Evo-lite TRAX SCWWL User manual

WWW.EVO-LITE.COM • [email protected] • 1-888-887-2980 • ©2020 EVO-LITE, LLC • 6240 W 54TH AVE., ARVADA, CO 80002 • V1–4420

INSTRUCTION MANUAL

BACKLIGHTING // RETICULAR LED SYSTEMS // TRAX // SCWWL

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTIFICATION

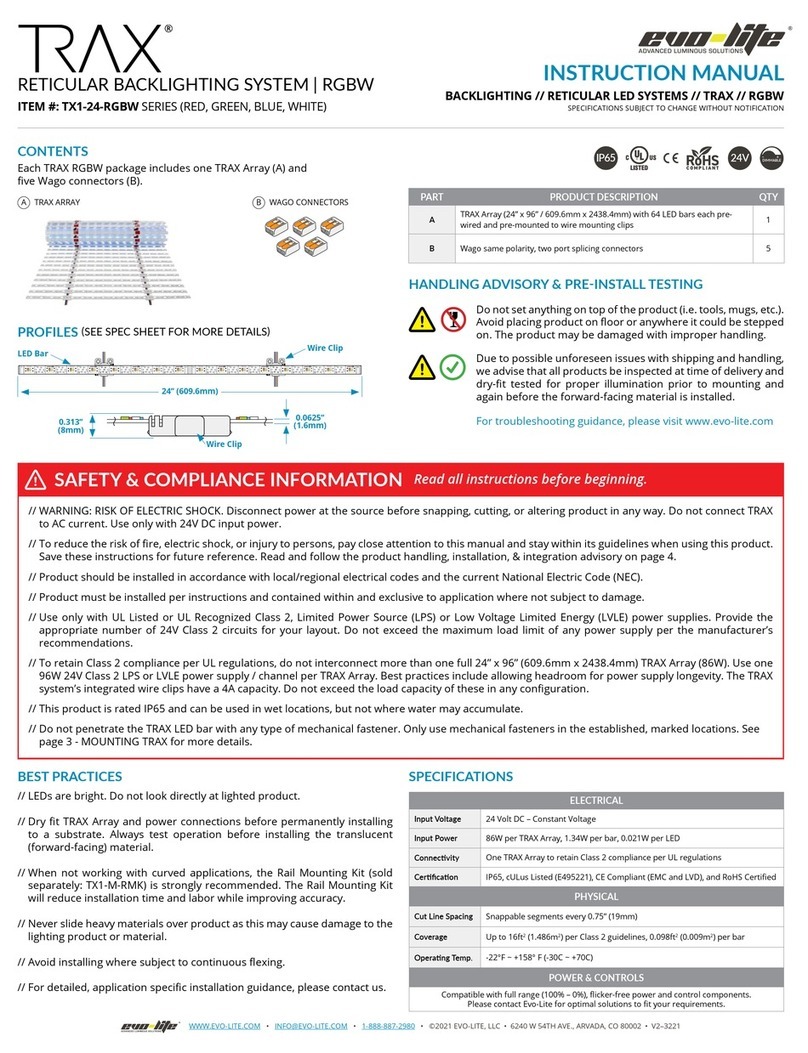

RETICULAR BACKLIGHTING SYSTEM | SCWWL

ITEM #: TX1-24-SCWWL SERIES (SINGLE COLOR WHITE WITH LENS)

