2. Small Two-finger Slide Type (RCP2-GRS), Medium Two-finger Slide Type (RCP2-GRM)

Three-finger Slide Type (RCP2-GR3SS/GR3SM)

Three-finger Lever Type (RCP2-GR3LS/GR3LM)

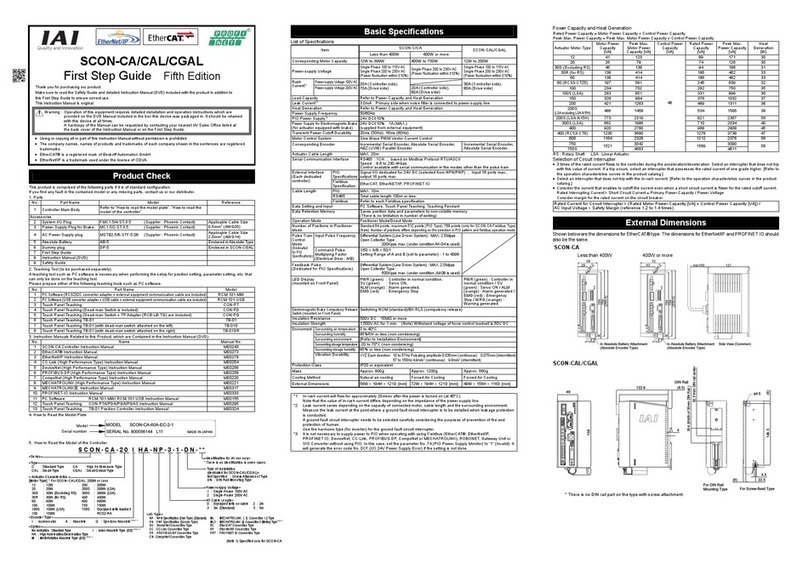

[Connection to the PCON, PSEL Controller]

Dedicated Connection Cable

•Motor Cable (Robot Cable) CB-RCP2-MA***

•Encoder Cable CB-RCP2-PB***/Encoder Cable Robot Cable CB-RCP2-PB***-RB

*** shows the cable length.

The max. length should be 20m.

Example) 080=8m

[Connection to the PMEC, PSEP Controller]

Dedicated Connection Cable

•Motor Encoder Cable CB-PSEP-MPA***

*** shows the cable length.

The max. length should be 10m.

Example) 080=8m

3. RCS2

[Connection to the SCON, SSEL Controller]

Dedicated Connection Cable

•Motor Cable CB-RCC-MA***/Motor Cable Robot Cable CB-RCC-MA***-RB

•Encoder Cable CB-RCS2-PA***/Encoder Cable Robot Cable CB-X3-PA***

*** shows the cable length.

The max. length should be 30m.

Example) 080=8m

[Connection to the X-SEL Controller]

Dedicated Connection Cable

•Motor Cable CB-RCC-MA***/Motor Cable Robot Cable CB-RCC-MA***-RB

•Encoder Cable for XSEL-J/K Type CB-RCBC-PA***

/Encoder Cable Robot Cable for XSEL-J/K Type CB-RCBC-PA***-RB

•Encoder Cable for XSEL-P/Q Type CB-RCS2-PA***

/Encoder Cable Robot Cable for XSEL-P/Q Type CB-X3-PA***

*** shows the cable length.

The max. length should be 15m. The max. length for other cables is 20m.

Example) 080=8m

[Prohibited Items in the Cable Processing]

•Do not pull or bend forcibly the cable so as not to give any extra load or tension to the

cable.

•Do not process the cable for extension or shortening by means of cutting out,

combination or connecting with another cable.

•Do not let the cable flex at a single point.

•Do not let the cable bend, kink or twist.

•Do not pull the cable with a strong force.

•Do not let the cable receive a turning force at a single point.

•Do not pinch, drop a heavy object onto or cut the cable.

•When fixing the cable, provide a moderate slack and do not tension it too tight.

•Separate the I/O line, communication line and power line from each other.

Arrange so that such lines are independently routed in the duct.

•Take care of the following items using the cable carrier.

•Arrange the wiring so that there is no entanglement or kink of the cables in the cable

carrier or flexible tube, and do not bind the cables so that the cables are relatively free.

(Do not bend it at an angle of 90°or less)

•The cable track capacity for cables to put in should be 60% or less to prevent cables

from breaking. (Cable heat is not considered.)

Note:

•When the cable is connected or disconnected, make sure to turn off the power to the controller.

When the cable is connected or disconnected with the controller power turned ON, it might cause a

malfunction of the actuator and result in a serious injury or damage to the machinery.

•When the connector connection is not correct, it would be dangerous because of a malfunction of

the actuator. Make sure to confirm that the connector is connected correctly.

