4

5.2 Removing Air From the System

When the wrench is first connected to the pump, air will be trapped

in the components. To ensure smooth operation, remove air by

cycling the wrench several times without load. Cycle until wrench

advances and retracts without hesitation.

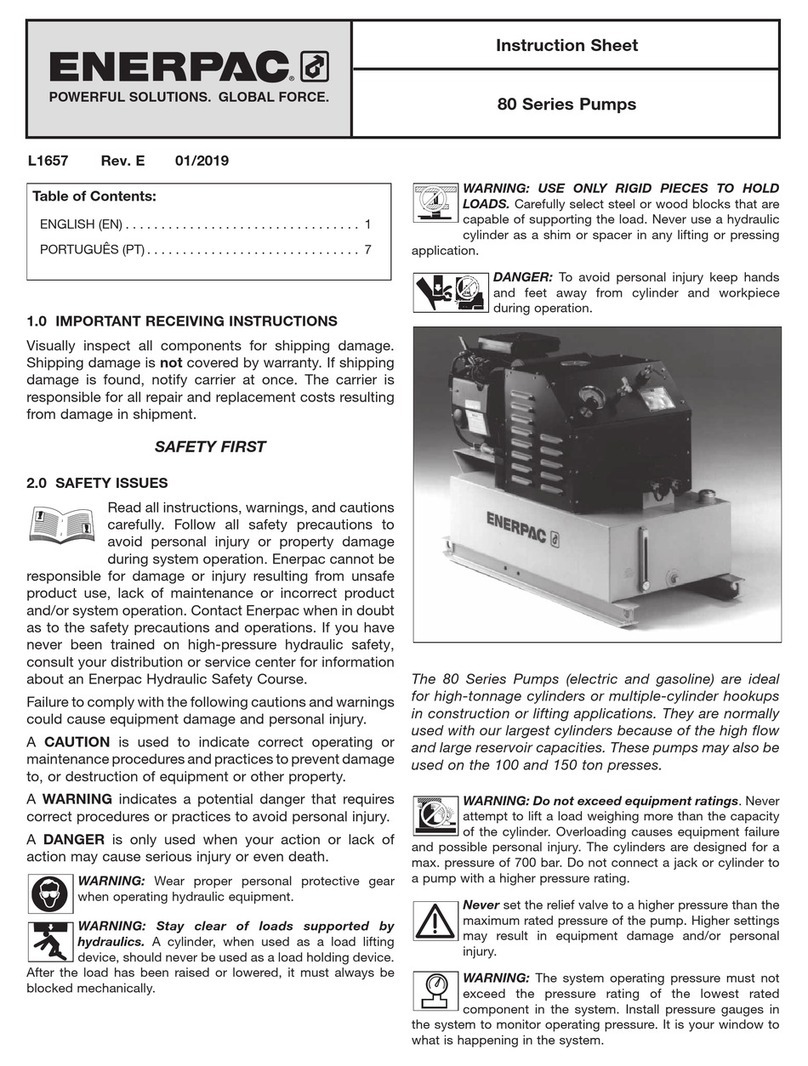

5.3 Gauge and Overlay

Operating Procedure

The pump is supplied with a

pressure gauge installed. A torque

overlay fits over the pressure

gauge dial face which easily

converts pressure readings to

torque readings (see Fig. 6).

The overlay has imperial units

(Ft.lbs) on one side and metric

units (Nm) on the other. To change

scales simply flip overlay over.

WARNING: Each overlay is sized for a specific Enerpac

torque wrench ONLY. Do not use with other

wrenches.