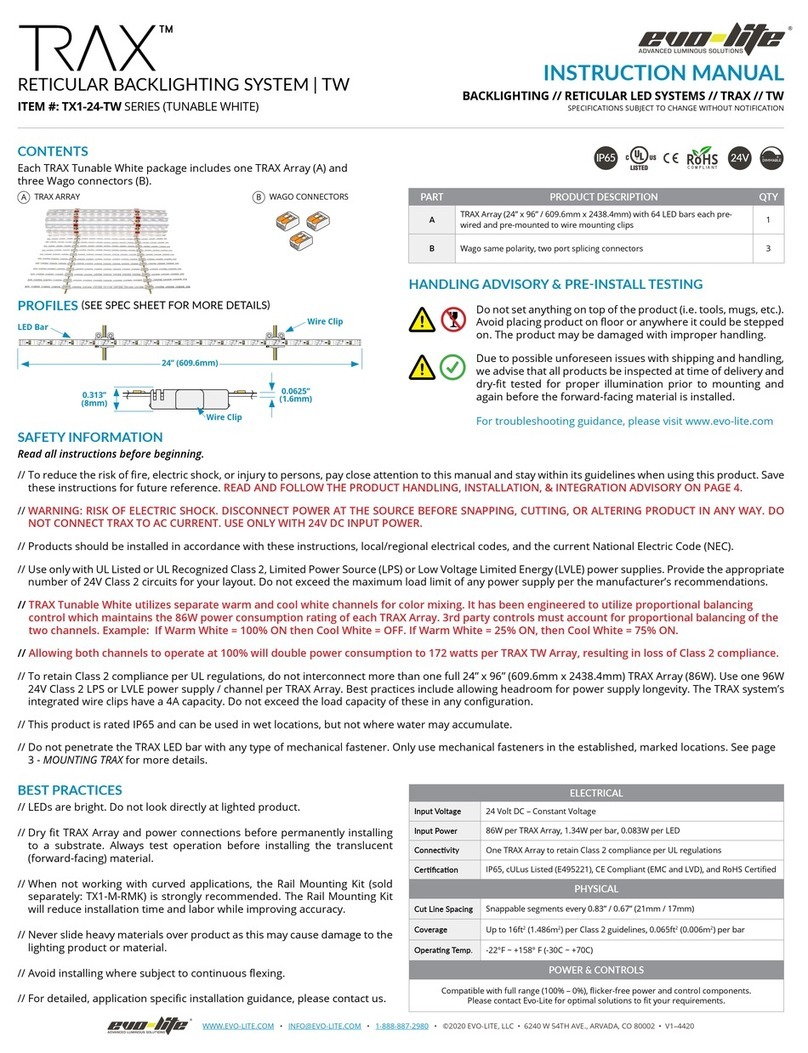

CONTENTS

SAFETY INFORMATION

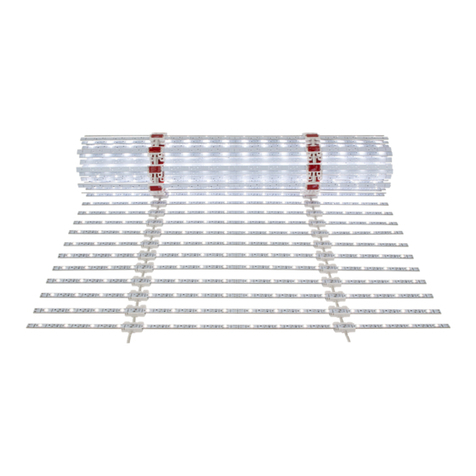

Each TRAX Single Color White With Lens package includes one TRAX Array

(A) and two Wago connectors (B).

Read all instructions before beginning.

PART PRODUCT DESCRIPTION QTY

ATRAX Array (24” x 96” / 609.6mm x 2438.4mm) with 32 LED bars each pre-

wired and pre-mounted to wire mounting clips 1

BWago same polarity, two port splicing connectors 2

ELECTRICAL

Input Voltage 24 Volt DC – Constant Voltage

Input Power 86W per TRAX Array, 2.69W per bar, 0.336W per LED

Connecvity One TRAX Array to retain Class 2 compliance per UL regulations

Cercaon IP65, cULus Listed (E495221), CE Compliant (EMC and LVD), and RoHS Certied

PHYSICAL

Cut Line Spacing Snappable segments every 1.5” (38.1mm)

Coverage Up to 16ft2(1.486m2) per Class 2 guidelines, 0.098ft2(0.009m2) per bar

Operang Temp. -22°F ~ +158° F (-30C ~ +70C)

POWER & CONTROLS

Compatible with full range (100% – 0%), icker-free power and control components.

Please contact Evo-Lite for optimal solutions to t your requirements.

