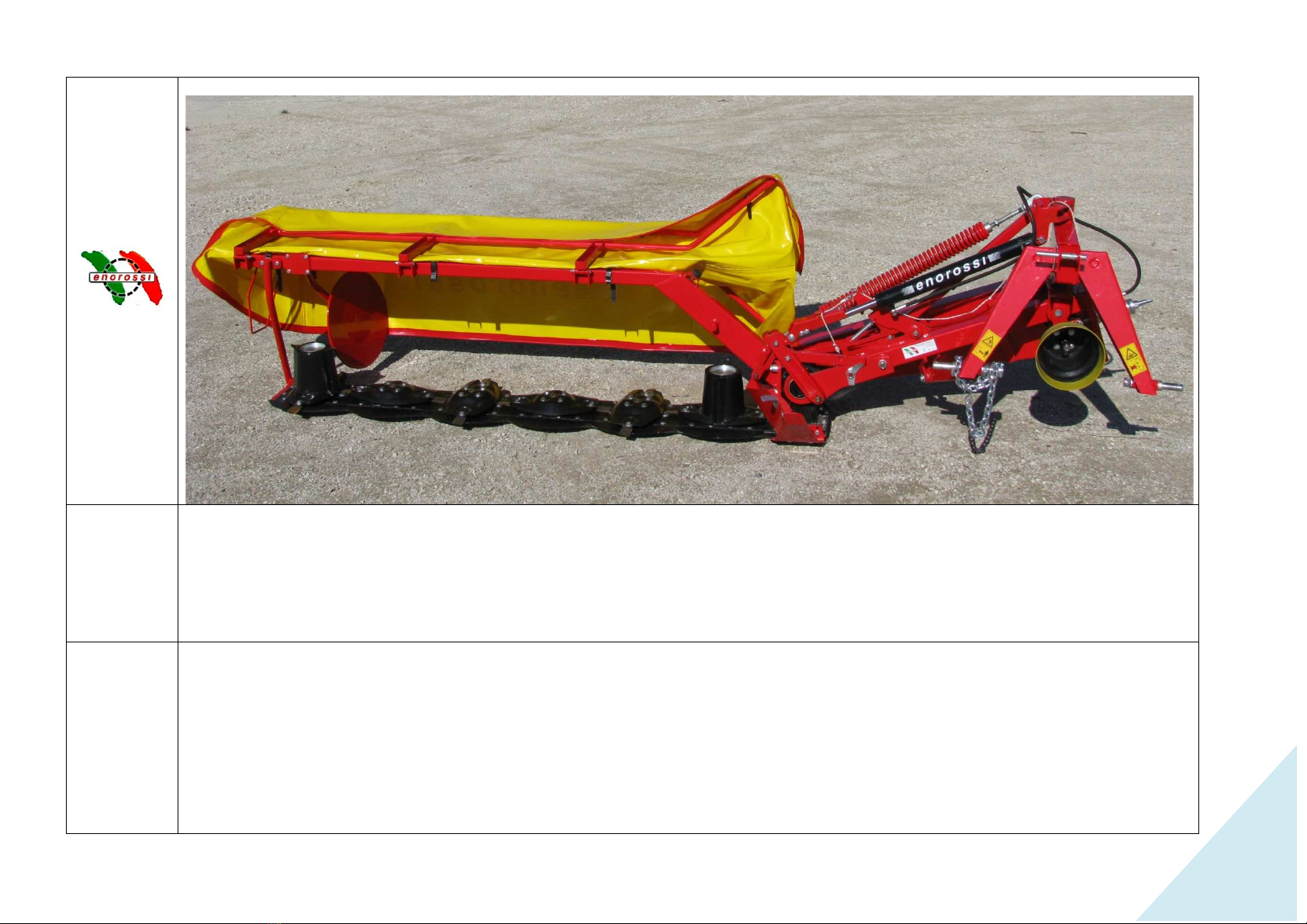

enorossi DM Series Operating instructions

DISC MOWER DM SERIES

USER’S AND MAINTENANCE MANUAL

web: http://www.enorossi.it

DISC MOWER DM SERIES

4-5-6

LIGHT SERIES

USER’S AND MAINTENANCE MANUAL

ENOAGRICOLA ROSSI s.r.l.

06018 Calzolaro di Umbertide – Perugia – Italy

Tel. (39) 075-930 22 22 – Telefax (39) 075-930 23 28

web: http://www.enorossi.it

- http://www.enoagricolarossi.com

1

LIGHT SERIES

Section 1 – General information

................................

Section 2 – Use of the manual

................................

Section 3 – Machine assembly

................................

Section 4 –

Attachment of the machine to the tractor

Section 5 – Cardan shaft

................................

Section 6 – Transport position

................................

Section 7 –

Work position and adjustments

Section 8 –

Use of the mowing machine

Section 9 – Adjustments for operation

Section 10 –

Checks, maintenance, adjustments.

Section 11 - Lubrication

................................

Section 12 – Requesting spare parts

................................

This document is the property of ENOAGRICOLA ROSSI s.r.l.

No parts herein may be reproduced without prior consent from the Company Management

Any

infringements will be punished by law

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

Contents

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

Attachment of the machine to the tractor

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

Work position and adjustments

................................................................

................................

Use of the mowing machine

................................................................

................................

................................................................................................

................................

Checks, maintenance, adjustments.

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

This document is the property of ENOAGRICOLA ROSSI s.r.l.

No parts herein may be reproduced without prior consent from the Company Management

.

infringements will be punished by law

.

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 2 di 52

2

................................

...................................3

................................

.....................................4

................................

....................................6

................................

.................................15

................................

...........................................19

................................

...................................20

................................

...............................................22

................................

....................................................24

................................

.......................25

................................

......................................28

................................

.............................................32

................................

.........................36

Section 1 – General information

Assistance

For any needs, contact the machine dealer or the ENOAGRICOLA ROSSI Technical Office.

CE Marking

This mark certifies that the machine complies with the safety

Union.

CE Conformity declaration

conforms to the essential safety requirements established by Directives 89/392/EEC, 91/368/EEC,

The legal representative

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

For any needs, contact the machine dealer or the ENOAGRICOLA ROSSI Technical Office.

This mark certifies that the machine complies with the safety

requirements set by the European

ENOAGRICOLA ROSSI

06018 Calzolaro di Umbertide-Perugia-

Italy

ROTARY DISC MOWER

ENOAGRICOLA ROSSI srl

06018 Calzolaro di Umbertide-

Perugia

declares under its

exclusive responsibility that the machine

ROTARY DISC MOWER

Mod.........................

Series...........................

to which this declaration refers,

conforms to the essential safety requirements established by Directives 89/392/EEC, 91/368/EEC,

93/44/EEC, 93/68/EEC.

