Table of ontents

Safety Instructions...........................................................................................................................5

1. Overview......................................................................................................................................8

2. PCB View with Connectors and LE s..........................................................................................9

2.1 LE isplay ..........................................................................................................................9

3. Connector Assignment...............................................................................................................10

3.1 CAN Connector....................................................................................................................10

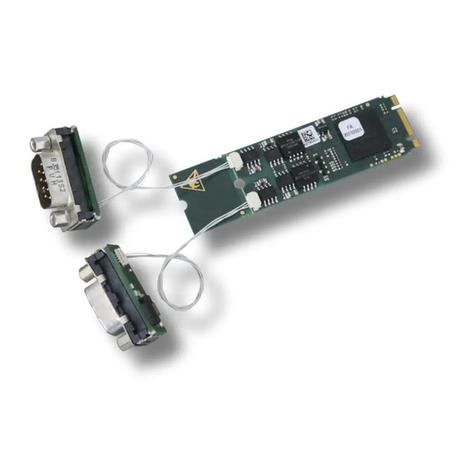

4. Adapter CAN-PCIeMini/402- SUB9 and Adapter Cable.............................................................11

4.1 Adapter View........................................................................................................................11

4.2 CAN Termination Jumper.....................................................................................................11

4.3 Connector Assignment of Adapter.......................................................................................12

4.3.1 CAN via SUB9..........................................................................................................12

4.3.2 CAN Cable Connector.................................................................................................12

4.4 Adapter cable.......................................................................................................................12

5. Hardware Installation..................................................................................................................13

6. Technical ata............................................................................................................................15

6.1 General Technical ata........................................................................................................15

6.2 Memory................................................................................................................................15

6.3 PCI Express Mini Interface...................................................................................................15

6.4 CAN Interface......................................................................................................................16

6.5 CAN-PCIeMini/402- SUB9 Adapter....................................................................................16

6.6 Software Support.................................................................................................................17

6.6.1 CAN-PCIeMini/402-2...................................................................................................17

6.6.2 CAN-PCIeMini/402-2-F .............................................................................................17

7. Correct Wiring of Electrically Isolated CAN Networks.................................................................18

7.1 Standards concerning CAN Wiring......................................................................................18

7.2 Light Industrial Environment (Single Twisted Pair Cable).....................................................19

7.2.1 General Rules.............................................................................................................19

7.2.2 Cabling........................................................................................................................20

7.2.3 Branching....................................................................................................................20

7.2.4 Termination..................................................................................................................20

7.3 Heavy Industrial Environment ( ouble Twisted Pair Cable).................................................21

7.3.1 General Rules.............................................................................................................21

7.3.2 evice Cabling............................................................................................................22

7.3.3 Branching....................................................................................................................22

7.3.4 Termination..................................................................................................................22

7.4 Electrical Grounding.............................................................................................................23

7.5 Bus Length...........................................................................................................................23

7.6 Examples for CAN Cables...................................................................................................24

7.6.1 Cable for light industrial Environment Applications (Two-Wire)....................................24

7.6.2 Cable for heavy industrial Environment Applications (Four-Wire)................................24

8. CAN Troubleshooting Guide.......................................................................................................25

8.1 Termination..........................................................................................................................25

8.2 Electrical Grounding.............................................................................................................26

8.3 Short Circuit in CAN Wiring..................................................................................................26

8.4 CAN_H/CAN_L-Voltage ......................................................................................................26

8.5 CAN Transceiver Resistance Test........................................................................................27

8.6 Support by esd.....................................................................................................................27

9. eclaration of Conformity...........................................................................................................28

10. Order Information.....................................................................................................................29

10.1 Hardware...........................................................................................................................29

10.2 Software for CAN-PCIeMini/402-2.....................................................................................29

10.3 Software for CAN-PCIeMini/402-2-F ...............................................................................30

10.4 Manuals.............................................................................................................................30

CAN-PCIeMini/402-2(-F ) Hardware Manual • oc. No.: C.2044.21/ Rev. 1.1 Page 7 of 30