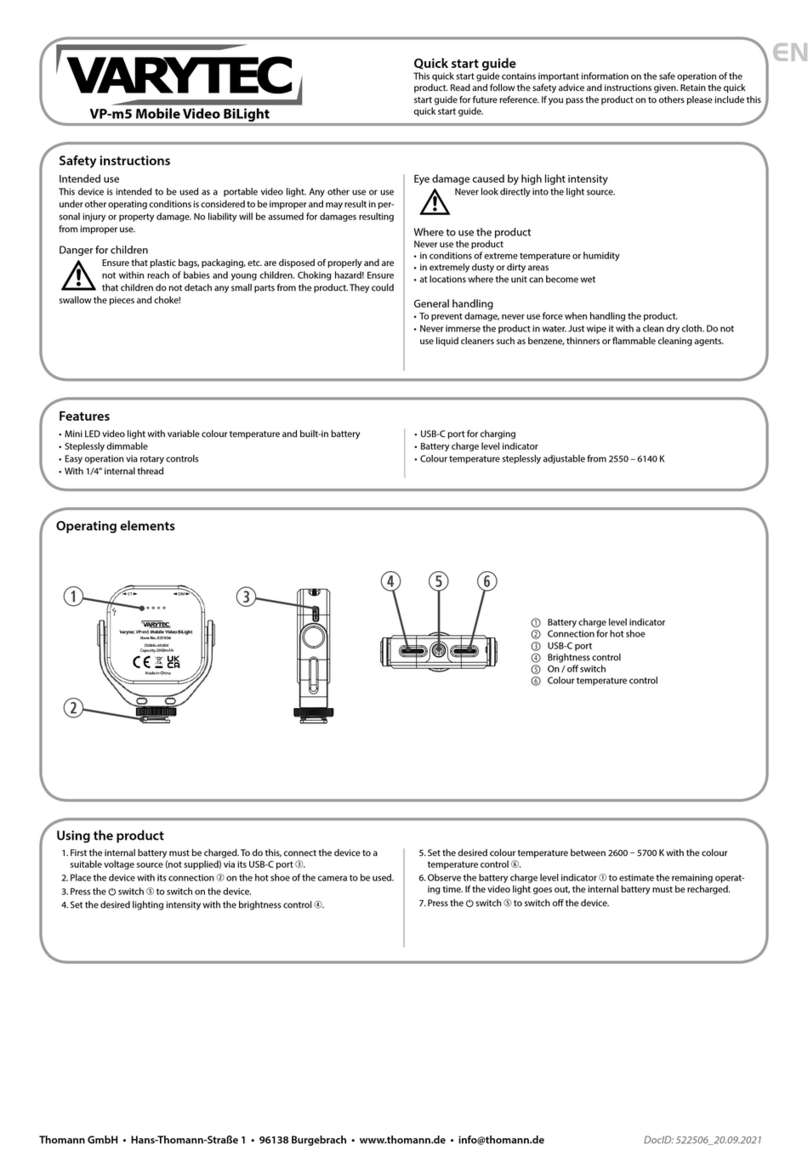

BWAGO CONNECTORS

24V

IP65

RoHS

COMPLIANT

DIMMABLE

+−

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

PROFILES (SEE SPEC SHEET FOR MORE DETAILS)

0.0625”

(1.6mm)

0.43”

(11mm)

Wire Clip

Wire Clip

LED Bar

24” (609.6mm)

BEST PRACTICES

// To reduce the risk of re, electric shock, or injury to persons, pay close attention to this manual and stay within its guidelines when using this product.

Save these instructions for future reference. READ AND FOLLOW THE PRODUCT HANDLING, INSTALLATION, & INTEGRATION ADVISORY ON PAGE 4.

// WARNING: RISK OF ELECTRIC SHOCK. DISCONNECT POWER AT THE SOURCE BEFORE SNAPPING, CUTTING, OR ALTERING PRODUCT IN ANY WAY. DO

NOT CONNECT TRAX TO AC CURRENT. USE ONLY WITH 24V DC INPUT POWER.

// Products should be installed in accordance with these instructions, local/regional electrical codes, and the current National Electric Code (NEC).