The legal representative

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 3 di 52

3

For any needs, contact the machine dealer or the ENOAGRICOLA ROSSI Technical Office.

requirements set by the European

Italy

Perugia

-Italy

exclusive responsibility that the machine

conforms to the essential safety requirements established by Directives 89/392/EEC, 91/368/EEC,

Section 2 – Use of the manual

BEFORE INSTALLING AND USING THE MACHINE

OR BEFORE CARRYING OUT ANY OPERATION

READ CAREFULLY THE INSTRUCTIONS CONTAINED IN THIS MANUAL

This manual has been

written for your safety. It is an integral part of this machine and must be kept for reference at all

times, protecting it from moisture, neglect, and sunlight in order to prevent its deterioration

The manual is intended for: the machine users, the o

use, supervision, maintenance, and final dismantling.

The manual provides indications on the correct use of the machine, its technical features, and safety measures; this

manual,

in any case, can never replace an adequate experience of the user.

The manual also gives information for personnel training, for guiding maintenance operations, facilitating the request for

spare parts, and warning about remaining risks that could no

The manual reflects the state of the machine’s technical status as sold and cannot be considered inadequate if

subsequently updated on the basis of new experience

The company supplying the machine

obligation to update previous production and related manuals

N.B.

Enoagricola Rossi accepts no liability for

accordance with national and Community workplace safety requirements

required maintenance, unauthorized changes or repairs,

failure to f

ollow the instructions contained in this manual

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

BEFORE INSTALLING AND USING THE MACHINE

OR BEFORE CARRYING OUT ANY OPERATION

READ CAREFULLY THE INSTRUCTIONS CONTAINED IN THIS MANUAL

written for your safety. It is an integral part of this machine and must be kept for reference at all

times, protecting it from moisture, neglect, and sunlight in order to prevent its deterioration

The manual is intended for: the machine users, the o

wner, the safety supervisors, those in charge of handling, installation,

use, supervision, maintenance, and final dismantling.

The manual provides indications on the correct use of the machine, its technical features, and safety measures; this

in any case, can never replace an adequate experience of the user.

The manual also gives information for personnel training, for guiding maintenance operations, facilitating the request for

spare parts, and warning about remaining risks that could no

t be eliminated in the design phase.

The manual reflects the state of the machine’s technical status as sold and cannot be considered inadequate if

subsequently updated on the basis of new experience

.

The company supplying the machine

reserves

the right to make any changes to the product and its manual without the

obligation to update previous production and related manuals

.

Enoagricola Rossi accepts no liability for

damages resulting from improper use by untrained personnel

accordance with national and Community workplace safety requirements

, incorrect installation, serious deficiencies in the

required maintenance, unauthorized changes or repairs,

use of unauthorised spare parts, acts of God, or total or partial

ollow the instructions contained in this manual

.

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 4 di 52

4

READ CAREFULLY THE INSTRUCTIONS CONTAINED IN THIS MANUAL

written for your safety. It is an integral part of this machine and must be kept for reference at all

times, protecting it from moisture, neglect, and sunlight in order to prevent its deterioration

.

wner, the safety supervisors, those in charge of handling, installation,

The manual provides indications on the correct use of the machine, its technical features, and safety measures; this

The manual also gives information for personnel training, for guiding maintenance operations, facilitating the request for

t be eliminated in the design phase.

The manual reflects the state of the machine’s technical status as sold and cannot be considered inadequate if

the right to make any changes to the product and its manual without the

damages resulting from improper use by untrained personnel

, use not in

, incorrect installation, serious deficiencies in the

use of unauthorised spare parts, acts of God, or total or partial

The machine has been designed in conformity with European machine safety standards and, in particular, the following

standards have been considered

1. EN 292/2 Ed. 1991:

Safety of machine. Fundamental

specifications and principles.

2. ISO 7000 Ed. 1994:

Safety decals to be used on machine

The machine must be used by operators who

1.

Have a good knowledge of safety standards and

2.

Are well informed on risks of this machine and dangerous areas and on the importance of not tampering with protection

guards.

3.

Have been well trained on how to operate the machine

4.

Will inform manufacturer of any malfunctioning

In the

event this manual is lost or damaged, a new copy may be requested from this address:

IMPORTANT!

If the machine is sold, please turn this manual over to the new owner.

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

The machine has been designed in conformity with European machine safety standards and, in particular, the following

standards have been considered

:

Safety of machine. Fundamental

concepts and general principles of mechanical design. Technical

Safety decals to be used on machine

.

The machine must be used by operators who

:

Have a good knowledge of safety standards and

regulations.

Are well informed on risks of this machine and dangerous areas and on the importance of not tampering with protection

Have been well trained on how to operate the machine

.

Will inform manufacturer of any malfunctioning

.

event this manual is lost or damaged, a new copy may be requested from this address:

ENOAGRICOLA ROSSI Srl

06018 Calzolaro di Umbertide – Perugia –Italy

Tel 075 / 930 22 22 Fax 075 / 930 23 28

If the machine is sold, please turn this manual over to the new owner.

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 5 di 52

5

The machine has been designed in conformity with European machine safety standards and, in particular, the following

concepts and general principles of mechanical design. Technical

Are well informed on risks of this machine and dangerous areas and on the importance of not tampering with protection

event this manual is lost or damaged, a new copy may be requested from this address:

