© EPS Stromversorgung in 2022, this information is subject to change without notice 1106230800_manual_psi_10000_4u_30kw_en_03

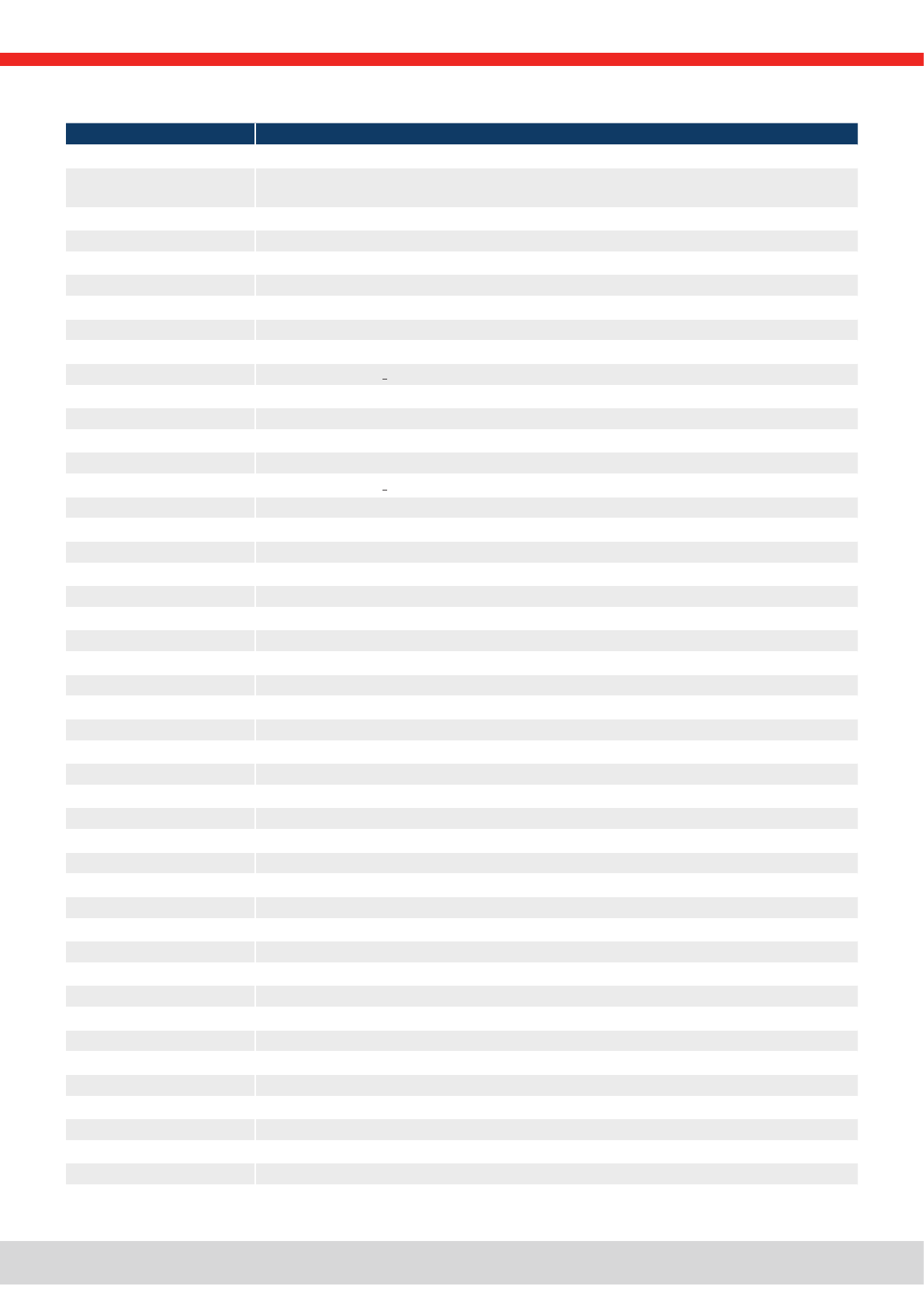

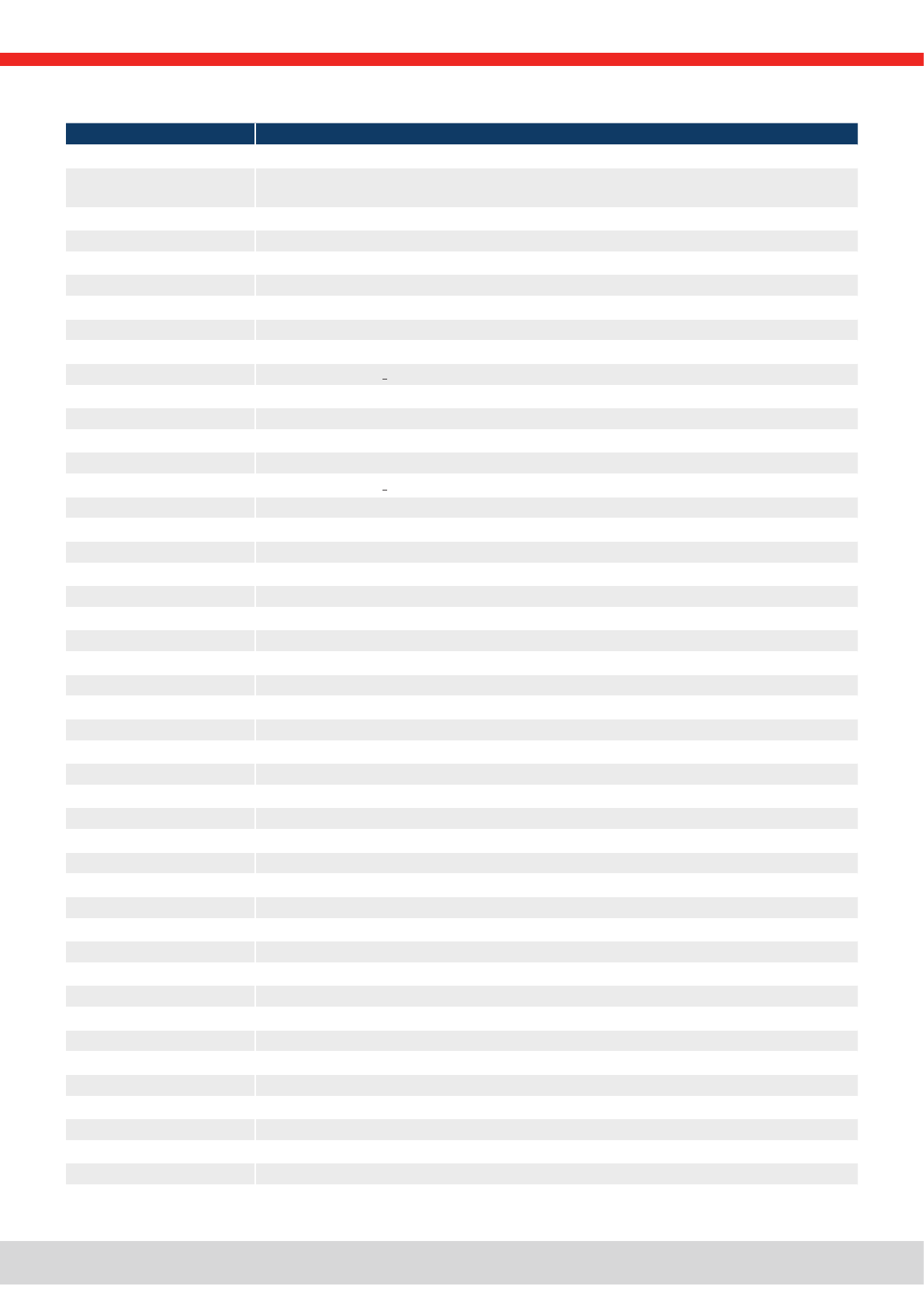

1.8.3 Specic technical data

General speci cations

AC input

Voltage, Phases Range 1: 208 V,

10%, 3ph AC (with DC output power derating to 18 kW)

Range 2: 380 - 480 V, ±10%, 3ph AC

Frequency 45 - 65 Hz

Power factor ca. 0.99

Leakage current <10 mA

Inrush current / Phase current ≤56 A

Overvoltage category 2

DC output static

Load regulation CV ≤0.05% FS (0 - 100% load, constant output voltage and constant temperature)

Line regulation CV ≤0.01% FS (208 V - 480 V AC +10% supply voltage, constant load and constant temperature)

Stability CV ≤0.02% FS (during 8 h of operation, after 30 minutes warm-up, at constant output voltage, load and temperature)

Temperature coeffi cient CV ≤30ppm/°C (after 30 minutes of warm-up)

Compensation (Remote Sense) ≤5% UNominal

Load regulation CC ≤0.1% FS (0 - 100% load, constant output voltage and constant temperature)

Line regulation CC ≤0.01% FS (208 V - 480 V AC +10% supply voltage, constant load and constant temperature)

Stability CC ≤0.02% FS (during 8 h of operation, after 30 minutes warm-up, at constant output voltage, load and temperature)

Temperature coeffi cient CC ≤50ppm/°C (after 30 minutes of warm-up)

(0 - 100% load, constant output voltage and constant temperature)

Load regulation CR ≤0.3% FS + 0.1% FS current (0 - 100% load, constant output voltage and constant temperature)