// Use only with UL Listed or UL Recognized Class 2, Limited Power Source (LPS) or Low Voltage Limited Energy (LVLE) power supplies. Provide the appropriate

number of 24V Class 2 circuits for your layout. Do not exceed the maximum load limit of any power supply per the manufacturer’s recommendations.

// To retain Class 2 compliance per UL regulations, do not interconnect more than one full 24” x 96” (609.6mm x 2438.4mm) TRAX Array (86W). Use one 96W

24V Class 2 LPS or LVLE power supply / channel per TRAX Array. Best practices include allowing headroom for power supply longevity. The TRAX system’s

integrated wire clips have a 4A capacity. Do not exceed the load capacity of these in any conguration.

// This product is rated IP65 and can be used in wet locations, but not where water may accumulate.

// Do not penetrate the TRAX LED bar with any type of mechanical fastener. Only use mechanical fasteners in the established, marked locations. See page

3 - MOUNTING TRAX for more details.

// LEDs are bright. Do not look directly at lighted product.

// Dry t TRAX Array and power connections before permanently installing

to a substrate. Always test operation before installing the translucent

(forward-facing) material.

// When not working with curved applications, the Rail Mounting Kit (sold

separately: TX1-M-RMK) is strongly recommended. The Rail Mounting Kit

will reduce installation time and labor while improving accuracy.

// Never slide heavy materials over product as this may cause damage to the

lighting product or material.

// Avoid installing where subject to continuous exing.

// For detailed, application specic installation guidance, please contact us.

TRAX ARRAY

A

HANDLING ADVISORY & PRE-INSTALL TESTING

Do not set anything on top of the product (i.e. tools, mugs, etc.).

Avoid placing product on oor or anywhere it could be stepped

on. The product may be damaged with improper handling.

Due to possible unforeseen issues with shipping and handling,

we advise that all products be inspected at time of delivery and

dry-t tested for proper illumination prior to mounting and

again before the forward-facing material is installed.

For troubleshooting guidance, please visit www.evo-lite.com

WWW.EVO-LITE.COM • [email protected] • 1-888-887-2980 • ©2020 EVO-LITE, LLC • 6240 W 54TH AVE., ARVADA, CO 80002 • V1–4420

The TRAX Array may be powered from any of the four wire leads. Choose the best wire lead according to power

supply location. Do not exceed the 4A maximum load capacity in any conguration. Use the included Wago

connectors in place of wire nuts for a secure connection of wires of the same polarity.

1. Ensure power is disconnected at source.

2. Strip wire ends where making power connection.

3. Route lead wires from power supply to TRAX Array’s lead wires (gure 5).

A. Connect live wire from power supply to TRAX Array’s grey striped positive wire (+).

B. Connect negative wire from power supply to TRAX Array’s white negative wire (–).

4. Reconnect power at source.

5. Test TRAX Array’s functionality.

TROUBLESHOOTING

If product fails to light, please check: polarity at the power supply, proper connection at the Wago connectors,

and supply power at the source. Contact Evo-Lite to get help troubleshooting your lighting system.

DIMMING

TRAX is dimmable and compatible with full-range (100%-0%) icker-free power and control components. Barrel connectivity options and accessories are sold

separately for use with barrel connected plug-in power supplies. Contact an Evo-Lite Systems Integration Specialist for optimal power and control solutions

to t the project needs.

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424

TX1-24-53-L175 TX1-24-53-L175

PA

TENT P

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175TX1-24-53-L175

PATENTPENDING

PROD#200424 TX1-24-53-L175 TX1-24-53-L175

Figure 1

Figure 4 // One power input is required for each Class 2 circuit

Figure 5

A

B

STANDARD BAR

RETENTION CLIPS

ADEEP BAR

RETENTION CLIPS

BRAIL MOUNTING KIT

NOT ALL COMPONENTS SHOWN

C

Snap Line

MAKING THE CONNECTION

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175

Figure 2

Figure 3

TRAX DRY FITTING AND SNAPPING / CUTTING TO SIZE

USING OPTIONAL TRAX ACCESSORIES (SOLD SEPARATELY)

POWER INPUT

Dry t TRAX Array and power connections before permanently mounting to the

substrate. Always test function before installing the translucent (forward-facing)

material. Alway disconnect power at the source prior to modifying lighting products

or accessories in any way.