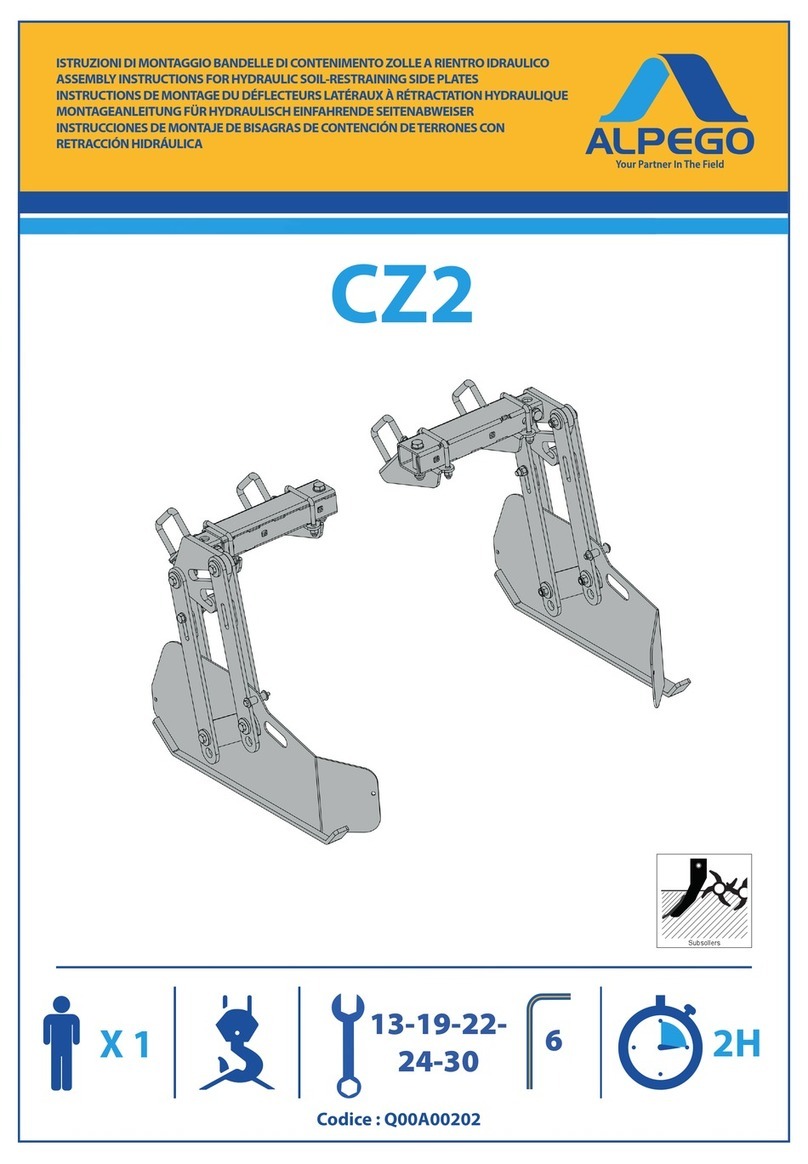

Section 3 – Machine assembly

To facilitate shipments of the machines, several parts have been disassembled to reduce the shipping dimensions. To

reassemble, proceed as follows:

•

Open the case and lay the mower disc bar flat as indicated in Fig. 1.

•

Turn the frame and the 3

as in Fig. 2

Fig. 1

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

To facilitate shipments of the machines, several parts have been disassembled to reduce the shipping dimensions. To

reassemble, proceed as follows:

Open the case and lay the mower disc bar flat as indicated in Fig. 1.

Turn the frame and the 3

rd

point using a lifting device (hoist, lift truck, etc.) and position the mower disc bar

Fig. 1

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 6 di 52

6

To facilitate shipments of the machines, several parts have been disassembled to reduce the shipping dimensions. To

point using a lifting device (hoist, lift truck, etc.) and position the mower disc bar

Fig. 2

1

st

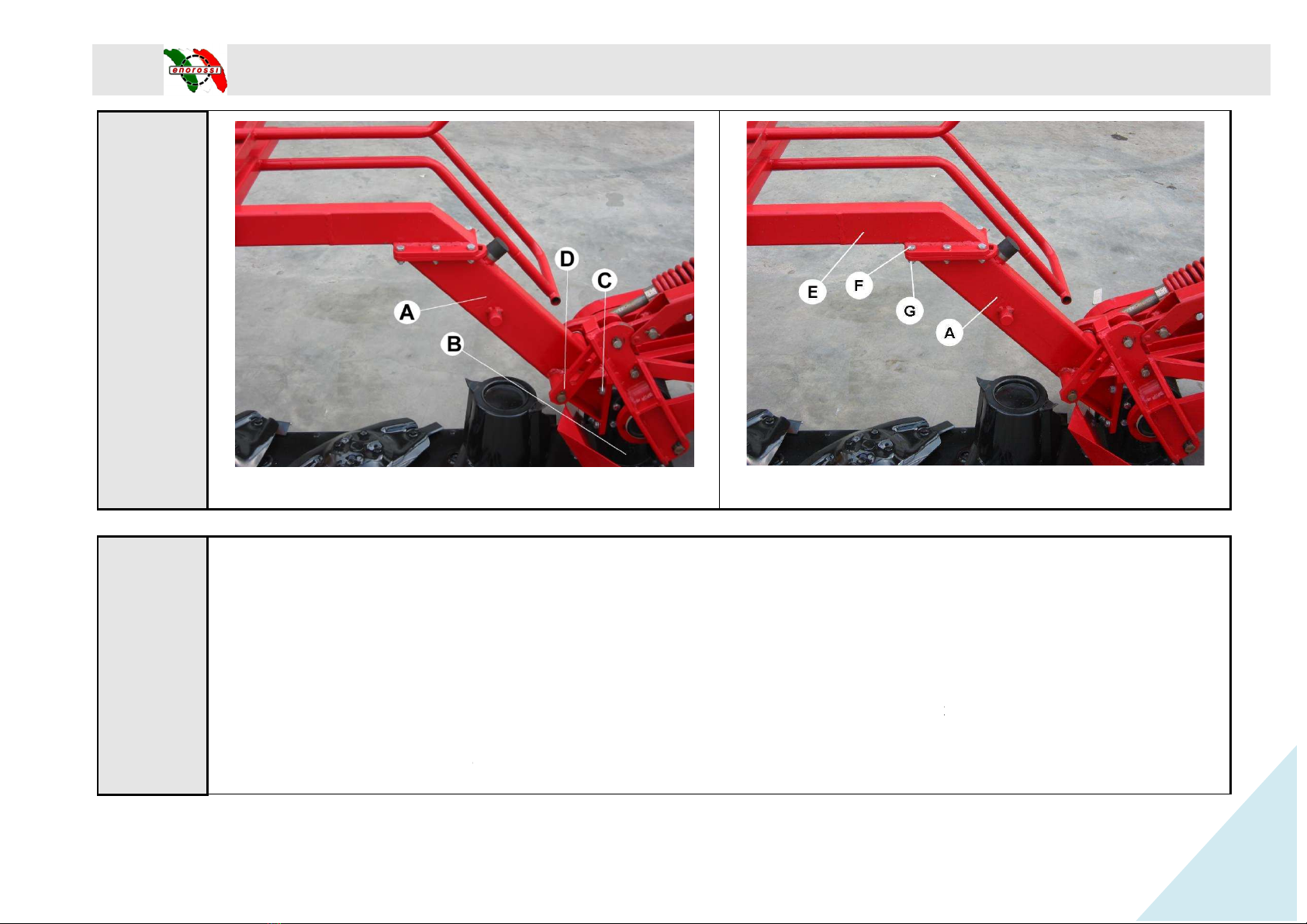

assembly –

assembly of the protection support.

Mount protection support A

(Fig. 3

connect the lifting rod hole to support

screws C(screw T.E. M12x5

0 and washer M12

2

nd

assembly –

assembly of the protection bar (only on DM

series).

Position the protection bar E

in support

F

(screw T.E. M10x35), six washers, and six self

DM-P series).

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

assembly of the protection support.

