PRELIMINARY SERVICE CHECKS (Continued)

SERVICE CHECKS

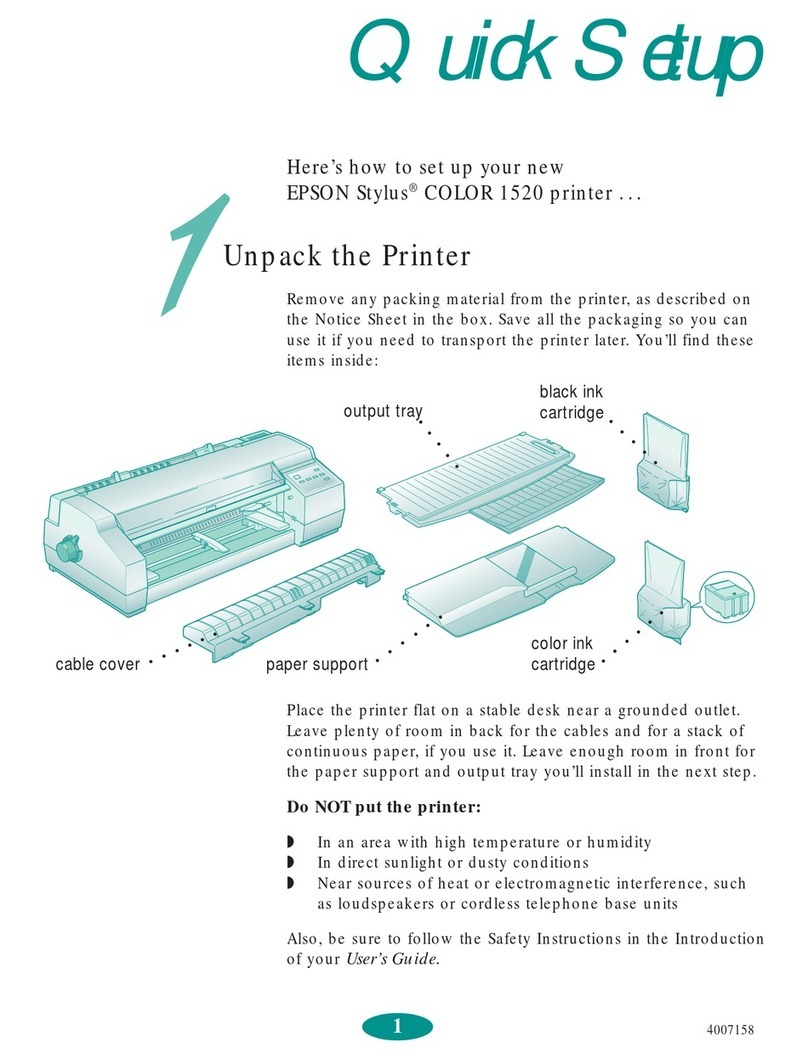

SEE INTERCONNECTING DIAGRAM, PLACEMENT CHART, AND PHOTOS TO MATCH

THE NUMBER IN THE CIRCLES WITH THOSE IN THE FOLLOWING DATA FOR SERVICE

CHECKS TO BE PERFORMED

©©

©

©

PRINTER DEAD

(a) Check Fuse F1. If bad, disconnect the Power

Transformer (T1) connectors CN2 and CN7. Check

for shorted windings or shorts from the windings

to the chassis. Replace Transformer T1 if bad.

(b) If Transformer T1 is good, disconnect connector

CN6 (On Control Board) and check the Regulator

Transistor (Q6) with atransistor tester. If Tran-

sistor Q6 is good, replace or troubleshoot the Con-

trol Board and the Driver Board.

(c) If Fuse F1 is good, apply AC power and check for

120VAC at pins 1and 2of connector CN7. If

120VAC is missing, check the AC Power Cord (P1)

and Master Power Switch (SW10).

(d) If 120VAC is present, disconnect connector CN2

and check the following AC voltages on the secon-

dary windings of Transformer T1 at connector

CN2. 9.83VAC at pins 1to 2, 25.8VAC at pins 3to 4,

10.33VAC at pins 5to 6and 16.63VAC at pins 7 to 8.

If any voltages are missing, replace Transformer

T1. If the voltages are good, replace or

troubleshoot the Control Board and the Driver

Board.

WILL NOT RECEIVE DATA FROM COMPUTER

(a) Check Microcomputer IC (1C) and Interface IC (8B)

by substitution.

PRINT HEAD WILL NOT PRINT

(a) Remove power. Check resistance of the print head

solenoids from pin 7 of connector CN10 to pins 1

thru 5and 9thru 12 of connector CN10 (23 ohms

each). If bad, replace the Print Head (H1). If good,

check the connections and wiring from connector

CN10 to connector CN6 (On Driver Board).

(b) If the connections are good, check the Interface IC ©

(8B) by substitution.

@PRINT HEAD HAS MISSING DOTS

(a) Check the print head solenoid resistance (23

ohms) of the solenoid producing the missing dot

(See Wiring Diagram). If the solenoids check good,

remove the Print Head and check the print head

wires for possible damage.

(b) If the print head is good, check the Microcomputer

IC (1C) and Interface IC (8B) by substitution.

PAPER FEED AND TIMING BELT MOTORS DO NOT

FUNCTION

(a) Check for 26.3V at pin 10 of connector CN6 (On

Driver Board). If 26.3V is missing, remove power

and check the Regulator Transistor (Q6) with a

transistor tester. If Transistor Q6 is good, replace

the Control Board or troubleshoot the power sup-

ply section on the Control Board.

(b) If 26.3V is present, check the Microcomputer IC

(1C) and Slave Microcomputer IC (9B) by substitu-

tion.

(c) If IC's 1C and 9B are good, remove power and

check the resistance of the motor windings (48

ohms each winding). Check the Timing Belt Motor

Assembly C(M1) from pin 13 of connector CN6 (On

Driver Board) to pins 21 thru 24 of connector CN6.

Check the Paper Feed Motor Assembly A(M2) from

pin 14 of connector CN6 to pins 25 thru 28 of con-

nector CN6.

(d) If the motors check good, check the Home Posi-

tion Sensor (PT1) by monitoring pin 20 of connec-

tor CN6 (On Driver Board) with alogic probe while

sliding apiece of paper in and out of the slot in the

Home Position Sensor. The probe should read low

with the paper out of the slot and high with paper

in. If the readings are not correct, check for 2.37V

at pin 12 of connector CN6. If 2.37V is present,

replace the Home Position Sensor (PT1). If 2.37V is

missing, replace or troubleshoot the Driver Board

and the Control Board.

(e) If the Home Position Sensor is good, check the

PTS (Position Timing Sensor) (PT2) by checking for

pulses at pin 19 of connector CN6 while manually

moving the Print Head. If no pulses appear,

replace the PTS Sensor (PT2). If pulses appear,

replace or troubleshoot the Control Board.

FUNCTION BOARD BUTTONS HAVE NO EFFECT

(a) Check connector CN1A for good connection.

(b) Remove power and check contacts of Switches

SW1A, SW2A and SW3 (On Function Board) with

an ohmmeter.

(c) If the IC's are good, replace or troubleshoot the

Control Board and the Driver Board.