Each LED bar on TRAX may be snapped to size along the pre-established snap lines

(gure 1). To snap an LED bar to size locate where the adjustment should be made

and nd the closest snap line. Pinch the LED bar on both sides of the snap line.

Then apply slight pressure with both thumbs until the bar snaps apart (gure 2).

TRAX may be cut to length by cutting the wires anywhere between the wire

mounting clips. Cuts may be made to one or both columns of wires (gure 3).

(A) STANDARD BAR RETENTION CLIPS (TX1-BRC-STD-15)

Sold in packs of 10. Adhesive-backed clips snap to LED bars and add extra support

in between rails or where LED bars were modied. Mounts directly to installation

surface with mechanical fasteners.

(B) DEEP BAR RETENTION CLIPS (TX1-BRC-RMK-15)

Sold in packs of 10. Use with Rail Mounting Kit only. Adhesive-backed clips snap to

LED bars and add extra support in between rails or where LED bars were modied.

Mounts directly to installation surface with mechanical fasteners.

(C) RAIL MOUNTING KIT (TX1-M-RMK)

Sold in single kits each sized for one full 24” x 96” TRAX Array. Contains 8 sections

of 24” Rails (which combine to create two 96” sections), 6 Rail to Rail Connectors,

16 Rail Mounting Clips, and 4 Rail End Mounting Clips. Use Rail Mounting Kit to

speed up installation and provide a rigid structure. See MOUNTING TRAX section.

To retain Class 2 compliance per UL regulations, do not interconnect more than one full 24” x 96” (61cm x 244cm) TRAX Array (86W). Use one 96W 24V Class

2 LPS or LVLE power supply / channel per TRAX Array. Best practices include allowing headroom for power supply longevity. The TRAX system’s integrated

bar to wire connectors have a 4A capacity. Do not exceed the load capacity of these connection blocks in any conguration.

WWW.EVO-LITE.COM • [email protected] • 1-888-887-2980 • ©2020 EVO-LITE, LLC • 6240 W 54TH AVE., ARVADA, CO 80002 • V1–4420

TX1-24-53

PATENTPENDING

24VDC 24VDC

TX1-24-53

PATENTPENDING

24VDC 24VDC

TX1-24-53

PATENTPENDING

24VDC 24VDC

TX1-24-53

PATENTPENDING

24VDC 24VDC

TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175 TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175

TX1-24-53-L175

AA

A A

A

B

C

C

C

D

24” RAILS

(QUANTITY 8)

ARAIL TO RAIL CONNECTORS

(QUANTITY 6)

BRAIL MOUNTING CLIPS

(QUANTITY 16)

C RAIL END MOUNTING CLIPS

(QUANTITY 4)

D

MOUNTING TRAX

TRAX may be mounted vertically or horizontally. Two dierent mounting methods may be used to secure it to the mounting surface. The rst method

involves using the built-in wire clips. The second method involves using the TRAX Rail Mounting Kit that is sold separately. Use the appropriate method or

combination of methods depending on the type of mounting surface and its orientation. Mechanical fastening is required.

Step 1 // Prepare Mounting Location

Determine mounting location and make

measurements. Wire clips are spaced 12”

on center. Line up TRAX Array’s wire clip

mounting holes to installation area.

Step 2 // Fasten To Surface

Use wire clip’s adhesive backing for

temporary placement, if necessary. Drive

mechanical fasteners through wire clip’s

mounting holes.

Step 3 // Secure All Wire Clips

Repeat the previous steps to secure all

wire clips to mounting surface, ensuring

the TRAX Array is taut with LED Bars

laying at.

Step 4 // Add Support As Needed

If needed, use Standard Bar Retention

Clips (sold separately: TX1-BRC-STD-15) to

provide additional LED Bar support.