(Fig. 3

– Fig. 3/A) in gear case B; first of all,

connect the lifting rod hole to support

D (Fig. 3). Fasten the support with

0 and washer M12

Yand spacer J.

assembly of the protection bar (only on DM

-P

in support

A (Fig. 4) and fasten it with six screws

(screw T.E. M10x35), six washers, and six self

-locking nuts GM10 (only on

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 7 di 52

7

Fig. 3/A

Fig. 3

3

rd

assembly –

support rod.

Mount support rod H

(Fig. 5), and fasten with screws

locking nut M10)

4

th

assembly –

assembly of the side rake disc.

Fasten rake disc unit Ion the

central

plate Z ( 115x95x10)

M

ake sure the rake disc does not touch the cone cover and blades. Observe the safety distance X= from 15 to 25 mm

(Fig. 6).

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

Fig. 3

support rod.

(Fig. 5), and fasten with screws

M(T.E. M12x80 + self locking nut

), and screws

assembly of the side rake disc.

central

bar M(Fig. 5). Fasten it using screws P

( T.E.M10x70 + self locking nut M10) and

ake sure the rake disc does not touch the cone cover and blades. Observe the safety distance X= from 15 to 25 mm

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 8 di 52

8

Fig. 4

), and screws

N(T.E. M10x30

+ self

( T.E.M10x70 + self locking nut M10) and

ake sure the rake disc does not touch the cone cover and blades. Observe the safety distance X= from 15 to 25 mm

.

Fig. 5

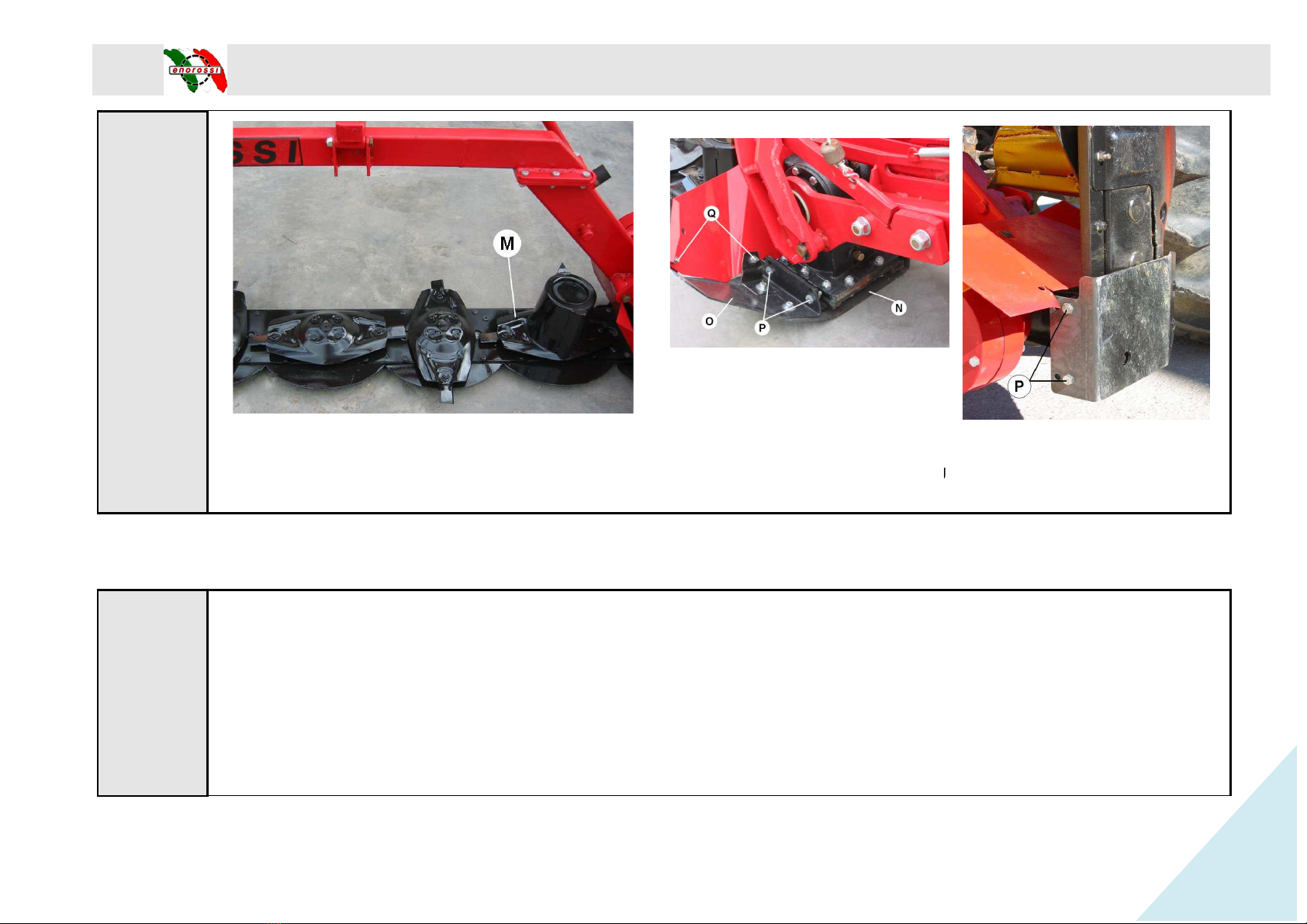

5

th

assembly –

assembly of the internal cone disc.

Mount internal cone disc M

(Fig. 7)

6

th

assembly –

assembly of the lower slide and protection plate.

Lift the mower and mount the lower slide

locking nuts + washer Ø12

) and two screws

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

Fig. 6

assembly of the internal cone disc.

(Fig. 7)

so that the largest dimension is oriented perpendicular to that of the nearby disc.

assembly of the lower slide and protection plate.

Lift the mower and mount the lower slide

N(Fig. 8) and slide tip O

. Fasten them with four screws

) and two screws

Q(TTQS M10x25 + washer M10+ self

locking nut M10

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 9 di 52

9

Fig. 6

so that the largest dimension is oriented perpendicular to that of the nearby disc.

. Fasten them with four screws

P(T.E. 12x30 + self-

locking nut M10

).

