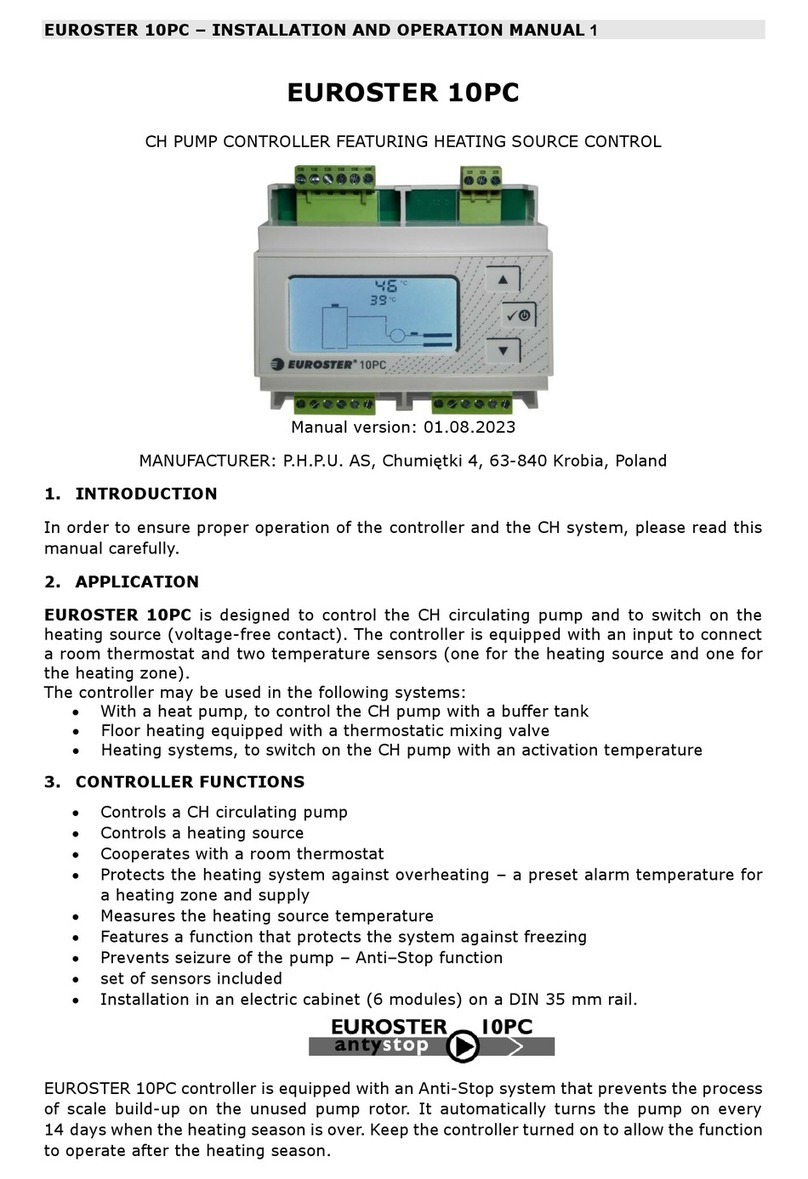

EUROSTER UNI2 User manual

EUROSTER UNI2 – INSTRUCTION MANUAL 1

EUROSTER UNI2

Weather-based heating system c ntr ller

MANUFACTURER: P.H.P.U. AS, Chumiętki 4, 63-840 Kr bia

Please read the instruction manual carefully to fully use the controller potential and to ensure

proper operation of central heating system.

Manual version: 01.08.2016

1. APPLICATION

UN 2 is a universal controller designed for heating systems equipped with:

two central heating circuits with mixing valves (e.g. for heater supply and floor heating)

