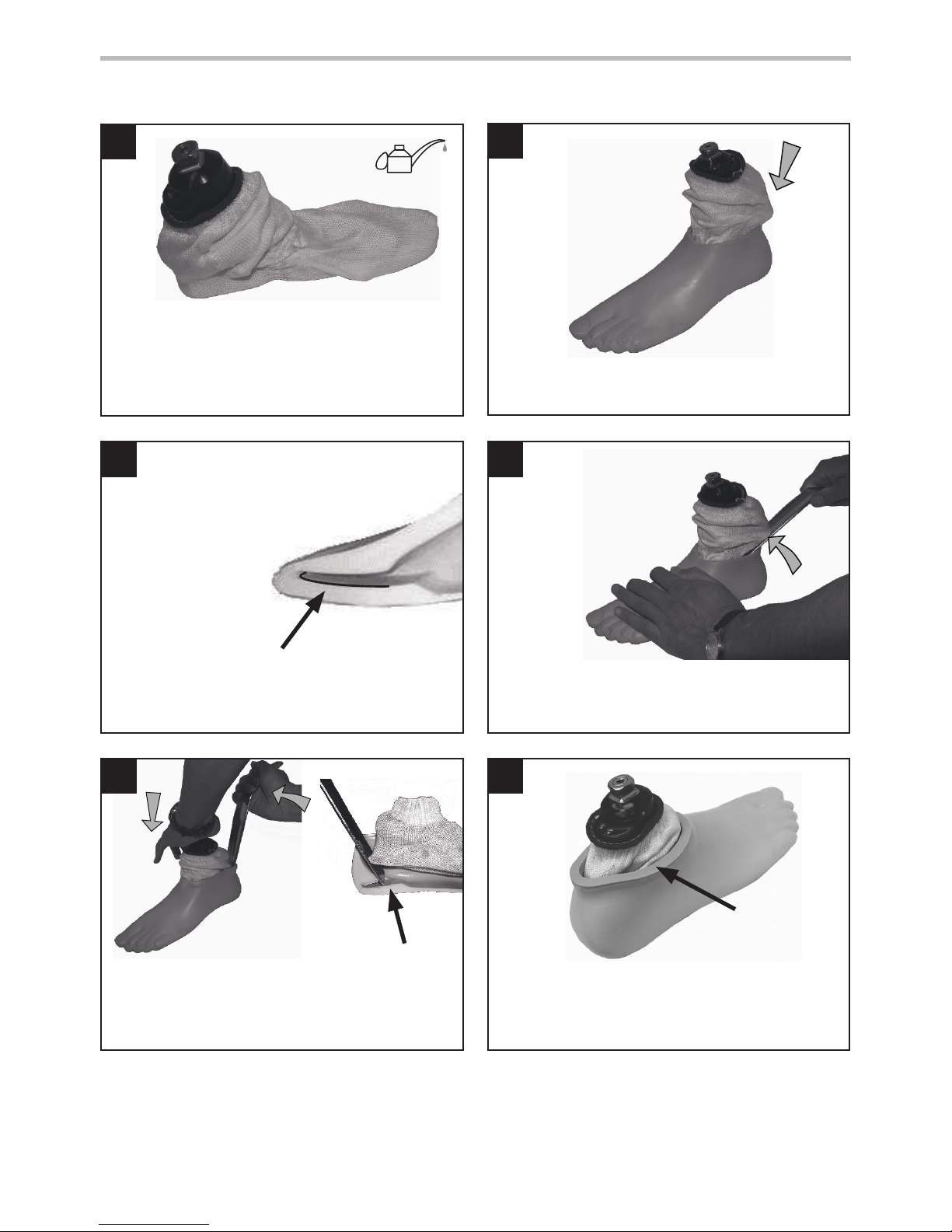

Lubricate toe and heel if required.

(Footshell is pre-lubricated).