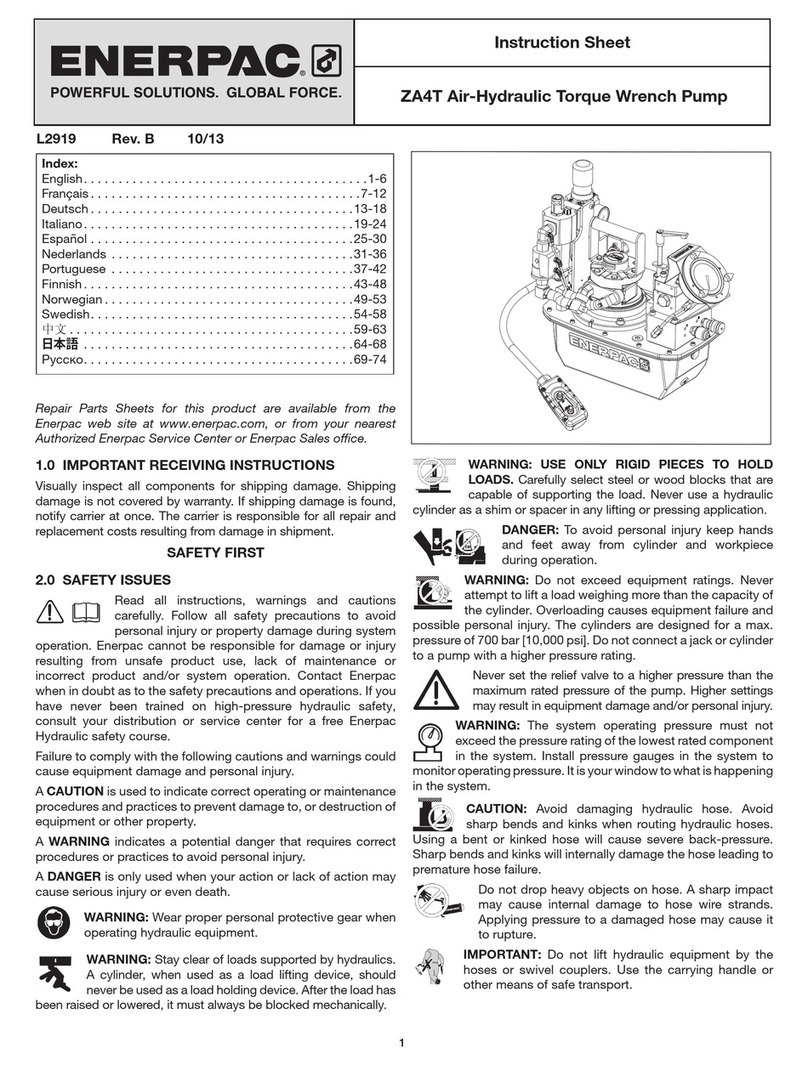

5.4 Changing the Overlay

1. Remove the three black wing

knobs which hold the front

gauge flange in place (see

Fig. 7).

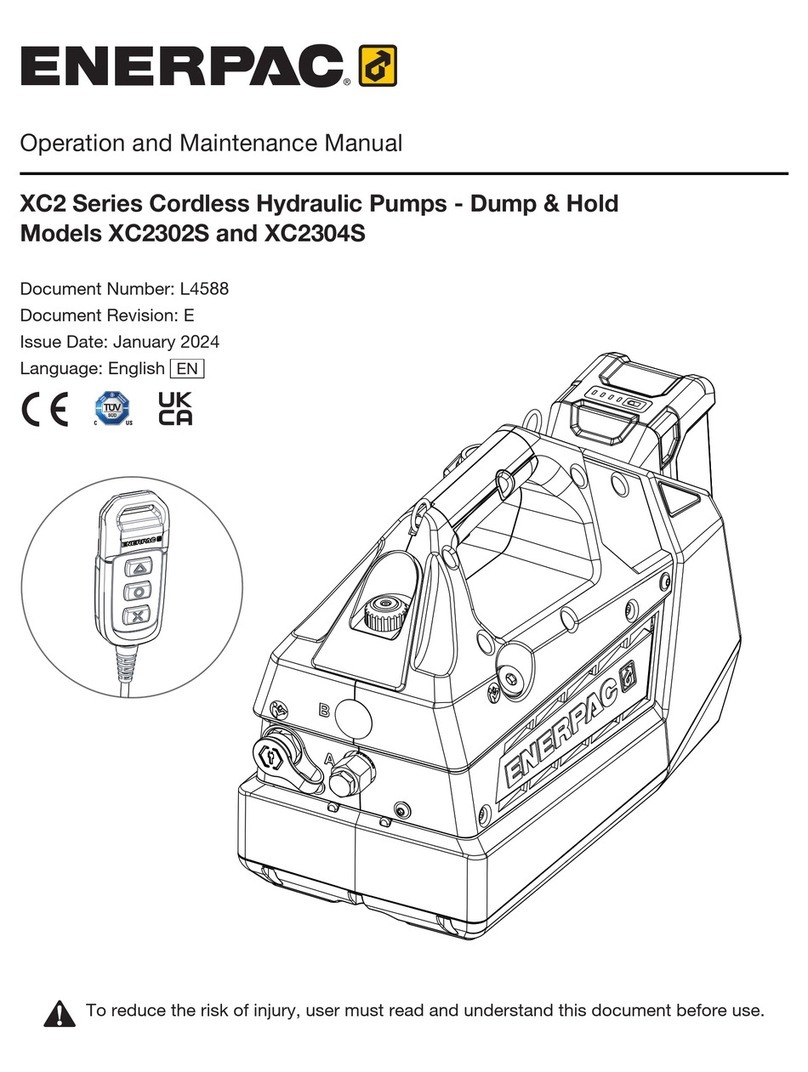

2. Remove the front flange and

overlay (see Fig. 8).

3. Insert new overlay (remember

to verify correct overlay to the

Enerpac torque wrench being

used) onto the flange,

aligning the overlay with the

dimples on the back of the

flange (see Fig. 9).

4. While holding the overlay

behind the flange (see Fig. 8.)

insert the flange onto the knob

studs, repositioning the

overlay as needed, and

secure knobs finger tight (see

Fig. 7).

The flange will press the

overlay onto the gauge and

secure it in place. See torque

wrench instructions for

amount of pressure required

to produce desired torque.

