Fein ASs 648 User manual

Other Fein Power Tools manuals

Fein

Fein JHM Magforce User manual

Fein

Fein AFMM18 QSL User manual

Fein

Fein BLK1.3T User manual

Fein

Fein AFMM14 User manual

Fein

Fein MultiMaster AFMM18QSL User manual

Fein

Fein CCG18-115-10PD-SEC AS Series User manual

Fein

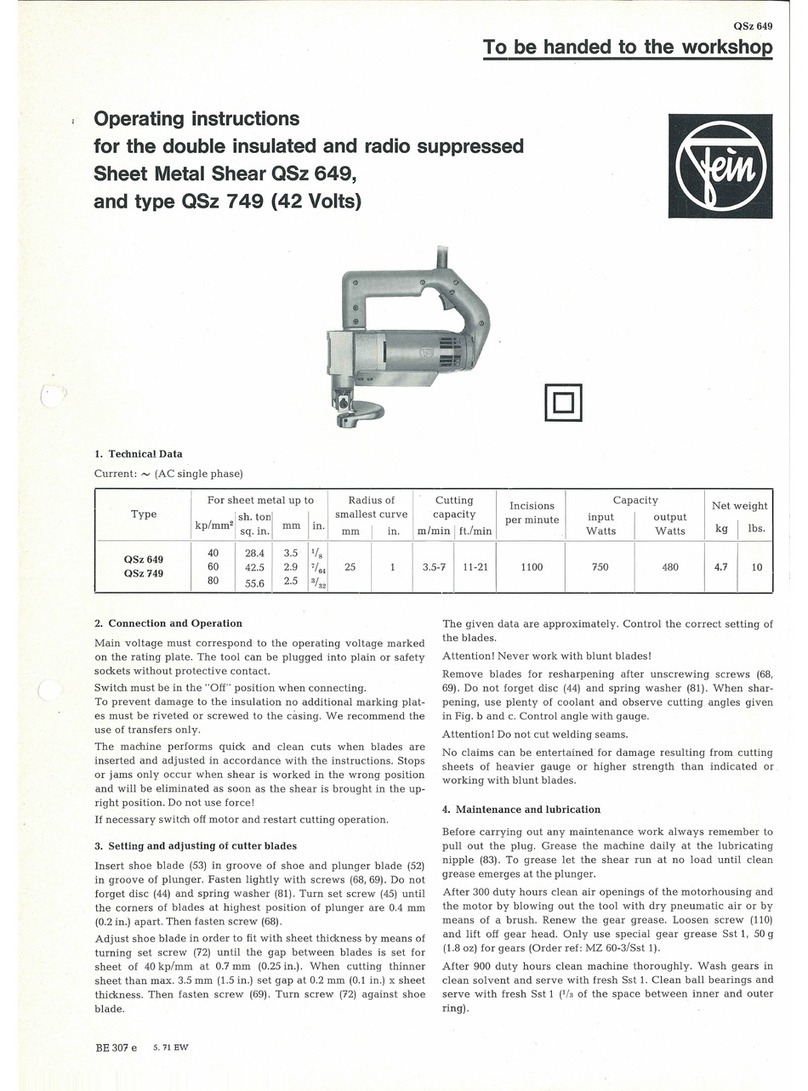

Fein QSz 7 49 User manual

Fein

Fein KBM80U User manual

Fein

Fein KBB30 User manual

Fein

Fein FMM350Q User manual

Fein

Fein ABLS18-1.6E User manual

Fein

Fein ASW14-6 PC User manual

Fein

Fein AFSC18Q User manual

Fein

Fein FMM350QSL User manual

Fein

Fein FMT250SL User manual

Fein

Fein MULTIMASTER FMM 250 User manual

Fein

Fein JCM125Q User manual

Fein

Fein ASCT 14 Setup guide

Fein

Fein ASb 636 User manual

Fein

Fein MM 700 MAX User manual

Popular Power Tools manuals by other brands

WABCO

WABCO OptiTire installation manual

EINHELL

EINHELL TE-MS 18/210 Li Original operating instructions

Orgapack

Orgapack OR-T 85 Operating and safety instructions

TOUGHCUT

TOUGHCUT Diamond 400 instruction manual

Yaros

Yaros PB-3603 user manual

Baileigh Industrial

Baileigh Industrial SS-2725 Operator's manual