Fig. 7

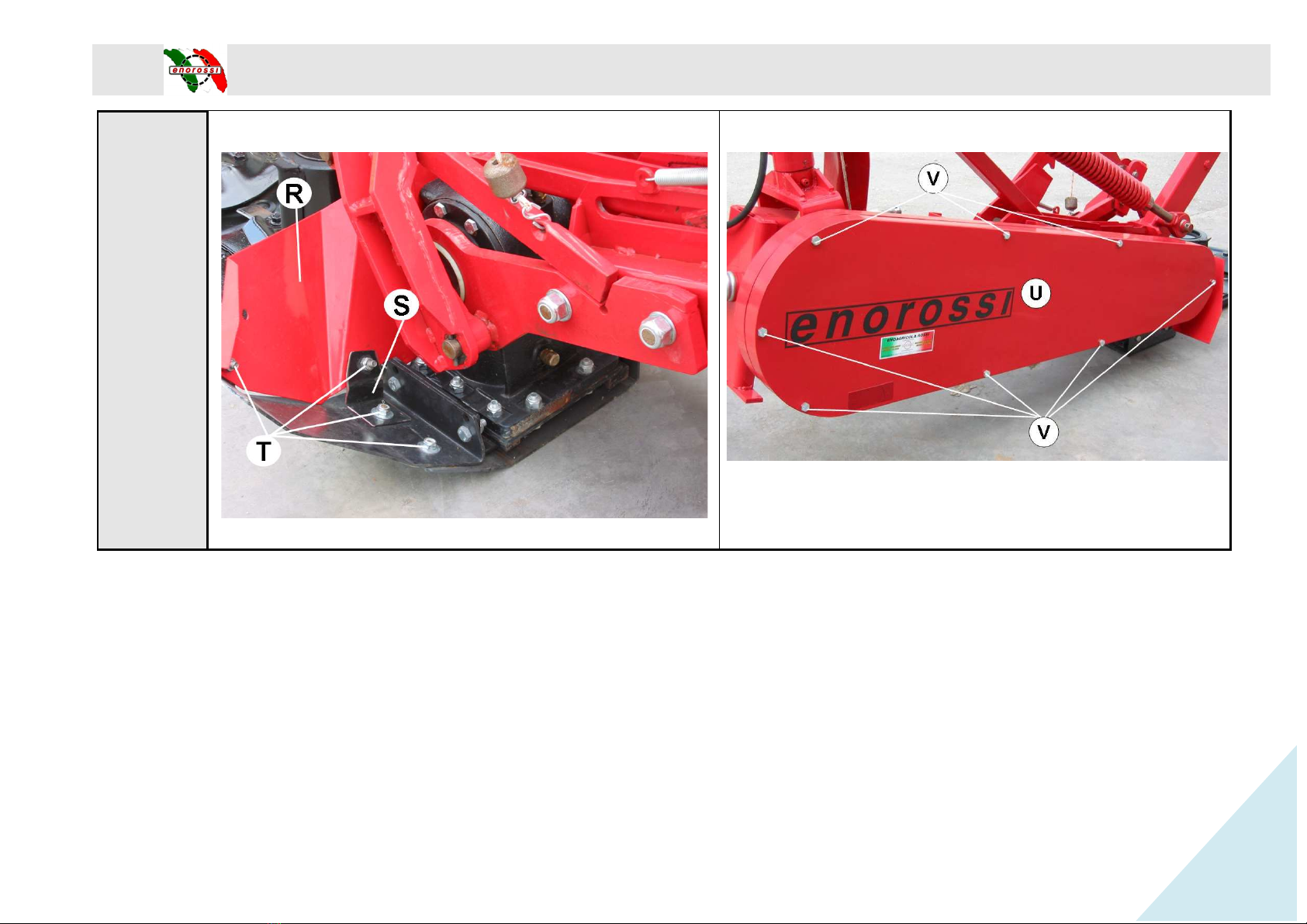

7

th

assembly –

assembly of internal protective flap.

Mount flap R(Fig. 9)

protecting the gear case and fasten it with connecting bracket

washer M10 + washer +

self locking nut M10

starting to tighten them.

8

th

assembly –

assembly of the belt protection case.

Mount case U (Fig. 10)

, fasten with screws

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

Fig. 8

assembly of internal protective flap.

protecting the gear case and fasten it with connecting bracket

S

and three screws

self locking nut M10

). To facilitate assembly of flap R

, it is advisable to insert all screws before

assembly of the belt protection case.

, fasten with screws

V(T.E. M10x120), washers and self-

blocking nuts (M10).

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 10 di 52

10

Fig. 8

and three screws

T

(TTQS M10x25 +

, it is advisable to insert all screws before

blocking nuts (M10).

Fig. 9

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

Fig. 9

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 11 di 52

11

Fig. 10

9

th

assembly –

compensating spring.

Hook spring W(Fig. 11) on pin

Y

To facilitate this operation, attach the machine to the tractor, lifting it until the support hole is aligned with pin

10

th

assembly –

assembly of the release cord.

Insert cord A (Fig. 12)

through ring

through ring E

and tie safety hook

Mount hydraulic pipe G

on the hydraulic piston, with the perforated screw, positioning the copper washers (Fig. 13).

Fig. 11

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

compensating spring.

Y

of the protection support and fast

en it with an elastic pin Ø 6x40

To facilitate this operation, attach the machine to the tractor, lifting it until the support hole is aligned with pin

assembly of the release cord.

through ring

B, then fasten the hook to safety hook C

. Close the hook with a pliers. Insert cord

and tie safety hook

C (Fig. 13), making a knot in the hole.

on the hydraulic piston, with the perforated screw, positioning the copper washers (Fig. 13).

Fig. 12

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 12 di 52

12

en it with an elastic pin Ø 6x40

.

To facilitate this operation, attach the machine to the tractor, lifting it until the support hole is aligned with pin

Y(Fig. 11).

. Close the hook with a pliers. Insert cord

D

on the hydraulic piston, with the perforated screw, positioning the copper washers (Fig. 13).

