5 Commissioning

5.1 Automatic switching point setting: auto teach-in

Prerequisite: proximity sensor is in delivery status.

1. Mount the proximity sensor roughly in the end positionè 4.2 Mechanical.

2. Connect the proximity sensorè 4.1 Electrical.

ÄProximity sensor is automatically taught in during operation, e.g. upon

initial commissioning of the complete system.

Application notes on auto teach-in

During auto teachin, each >100ms stop of the piston within the sensing range is

output as a switching point. If the piston at this position reverses its direction of

movement and leaves the sensing range without further stops, this switching

point is saved temporarily.

If the piston stops 4x consecutively at the same position, reverses its direction of

movement and leaves the sensing range without further stops, this position is

saved as a final switching point. Auto teachin is complete.

The process described corresponds with the classic use case: proximity sensor

query at the end stop of the piston stroke or at the end stop of the customer

application.

If the piston stroke is smaller than the sensing range of the SDBTMSX, ensure

that the second reversal point of the piston is outside the sensing range during

auto teachin è Tab. 3.

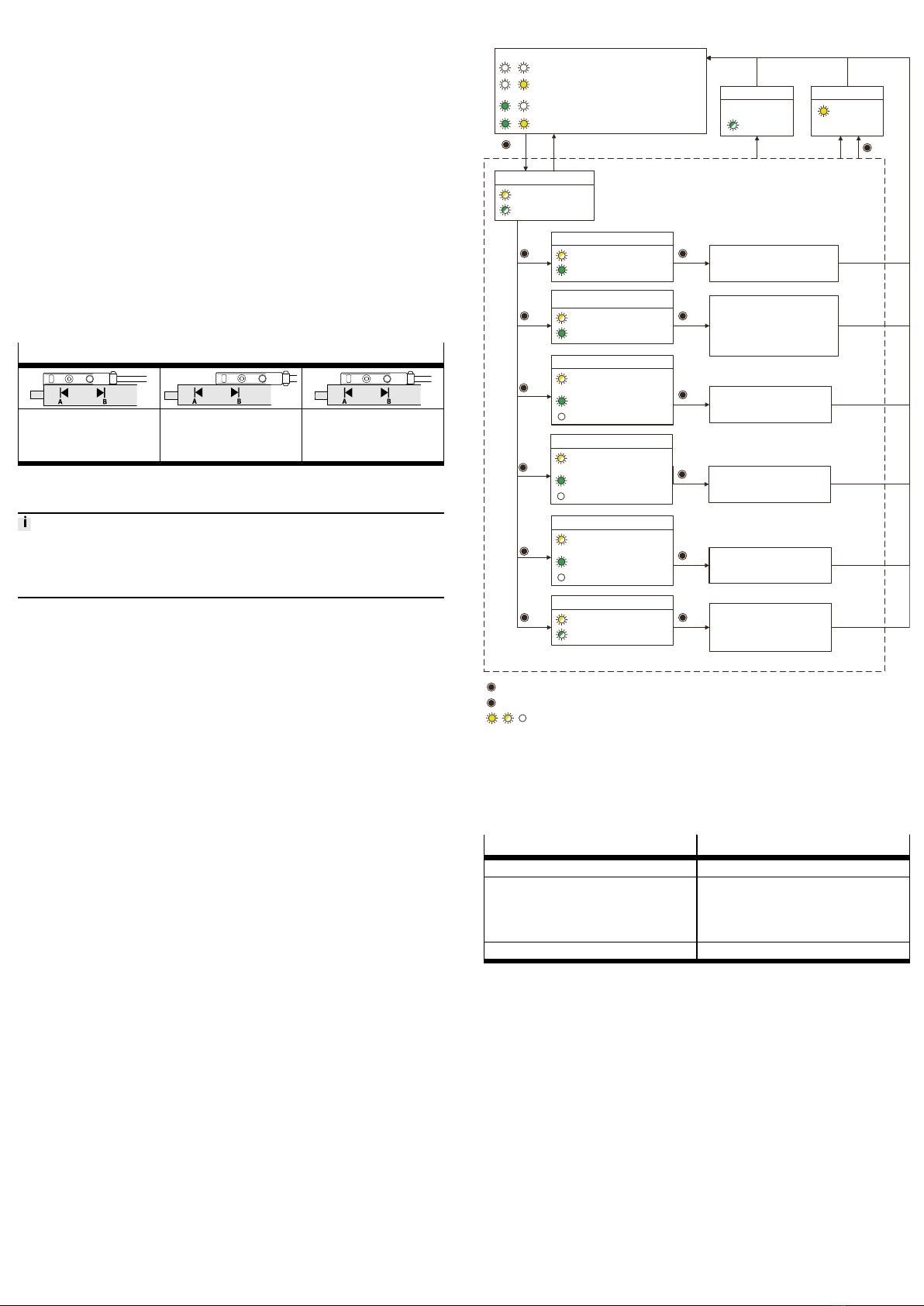

Application notes on auto teach-in

Auto teachin possible:

End position A

Auto teachin possible:

End position B

Auto teachin not possible. The

switching point must be set

using the capacitive operating

key.