928017

Slide carrier/Heel Spring Assembly into the Foot

Shell.

toe spring location in Foot Shell Use a suitable lever to encourage the Heel Spring

into location in the Foot Shell.

Press Heel Spring into location in shell as shown.

Heel Spring

location slot

Ensure Glide Sock does not get trapped when

assembling to female pyramid part.

Cosmetic

Attachment

Plate

Fit Sock as shown.

Assembly Instructions continued

16

938367/1-0816

Vacuum System Assembly

1 Push the In-line Filter on to a short piece of vacuum tubing and connect it to the Vac Barb

90deg on the socket. The barb outlet should be positioned pointing downwards by releasing

the centre screw and rotating the body of the unit. Tighten the screw when the barb outlet is in

the required position.

2 Attach a length of vacuum tubing to the In-line Filter and wrap it around the pylon. Connect

the other end of the tube to the Check Valve ensuring that the ow arrow points towards the

ankle. For maximum vacuum, position the Check Valve close to the inlet on the EchelonVAC.

Connect a short length of vacuum tubing from the Check Valve to the inlet on the ankle to

complete the vacuum system.

Auto-Expulsion

Valve

In-line Filter

Inlet

Vac Barb 90deg

Assembly Instructions: Vacuum System

Check Valve

17

938367/1-0816

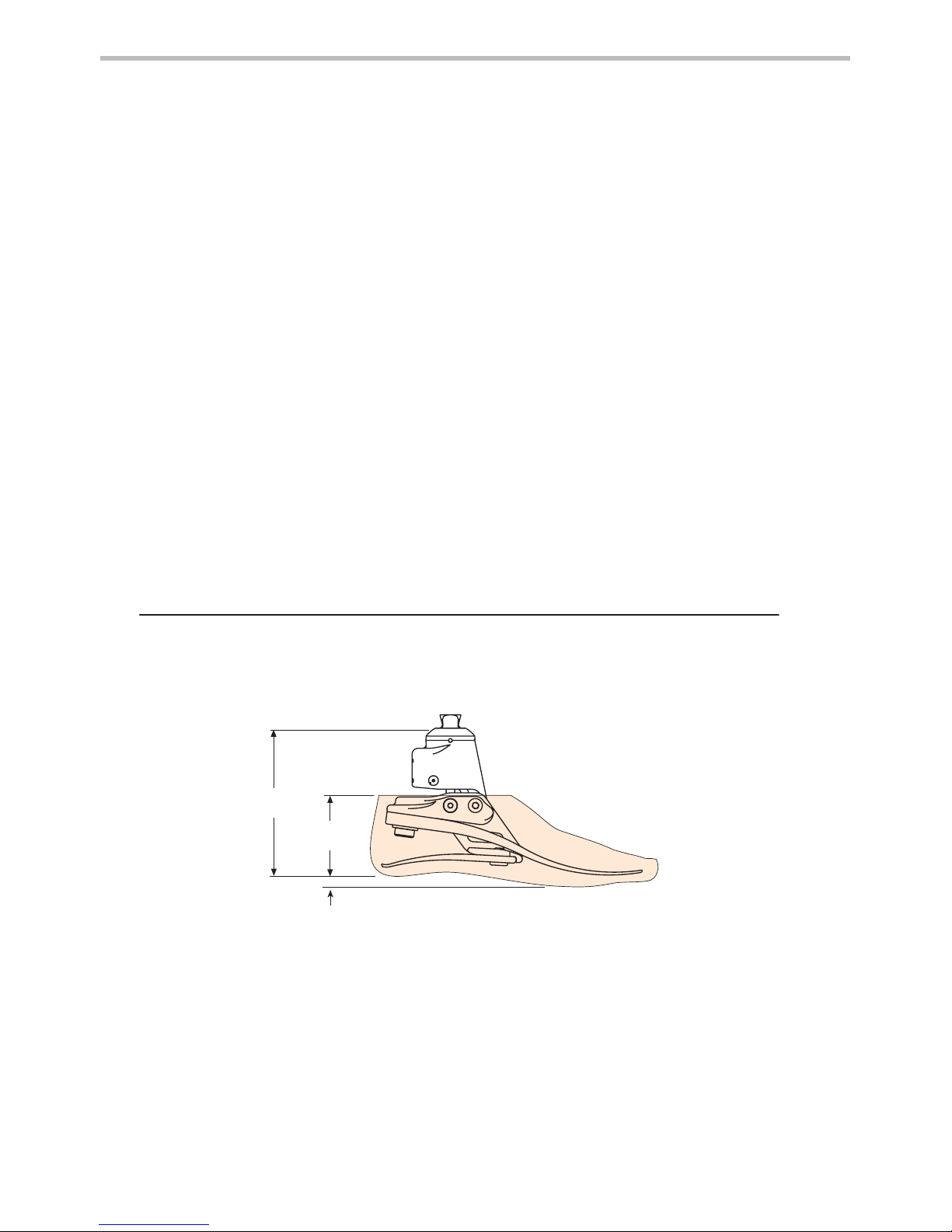

* sizes

22 - 24 = 121mm

25 - 26 = 126mm

27 - 30 = 131mm

** sizes

22 - 24 = 70mm

25 - 30 = 75mm

Fitting length

9 Technical Data

Operating and

Storage Temperature Range: -15˚C to 50˚C

(5˚F to 122˚F)

Component Weight [size 26]: 930g (2lb 1oz)

Recommended Activity Level: 2, 3, 4

Maximum User Weight: 125kg (275lb)

Proximal Alignment Attachment: Male Pyramid (Endolite)

Range of Hydraulic Ankle Motion:

(excludes additional range of motion