Step 1 // Assemble The Rails

Assemble the Rail Mounting Kit Rails (A)

using the kit’s included Rail To Rail

Connectors (B) and End Mounting Clips

(D). These pieces slide and click into place,

no tools required. Rails may be cut to size.

Step 2 // Prepare Mounting Location

Mark the desired location for Rails (A).

The correct distance between left rail and

right rail is 12” (30.48cm) on center. Fasten

Rail Mounting Clips (C) to marked surface.

Once mounted, these clips can slide left or

right, adding a small degree of tolerance

to rail location.

Step 3 // Mount To Surface

Snap the TRAX Array into Rails (A) ensuring

it’s taut with LED bars laying at. Test

t assembly to Rail Mounting Clips (C) to

conrm alignment. In vertical applications,

it is advised to apply the TRAX wire clip’s

adhesive backing to the Rail (A) at several

points. This eliminates any undesired

movement from occurring over time.

Step 4 // Add Support As Needed

If needed, use Deep Bar Retention Clips

(sold separately: TX1-BRC-RMK-15) to add

extra support to LED bars in between rails

or where LED bars were modied.

MOUNT USING BUILT-IN WIRE CLIPS

The wire clips that come pre-assembled to the TRAX Array feature mounting holes. Insert mechanical fasteners through these mounting holes (Step 2) to

attach the product to the mounting surface. This method is ideal for installations that involve curved mounting surfaces.

MOUNT USING TRAX RAIL MOUNTING KIT (SOLD SEPARATELY: TX1-M-RMK)

The TRAX Rail Mounting Kit is a recommended accessory for non-curved applications that oers several advantages. It speeds up installations, reduces

labor, keeps install square, and provides a rigid structure that assists with product alignment. For more detailed information, please reference the TRAX Rail

Mounting Kit Instructions (included with each Rail Mounting Kit) and the Rail Mounting Kit Specication Sheet (digital only).

INSTALLATION TIPS

TRAX may be mounted vertically or horizontally. It can be advantageous to pre-mount the TRAX Array to a substrate such as die-bond to help with installation.

When mounting TRAX in a ceiling application (horizontal) the Rail Mounting Kit can be useful for preventing product from sagging and ensuring accurate

alignment. Individual LED bars may be replaced should damage occur during handling / product installation. Please contact Evo-Lite for details.

WWW.EVO-LITE.COM • [email protected] • 1-888-887-2980 • ©2020 EVO-LITE, LLC • 6240 W 54TH AVE., ARVADA, CO 80002 • V1–4420

TEST BEFORE

INSTALLING

Our production, packaging and shipping process is accompanied by rigorous quality control procedure.

All TRAX Arrays are subjected to a burn in period and are tested before packaging to ensure operation

of the highest quality. Due to possible unforeseen issues with shipping and handling, we advise that

all TRAX products be inspected at time of delivery and dry-t tested for proper illumination prior to

mounting and again before the forward facing material is installed.

PRODUCT HANDLING, INSTALLATION & INTEGRATION ADVISORY

INSTALLATION

TEMPERATURE

Due to the characteristics of the adhesive backing present on TRAX Array’s wire clips, installation

environments and locations should be taken into consideration. Low temperatures can cause longer

cure times for permanent adhesion. The adhesive backing is not a permanent mounting solution.

Always use mechanical fasteners.

STORAGE Store

TRAX products

in a clean, dry area on a at, horizontal surface. Do not open the anti-static bag

until ready to install. Ideal storage conditions: Temperature of 68° – 77° F, 50% humidity.

STORAGE

DO NOT CONNECT

TO AC POWER

ANY DIRECT CONNECTION OF TRAX TO AC CURRENT WILL DAMAGE THE LEDs. Be sure to use a UL

Listed or UL Recognized Class 2, LPS or LVLE low voltage power supply that conforms to the voltage

requirements of the TRAX product. This information can be found on the TRAX spec sheet and its

packaging, as well as the power supply labeling.