Tab. 3

5.2 Manual operation using capacitive operating key

The proximity sensor is parameterised once it is installed.

• Be mindful of the surface temperature of the capacitive operating key and of

the drive.

• Avoid contamination and moisture on the proximity sensor.

5.2.1 Setting the switching point

1. Move the piston into the sensing range of the proximity sensor.

2. Actuate the capacitive operating key 3 times to activate setup mode.

3. Actuate the capacitive operating key once to switch to the menu item "Set

switching point".

4. Actuate the capacitive operating key once.

ÄThe current piston position is taught in as the switching point.

5.2.2 Setting the switching point with variable switching window width

1. Move the piston into the sensing range of the proximity sensor.

2. Actuate the capacitive operating key 3 times to activate setup mode.

3. Actuate the capacitive operating key twice to switch to the menu item "Set

switching point with variable switching window width".

4. Actuate the capacitive operating key once.

ÄThe current piston position is taught in as a switching point with approx.

2mm switching window width.

Every other keystroke increases the switching window width by approx.

1mm. A max. switching window width of 15mm is possible.

5.2.3 PNP/NPN switch-over

1. Actuate the capacitive operating key 3 times to activate setup mode.

2. Actuate the capacitive operating key 3 times to switch to the menu item

"Switch over between PNP / NPN".

3. Actuate the capacitive operating key once to switch between PNP> NPN or

NPN> PNP.

5.2.4 NO/NC switch-over

1. Actuate the capacitive operating key 3 times to activate setup mode.

2. Actuate the capacitive operating key 4 times to switch to the menu item

"Switch over between NO / NC".

3. Actuate the capacitive operating key once to switch between NO> NC or

NC> NO.