domestic hot water (DHW) circuit

DHW circulation circuit

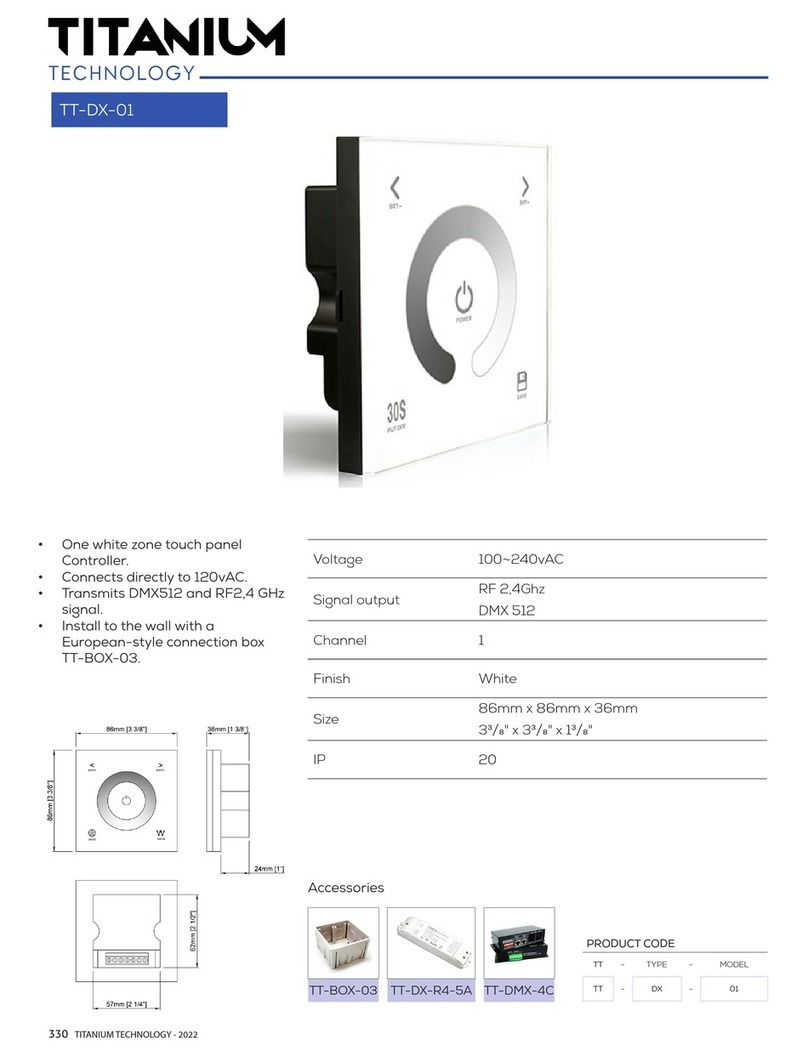

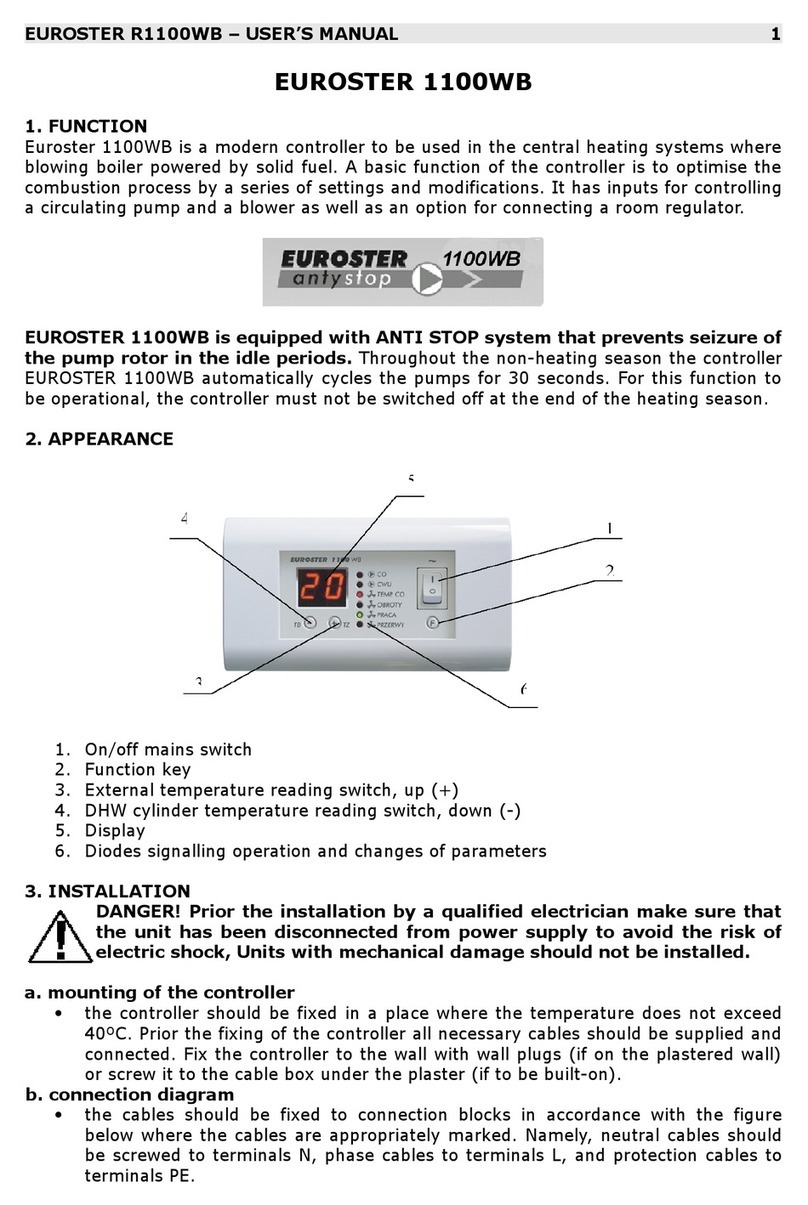

1. External temperature sensor

2. Room control unit for circuit 1

3. Temperature sensor for circuit 1

4. Central heating pump for circuit 1.

5. Mixer for circuit 1

6. Supply temperature sensor

7. Room control unit for circuit 2

8. Temperature sensor for circuit 2

9. Central heating pump for circuit 2.

10. Mixer for circuit 2

11. Feed pump for DHW tank

12. Temperature sensor for DHW tank

13. DHW circulation pump

14. Temperature sensor for DHW

circulation

EUROSTER UNI2 – INSTRUCTION MANUAL 2

2. FUNCTIONS

2.1. Central Heating Circuits

independent setting of temperature and weather curve for each circuit

independent control of each circuit with room control unit and weekly schedule

ability to disable circuits,

manual or automatic switching of summer/winter seasons – ability to set the start and

end dates of the heating season

selection of circuit operation: by switching the pump on and off or by lowering the

temperature with a mixer when the pump is continuously switched on

work with floor heating distributor

ability to switch on the anti-frost mode

2.2. DHW Circuit

control of weekly schedule

DHW priority

temporary limitation of DHW priority

disinfection of DHW circuits

2.3. DHW Circulati n Circuit

control of weekly schedule

time or temperature-based control of circulation

2.4. C mmunicati n

possibility to combine several UN 2 and UN 3 controllers

common weather sensor

common supply temperature sensor

common (one) boiler control output

common (one) control output for audible alarm

enabled remote reading of temperatures and status of transmitters (with the use of a

special converter and software)

2.5. Utility Functi ns

control of gas or other heating device using an auxiliary potential-free output (normally

closed relay contact)

alarm output (230V 50Hz output)

event log (the controller records 100 most recent alarms or irregularities)

language support: Polish, English, German and Czech

ability to test each output

overheating protection

work with systems with high supply temperature (up to 120°C) – at customer's request

freeze protection

Anti-Stop algorithm – protection of pumps and valves against wear

3. USER INTERFACE

3.1. Main Screen

The main screen shows the following information:

Circuit temperatures: current and set (e.g. calculated based on the weather algorithm)

devices switched on (pump, mixer, boiler)

controller status (anti-stop, disinfection, heating season: W NTER/SUMMER and others)

time and date

Example of screen with description is shown below.

