Set the switching pressure with two teach pressures TP1/TP2

Note

The sequence of the teach pressures for the switching pressure setting affects

the switching element function (normally closed contact/normally open contact)

of the SDE5.

• Take the following relationship into account:

TP1 ‹ TP2: Programming as NO contact

TP1 › (TP2 + 2 % Full Scale): Programming as NC contact

1. Note down the teach pressures TP1 and TP2.

2. Pressurize the SDE5 with the first teach pressure TP1.

3. Press the Edit button (› 2 s) until the LED flashes.

4. Let go of the Edit button.

The current teach pressure TP1 is saved.

The LED flashes.

5. Pressurize the SDE5 with the second teach pressure TP2.

6. Press the Edit button until the LED stops flashing.

7. Let go of the Edit button.

The current teach pressure TP2 is saved.

8. Ensure that there is power supply for at least 10 seconds.

9. Carry out a test run with various pressures to ascertain whether the SDE5 switches

as desired. When the switching signal is emitted, the LED also lights up.

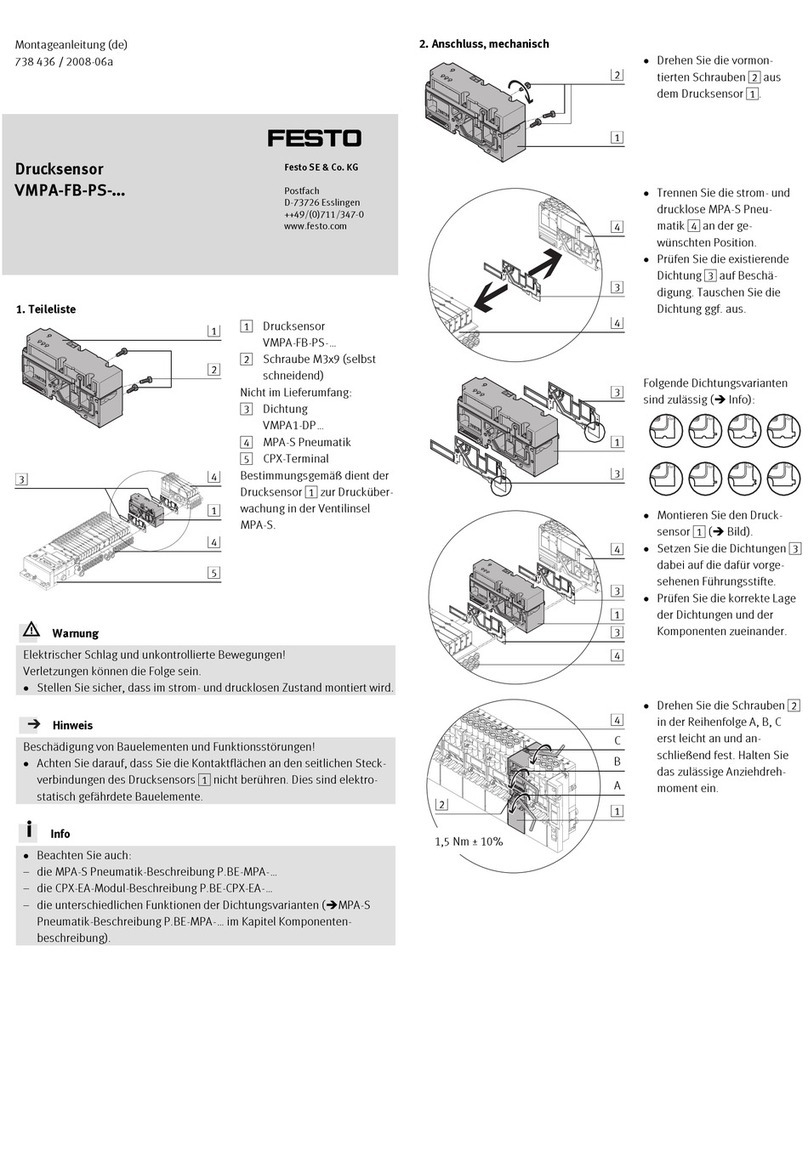

Signal curve over the applied pressure p with switching points

The diagrams for NO (normally open contact, TP1 < TP2) and NC (normally closed

contact, TP1 ‹ TP2 + 2 % Full Scale)), show the relationship between teach

pressure, switching pressure and hysteresis, (Fig. 15).

