3

24 V DC

3W

12 V AC

FCC2

LIMIT-SWITCHES

230 VAC

or

115 VAC

60 Hz

VAC MAX.

60W

OPEN A

OPEN B

STOP

BLUE

BLUE

NO NC

Maglock

+

-

Note: Capacitors are supplied with the operator or the prewired enclosure

For connection

of the safety

devices, see the

next paragraph

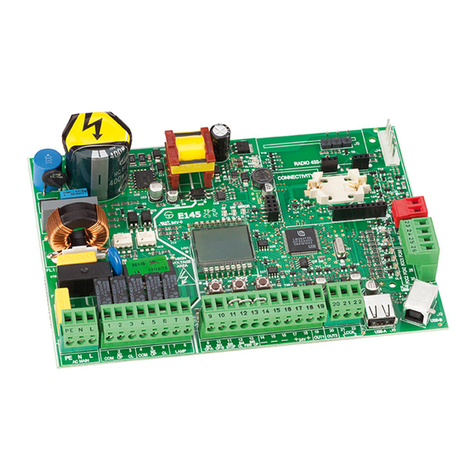

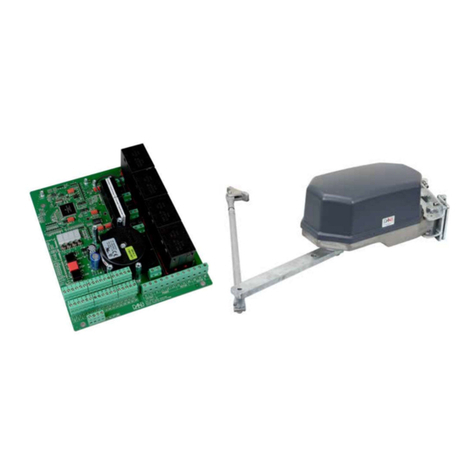

Terminal Block J4 - Motors and Warning Lamp

M1: COM / OP / CL: Connection to Motor 1

Must be used for single-leaf configuration

M2: COM / OP / CL: Connection to Motor 2

Cannot be used in single-leaf configurations

LAMP: Warning lamp output ( AC V ~)

Terminal Block J1 - Accessories

OPEN A - “Total Opening” Command (N.O.):

Any pulse generator (push-button, detector, etc.) which, by

closing a contact, commands opening and/or closing of

both gate leaves. To install several full opening pulse gen-

erators, connect the N.O. contacts in parallel.

OPEN B - “Partial Opening” Command (N.O.) / Closing:

Any pulse generator (push-button, detector, etc.) which, by

closing a contact, commands opening and/or closing of

the leaf driven by motor M1. In the B and C logics, it always

commands closing of both leaves. To install several partial

opening pulse generators, connect the N.O. contacts in

parallel. See logic chart for exact operation.

STP - STOP Contact (N.C.):

Any device (e.g. a push-button) which, by opening a con-

tact, is able to stop gate movement. To install several STOP

devices, connect the N.C. contacts in series. It also can act

as an addional monitored opening safey.

Note: If STOP devices are not used, connect a jumper between

the STP terminals and -.

CL FSW - Closing Safety Contact (N.C.):

The closing safety input is used to protect the leaf move-

ment area during closing. While closing, an activation of

the the safety device connected to this input will reverse the

movement of the gate leaves. This input is inactive during

the opening cycle. To be compliant with the UL325 standard

at least one monitored safety device must be connected

to this input. See the next paragraph on how to connect

a monitored device. If this input is active when the gate is

open it will prevent the leaf closing movement.

OP FSW - Opening safety devices contact (N.C.):

The opening safety input is used to protect the leaf move-

ment area during opening. While opening, an activa-

tion of the the safety device connected to this input will

reverse the movement of the gate leaves. This input is

inactive during the closing cycle. To be compliant with the

UL325 standard if this input is used to protect an entrap-

ment zone at least one monitored safety device must be

connected to it. See the next paragraph on how to con-

nect a monitored device. If this input is active when the

gate is closed it will prevent the leaf opening movement.

– - Negative for power supply to accessories

+ - 24 VDC - Positive for power supply to accessories

Important: Accessories max. load is 500 mA. To calculate

current draw, refer to the instructions for individual

accessories.

-TX FSW - Negative Power to photocell transmitters.

This terminal is used for the photocells monitoring feature.

Compliance with the UL325 standard requires connecting

the transmitter photocell negative power to this input and

activating the FAIL SAFE function (see Advanced Program-

ming). This will allow the 455 D board to check the correct

operation of the safety photecells before each opening

or closing cycle.

Terminal Block J5 - Indicator-Light and Electric Lock

W.L. - Power supply to indicator-light

Connect a 24 VDC - 3 W max. indicator-light, if neces-

sary, between this terminal and the +24V supply. To avoid

compromising correct operation of the system, do not

exceed the indicated power.

LOCK - Power supply to electric lock

If necessary, connect a 12 Vac electric strike lock be-

tween this terminal and the +24V power supply. Or con-

nect a 12 Vac relay and a Maglock following the sche-

matic above.

Terminal Block J6 - Limit-Switches

These inputs are dedicated to the connection of opening

and closing limit switches

5. Electric Connections