EUROSTER UNI2 – INSTRUCTION MANUAL 3

The symbols shown in the controller mean the following:

pump operation

mixer operation

heating switched on by room control unit

active Anti-Stop algorithm

error

lack of communication

DHW disinfection

boiler input switched on

DHW priority function switched on

AF – fr st pr tecti n turned n

3.2. Multifuncti n Kn b

The control is operated with a multifunction knob. n addition to a rotary face used to change

the set value, it contains 4 buttons used for navigation (between menu items: up, down, next,

previous) and a confirm button, located in the middle of the knob, which also clears the display

of alarm warnings.

CAUTION! When the setting is changed, the new value is remembered after

c nfirmati n with middle r right butt n.

3.3. Light-emitting Di de

A light-emitting diode is located on the left-hand side of the display. Respective colors mean

the following:

green: Operation without errors

red: Error has occurred

blue: Active Menu

yellow: Output test mode

in case the communication is switched on a diode is flashing when the information are

transmitted between the controllers

3.4. Reset and rest ring fact ry settings

To restart a controller press Reset button, use e.g. a toothpick or a pen. Using reset does not

delete settings.

To restore factory settings, press Reset button and hold it for at least 5 s, until “Restoring

factory settings” is displayed.

After restoring factory settings language selection menu is displayed and operation parameters

of the system circuits must be set up again.

3.5. List screens

The controller settings are arranged hierarchically, based on the circuit -> parameters order.

Only the basic settings are available for the user. Advanced options are included in "Settings"

and are protected with an access code.

3.6. Setting Screens

Selected parameters with commentaries are shown below.

EUROSTER UNI2 – INSTRUCTION MANUAL 4

3.6.1. User settings

CH1 circuit

schedule

t can be used to switch off the circuit for selected time on selected days of the week.

circuit temperature

t is the circuit temperature maintained with the use of the mixer. Three settings: for

-20, 0, +10 for work with the weather compensator. One setting for work without the

weather compensator.

CH2 circuit

parameters identical to the CH1 circuit

DHW circuit

schedule

t can be used to switch off the DHW circuit for selected time on selected days of the

week.

DHW temperature

t is the tank temperature to be maintained by the controller.

thermal cleansing f DHW

The proper cleansing consists in heating the DHW tank to the temperature of 70°C and

flushing the pipes with hot water.

Turning the thermal cleansing on enables heating of the tank to the temperature of

70°C and turning on the flow in the circulation circuit.

CAUTION! F r the pr per thermal cleansing, the minimum alarm temperature

f the DHW sh uld be 80°C.

DHW circulati n circuit

schedule

t can be used to set the time of DHW circulation circuit operation on selected days of

the week.

circulati n temperature

The circulation pump is turned on when the temperature of the circulation sensor drops

below the preset circulation temperature by the hysteresis value.

This option is active only if the temperature-based control of circulation is set.

Heating seas n

Turning the heating season off results in switching off CH circuits. The DHW circuits work

normally.

W NTER sign is displayed to indicate activation of the heating season and SUMMER is

displayed to indicate its deactivation.

Aut

This function enables automatic turning on and off for the heating season according to

the preset start and end dates.

nformation on the date and time is used by a schedule algorithm and events log.

turning n/ ff

This parameter enables to turn the heating season on or off manually.

Date and time

This window enables to enter a current date and time. Please remember that only correct

settings enable a proper operation of the schedules and controlling algorithms as well as

events log.

Settings

Entering advanced settings (installer settings).

3.6.2. Installer settings

The installer settings are available after entering the access code. The default c de is “1, 2,

3”.

CAUTION! It is rec mmended t rest re fact ry settings bef re c nfiguring a new

EUROSTER UNI2 – INSTRUCTION MANUAL 5

c ntr ller.

Settings f r CH1 heating circuit and identical nes f r CH2 circuit

turning the circuit n/ ff

This item enables to turn off the unused circuit.

Mixer

turning the mixer n/ ff

This option enables to turn the mixer control off if it is not used in the CH circuit.

n such case the (current and preset) temperatures are not displayed for the

particular circuit.

When operating with turned off mixer the functions responsible for controlling

the temperature and the continuous operation function are not available. The

circuit overheating protection is unavailable as well.

mixer dynamics

Determines the mixer response time to changes in the circuit temperature. An

excessive value may cause frequent cycling of the mixer, whereas the insufficient

value may cause slowness in achieving the preset temperature.

mixer hysteresis

f the measured temperature of the circuit differs from the preset one by half of the

value of the preset hysteresis, then the mixer position is not corrected.

alarm temperature

CAUTION! Alarm temperatures f r all circuits sh uld be selected carefully.

Inc rrect setting f temperature level may cause impr per perati n r maj r

failure f the system c mp nents.

The alarm temperature should be preset as the maximum safe temperature for a

particular circuit.

r m c ntr l unit

This item enables to turn off the inputs of room control units. n such case heating will

be switched on regardless of control units request.

c ntinu us perati n, reducti n f CH temperature

n certain cases continuous operation of the central heating pump is recommended

regardless of whether the room is fully heated or not. n such case the “continuous

operation” option should be activated. Heating is then switched off by reducing the

temperature of the heating medium with the mixer, without switching the pump off.

