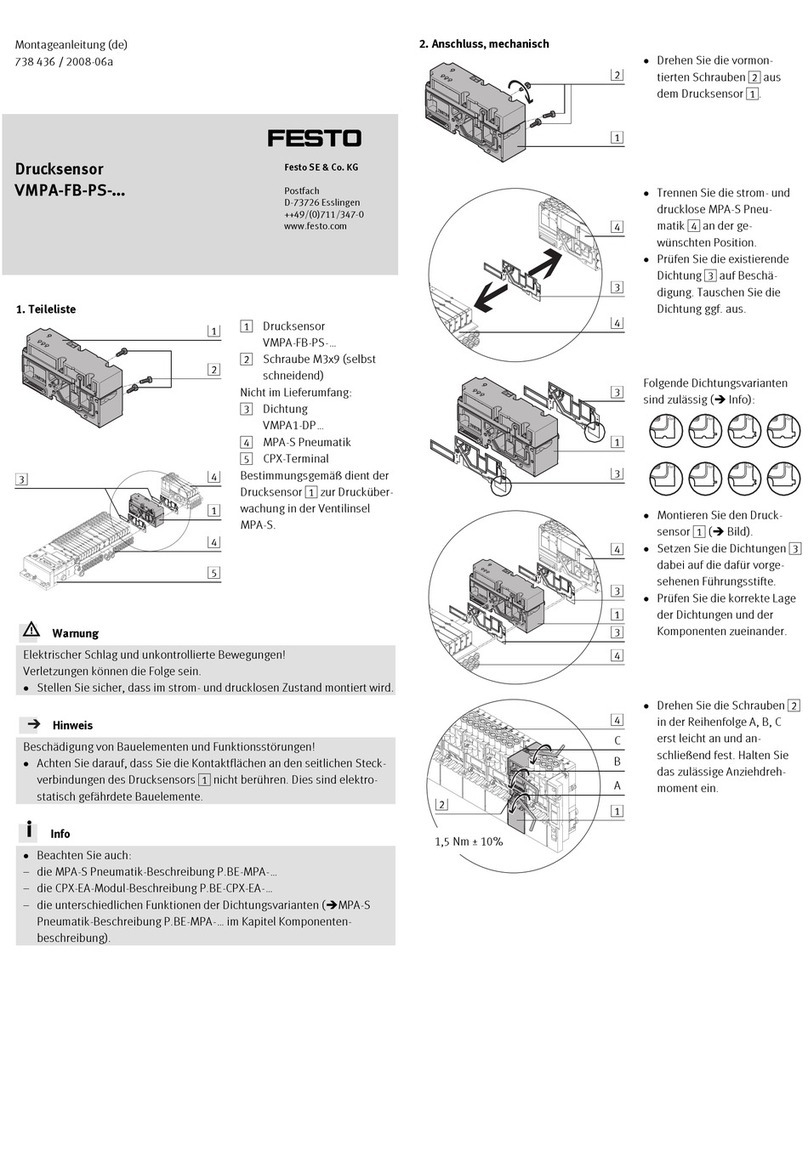

Type Circuit diagram 1)

SRAPMCA1...

1) For pin allocation, see Fig.14

Fig.13:

Pin Allocation Connection

1 Plus (+) 1)

2 Minus () 1)

3 (+) Out 4 ... 20 mA (sensor signal +)

4 () Out 4 ... 20 mA (sensor signal )

5 External Teach 2) (+24 V DC)

6 MV_IN (+) 3) 4)

7 MV_IN () 3) 4)

8 MV_OUT () 3) 5) 1

9 MV_OUT (+) 3) 5)

1) For the permissible operating voltage range, see section 13, Technical data

2) Input for an external teach signal, as an alternative to the teach button. For the current position to be

adopted, the teach signal (+24 V) must be present for min. 500 ms as when pressing the teach button.

3) Can only be used with variants with valve connection SRAP−...−...−...−2..

4) For optional use to relay the control signal for the solenoid valve (MV) infeed

5) For optional use to relay the control signal for the solenoid valve (MV) forward relay

Fig.14

4. Connect the earth connection (èFig.1 aJ ) with low impedance (short cable

with large cross−sectional area) to the earth potential.