Protective functions

OVP Overvoltage protection, adjustable 0 - 110% UNominal

OCP Overcurrent protection, adjustable 0 - 110% INominal

OPP Overpower protection, adjustable 0 - 110% PNominal

OT Overtemperature protection (DC output shuts down in case of insuffi cient cooling)

DC output dynamic

Rise time 10 - 90% CV ≤10 ms

Fall time 90 - 10% CV ≤10 ms

Rise time 10 - 90% CC ≤2 ms

Fall time 90 - 10% CC ≤2 ms

Display accuracy

Voltage ≤0.05% FS

Current ≤0.1% FS

Insulation

AC input to DC output 3750 Vrms (1 minute, creepage distance >8 mm) *1

AC input to case (PE) 2500 Vrms

DC output to case (PE) Depending on the model, see model tables

DC uutput to interfaces 1000 V DC (models up to 360 V rating), 1500 V DC (models from 500 V rating)

Interfaces digital

Built-in, galvanically isolated USB, Ethernet (100 MBit) for communication, 1x USB host for data acquisition

Optional, galvanically isolated CAN, CANopen, RS232, ModBus TCP, Profi net, Profi bus, EtherCAT, Ethernet

Interfaces analog

Built-in, galvanically isolated 15 pole D-Sub

Signal range 0 - 10 V or 0 - 5 V (switchable)

Inputs U, I, P, R, remote control on/off, DC output on/off, resistance mode on/off

Outputs Monitor U and I, alarms, reference voltage, DC output status, CV/CC regulation mode

Accuracy U / I / P / R 0 - 10 V: ≤0.2%, 0 - 5 V: ≤0.4%

*1 Models up to 80 V DC rating have reinforced insulation while all other models from 200 V DC rating have basic insulation