The circuit temperature is reduced by the value determined with the “CH temperature

reduction” parameter.

When the “continuous operation” option is turned off, the pump will be turned off once

the mixer is closed (when the room control unit or schedule requests the circulation

turn-off).

The pumps are also switched off when the supply temperature drops below the

shutdown temperature.

weather c ntr l unit

The weather control allows for achieving thermal comfort, regardless of the external

temperature. t is only required to connect an external temperature sensor.

Once the weather control is activated, the central heating circuit temperatures should

be set for three external temperatures. On their basis the controller calculates the

currently required circuit temperatures every 10 minutes.

CAUTION! Temperatures must meet the c nditi n T10ºC ≤ T0ºC ≤ T-20ºC,

therwise the c ntr l will n t w rk pr perly.

EUROSTER UNI2 – INSTRUCTION MANUAL 6

fr st pr tecti n, anti-fr st temperature

The anti-frost algorithm is activated when the temperature of the particular circuit

sensor drops below the preset level. n such case both the boiler and the pump are

activated. The schedule settings do not affect the operation of this protection.

CAUTION! The pr tecti n is disabled by default.

sens r c rrecti n

CH1 or CH2 circuit sensor correction allows to correct temperature reading errors, such

as the ones resulting from improper contact between the sensor and the pipe.

test

The test option allows to switch on the connected devices manually. For safety reasons,

when the selected output is being tested, all other outputs are switched off.

Settings f r DHW circuit

turning the circuit n/ ff

This item enables to switch off the DHW circuit if it is not used.

hysteresis

t is a difference between the temperature at which the tank supplying pump is turned

off and turned on.

excess f DHW

The “excess of DHW” parameter determines the value by which the temperature of the

heat source must exceed the temperature of the tank. Setting a higher temperature

ensures an adequate heating capacity and compensates the heat loss due to the

imperfect insulation of pipes connecting the boiler and the tank.

f the temperature of the heat source is not sufficiently high, then the DHW tank

supplying pump is not switched on.

DHW pri rity

Switching on of the DHW priority means that the controller switches off the CH circuits

for the time of DHW heating in order to achieve the temperature preset for the tank as

fast as possible.

n case of operation with active communication mode, the circuits to perform DHW

priority must be selected in the communication menu.

pri rity perati n time, pri rity break time

Time limit for the DHW priority operation prevents excessive cooling of rooms when the

tank may not be properly heated in a reasonable time.

Non-zero priority break time must be set to use this function.

The DHW tank is heated for the time preset by the “priority operation time” parameter (

symbol active on the display screen), then the DHW priority is switched off for the

“priority break time” ( symbol flashing on the display). Subsequently, the DHW

priority is switched on again.

alarm temperature

f the tank is fed by another, additional heat source and if the tank temperature

exceeds the alarm temperature, then the controller switches on the DHW pump which

cools the tank. The pump is switched on only if the feeding temperature is lower than

the preset alarm temperature of the DHW tank. t is indicated with an error of DHW

overheating.

When using hot water special precautions must be taken in order to avoid burning.

fr st pr tecti n

The anti-frost algorithm is activated when the temperature of the DHW circuit sensor

drops below the preset level. n such case the boiler and the pump are switched on and

“AF” symbol flashes on the display. The schedule settings do not affect the operation of

this protection.

sens r c rrecti n

DHW circuit sensor correction allows to correct temperature reading errors, such as the

ones resulting from improper contact between the sensor and the pipe.

test

The test option allows to switch on the connected devices manually. For safety reasons,

when the selected output is being tested, all other outputs are switched off.

EUROSTER UNI2 – INSTRUCTION MANUAL 7

Settings f r DHW circulati n circuit

turning the circuit n/ ff

This item enables to switch off the circulation circuit if it is not used.

C ntr l

temperature-based c ntr l f circulati n

Circulation may operate according to time or temperature parameters.

n case of temperature-based control, the circulation pump is running until the

temperature of the circulation temperature sensor reaches the preset value.

perati n time, circulati n break time

The parameters used only in the case of temporary control of circulation. The

pump operation and idle times are preset.

fr st pr tecti n

t is activated if the temperature of the circulation sensor drops below the preset level.

n such case the boiler and the circulation pump are switched on and “AF” symbol

flashes at the display.

sens r c rrecti n

Circulation circuit sensor correction allows to correct temperature reading errors, such

as the ones resulting from improper contact between the sensor and the pipe.

test

The test option allows to switch on the connected devices manually. For safety reasons,

when the selected output is being tested, all other outputs are switched off.

Supply

shutd wn temperature

The controller operates only when the supply temperature is higher than the shutdown

temperature. t is aimed at reducing consumption of electricity.

shutd wn hysteresis

t is a parameter which is added to the preset shutdown temperature in order to

determine the temperature on the basis of which the controller switches on the heating

circuits, e.g.

shutdown temperature – 30°C, shutdown hysteresis – 5°C, the controller turns on the

heating circuits when the supply temperature reaches 35°C.

excess f supply

The excess of supply parameter determines by how much the supply temperature

should exceed the temperature calculated by the controller for circuits. t allows the

user to set the proper temperature at the boiler (temperature item required for supply).

supply alarm temperature

f the alarm temperature is exceeded at the supply, the alarm algorithm is activated to

attempt to cool down the boiler.

CAUTION! The alarm alg rithm heats circuits t temperatures appr ximate t

alarm temperatures. It is imp rtant t ensure safe level f alarm temperature

f r each circuit.

Fr st pr tecti n

f the temperature of the supply sensor drops below the preset temperature, the

controller switches on the transmitter, which controls the boiler, and “AF” sign flashes

on the display.

supply sens r c rrecti n

Supply temperature sensor correction allows to correct temperature reading errors,

such as the ones resulting from improper contact between the sensor and the pipe.

