2

CAUTION: Avoid damaging hydraulic

hose. Avoid sharp bends and kinks

when routing hydraulic hoses. Using a

bent or kinked hose will cause severe back-

pressure. Sharp bends and kinks will internally

damage the hose leading to premature hose

failure.

®

Do not drop heavy objects on hose. A

sharp impact may cause internal

damage to hose wire strands. Applying

pressure to a damaged hose may cause it to

rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or swivel

couplers. Use the carrying handle or

other means of safe transport.

CAUTION: Keep hydraulic equipment

away from flames and heat. Excessive

heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens hose

materials and packings. For optimum

performance do not expose equipment to

temperatures of 65°C [150°F] or higher. Protect

hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized

hoses. Escaping oil under pressure

can penetrate the skin, causing

serious injury. If oil is injected under the skin,

see a doctor immediately.

WARNING: Only use hydraulic

cylinders in a coupled system. Never

use a cylinder with unconnected

couplers. If the cylinder becomes extremely

overloaded, components can fail

catastrophically causing severe personal injury.

IMPORTANT: Hydraulic equipment

must only be serviced by a qualified

hydraulic technician. For repair

service, contact the Authorized ENERPAC

Service Center in your area. To protect your

warranty, use only ENERPAC oil.

WARNING: Immediately replace worn

or damaged parts with genuine

ENERPAC parts. Standard grade

parts will break causing personal injury and

property damage. ENERPAC parts are designed

to fit properly and withstand high loads.

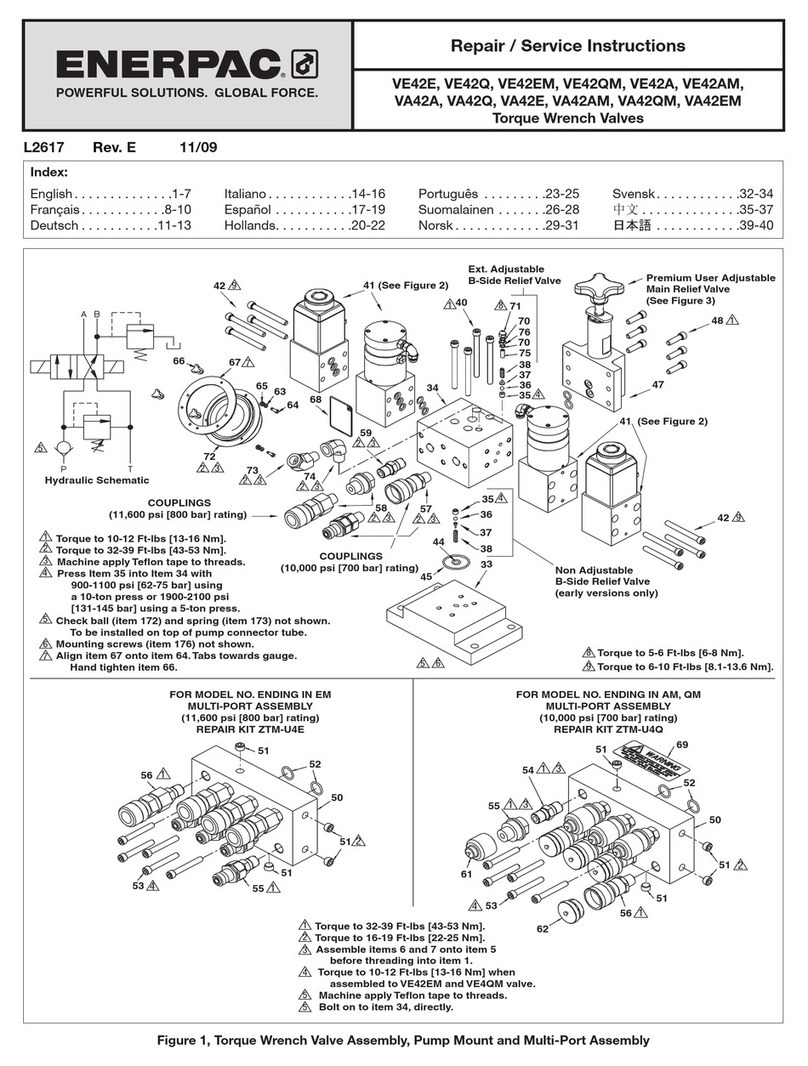

4.0 PRV-8 AND PRV-9 PRESSURE

REDUCING VALVES

The PRV-8 and PRV-9 remote mount pressure

reducing valves can be used with fittings

and tubing or can be manifold mounted. The

valve section is normally open, and closes

when the cylinder pressure downstream of the

valve reaches the customer adjusted pressure

setting.

When pressure in the incoming side drops

below that of the cylinder side, reverse flow is

allowed, enabling clamped cylinders to unclamp.

Pressure adjustment is through an adjustment

screw. Adjustment is clockwise to increase

the pressure setting and counterclockwise

to reduce the pressure setting. A locknut is

provided to secure the setting.

A 1/8"-27 NPT port on the manifold body allows

the mounting of a gauge to read the cylinder

pressure past the valve section.

Refer to figures 1 and 2 for additional

information.

WARNING: Maximum allowable

system pressure for the PRV-8 and

PRV-9 valves is 350 bar [5000 PSI].

Do not exceed this pressure rating.

5.0 PRVM-2 MANIFOLD

The PRVM-2 manifold is included as part of the

PRV-8 and PRV-9 pressure reducing valves.

If desired, the PRVM-2 manifold may also be

purchased separately.

• Assembling a PRVM-2 manifold and a PRV-3T

valve module will create a PRV-8 pressure

reducing valve.

• Assembling a PRVM-2 manifold and a PRV-4T

valve module will create a PRV-9 pressure

reducing valve.

Refer to figures 3 and 4 for additional

information.

AP

Figure 1, PRV-8 and PRV-9 Valve Function