Head Office: 577-1 Obane Shimizu-KU Shizuoka City Shizuoka 424-0103, Japan

TEL+81-54-364-5105 FAX+81-54-364-2589

website: www.iai-robot.co.jp/

Ober der Röth 4, D-65824 Schwalbach am Taunus, Germany

TEL 06196-88950 FAX 06196-889524

SHANGHAI JIAHUA BUSINESS CENTER A8-303, 808, Hongqiao Rd. Shanghai 200030, China

TEL 021-6448-4753 FAX 021-6448-3992

website: www.iai-robot.com

Technical Support available in USA, Europe and China

Head Office: 2690 W, 237th Street Torrance, CA 90505

TEL (310) 891-6015 FAX (310) 891-0815

Chicago Office: 1261 Hamilton Parkway Itasca, IL 60143

TEL (630) 467-9900 FAX (630) 467-9912

TEL (678) 354-9470 FAX (678) 354-9471

website: www.intelligentactuator.com

Atlanta Office: 1220 Kennestone Circle Suite 108 Marietta, GA 30066

Steel Strap

(Piano Wire)

Tie them up softly.

Do not use spiral tube in any

position where cables are bent

frequently.

Power Line

Duct

I/O Line

(Flat Cable, etc.)

Cable

Cable Track

Manual No.: ME3697-1A

Dedicated Connection Cable

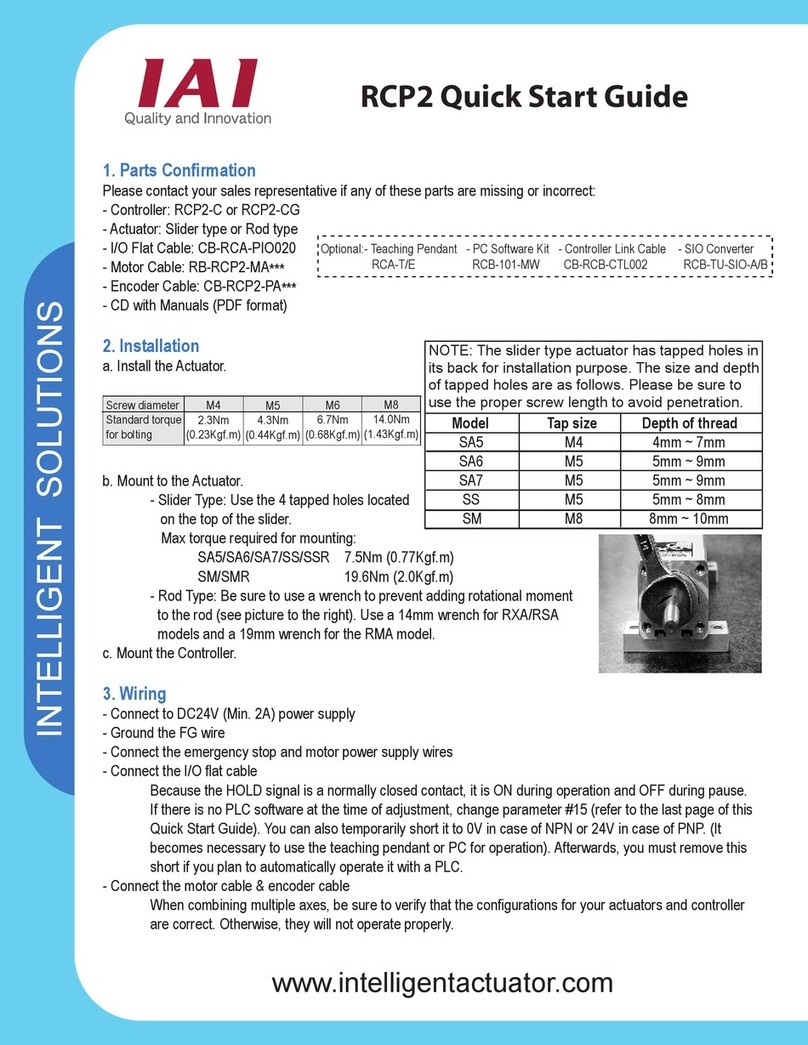

(Connect RCP2, RCP2CR, RCP2W with the dedicated controller)

Robot Cable

r = 54mm or more (Movable Use)

Standard Cable

r = 75mm or more (Fixed Use)

Apply a robot cable for moveable area.

Dedicated Controller

PCON

PSEL

Dedicated Connection Cable

(Connect RCP2, RCP2CR, RCP2W with the dedicated controller)

r = 84mm or more (Movable Use)

r = 42mm or more (Fixed Use)

Dedicated Controller

PSEP

Dedicated Connection Cable

(Connect RCS2 with the dedicated controller)

Dedicated Controller

SCON

SSEL

Robot Cable

r = 58mm or more (Movable Use)

Standard Cable

r = 93mm or more (Fixed Use)

Apply a robot cable for moveable area.

Dedicated Connection Cable

(Connect RCS2 with the dedicated controller)

Robot Cable

r = 58mm or more (Movable Use)

Standard Cable

r = 93mm or more (Fixed Use)

Dedicated Controller

XSEL

Apply a robot cable for moveable area.