C mm n

external sens r c rrecti n

Correction allows to correct temperature reading errors, such as the ones resulting from

improper location of the sensor.

audible alarm

The “audible alarm” all ws t switch ff audible alarms generated by the

c ntr ller. This d es n t affect the perati n f the alarm utput.

C mmunicati n

switching n/ ff

EUROSTER UNI2 – INSTRUCTION MANUAL 8

Enables t switch n c mmunicati n c ntr l. D n t switch n

c mmunicati n when the c ntr llers are n t c nnected int a netw rk.

device addresses

Enables to determine the addresses of the individual inputs and outputs.

Device addresses Descripti n

Pr per Physical address of the particular controller (identifier). Range

from 1 to 247. For the proper functioning each controller in the

network must have a unique address assigned.

Supply sens r dentifies a controller that feeds a supply temperature. t may be

a proper address or an address of another controller.

External sens r dentifies a controller that feeds an external temperature. t may

be a proper address or an address of another controller.

B iler utput dentifies a controller with a boiler output active. t may be a

proper address or an address of another controller.

Alarm utput dentifies a controller with an alarm output active. t may be a

proper address or an address of another controller.

DHW-CH1, CH2 pri rity

n case of connecting UN 2 and UN 3 controllers and using DHW priority

function, it is possible to define, which circuits are to operate the DHW tank

feeding priority. The priority switched on – a particular circuit will be switched off

during feeding of the DHW tank; the priority switched off – a particular circuit

operates according to its settings while feeding DHW tank.

CAUTION! If nly ne UNI c ntr ller is perating in the system, r c nnecti n f

independent supply and external sens rs f r each c ntr ller is n t pr blematic, then

the c mmunicati n sh uld n t be switched n. Installing the c ntr ller functi ns as

parallel t each ther will impr ve reliability f the wh le system.

Each controller in the network must have a unique address – identifier assigned. During the

manufacturing process randomly selected addresses are assigned to each controller, however

each system is different and generally requires assigning its own addresses.

Assigning an address in the field of the chosen temperature sensor indicates which controller

will feed the measured temperature. t may be a proper address or an address of another

controller.

More information is included in “ nstallation” Chapter.

events

The device records hazardous events. The display screen shows the following: Event

number (from the time of installation), date, time, and comment, for example:

30. 19-09 14:16:38 DHW overheat

versi n

You must indicate the software version number when contacting the technical support

center. These are two dates.

A: 23:07 24/4/2014 – display driver program

B: 10:08 10/2/2014 – relay driver program

EUROSTER UNI2 – INSTRUCTION MANUAL 9

4. INSTALLATION

4.1. C nnecti n

GENERAL SAFETY RULES

It is necessary t read this user manual carefully pri r t the c mmencement

f the installati n w rks. Inc rrect installati n and impr per use may lead t a

seri us hazard t a user r ther pers ns and result in material damage! Pri r

t m unting r dismantling and maintenance f the c ntr ller, make sure that

it is de-energized!

Danger us v ltages, hazard us t life, may be present n the c ntr ller and

its cables, theref re nly qualified technicians h lding auth rizati n f r

electrical w rks may be entrusted with the installati n f the c ntr ller!

D n t install the c ntr ller in r ms f increased humidity, substantial

dustiness r with presence f caustic r flammable vap rs, pr tect

it against water and ther liquids!

D n t install any c ntr ller sh wing signs f mechanical damage.

The c ntr ller is n t a safety c mp nent f the heating system in the systems

with a risk f damage.

In the case f failure f c ntr l systems, use additi nal pr tective equipment.

Pay careful attenti n t c rrect c nnecti n f pr tective c nduct rs (PC) when

c nnecting p wer cables!

D n t misuse the c ntr ller!

The device is n t intended f r use by children!

Failure t meet the safety and maintenance rules results in l ss

f warranty!

Temperature sens rs are n t adapted t immersi n in liquids.

The c ntr ller w rks nly with actuat rs equipped with limit switches.

The controller should be installed in a location where the temperature does not

exceed 40°C. All the necessary cables should be brought before mounting. The controller is

designed for mounting on a 35mm D N rail. t is recommended to install the controller in a

protective cabinet.

Electrical conductors must be screwed to cubes in accordance with description and drawing,

with proper labeling of wires. Neutral conductors should be screwed to N terminals, phase

conductors to L terminals, and protective conductors to PE terminals. Conductors with cross-

section of at least 0.75mm² should be used for connection.

The controller is equipped with six temperature sensors. There is no need for connecting the

sensors related to circuits / functions that are switched off.

The sensors can be freely connected to the controller, without the need to maintain cable

polarity. During assembly, the sensors should not be lead in parallel with electric conduits

under voltage. t should also be kept in mind to ensure proper contact with the measured

surfaces.

External temperature sensor should be placed in a shaded area, away from windows and

doors, at a height of approximately 2 m above the ground.

Similarly, the support of room control unit may be activated or deactivated for each heating

circuit. t is allowed to switch off control units with n rmally pen dry c ntact. We

recommend the use of Euroster devices.

N te! Eur ster Uni2 c ntr ller and the heating device c nnected t the "B iler"

utput must be p wered fr m the same p wer system phase.