6Operation

Warning

Danger of injury from high temperatures.

Extreme pneumatic conditions (high cycle rate with large pressure amplitude)

can heat the device over 80 °C.

• Select the operating conditions (in particular the ambient temperature,

pressure amplitude, cycle rate) such that the device does not heat up above

the maximum permitted operating temperature.

• Comply with the operating conditions.

• Switch on the operating voltage.

The device is working in the RUN mode (basic status).

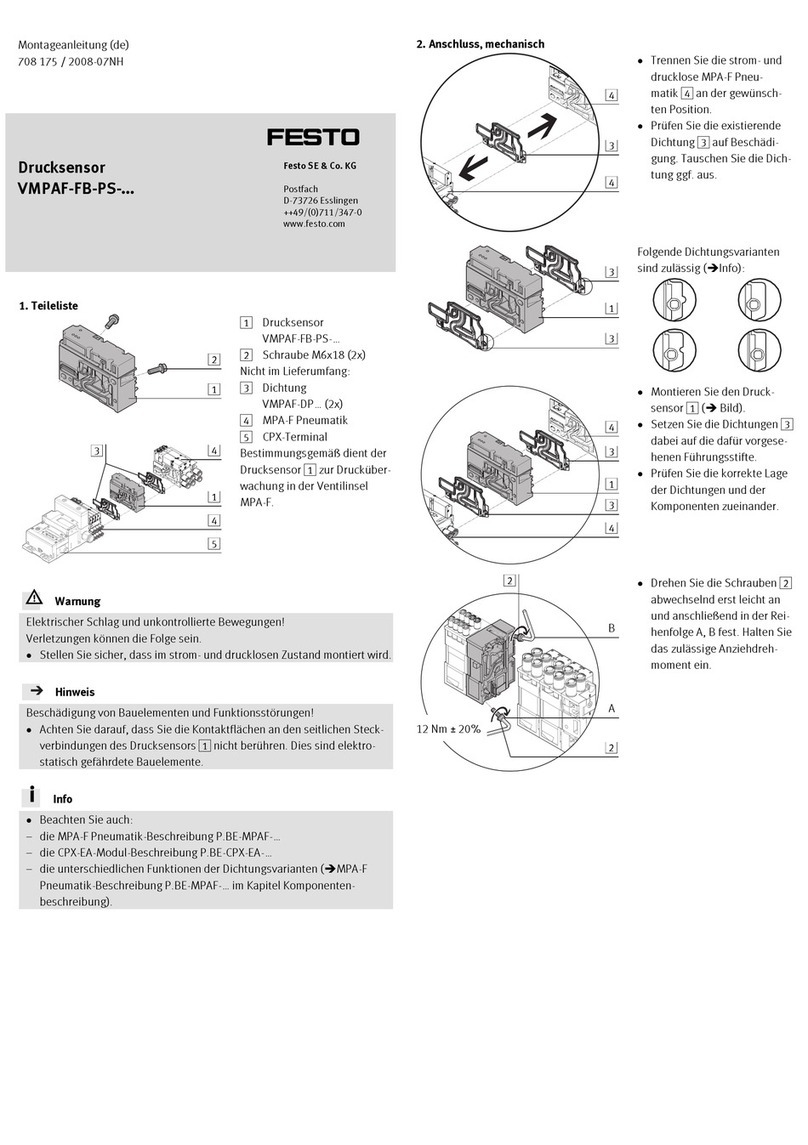

LED display Meaning

LED illuminated yellow SDE5-…-P/-N-…(switching output): pressure p > switching pressure

LED not lit SDE5-…-P/-N-…(switching output): pressure p < switching pressure

LED flashes quickly Teach procedure (Fig. 12)

LED flashes slowly Only SDE5-…-FP: display and setting of the switching function

LED illuminated green Only SDE5-…-V (analogue output): ready status (RUN mode)

Fig. 17

7 Maintenance and care

Clean the SDE5 on the outside

1. Switch off the operating voltage.

2. Switch off the compressed air.

3. Clean the outside of the SDE5 with a soft cloth.

Permissible cleaning agents are soapy water (max. +50 °C) and all non-abrasive

agents.

