Repair Parts Sheets for this product are available from the Enerpac web

site at www.enerpac.com, or from your nearest Authorized Enerpac

Service Center or Enerpac Sales office.

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping damage is

not covered by warranty. If shipping damage is found, notify carrier at once.

The carrier is responsible for all repair and replacement costs resulting from

damage in shipment.

SAFETY FIRST

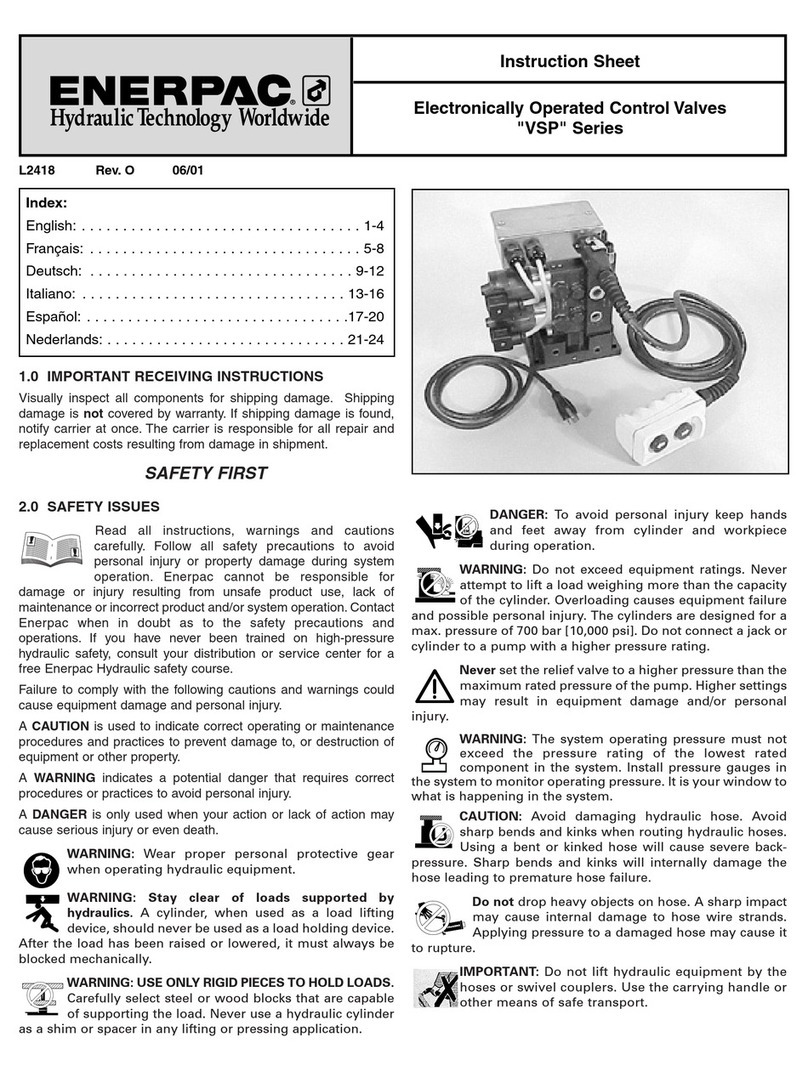

2.0 SAFETY ISSUES

Read all instructions, warnings and cautions carefully.

Follow all safety precautions to avoid personal injury or

property damage during system operation. Enerpac

cannot be responsible for damage or injury resulting from unsafe product use,

lack of maintenance or incorrect product and/or system operation. Contact

Enerpac when in doubt as to the safety precautions and operations. If you

have never been trained on high-pressure hydraulic safety, consult your

distribution or service center for a free Enerpac Hydraulic safety course.

Failure to comply with the following cautions and warnings could cause

equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction of

equipment or other property.

A WARNING indicates a potential danger that requires correct procedures

or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may cause

serious injury or even death.

• Check all Coupler Connections: Make sure all coupler

connections are complete. Loose or incomplete coupler

connections will cause complete or partial blockage of oil flow.

• Check all Hose Connections: Make sure all hose connections are

properly mated and secured.

• Do Not use excessive closing torque on valve handle or use any handle

extension. This will cause unnecessary wear on valve stem and seat and

may damage the spring.

• Check for Safe System Setups: Make sure that your valve, connecting

hoses, etc. are protected from any external source of damage, such as:

excessive heat, flame, moving machine parts, sharp edges, falling

objects, corrosive chemicals, dripping, etc.

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

WARNING: Stay clear of loads supported by hydraulics. A

cylinder, when used as a load lifting device, should never be

used as a load holding device. After the load has been raised or

lowered, it must always be blocked mechanically.

WARNING: USE ONLY RIGID PIECES TO HOLD LOADS.

Carefully select steel or wood blocks that are capable of

supporting the load. Never use a hydraulic cylinder as a shim or

spacer in any lifting or pressing application.

DANGER: To avoid personal injury keep hands and feet away

from cylinder and workpiece during operation.

WARNING: Do not exceed equipment ratings. Never attempt to

lift a load weighing more than the capacity of the cylinder.

Overloading causes equipment failure and possible personal

injury. The cylinders are designed for a max. pressure of 700 bar

[10,000 psi]. Do not connect a jack or cylinder to a pump with a higher

pressure rating.

Never set the relief valve to a higher pressure than the maximum

rated pressure of the pump. Higher settings may result in

equipment damage and/or personal injury.

WARNING: The system operating pressure must not exceed the

pressure rating of the lowest rated component in the system.

Install pressure gauges in the system to monitor operating

pressure. It is your window to what is happening in the system.

CAUTION: Avoid damaging hydraulic hose. Avoid sharp bends

and kinks when routing hydraulic hoses. Using a bent or kinked

hose will cause severe back-pressure. Sharp bends and kinks

will internally damage the hose leading to premature hose failure.

Do not drop heavy objects on hose. A sharp impact may cause

internal damage to hose wire strands. Applying pressure to a

damaged hose may cause it to rupture.

IMPORTANT: Do not lift hydraulic equipment by the hoses or

swivel couplers. Use the carrying handle or other means of safe

transport.

CAUTION: Keep hydraulic equipment away from flames

and heat. Excessive heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens hose materials and

packings. For optimum performance do not expose

equipment to temperatures of 65°C [150°F] or higher. Protect hoses and

cylinders from weld spatter.

DANGER: Do not handle pressurized hoses. Escaping oil under

pressure can penetrate the skin, causing serious injury. If oil is

injected under the skin, see a doctor immediately.

WARNING: Only use hydraulic cylinders in a coupled system. Never

use a cylinder with unconnected couplers. If the cylinder becomes

extremely overloaded, components can fail catastrophically causing

severe personal injury.

WARNING: BE SURE SETUP IS STABLE BEFORE LIFTING

LOAD. Cylinders should be placed on a flat surface that can

support the load. Where applicable, use a cylinder base for added

stability. Do not weld or otherwise modify the cylinder to attach a

base or other support.

Avoid situations where loads are not directly centered on the

cylinder plunger. Off-center loads produce considerable strain on

cylinders and plungers. In addition, the load may slip or fall,

causing potentially dangerous results.