EUROSTER UNI2 – INSTRUCTION MANUAL 10

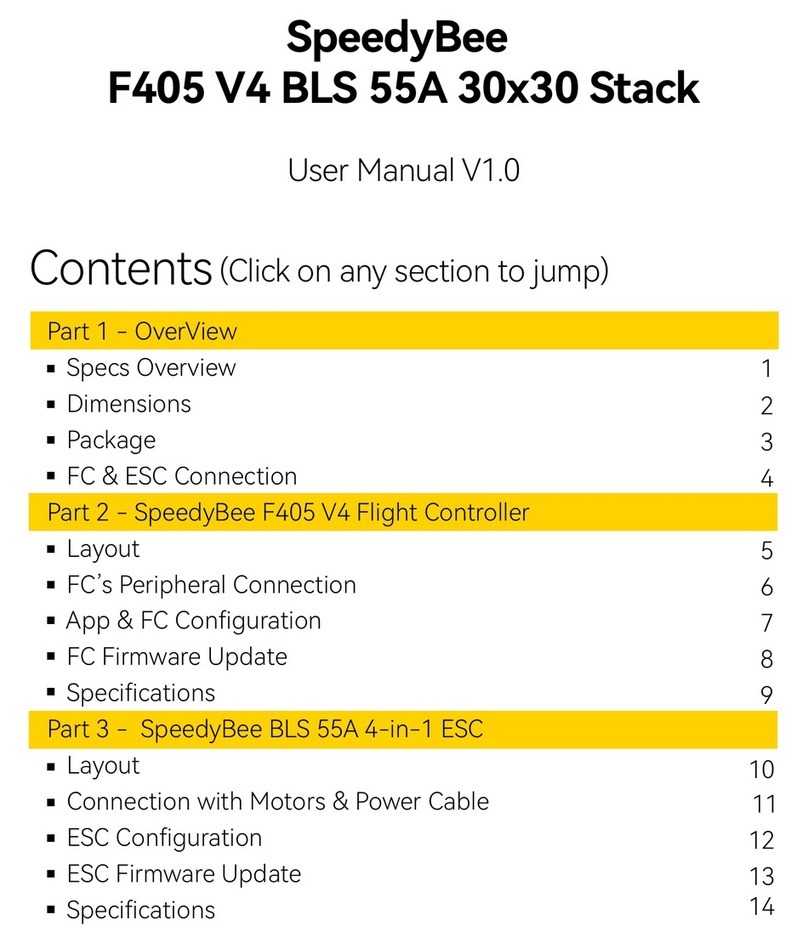

The connection diagram is shown below.

4.2.Maintenance

Before each and every heating season, the controller must be cleaned of any dust and dirt, the

cables must be checked for tight fixing. f necessary, wipe it carefully with a soft cloth. Do not

use solvents and aggressive detergents since they may damage the surface of the housing and

the display. Avoid contact with water or other liquids.

4.3. C mmunicati n

4.3.1. RS-485 c nnecti n

UN 2 controller is equipped with a possibility to communicate with use of RS-485 interface. The

connection should be made with use of a shielded twisted pair in bus topology. A, B and GND

terminals of the controller should be connected with A and B cables of the bus and a shield

(figure).

The controllers are equipped with a linear polarization and return loss system. t is sufficiently

effective in case of short connections. With connections of several hundred meters, termination

resistors with resistance of 120 Ω should be placed at both ends.

EUROSTER UNI2 – INSTRUCTION MANUAL 11

4.3.2. Address all cati n

After connecting a twisted pair, activate the communication and select the addresses of

controllers in all connected controllers. Each of the controllers must be provided with a

different address. t is advised to write down the addresses in a visible place in a boiler room,

which will facilitate the configuration process.

4.3.3. B iler c ntr l

The communication feature enables to control the boiler with the use of one controller output.

The boiler will be switched on by any controller in the network.

UN 3 operates additional heat sources. This function is strictly connected with controlling the

main boiler and is not operated by the communication protocol (it does not feature in UN 2).

Therefore, in case of using an additional heat source, the operation of the additional heat

source must also be switched on in the controller that switches on the main boiler. n other

words, the main boiler must be connected to the output of the same controller, to which the

sensor of the additional heat source is connected.

Moreover, in other controllers the parameter of boiler output to the address of the controller

which controls the boiler should be set.

Sample configuration of UN 2 and UN 3 controllers connected to each other:

Address UNI2 UNI3 Descripti n

Pr per 1 2 Unique address of each of the devices.

Supply sens r 1 1 A common supply sensor connected to UN 2

controller is used.

External sens r 2 2 A common supply sensor connected to UN 3

controller is used.

B iler utput 1 1 A common boiler switch-on output in UN 2 controller

is used.

Alarm utput 1 2 Alarm outputs are individual in each controller

separately (assigned proper addresses).

5. CONTROLLER OPERATION

CAUTION! Once the c ntr ller is switched n the Anti-St p alg rithm is activated

(pump and mixer utputs are switched n f r 30 s). The Anti-St p m de is repeated

every tw weeks, regardless f the heating seas n.

5.1. Supply temperature

UNI2 c ntr ller d es n t affect the temperature at the b iler (system supply).

H wever, it calculates it and sh ws it n the display, and the user sh uld ensure that

the supply temperature exceeds the temperature currently required by the c ntr ller

EUROSTER UNI2 – INSTRUCTION MANUAL 12

(alth ugh d es n t exceed the alarm temperature). Otherwise, it is n t p ssible t

maintain pr per temperatures in the system.

5.2. Heating Circuits

Heat in the selected circuit is activated if:

the CH circuit is switched on

the heating season mode is on (W NTER)

the current time is indicated in the schedule of the selected circuit

the room control unit is switched on or work with room control unit is off

the DHW tank is heated or the DHW priority is off

the supply temperature is higher than required

Normally, the circulation pump is switched on when the heating is switched on and the mixer is

not closed. However, if the "continuous operation" is switched on, the pump runs continuously,

while the room temperature is achieved by adjusting the circuit temperature. Details are

described in Section "3.5.3. nstaller Settings".

CAUTION!

