8

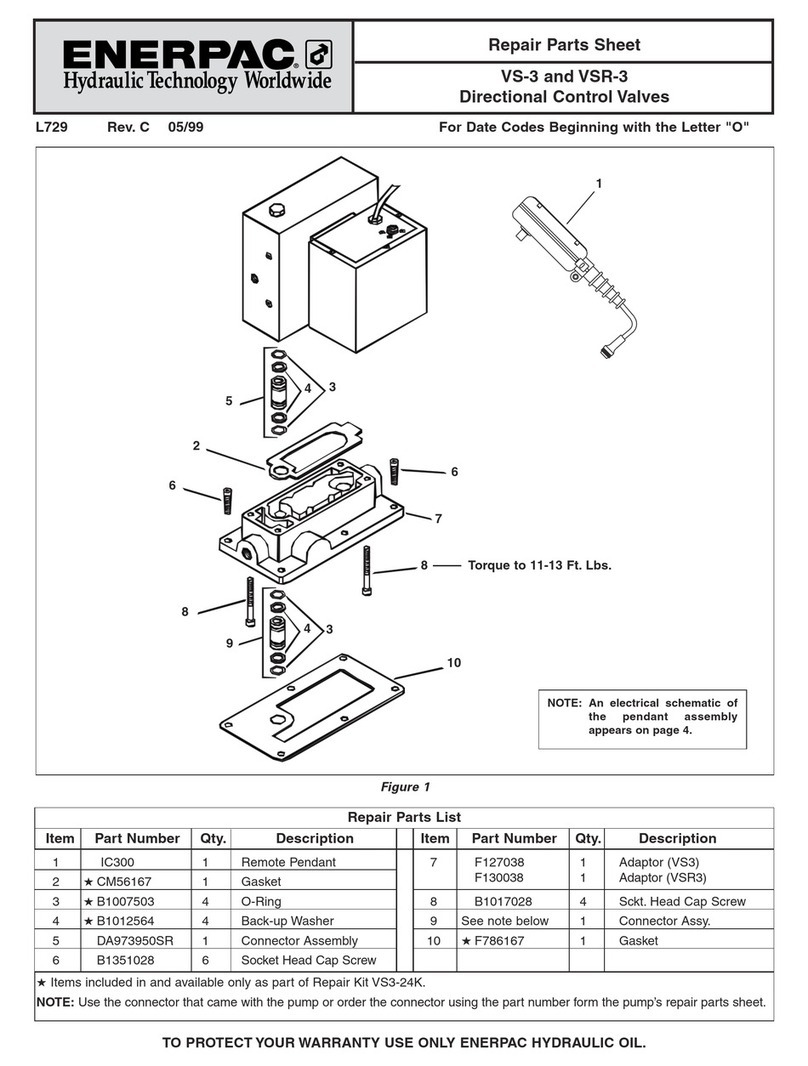

3.0 ADJUSTING THE B-PORT RELIEF VALVE

(Retract Pressure Setting)

A separate relief valve limits the maximum B-Port retract

pressure. See Figure 9. Check the retract pressure as described

in steps 1 through 4 of this section. If it is not within allowable

limits, make adjustments as described in steps 5a through 5e.

1. Set the main relief valve (A-Port) pressure to the desired

setting as described in Section 2.1.

2. Be sure that all hydraulic hoses are disconnected from

couplers on valve.

WARNING: Ensure all couplers have the protective

caps fully installed before starting pump.

3. Use the menu button and ARROW keys to change LOCAL

mode to ON.

4. Press and release the ARROW UP button on the keypad.

The pump will start (refer to pump instruction sheet for

complete operating instructions).

5. After releasing the ARROW UP button, check the retract

pressure on the pressure gauge or LCD screen.

Pressure should read 220 BAR +/- 10 BAR"

6. If the retract pressure reading is not within the allowable

range, follow steps a through e, otherwise follow up with

instructions in paragraph 2.1.12 on page7.

IMPORTANT: The B-Port relief valve should be adjusted only by

qualified hydraulic service personnel.

a. Remove acorn nut using a 9/16" socket wrench. This will

expose the adjustment set screw. See Figure 9.

b. Remove copper gasket and loosen jam nut.

c. Using a 5/32" Allen wrench, turn the adjustment set screw

clockwise to increase pressure or counter-clockwise to

reduce pressure (as required).

d. To secure the setting, torque jam nut to 5-6 ft-lbs [6-8

Nm] while holding the adjustment set screw in place with

a 5/32" Allen wrench.

e. Reinstall copper gasket and acorn nut and torque to

5-6 ft-lbs [7-8 Nm] using a 9/16" socket wrench. (Do

not overtighten as threads will strip out). Verify pressure

setting and readjust if necessary.

Australia and New Zealand

Actuant Australia Ltd.

Block V Unit 3, Regents Park Estate 391

Park Road,

Regents Park NSW 2143, (P.O. Box 261)

Australia

T +61 297 438 988

F +61 297 438 648

Brazil

Power Packer do Brasil Ltda.

