ESCO EURO BEAD BREAKER Model #10107

Troubleshooting

SYMPTOM PROBABLE CAUSE RESOLUTION

Check air supply.Rods extend too slowly. Insucient hydraulic pressure

frompump. Check clearanceofinlet check ball. Ball must

beush with or below end of lter adapter.

Hydraulicpump does not

release. Dirtunder pedal inreleasevalve area. Clean

pedal.

Bearing is misaligned on

breakerrod. Correct or replace.

Rods failto retract.

Broken or weak springs. Replace.

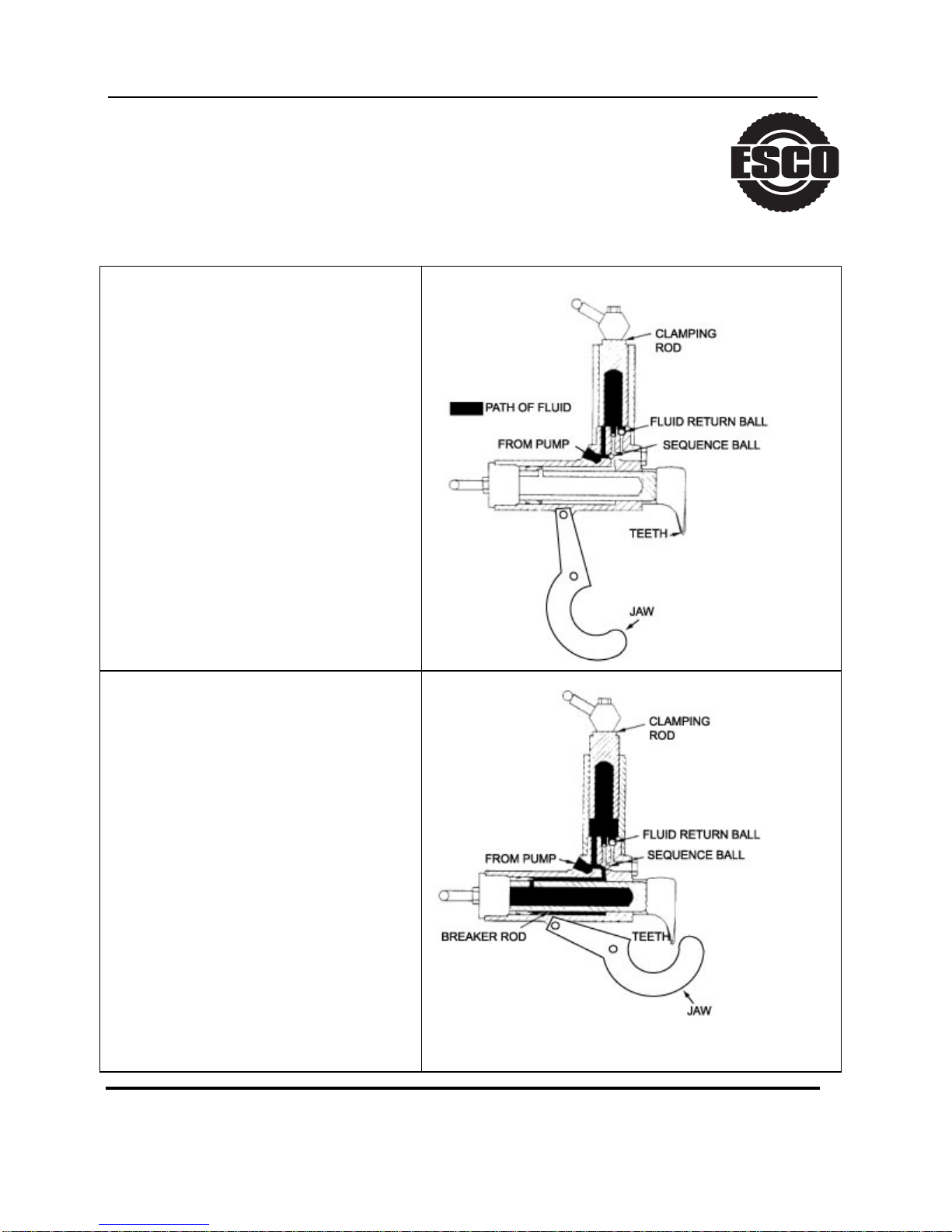

Sequence ball not seated,or

springis broken or weak. Correct or replace.Both rods extend at the

sametime. Hydraulic

pressure in breaker cylinder

isnot being released. Loose screw and ball not

seated. Correct or replace.

Fluid return ball did not restart. Correct or replace.

Dirt plugging return port. Clean port.

Breaker rod retracts after

clampingrod. Hydraulic

pressure in breaker cylinder

isnot being released. Weak or broken spring in

breakercylinder. Replace.

Airpiston stuck. Checkcylinder bore of pump for contamination

or lack of lubrication.

Pump does not reciprocate.

Piston poppet not sealing. Replace.

Pumpreciprocates. Ram

willnot extend.

Check prime. Depress both air valveand hydraulic release

valve at the same time.

Outlet check ball not sealing

properly. Correct or replace.Pump extends ram but will

nothold system pressure. Release valve mechanism not

sealingproperly. Checkpin, ball, release poppet,and poppet

retainer. Correct or replace.

Check air supply. 5 - 10 CFM at 100 PSI

Release valve mechanism.

Low relief valve setting.

Pump extends ram but will

not build to maximum

pressure. Novisible sign of

leakage.

Check for internal leakage.

Inletcheck ball not seatingproperly. Correct or

replace.

Replace copper gasket and assemble in

vertical position.

Pump extends ram but will

not build maximum pressure.

Visiblesign of leakage

through exhaust muer.

Check piston sub-assembly.

Replace piston packing.