(

DSk

636

To be handed to the workshop

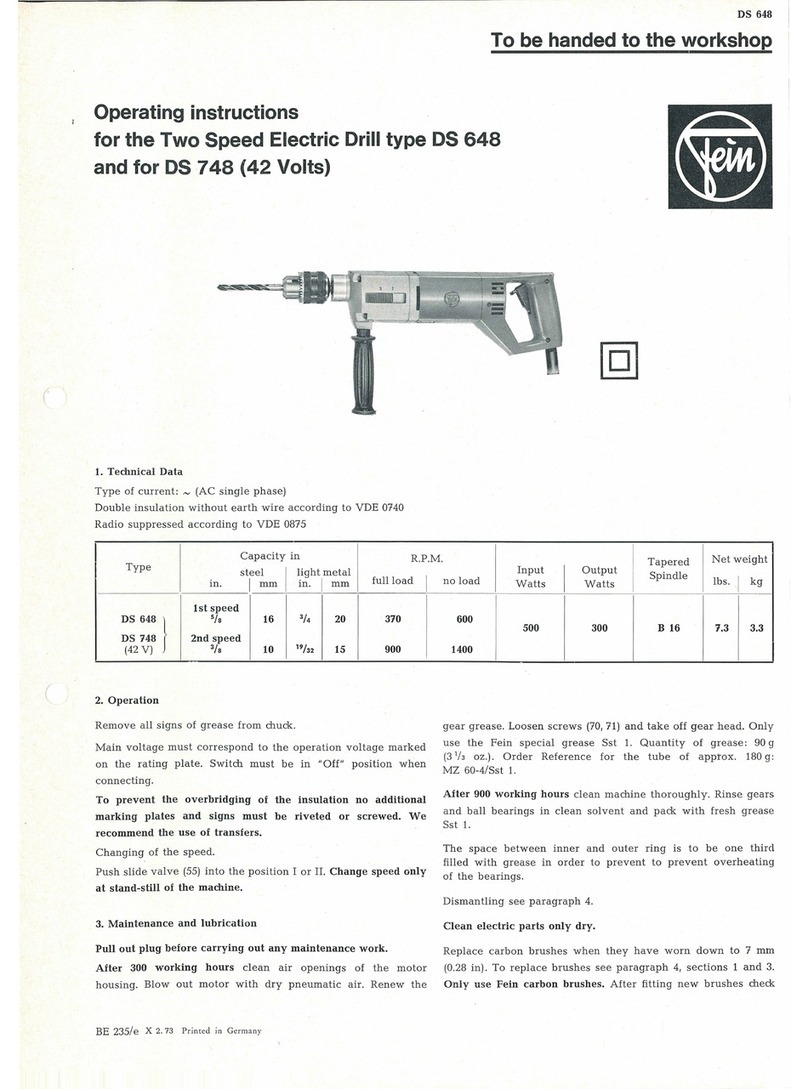

Operating instructions

for the double insulated and radio suppressed

Two Speed Electric Drill type DSk

636

and for DSk

736

(42

Volts)

1.

Technical

Data:

Current:

-(AC

single

phase)

Capacity

in

I

Speed

R.P.M. T

apered

N

et

weigh

t

Ty

pe

stee

l I

ligh

t

alloy

in. 1

mm

, in. I

mm

I full

load

I

I

~-

~

--

-

--

~

I

--·

I

DSk

636 1

/4

I 5

h6

I 3

/s

I

15

/32

10/12 1050/430

6/8 I

I

DSk

736 I . I

I

2.

Construction

This

two-speed

percussion

drill

is

an

electric

tool

of

Class

II

with

protective

insulation

without

earth

wire

and

in

accordance

with

VDE

regulations

0740.

The

protecti

ve

insul

a

tion

is

addi-

tional

to

the

normal

insulation

and

is

attained

by

the

shockproof

motor

housing

made

of

Polyamide

and

by

insulating

the

arma-

ture

shaft

against

the

gearing.

The

drill

is

tested

with

the

pre-

scribed

test

voltage

of 4000

V.

The

machine

is

radio

suppressed

according

to

radio

interference

degree

N.

It

is

supplied

with

a

two-cor

e

cable

without

earth

wire

and

mu

st

not

be

ear

thed

.

Type

DSk

736

for

low

tension

(v

oltag

e 42

Volts)

is

of

the

same

design

but

without

double

insulation

and

not

radio

suppressed.

To

prevent

damage

to

the

insulation

no

additional

marking

pl

ates

and

signs

must

be

riveted

or

screwed

on

th

e

housing.

We

recommend

the

use

of

transfers

only.

Input

I

Ou

tp

ut

Spin

dle

with

chuc

k

no

load

Watts

Wa

tts

lbs

I

kg

I I

I I

1700/730 I 280 150 B 12 3.3 1.5

·I

I I

I I

3.

Connection

and

Operation

Main

vo

ltage

must

corre

s

pond

to

the

operq.

ti

ng

volt

age

marked

on

the

r

ati

ng

plate.

The

to

ol

can

be

plugged

in

to

plain

or

safet

y

sockets

.

Switch

must

be

in

the

uoff"

position

when

connecting!

Remove

the

grease

of

the

cones

before

dismantling

the

morse

taper.

Attention!

Before

changing

speed,

machine

has

to

be

switched

off.

4.

Maintenance

Before

carrying

out

any

maintenanc

e

work

always

remember

to

pull

out

the

plug.

To

guar

a

ntee

the

security

provided

by

the

double

insulation

clean

the

machine

regularl

y

every

300

dut

y

hours

.

This

is

done

with

a

brush

or

by

blowi

ng

out

the

carbon

hold

ers

an

d

the

insulated

p

art

s

with

dr

y pn

eumatic

air.

After

checking

the

carbon

brushes

make

sure

to

re

fit t

hem

in

th

eir

original

position

and

check

that

the

y

mo

ve

easil

y

in

th

e

ir

hold

er.

BE 202/e X I

I.

69

Print

ed

in

Germa

ny

IFrom

August

1970,

gear

and

ball

bearings

are

provided

with

the

special

grease

Sst

1.

Correct

quantity

for

gear

25 g.