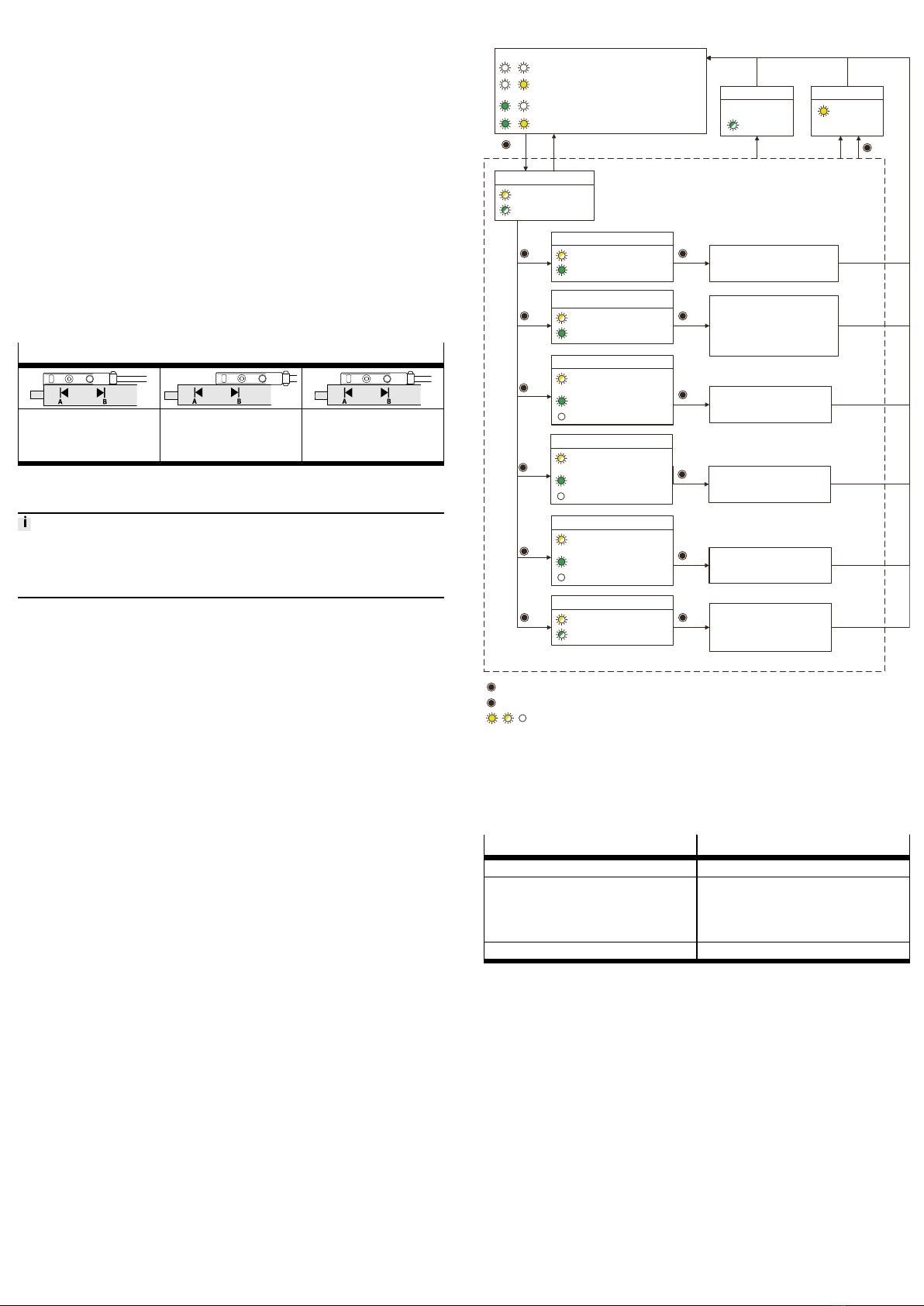

5.3 Menu structure

Green LED on & yellow LED off:

piston magnet in sensing range; no switching point

Set-up mode

Flashes yellow and

green in the form of

moving lights

Set switching point

Green ON: teach-in possible1)

Flashes yellow once, then 2 s

pause

Set switching point with variable width

of switching window

Flashes yellow 2 times, then 2 s

pause

Switch: PNP ßà NPN

Flashes yellow 3 times, then 2 s

pause

Current status: Green ON: PNP

green OFF: NPN

Reset to factory settings

Yellow + green flash

simultaneously at 2.5 Hz

3 x Number of actuations invalid

1 x

2 x

3 x

10 x

Switching point set

Width of switching window 2 mm

1 x

N x

1 x

No switching point set

PNP (SDBT-…-PU)

NPN (SDBT-…-NU)

NO

1 x

Termination

Yellow lights up

for 0.5 s

3 s

t > 60 s

Error

Green flashes at

3 Hz for 1 s

N x = press capacitive operating key (e.g.: 3 x);

Max. 1 second pause between two consecutive presses. After a 1 second pause, entry is copied.

= LED ON / LED flashes / LED OFF (e.g.: yellow LED)

1) A switching point can only be set when the green LED is ON.

When the green LED is flashing at 1.5Hz, the magnet is located in the region of the function reserve. It is not possible to set a

switching point. The function reserve is required for the safe setting of switching points in the edge region.

When the green LED is OFF, the magnet is outside the sensing range. It is not possible to set a switching point.

Switch:

PNP àNPN or:

NPN àPNP

3 s = hold the capacitive operating key pressed for at least 3 seconds

Menu: (green LED flashes when the capacitive operating key is pressed)

Both LEDs off:

Outside the sensing range; no switching point

Both LEDs on:

Piston magnet in sensing range; switching point

Green LED off & yellow LED on: cylinder switch operation:

switching point finally programmed as a teach-in value

Green ON: teach-in possible1)

Switching point set & width of switching

window + 1 mm:

N=1: 2 mm

N=2: 3 mm

…

N=14: 15 mm (max. width of switching

window)

Display: PNP / NPN

Flashes yellow 5 times, then 2 s

pause

Current status: Green ON: PNP

green OFF: NPN

5 x 1 x

Exit

Switch: NO ßà NC

Flashes yellow 4 times, then 2 s

pause

Current status: Green ON: NO

Green OFF: NC

4 x

1 x Switch:

NO àNC or:

NC àNO

Display with factory settings [NO]

Fig. 4

6 Reset to factory settings.

Parameter Factory setting

Operating mode Auto teachin

Switching output No switching point programmed

Configuration of the switching output:

– SDBT…PU: PNP

– SDBT…NU: NPN

Switching element function: NO

Variable switching window width Not programmed

Tab. 4

1. Actuate the capacitive operating key 3 times to activate setup mode.

2. Actuate the capacitive operating key 10 times to switch to the menu item

"Reset to factory settings".

3. Actuate the capacitive operating key once.

ÄProximity switch is reset to factory settings.