The temperature set for the CH circuit is not displayed when:

CH circuit is switched off

the room control unit has reached the set temperature and has switched off the circuit

break in the schedule work of the selected circuit is set

DHW priority function is active

5.3. DHW Circuit

Heating of the DHW tank is on if:

the DHW circuit is switched on

the current time is indicated in the DHW schedule

the tank temperature is too low

the supply temperature is adequate

5.3.1. Disinfecti n f the DHW System

Maintaining low temperature of DHW (approximately 40ºC) may lead to development of

bacterial flora in the system. The following must be done in order to carry out disinfection:

turn on disinfection at the controller

ensure that the supply temperature is not lower than the temperature indicated by the

controller – heating of tank and circulation circuit is initiated

when the tank is properly heated the controller shows the "Disinfection complete"

message

open taps and flush the system with hot water (be careful – possible burn)

5.4. DHW Circulati n

Circulation circuit is active when:

the circulation circuit is switched on

the current time is indicated in the circulation schedule

the supply temperature is adequate

and during disinfection

The circulation pump works in accordance with the set work and break times, or if the

temperature of circulation sensor is too low.

5.5. Alarm Output

The alarm output is used to connect an additional, external alarm signaling device.

Voltage is applied to the alarm output in the case of sensor failure, circuit overheat, or other

errors.

CAUTION! The alarm signaling device must be adjusted t v ltage in 230V netw rk.

At the same, relevant information will appear on the display screen, along with the time of

error.

EUROSTER UNI2 – INSTRUCTION MANUAL 13

5.6. B iler Output

The Boiler output is used to switch on the heat source, for example gas boiler. t is equipped

with 3 contacts, marked NC, NO and COM. They are galvanically isolated from the rest of the

system. They withstand a network voltage of 230V and a load of 4A.

The boiler output is switched on if it is necessary to heat any of the circuits.

CAUTION! The utput status is n t affected by the supply temperature.

5.7. The perati n f the c ntr ller in arrangement with ut supply temperature

sens r

n case if supply temperature sensor is not used, RZ resistors (included in the kit) with 1K5

value should be installed instead.

The temperature at the supply part of the heating system will be approximately 83°C, which

will enable the correct operation of all algorithms.

6. POSSIBLE ERRORS IN THE CONTROLLER OPERATION

6.1. The selected circuit d es n t pr vide heat – cl sed valve r deactivated pump

Check:

whether the heating season mode is activated

whether a correct date (day of the week) and time is set

whether heating is active in the schedule for the current day of the week and time

in a system equipped with a weather sensor – whether indication of external

temperature is correct and whether the temperatures are set correctly

whether DHW with priority is activated

in a system without a room control unit – whether it is deactivated in the controller

in a system with a room control unit – whether it is activated and properly connected to

the controller

whether the mixer is not connected inversely and whether it is not jammed

6.2. The selected circuit is verheating

Check:

whether the valve is not stuck

whether the mixer actuator is running

whether the actuator conduits are connected properly

the mixer dynamics value

6.3. "Aut matic reset" message

dentify the conditions under which the reset takes place. Check the software version. Contact

the technical support centre.

6.4. Lack f c mmunicati n (in case if c mmunicati n is switched n)

Check:

if the communication is switched on

if there is a unique address assigned to each controller

if the entered addresses of the sensors and outputs correspond to the addresses of the

controllers

if the voltages on A and B (RS-485) terminals in all controllers with no twisted par

connected are similar to the voltages of the twisted par

EUROSTER UNI2 – INSTRUCTION MANUAL 14

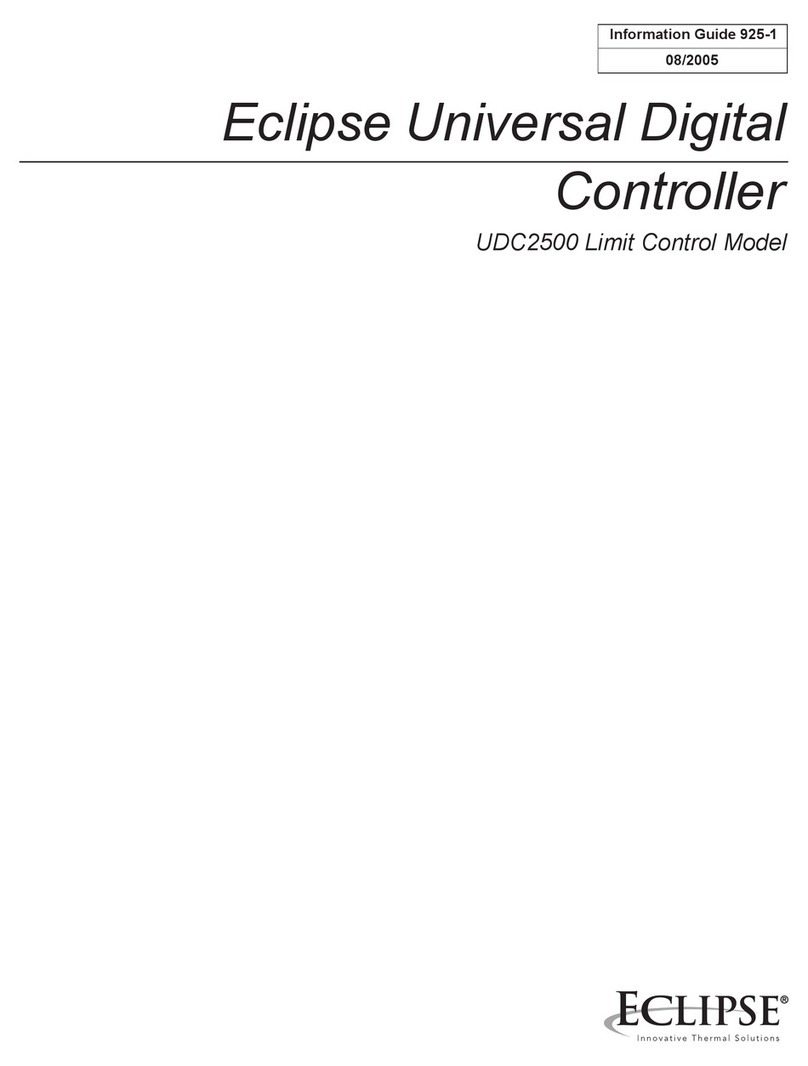

7. DIMENSIONS

8. TECHNICAL DATA

Power supply: 230 V 50 Hz

Maximum power consumption: 4W

Maximum output load: 100W (each output)