Fig. 13

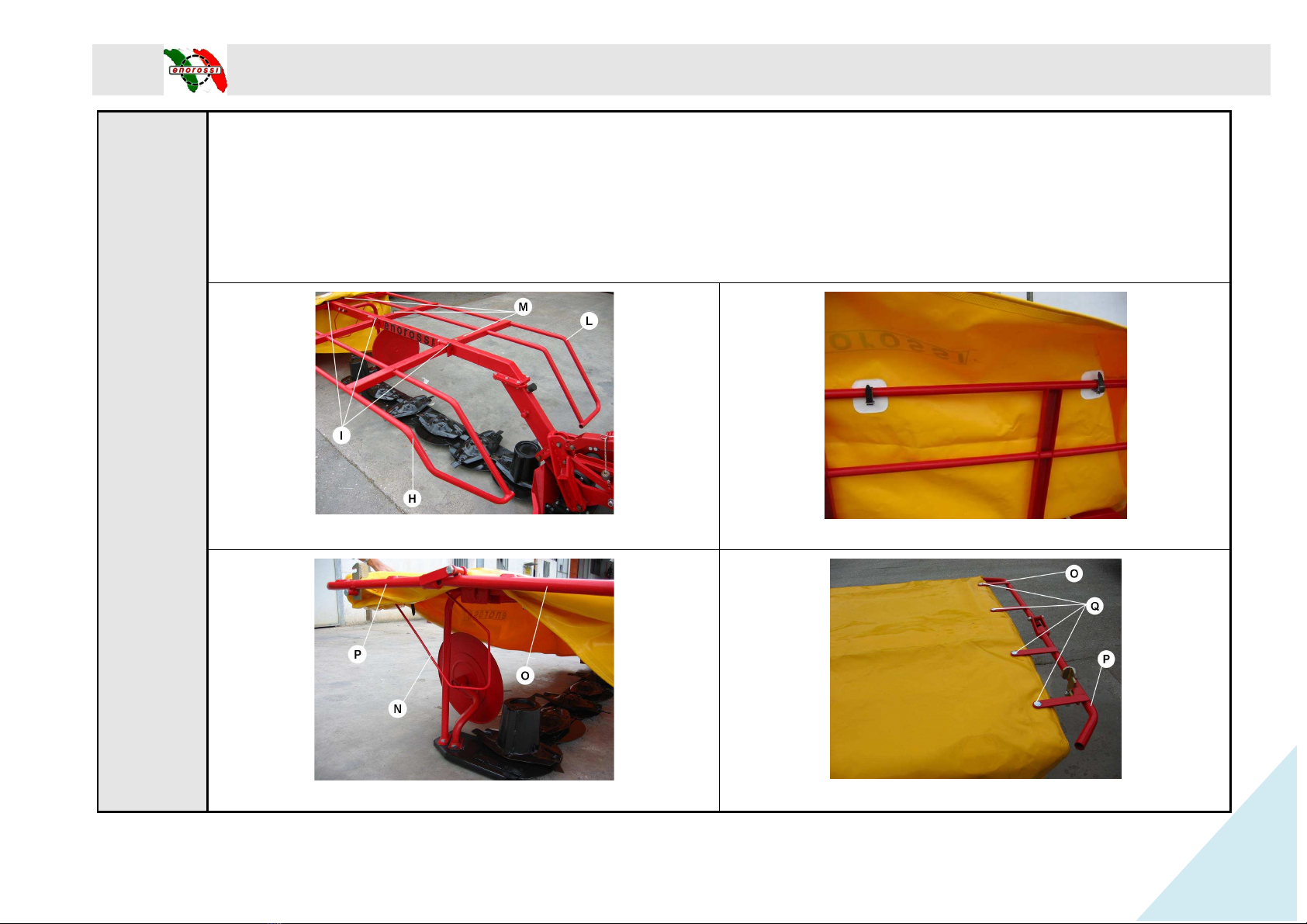

11

th

assembly –

assembly of protection guards.

Mount front guard H(Fig. 14)

on the three hinges and fasten with screws

Mount rear guard L

with six screws

Assemble the protection guard frame and fasten it to the supporting structure using the ties found under the tarpaulin (Fig.

Assemble the protection rod for tarpaulin

Fasten rear handle Pwith screws

Q

Fig. 14

Fig. 16

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

assembly of protection guards.

on the three hinges and fasten with screws

I(T.E. M10x85

) and self

with six screws

M(TTQS M10x25) and self-locking nuts M10.

Assemble the protection guard frame and fasten it to the supporting structure using the ties found under the tarpaulin (Fig.

Assemble the protection rod for tarpaulin

N(Fig. 17)

and at the same time assemble (Fig. 16) front handle

Q

(TTQS M10x35), washers, and self-locking nuts M10.

Fig. 14

Fig. 16

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 13 di 52

13

) and self

-locking nuts M10 + washer.

Assemble the protection guard frame and fasten it to the supporting structure using the ties found under the tarpaulin (Fig.

15).

and at the same time assemble (Fig. 16) front handle

Oand rear handle P.

Fig. 15

Fig. 17

12

th

assembly –

blade assembly.

Check the

rotation direction of the discs; each blade has an arrow indicating the rotation direction. After tightening the

screw and nut, make sure the blade can rotate fre

13

th

assembly –

assembly of the protective guard.

Insert the

guard into the power takeoff tube an

14

th

Insert pin A

Ø40x274 on left side

washers Ø24

Fig. 18

Free

Rotation

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

blade assembly.

rotation direction of the discs; each blade has an arrow indicating the rotation direction. After tightening the

screw and nut, make sure the blade can rotate fre

ely from the oval disc (Fig. 18).

assembly of the protective guard.

guard into the power takeoff tube an

d fasten with the band

screw T.E. M8x16 and washer M8x24

Ø40x274 on left side

; insert pin BØ40x219

on right side see fig. 19. Fasten the pins using nuts

Fig. 18

Rotation

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 14 di 52

14

rotation direction of the discs; each blade has an arrow indicating the rotation direction. After tightening the

screw T.E. M8x16 and washer M8x24

(Fig. 19).