8 Disassembly

1. Switch off the operating voltage.

2. Switch off the compressed air.

3. Disconnect the electrical and pneumatic connections from the SDE5.

4. Release the SDE5 from the wall holder.

For this, slide a screwdriver into the

groove 1and prise the SDE5 out of the

wall holder.

1

Fig. 18

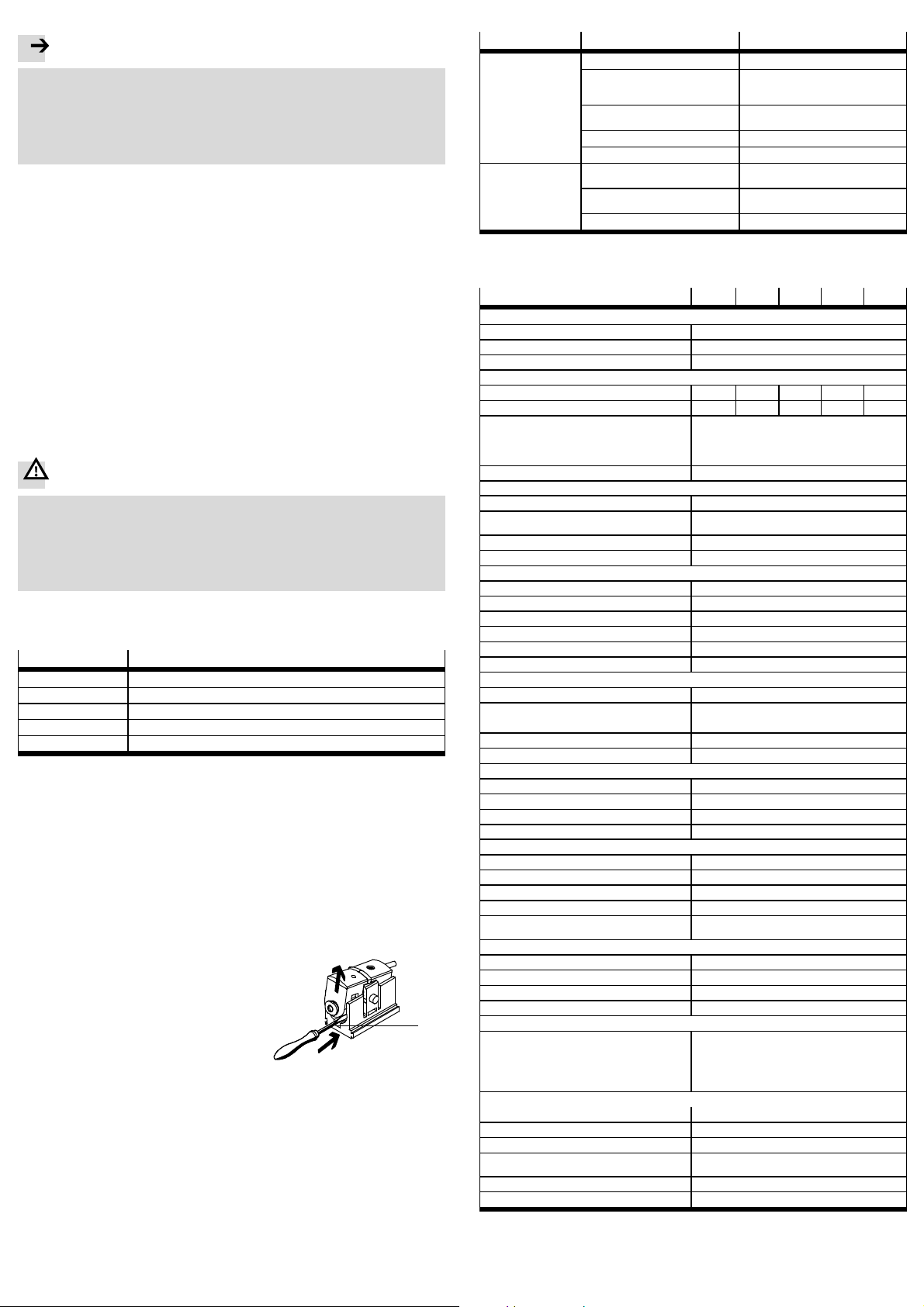

9 Troubleshooting

Malfunction Possible cause Remedy

No LED display Pressure p < switching pressure SP Regular operating status (Fig. 17)