Rua dos Inocentes, 587

04764-050 - Sao Paulo (SP)

T +55 11 5687 2211

F +55 11 5686 5583

Toll Free: 0800 891 5770

Canada

Actuant Canada Corporation

6615 Ordan Drive, Unit 14-15

Mississauga, Ontario L5T 1X2

T +1 905 564 5749

F +1 905 564 0305

Toll Free:

T +1 800 268 4987

F +1 800 461 2456

China (Taicang)

Actuant (China) Industries Co.Ltd.

No. 6 Nanjing East Road,

Taicang Economic Dep Zone,

Jiangsu, China

T +86 0512 5328 7500

F +86 0512 5335 9690

Toll Free:

T +86 400 885 0369

France, Switzerland, North Africa and

French speaking African countries

ENERPAC

Une division d’ACTUANT France S.A.S.

ZA de Courtaboeuf

32, avenue de la Baltique

91140 VILLEBON /YVETTE

France

T +33 1 60 13 68 68

F +33 1 69 20 37 50

Germany and Austria

ENERPAC GmbH

P.O. Box 300113

D-40401 Düsseldorf

Willstätterstrasse 13

D-40549 Düsseldorf

Germany

T +49 211 471 490

F +49 211 471 49 28

India

ENERPAC Hydraulics Pvt. Ltd.

No. 1A, Peenya Industrial Area

IInd Phase, Bangalore

560 058, India

T +91 80 40 792 777

F +91 80 40 792 792

Italy

ENERPAC S.p.A.

Via Canova 4

20094 Corsico (Milano)

T +39 02 4861 111

F +39 02 4860 1288

Japan

Applied Power Japan LTD KK

Besshocho 85-7, Kita-ku,

Saitama-shi 331-0821, Japan

T +81 48 662 4911

F +81 48 662 4955

Middle East, Egypt and Libya

ENERPAC Middle East FZE

Office 423, LOB 15,

P.O. Box 18004, Jebel Ali, Dubai

United Arab Emirates

T +971 (0)4 8872686

F +971 (0)4 8872687

Russia

Rep. office Enerpac Russian Federation

Admirala Makarova Street 8

125212 Moscow, Russia

T +7 495 98090 91

F +7 495 98090 92

Singapore

Actuant Asia Pte Ltd.

83 Joo Koon Circle, Singapore 629109

T +65 68 63 0611

F +65 64 84 5669

Toll Free:

T +1800 363 7722

South Korea

Actuant Korea Ltd.

3Ba 717, Shihwa Industrial Complex

Jungwang-Dong, Shihung-Shi

Kyunggi-Do

Republic of Korea 429-450

T +82 31 434 4506

F +82 31 434 4507

Spain and Portugal

ENERPAC SPAIN, S.L.

Avda. Los Frailes, 40 – Nave C & D

Pol. Ind. Los Frailes

28814 Daganzo de Arriba

(Madrid) Spain

T +34 91 884 86 06

F +34 91 884 86 11

Sweden, Denmark, Norway, Finland

and Iceland

Enerpac Scandinavia AB

Fabriksgatan 7

412 50 Gothenburg, Sweden

T +46 (0) 31 799 0281

F +46 (0) 31 799 0010

The Netherlands, Belgium, Luxembourg,

Central and Eastern Europe, Baltic

States, Greece, Turkey and CIS

countries

ENERPAC B.V.

Galvanistraat 115

6716 AE Ede

P.O. Box 8097

6710 AB Ede

The Netherlands

T +31 318 535 911

F +31 318 535 848

Enerpac Integrated Solutions B.V.

Opaalstraat 44

7554 TS Hengelo

P.O. Box 421

7550 AK Hengelo

The Netherlands

T +31 74 242 20 45

F +31 74 243 03 38

South Africa and other English speaking

African countries

ENERPAC AFRICA ( PTY ) Ltd.

Cambridge Office Park, Block E

5 Bauhinia Avenue

Highveld Techno Park, Centurion

Republic of South-Africa

T 0027 (0) 12 940 0656

United Kingdom and Ireland

ENERPAC Ltd.,

Bentley Road South

Darlaston, West Midlands

WS10 8LQ

England

T +44 (0)121 50 50 787

F +44 (0)121 50 50 799

USA, Latin America and Caribbean

ENERPAC World Headquarters

P.O. Box 3241

Milwaukee, WI 53201-3241 USA

N86 W12500 Westbrook Crossing

Menomonee Falls

Wisconsin 53051

T +1 262 293 1600

F +1 262 293 7036

User inquiries:

+1 800 433 2766

Distributor inquiries/orders:

+1 800 558 0530

+1 800 628 0490

Technical inquiries:

Enerpac Worldwide Locations

www.enerpac.com

Jam Nut

Adjustment

Set Screw

Copper

Gasket Acorn

Nut

Figure 9, B-port Relief Valve Adjustment (typical)