Evo-Lite’s experience in providing backlighting solutions yields a unique perspective on the characteristics and underlying intuitive knowledge necessary to

complete a successful installation of TRAX. Evo-Lite is committed to educating and supporting all our customers so every installation proceeds as smoothly

as possible. Most installations oer their own unique challenges. We hope by making you aware of the following handling and installation guidelines you

are empowered with knowledge for a successful installation. As always, Evo-Lite is ready to assist you with any questions that arise during your installation.

TRAX has an advanced 5-year warranty. Please review section 19 of Terms & Conditions of Sale at www.evo-lite.com/legal-documents/#TermsSale

SNAPPING

LED BARS

DISCONNECT POWER AT THE SOURCE BEFORE ALTERING TRAX IN ANY WAY. NEVER CUT OR SNAP

TRAX WHILE POWERED. Field snapping and cutting of TRAX does not void UL Listing. LEDs can lose

input power if snap lines are not followed. Avoid cut edge contact with any conductive material(s),

including other cut edges of TRAX Arrays. See also Wet Location Use below.

SOLDERING

DISCONNECT POWER AT THE SOURCE BEFORE ALTERING THE PRODUCT IN ANY WAY. The unique

power grid of TRAX prevents the need for soldering in most cases. The LED bar’s copper pads are

engineered to handle 4A of load and polarity is noted by the + and - next to each copper pad. Use 18

AWG stranded copper wire for up to 4A of load and follow electronics soldering best practices.

FASTENING

USE PAN HEAD, DOMED, ROUND HEAD FASTENERS, OR TAPERED SCREWS. Never screw the fastener

so much that it deforms TRAX or its components. Fastening only takes place through the mounting

holes on wire clips, Standard / Deep Bar Retention Clips, Rail End Mounting Clips, or Rail Mounting

Clips. For suspended applications, use mechanical fasteners with appropriate spacing to avoid sagging

or use the TRAX Rail Mounting Kit.

WET LOCATION

USE

TRAX is IP65 rated. This rating is total protection against dust ingress as well as water projected by a

nozzle against the enclosure from any direction for a limited time and may be used in wet locations, but

not where standing water can accumulate. Cut edges of IP65 can optionally be sealed from moisture

with an RTV Silicone Sealant or conformal coating.

IP65

POWER, CONTROL

& WIRING

For optimal power distribution and to minimize voltage drop, it is recommended that multi-strand, high

strand count wiring be used for all low voltage DC connections. Wire gauge should be appropriate based

upon system voltage and wire lengths to further minimize voltage drop. Power supplies, drivers and

controls should be installed in well ventilated enclosures and/or per manufacturers recommendations.

It is the customer’s responsibility to ensure all components and installation practices meet or exceed

local codes and requirements.

DO NOT OVER-

BEND LED BARS

The LED bars on TRAX oer limited exibility. In some circumstances a very slight bend to the bars may

be desired and implemented. Consult with your Evo-Lite Systems Integration Specialist to see if there

may be a better product for your application.

PRE-INSTALLATION Before mounting, unroll TRAX and pull ends apart so that the TRAX Array is taught. This will help take

out the bends and kinks in the wire so that the intended bar-to-bar spacing is realized.

DO NOT DRILL

Do not drill through TRAX LED bars. It will result in damage to the LEDs and denial of any warranty claims.

Use the wire clip’s’ mounting holes to attach the bars to a mounting surface as depicted on page 3,

Step 2 // Fasten To Surface. Use fasteners that are appropriate for the mounting surface.

This manual suits for next models

1

Other Evo-lite Lighting Equipment manuals

Evo-lite

Evo-lite MaxBAR 180 UV User manual

Evo-lite

Evo-lite Cyclop User manual

Evo-lite

Evo-lite TRAX TX1-24-TW Series User manual

Evo-lite

Evo-lite MOVING BEAM 1R User manual

Evo-lite

Evo-lite MOVING WASH 36x8Z User manual

Evo-lite

Evo-lite ArchiTECH 270 User manual

Evo-lite

Evo-lite EVO Spot 60 User manual

Evo-lite

Evo-lite TRAX TX1-24-SCW Series User manual

Evo-lite

Evo-lite LASERBAR 8X500RED User manual

Evo-lite

Evo-lite MOVING WASH 36x8Z User manual