Temperature adjustment range:

CH circuits: 15°C to 90°C

DHW circuit: 40°C to 75°C

DHW circulation circuit: 20°C to 50°C

Temperature measurement range: -30°C to 120°C

Accuracy of temperature control and readings: 1°C

Work temperature range: 0-40°C

Storage temperature range: 0-55°C

Protection rating: P20

Colour: grey, RAL7035

Assembly: on a 35mm D N rail, in protective enclosure

Alarm output: 230 V 50 Hz

Boiler output: potential-free, normally closed, maximum load of 4A 230V 50Hz

Pump supply output: 230 V 50 Hz

Supply outputs for mixer actuators: 230 V 50 Hz

Controller weight: 545g

9. CONTENTS

UN 2 controller

External temperature sensor (5m)

Supply temperature sensor (1.5m)

Tank temperature sensor (2.5m)

Circulation temperature sensor (2.5m)

CH circuit temperature sensor (2 x 1.5m)

Sensor bands (5 pcs)

Dowels for external temperature sensor – 2 pcs

User Manual with warranty card

Power cord (1.5m)

10. SIMPLIFIED DECLARATION OF EU CONFORMITY

P.H.P.U. AS AGN ESZKA SZYMAŃSKA-KACZYŃSKA hereby declares that the type of EUROSTER

UN 2 equipment conforms to the following directives: 2014/35/EU (LVD), 2014/30/EU (EMC),

2011/65/EU (RoHS).

The complete text of the Declaration of EU conformity is available at the following nternet

address: www.euroster.pl

EUROSTER UNI2 – INSTRUCTION MANUAL 15

ELECTRONIC WASTE MANAGEMENT INFORMATION

This product is designed and manufactured of high quality materials and

components suitable for reuse.

The crossed out wheelie bin symbol located at the product means that the product

is subject to selective collection in accordance with the provisions

of the Directive 2012/19/EU of the European Parliament and of the Council.

The product contains an internal battery subject to the selective collection in accordance with

the provisions of the Directive 2006/66/EC of the European Parliament and of the Council.

Such marking informs that the electrical and electronic equipment and batteries may not be

disposed of together with other household waste after their service life. The user

is obliged to take the used devices and batteries to a point of collection of waste electrical and

electronic equipment and batteries. The entities collecting such equipment, including the

collection points, shops, and municipal entities, set up an appropriate system enabling

handover of such equipment and batteries.

The proper disposal of waste equipment and batteries contributes to prevention

of consequences hazardous to the health of persons and nature, resulting from the possible

presence of hazardous components in the equipments and batteries and from inaccurate

storage and processing of such equipment and batteries. The guidelines regarding disposal of

the batteries are included in the user manual.

A household plays an important role in contributing to reuse and recovery including recycling,

of the waste equipment. The attitudes influencing protection of the common good of clean

environment are shaped at this level. Households are also one of the larger users of small

equipment and its rational management at this stage impacts the recovery of recyclables.

naccurate disposal of this product may be penalised in accordance with national legislation.

EUROSTER UNI2 – INSTRUCTION MANUAL 16

WARRANTY CARD

EUROSTER UNI2 C ntr ller

Warranty Terms and Conditions:

1. The warranty is provided for a period of 24 months from the date of sale.

2. A faulty controller with the warranty card should be delivered to the point of sale.

3. Claims under the warranty shall be examined within 14 working days from the date on

which the manufacturer receives the device.

4. Only the manufacturer or other entity, explicitly authorized by the manufacturer, can

make any repairs of the product.

5. The warranty becomes void in the case of mechanical damage, improper use and

repairs by unauthorized persons.

6. The warranty on the consumer product does not exclude, limit or suspend the buyer's

rights resulting from the product non-conformity.

...................................................................................................................................

Date of sale serial number/date of

manufacture

company stamp

and signature

technical support:

tel. 65-57-12-012

The warranty is provided by:

P.H.P.U. AS Agnieszka Szymańska-Kaczyńska, Chumiętki 4, 63-840 Krobia

Table of contents

Other EUROSTER Controllers manuals

EUROSTER

EUROSTER 11WB User manual

EUROSTER

EUROSTER UNI3 User manual

EUROSTER

EUROSTER 10M User manual

EUROSTER

EUROSTER 813 User manual

EUROSTER

EUROSTER 11WBZ User manual

EUROSTER

EUROSTER 1100K User manual

EUROSTER

EUROSTER FH1 User manual

EUROSTER

EUROSTER C6RX User manual

EUROSTER

EUROSTER 10PC User manual

EUROSTER

EUROSTER R1100WB User manual

EUROSTER

EUROSTER 12 User manual

EUROSTER

EUROSTER 11K User manual

EUROSTER

EUROSTER 11W User manual

EUROSTER

EUROSTER 11M User manual

EUROSTER

EUROSTER UNI4 User manual

EUROSTER

EUROSTER 11Z User manual

EUROSTER

EUROSTER 11B User manual

EUROSTER

EUROSTER 11WB User manual

EUROSTER

EUROSTER 11E User manual

EUROSTER

EUROSTER 12M User manual