on right side see fig. 19. Fasten the pins using nuts

CM24 +

Fig. 19

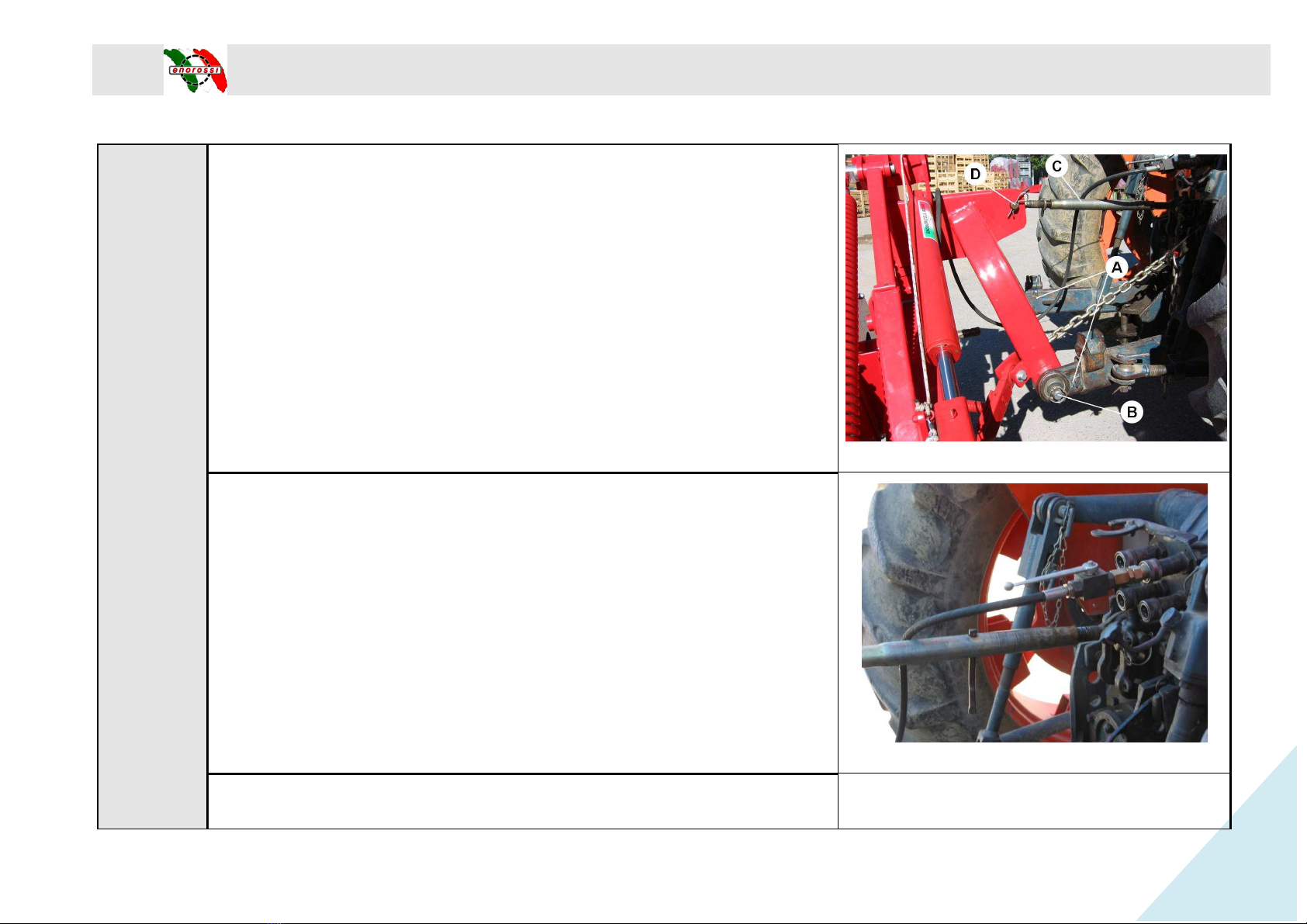

Section 4 –

Attachment of the machine to the tractor

NB: The mower must be attached to a tractor with a power takeoff of 540

rpm and to a 3-

point attachment (Fig. 20).

Instructions for attachment to the

1)

Insert the tractor’s lifting arms

fasten them with split pins.

2) Insert 3

rd

point C

and fasten it with pin

3)

Connect the hydraulic pipe of the piston to th

21)

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

Attachment of the machine to the tractor

NB: The mower must be attached to a tractor with a power takeoff of 540

point attachment (Fig. 20).

Instructions for attachment to the

tractor:

Insert the tractor’s lifting arms

A (Fig. 20) into attachment pins Band

and fasten it with pin

D(Fig. 20).

Connect the hydraulic pipe of the piston to th

e tractor’s distributor (Fig.

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 15 di 52

15

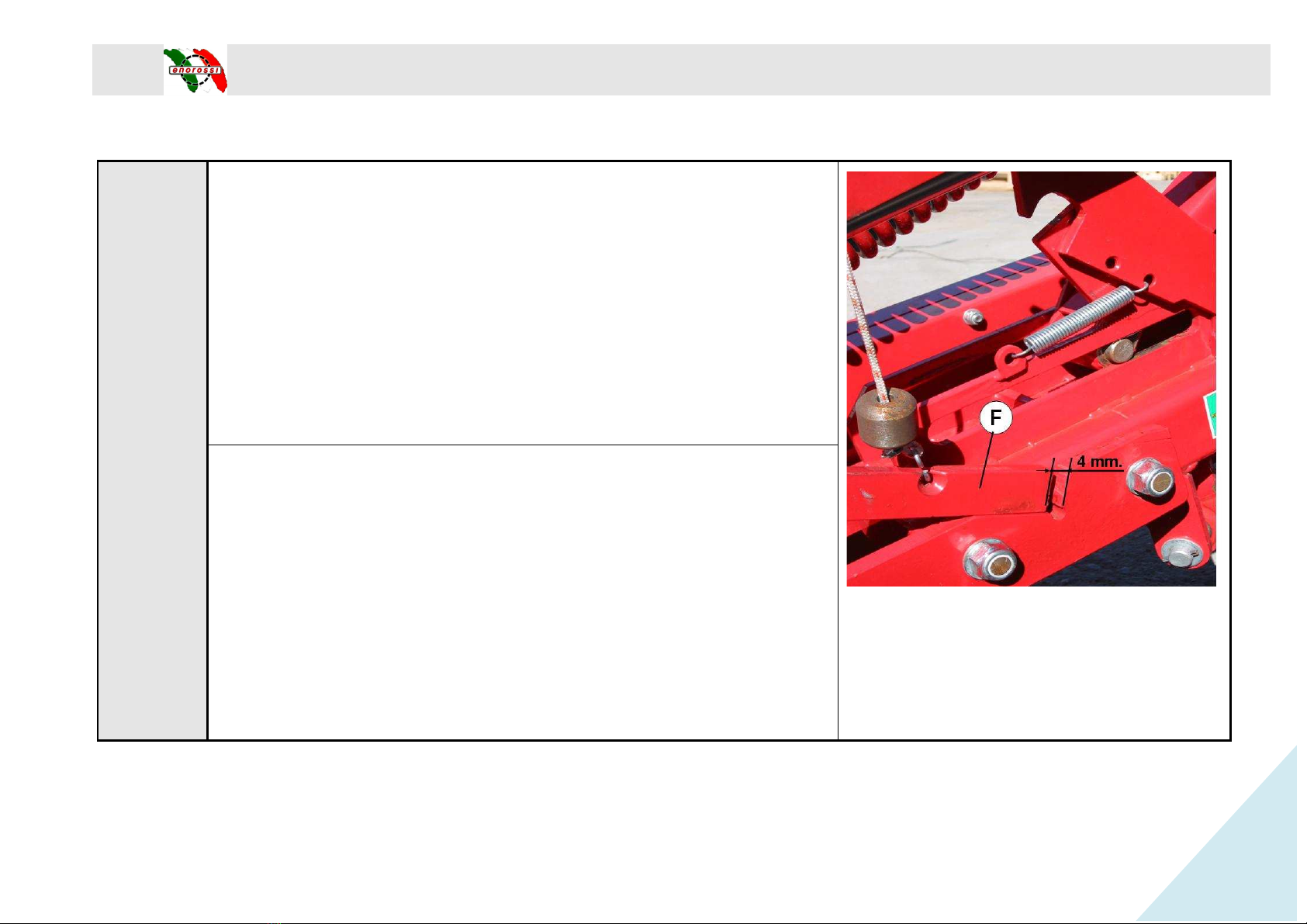

Fig. 20

Fig. 21

4) Connect the tractor’s cardan shaft to the power takeoff of the mower;

use chains to prevent rotation of the protection pipe.

5) Lift the machine using the hydraulic lift; turn edge

6) IMPORTANT!!!

During work and transport, edge

turned upwards as in Fig. 23.

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

4) Connect the tractor’s cardan shaft to the power takeoff of the mower;

use chains to prevent rotation of the protection pipe.