No power supply or there is a

non-permissible operating voltage Switch on power supply/adhere to

the permitted operating voltage

range

Connections swapped

(incorrect polarity) Wire the SDE5 as shown in the

circuit diagram

Pressure failure Eliminate pressure failure

SDE5 defective Replace device

LED display or

switching output

does not react in

accordance with the

settings made

Short circuit or overload at the

output Eliminate short circuit/overload

Incorrect switching point

(e.g. at 0 bar) Repeat teach procedure

SDE5 defective Replace device

Fig. 19

10 Technical data

Type SDE5 -V1 -B2 -D2 -D6 -D10

General

Certification C-Tick, c UL us – Recognized (OL)

CE marking (declaration of conformity) in accordance with EU EMC Directive

Note on materials RoHS-compliant

Input signal/measuring element

Pressure measuring range

1)

[bar] 0…–1 –1 … 1 0…2 0…6 0…10

Max. overload pressure [bar] 5 5 6 15 15

Operating medium Compressed air in accordance with ISO 8573-1:

2010

[7:4:4] – Lubricated operation possible

Temperature of medium [°C] 0 … +50

Ambient temperature [°C] 0…+50

Output, general

Repetition accuracy [% full scale] ± 0.3 (short time)

Temperature coefficient [% full

scale/Kelvin] Max. ±0.05

Protection against short circuit Yes

Protection against overloading Yes

Switching output

Accuracy [% full scale] Max. ±0.5

Switching time (on/off) [ms] 2 (typical)/4 (max.)

2)

Maximum output current [mA] 100

Capacitive load max. DC [nF] 100

Voltage drop [V] max. 1.8

Inductive protective circuit Adapted to MZ, MY, ME coils

Analogue output

Output characteristic curve

1)

[V] 0…10

Accuracy [% full scale] ±3 (room temperature: 20 … 25 °C)

[% full scale] max. ±4 (room temperature: 0 … 50 °C)

Rise time [ms] 5 (typical) with ohmic load

Min. load resistance [kΩ] 2

Electronics

Operating voltage range [V DC] 15 … 30

Idle current [mA] max. 34

Ready-state delay [ms] š10

Reverse polarity protection For all electrical connections

Electromechanics

Max. cable length [m] 30

Information on cable sheath material PUR

Informationonplughousingmaterial Brass (nickel-plated, chromed)

Cable diameter [mm] 2.9

Nominal cross section of

conductor [mm

2

]0.14

Mechanics

Mounting position As desired, preferably vertical

3)

Information on housing material Polyamide (POM) reinforced

Information on keyboard material Polyamide (POM) reinforced

Information on fibre-optic cable material PA

Display/operation

Setting range threshold values:

– Switching pressure [% full scale] 0 … 100 (recommended operating range 1 … 99)

–Hysteresis(mode2) [% full scale] 0 … 100 (recommended operating range 1 … 99)

– Hysteresis (mode 1, 3) [% full scale] 2 (permanently set)

Immission/emission

Storage temperature [°C] –20 … +80

Protection class (as per EN 60529) IP40

Protection class (as per DIN VDE 0106-1) III

Resistance to shocks (as per EN 60068-2) 30 g acceleration with 11 ms duration

(half-sine)

Vibration resistance (as per EN 60068-2) 0.35 mm travel, 5 g acceleration at 10 … 150 Hz

Corrosion resistance class CRC 2

1) Starting value…Final value.

2) Switching times do not apply with additional function activated ...- TF (filter function).

3) No condensed water should be allowed to accumulate in the pressure measuring cell.