Note that the maximum

pressure varies for different

wrenches and accessories.

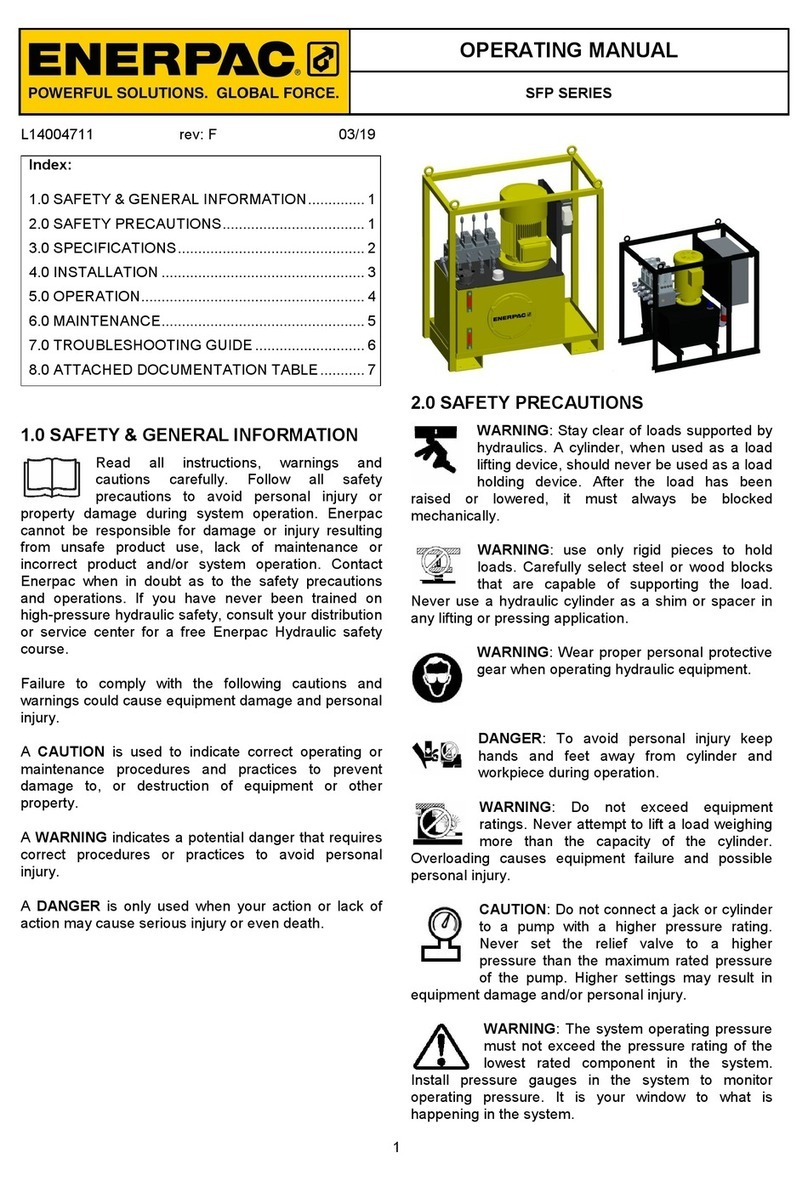

5.5 Setting Pump to Torque Value

Pressure and torque are set by adjusting the relief valve. The

external relief valve is located on top of the pump. It is adjustable

from 11,600 psi (800 bar) down to 2000 psi (140 bar). Operating

pressure cannot be adjusted to above 11,600 psi (800 bar). To get

the most accurate relief valve setting, start at a lower pressure and

adjust up to the desired relief valve.

Warning: Make these adjustments BEFORE putting

torque wrench on nut or bolt head. The pump

pressure setting may be above the pressure needed

to provide the required torque for your application. Exceeding

required torque will cause equipment damage and may lead

to serious personal injury.

1. The pump is supplied with a pressure gauge installed. See the

torque wrench instructions for the amount of pressure needed

to produce the required torque. Note that the maximum

pressure varies for the different wrenches and accessories.

2. Loosen the locknut on the relief valve adjustment screw. Using

the knurled knob, turn the adjustment screw counter-

clockwise to decrease pressure setting (see Fig. 10).

3. Turn the pump on, and press and hold "ADV". Observe the

pressure gauge reading. Adjust the relief setting up to the

desired pressure.

4. Verify the setting by running the pump several times.

5. Tighten lock nut to secure setting on relief valve.

Figure 10

6.0 MAINTENANCE

6.1 Change Oil and Clean Reservoir

IMPORTANT: You will need a new reservoir gasket to reassemble

the pump after changing the oil.

1. Completely drain and clean the reservoir after every 100

hours of operation. Refill with new Enerpac hydraulic oil. If

pump is used infrequently, clean the reservoir once a year.

NOTE: This procedure requires that you remove the pump

from the reservoir. Work on a clean bench and use proper oil

disposal methods.

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Relief Valve