5) Lift the machine using the hydraulic lift; turn edge

Eupwards (Fig. 22)

During work and transport, edge

Emust always

be

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 16 di 52

16

Fig. 22

Fig. 23

7)

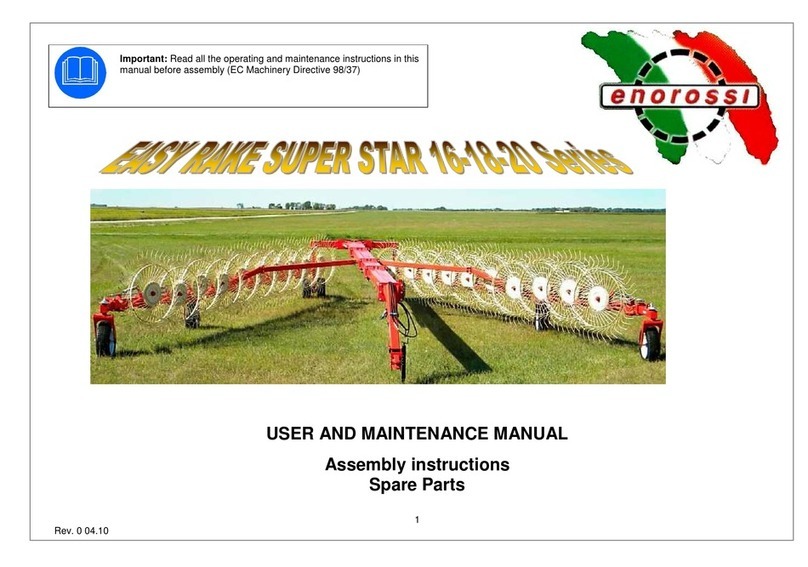

ADJUSTMENT OF FRAME HEIGHT FROM THE GROUND.

A -

for tractors equipped with hydraulic lift position control:

Position the tractor on level ground and lower the hydraulic lift until the

lifting lever F

is positioned at a distance of 4 mm from the edge, as shown

in Fig. 24.

After adjusting the height of the mower frame, set the lift control

tractor driver’s seat. In this case it is not necessary to use the limiting chain

supplied with the machine.

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

ADJUSTMENT OF FRAME HEIGHT FROM THE GROUND.

for tractors equipped with hydraulic lift position control:

Position the tractor on level ground and lower the hydraulic lift until the

is positioned at a distance of 4 mm from the edge, as shown

After adjusting the height of the mower frame, set the lift control

from the

tractor driver’s seat. In this case it is not necessary to use the limiting chain

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 17 di 52

17

Fig. 24

B –

for tractors not equipped with hydraulic lift position control:

The chain supplied with the machine must be used.

Fasten bracket G

(Fig. 25) and the limiting chain

free holes of the tractor’s third point.

Lower the machine to work position, until lifting lever

distance of 4 mm from the edge, as shown in Fig. 24. Limiting

must be taut (Fig. 25

), and the lifting lever must be at a distance of 4 mm.

as per Fig. 24.

To be able to always recognize this position, mark the chain ring that will

be hooked with bracket G.

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

for tractors not equipped with hydraulic lift position control:

The chain supplied with the machine must be used.

(Fig. 25) and the limiting chain

Hsupplied, to one of the

free holes of the tractor’s third point.

Lower the machine to work position, until lifting lever

F is positioned at a

distance of 4 mm from the edge, as shown in Fig. 24. Limiting

chain H

), and the lifting lever must be at a distance of 4 mm.

To be able to always recognize this position, mark the chain ring that will

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 18 di 52

18

Fig. 25

Section 5 – Cardan shaft

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

The cardan shaft supplied with the mower is of the correct size for coupling

with most tractors on the market.

In any case, before starting work for the first time, it is advisable to check its

length.

If adaptation is required, proceed as follows:

Important!

Use only the cardan shaft supplied or recommended, otherwise any warranty

claim or request will be considered null and void.

If the cardan shaft is too long, open the two halves and overlap them; this way

it will be possible to determine how much longer it is in cm.

Cut both tubes of the internal and external cardan shaft to the same length, as

well as their guards.

Clean the cut edges of the tubes with a file, grease them, and reclose the

cardan shaft.

Important!

The maximum work length (L1)

must allow an overlapping of the tubes equal to

half the length of the closed cardan shaft (min. _X).

Always make sure that the cardan shaft is correctly tightened before starting

work

Support chain

Use the chain to prevent rotation of the protection tube.

Make sure that the chain does not hamper the side movements of the cardan

shaft.

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 19 di 52

19

The cardan shaft supplied with the mower is of the correct size for coupling

In any case, before starting work for the first time, it is advisable to check its

Use only the cardan shaft supplied or recommended, otherwise any warranty

If the cardan shaft is too long, open the two halves and overlap them; this way

Cut both tubes of the internal and external cardan shaft to the same length, as

Clean the cut edges of the tubes with a file, grease them, and reclose the

must allow an overlapping of the tubes equal to

Always make sure that the cardan shaft is correctly tightened before starting

Make sure that the chain does not hamper the side movements of the cardan

Section 6 – Transport position

Before moving the mower into transport position, send away

all persons who may be in the manoeuvring area.

To

position for road transport or for moving from one field to

another, carry out the following operations:

1)

Disconnect the tractor power takeoff, and make sure the

discs have stopped rotating.

2) Turn front guard I

backward until the fastening point with

hook L(Fig. 26).

3) Lift the bar using the tractor’s hydraulic lift, positioning

lower slide Mat about 15-

20 cm from the ground (Fig. 27).

4) Edge E

must be turned upwards (Fig. 22

15).

ROTARY DM 4-5

U

SER’S AND MAINTENANCE MANUAL

Before moving the mower into transport position, send away

all persons who may be in the manoeuvring area.

position for road transport or for moving from one field to

another, carry out the following operations:

Disconnect the tractor power takeoff, and make sure the

discs have stopped rotating.

backward until the fastening point with

3) Lift the bar using the tractor’s hydraulic lift, positioning

20 cm from the ground (Fig. 27).

must be turned upwards (Fig. 22

– Fig. 23 Pag.

SER’S AND MAINTENANCE MANUAL

Edition March 2010 -

Pagina 20 di 52

20

Fig. 26

Fig. 27

This manual suits for next models

3

Table of contents

Other enorossi Farm Equipment manuals

enorossi

enorossi G4V-3P User manual

enorossi

enorossi 16 Series Operating instructions

enorossi

enorossi ENODUO TRACER 780 User manual

enorossi

enorossi ENODUO 610 User manual

enorossi

enorossi ENOSPE US User manual

enorossi

enorossi RAKE CADDY Series Operating instructions

enorossi

enorossi EASY RAKE 10 User manual

enorossi

enorossi RT7 User manual

enorossi

enorossi DR 420 4R User manual

enorossi

enorossi G2 Series User manual