Quick reference

(SOFT 03.1X)5

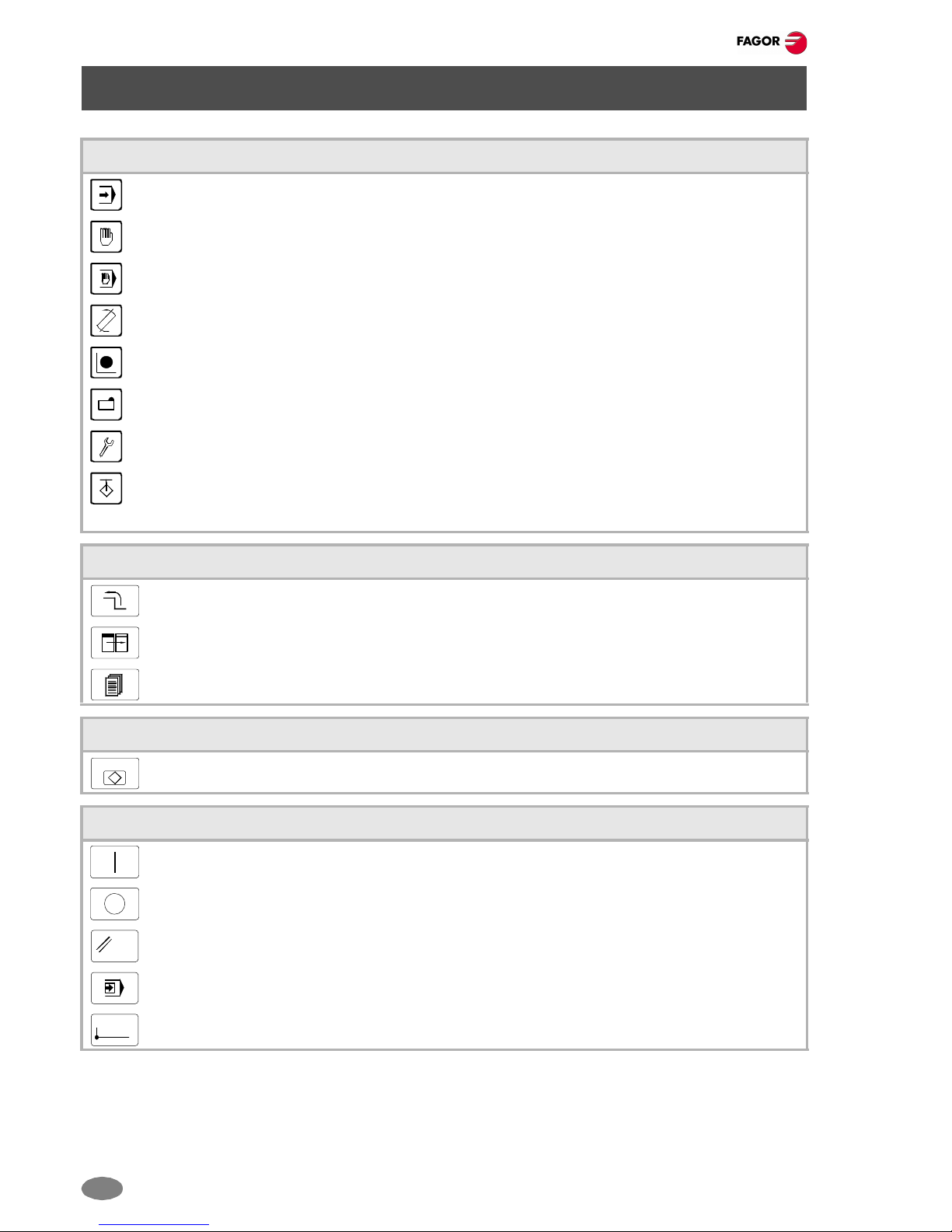

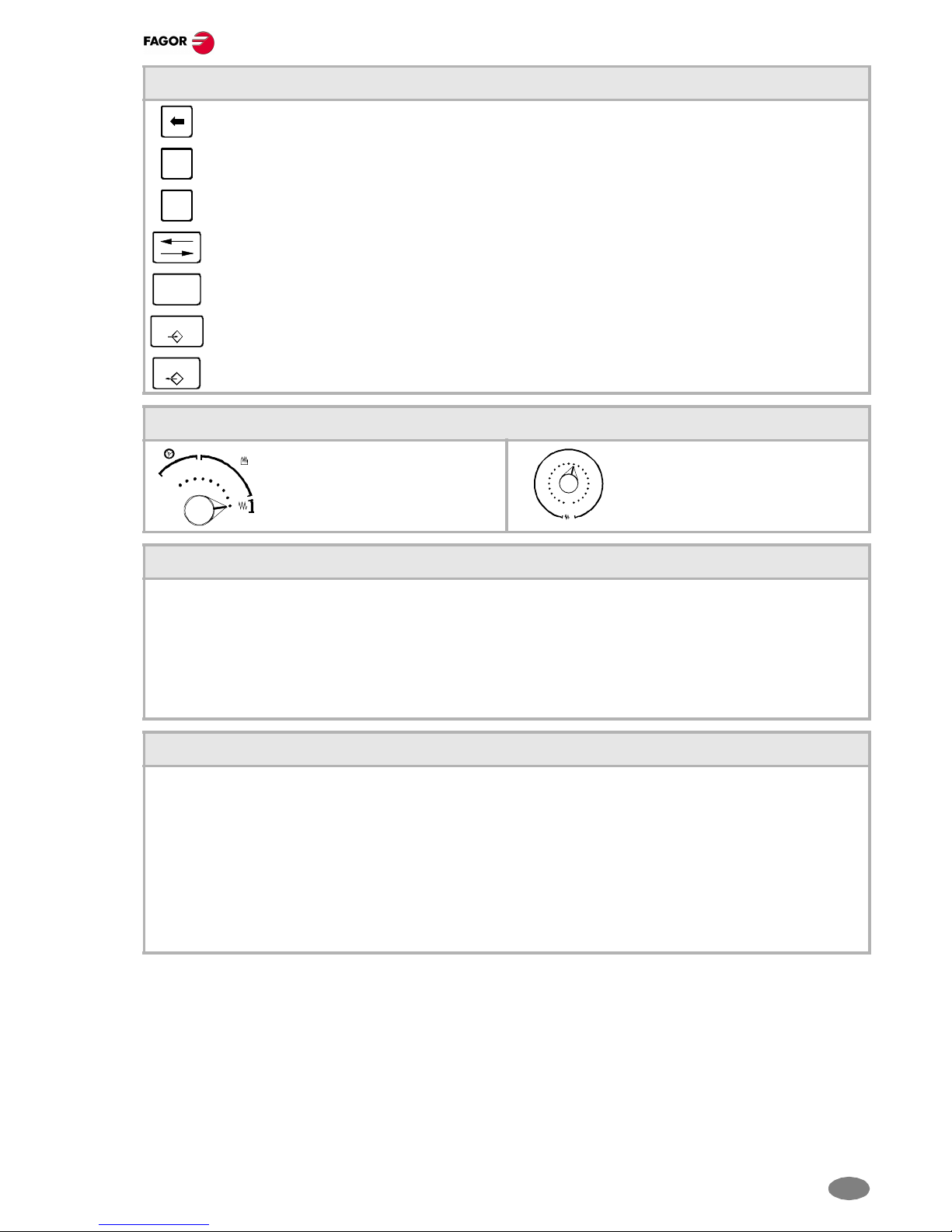

Movement of the axes

Manual movement (jogging) of the axes using JOG:

Continuous jog, (the axis moves while acting on the keyboard).

Turn the jog-type selector switch of the operator panel to the continuous jog position on

the dial.

Jog the desired axis using the JOG panel (keypad).

Incremental jog, (the axis moves a specific distance every time the operator acts on the keyboard).

Turn the jog selector switch of the operator panel to one of the incremental jog positions.

Jog the desired axis using the JOG panel (keypad).

Jogging the axes with handwheels:

Electronic handwheels may be used to move the axes.

Turn the jog selector switch of the operator panel to one of the handwheel positions.

Once the desired resolution has been selected and depending on the type of handwheel being used, general

or individual, proceed as follows:

1. General handwheel (may be used to jog any axis of the machine):

On the JOG keyboard, press one of the keys for the axis to be jogged. If several axes are selected

simultaneously, they all move at the same time. The CNC moves each axis as the handwheel is turned

depending on the setting of the selector switch and on the turning direction of the handwheel.

2. Individual handwheel (it is associated with a particular axis):

The CNC moves each axis as its relevant handwheel is turned depending on the setting of the selector

switch and on the turning direction of the handwheel.

Definition of machining conditions

Press the [S] key to select a spindle speed.

Press the [F] key to select a feedrate.

Enter the desired spindle speed or feedrate.

Press [START] to assume the entered value.

Press [ESC] to cancel the operation.

Spindle control

It is recommended to set the spindle turning speed (using the MDI mode) before selecting the turning direction.

Starts the spindle clockwise at the active speed.

Starts the spindle counterclockwise at the active speed.

To stop the spindle.

Spindle override (it may be used to vary the spindle turning direction).

Spindle orientation (it orients the spindle).

10010 10100

11

1000

10000

JOG

10010 10100

11

1000

10000

JOG

10010 10100

11

1000

10000

JOG

ESC