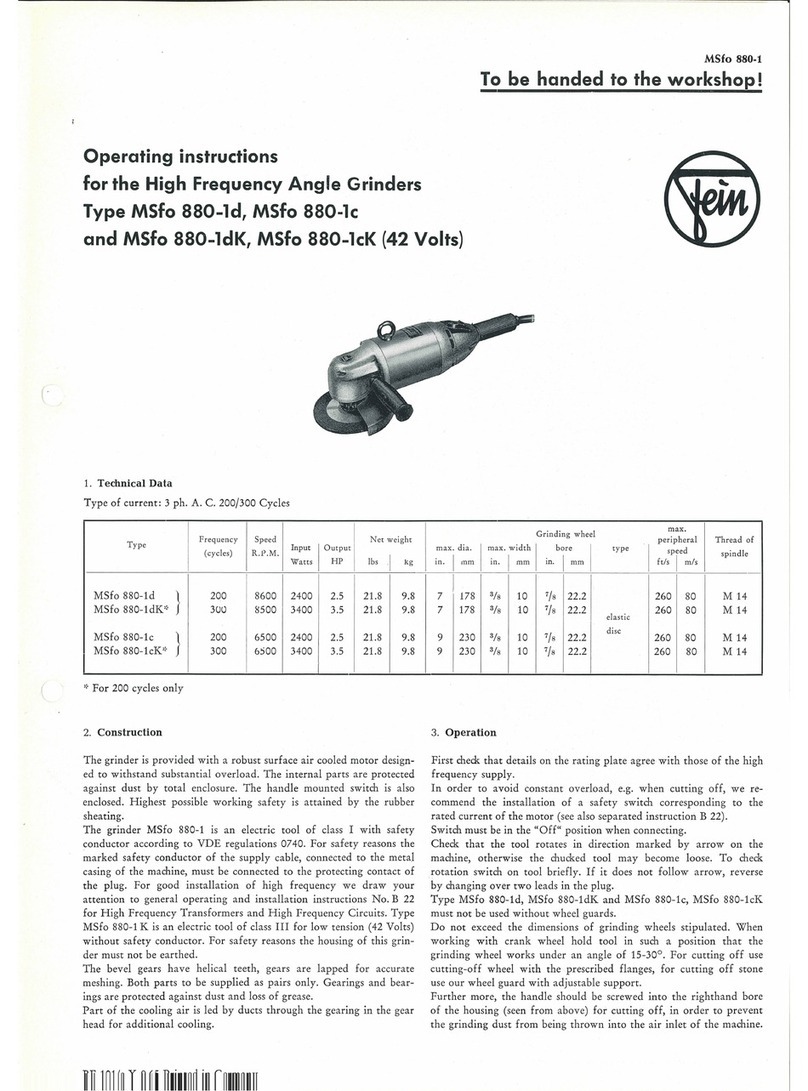

To be handed to the workshop

Operating instructions

for the Angle Grinder type MSf

679

b

1.

Technical

Data

Type

of

current

:

"'

(AC

single

phase)

Fuses

for

220

V:

10 A

slow

or

15 A

fast

or

automatic

fuse

10 A

type

G.

'

Speed

Input

Output

Net

Weight

T

ype

R.P.M.

Watts

Watts

I

lbs

kg

MSf

679b

5100 2000 1400

16

7,2

I

2.