provided by heel and toe springs)

6 degrees plantar flexion

to 3 degrees dorsiexion

Build Height:

[See diagram below]

[sizes 22-24] 120mm

[sizes 25-26] 125mm

[sizes 27-30] 130mm

Heel Height: 10mm

Maximum Vacuum: 17in Hg

10mm

***

18

938367/1-0816

10 Ordering Information

Cosmetic interface (for dark add‘D’)

22-24L&R 530138 25-26 L&R 531035

27L&R 531935 28 L&R 531936

29L 532831 29R 532832

30L 532833 30R 532834

Glide Sock

One size ts all Part No. 532811

DF/PF Adjuster Key

4.0 A/F Allen Part No. 940236

Spring Kits

Rate

Foot sizes

22-24 25-26 27-28 29-30

Set 1 539801 539810 539819 539828

Set 2 539802 539811 539820 539829

Set 3 539803 539812 539821 539830

Set 4 539804 539813 539822 539831

Set 5 539805 539814 539823 539832

Set 6 539806 539815 539824 539833

Set 7 539807 539816 539825 539834

Set 8 539808 539817 539826 539835

Foot shell (for dark add‘D’)

Small Medium Large Extra Large

22L 539038 25L 539044 27L 539048 29L 539052

22R 539039 25R 539045 27R 539049 29R 539053

23L 539040 26L 539046 28L 539050 30L 539054

23R 539041 26R 539047 28R 539051 30R 539055

24L 539042 -- -- --

24R 539043 -- -- --

Vacuum System Parts:

Socket Connection Kit Part No. 409663

Check Valve

Service Kit Part No. 409863

Table of contents

Languages:

Other endolite Medical Equipment manuals

endolite

endolite Smart IP System SMARTIPSFPYR User manual

endolite

endolite Navigator Foot User manual

endolite

endolite aqualimb TF User manual

endolite

endolite Smart IP User manual

endolite

endolite Echelon User manual

endolite

endolite BladeXT User manual

endolite

endolite Comfort Cushion Liner CTTCP22L User manual

endolite

endolite linx User manual

endolite

endolite AvalonK2 User manual

endolite

endolite AqualimbTT User manual