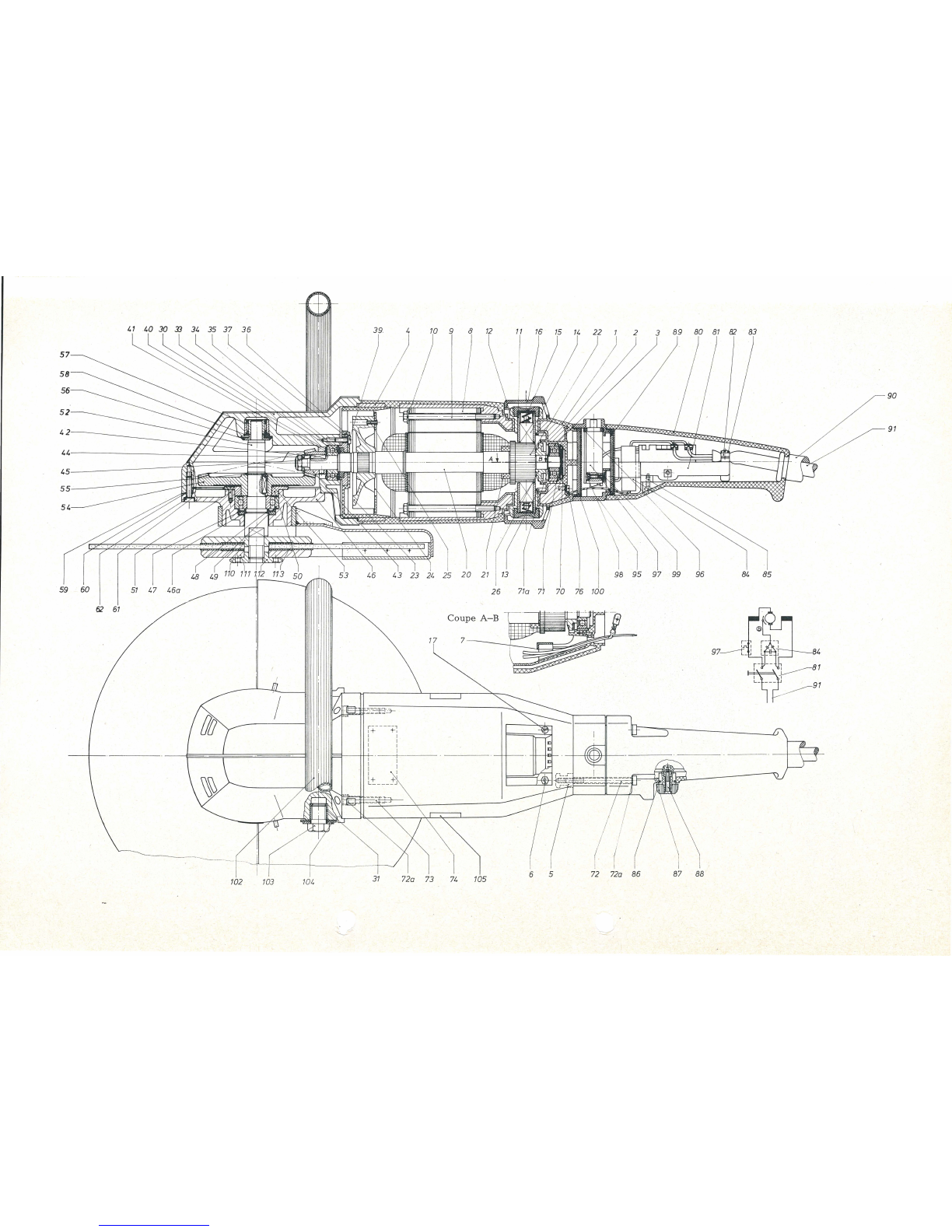

Construction

The

angle

grinder

MSf

679 b

is

an

electric

tool

of

Class

II

according

to

VDE

regulations

0740.

The

protective

insu

la

tion

·

is

additional

to

the

normal

insulation

and

protects

the

operator

against

electric

acciden

ts

caused

by

defective

normal

insulation.

The

protective

insulation

is

attained

by

the

motor

housing

made

of

polyamide-

shockproof

an

d

resistant

to

leakag

e

curren

ts

-

a

nd

by

in

sulating

the

armature

aga

i

nst

th

e

pinion

.

The

machine

is s

upplied

with

a

two-

core

cable

w

ithout

earth

wire

a

nd

must

not

be

earthed.

The

dustproof

switch

is

mounted

in

the

handle.

The

angle

grinder

is

equipped

with

a

protective

motor

switch.

When

overloaded,

it

disconnects

th

e

motor.

When

th

e

prot

ec

tiv

e

motor

switch

is

released,

it

can

again

be

con

n

ected

after

20

or

30

seconds.

Switch

must

be

in

the

"Off"

position,

before

connectin

g

again

the

protective

motor

switch.

The

machine

is

test

ed

with

the

prescribed

test

v

oltage

of

4000 V.

It

is

radio

suppressed

according

to

radio

interf

ere

nce

VD

E 0875.

Th

e

bevel

gear

hav

e he

li

ca

l

teeth.

Gears

are

l

apped

for

accura

te

meshing;

both

p

ar

ts

to

be

supplied

as

pairs

only

.

Gea

rs a

nd

bearings

ar

e

protected

aga

inst

dust

~

nd

l

oss

of

gre

ase

.

-

Th

e

slots

for

the

coo

l

ing

air

of

th

e

motor

are

lo

cated

in

th

e

gear

head.

They

allow

an

additional

cooling

of

the

gear

head.

BE

443/e

GW

5.

73

. P.rint

ed

in

German

y

max.

Thread

Grinding

wheel

periphera

l

speed

of

I

ma

x.

dia

I

ma

x. w

id

th I

bore

type

in.

I

mm

in.

I

mm

in.

i ft/s I m/s

spindle

mm

flexib

le

grinding

11

13j,6

300

.,32

4 7

Ia

22.2 262 80 M 14

wheel

To

p

reven

t

the

overbridg

i

ng

of

the

insul

a

tion

no

addition

al

markfng

plates

and

signs

mus

t

be

ri

vete

d

or

scre

wed

on

th

e

housing

. W e

recommend

the

u

se

of

transfers

only.

3.

Connection

and

operation

Main

voltage

must

correspon

d

to

the

opera

ti

ng

volt

age

marked

on

the

rating

plate.

Th

e

tool

ca

n

be

plugg

ed

into

pla

in

or

safet

y

sockets.

Switch

must

be

in

th

e

"Off"

po

s

iti

on

w

he

n

co

nn

ecting.

The

gr

i

nders

must

not

be

used

w

ithout

wh

eel

guards.

Do

not

exceed

the

dime

ns

ions

·

of

grinding

wheels

stipulated

.

For

cutting

off,

use

cutting

wheels

together

with

the

prescribed

flanges

and,

in

addition

to

this,

our

wheel

guard

with

adjustable

support

for

cutting

off

stone.

4.

Maintenance

and

lubrication.

The

ang

le

grinder

requires

ad

equate

maintena

nce.

Before

star

-

ting

any

maintenance

work

pull

plug

from

socket.

After

3-4

weeks

the

m

achi

ne,

in

particular

ca

r

bon

hold

e

rs

and

insula

te

d

par

ts

,

should

be

cleaned

of

carbon

dust

a

nd

dirt.

Th

is

is

done

by

m

ea

ns

of

a

brush

or

compressed

air.

Worn

ca

r

bon

brush

es

automatica

ll

y

switch

off

the

mach

in

e

utte

r

re

ach

ing

their

minimum

le

ngth

.

After

checkin

g

the

carbon

brushes

make

sure

to

refit

them

in

their

origina

l

position

and