5. Carefully plug the terminal strip onto the pin strip. Make sure that release levers

engage properly.

6. Tighten the union nut on the cable connector. This ensures the right tensile load

capacity and IP protection class.

8 Commissioning

Warning

· Keep hands away from movingparts (see section 6).

During commissioning you define the two end positions of the actuator or process

valve corresponding to the end points of the desired measuring range. In order to

do this proceed as follows:

1. Switch on the operating voltage. The green LED lights up (power supply indica

tor èFig.1 aB ).

2. Move the quarter−turn actuator into the position which is to be adopted as the

minimum teach point (teach Min. teach point for 4mA signal).

3. Hold down the teach button for at least about 0.5 sec or supply a corresponding

external teach signal (see Fig.14, pin 5). The current position will then be

adopted as the lower teach point, which is signalled by the yellow LED flashing.

The new teach point is effective immediately. However it is initially saved to a

volatile buffer memory which is cleared if there is a voltage drop.

4. Move the quarter−turn actuator into the position which is to be adopted as the

maximum teach point (teach Max. teach point for 20mA signal).

5. Hold down the teach button again for at least about 0.5 sec or supply a corre

sponding external teach signal (see Fig.14, pin 5). Both teach points are then

adopted permanently as the new end points of the measuring range. This is

signalled by the yellow LED (èFig.1 9) lighting up for 3seconds. The LEDthen

goes out. That completes the teaching procedure.

6. Now, check the signalling response of the sensor box in a test run. If the end

points have been taught correctly, the sensor box will return a corresponding

signal curve (examples èFig.4and Fig.5). If an error was made, repeat

points 2. to 6.

7. When commissioning is finished, mount the cover on the sensor box torque

max. 5 Nm.

9 Operation

· Compare the maximum values specified in these operating instructions with

your actual application (e.g. pressures, forces, torques, masses, speeds, tem

peratures). The product can only be used in accordance with the relevant safety

guidelines if the maximum load limits are observed.

10 Service and maintenance

If used as designated in the operating instructions, the device will be free of main

tenance.

· Clean the outside of the product with a soft cloth. The permitted cleaning agent

is soap suds.

11 Removal and repairs

Make sure that the following energy sources are switched off:

Electrical power supply

Compressed air supply

· Remove the sensor box in the reverse order of installation

(èsection 7.1).

For information about spare parts and auxiliary means èwww.festo.com/spare

parts.

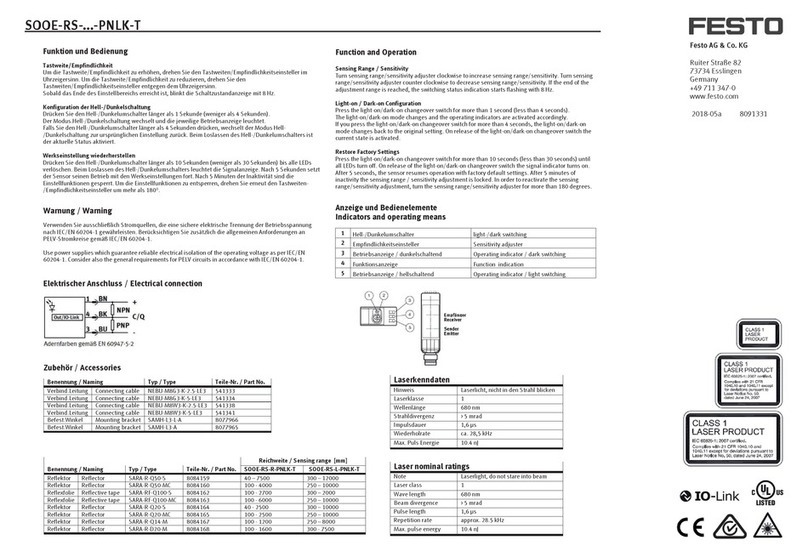

12 Eliminating malfunctions

Malfunction Possible cause Remedy

Incorrect or unex

pected signal at the

analogue output

Operating voltage below the per

mitted range

Adjust the operating voltage to

within the permitted tolerance

range

Short circuit/overload at relevant

output

Eliminate short circuit/overload

Broken wire Replace cable

End points of the measuring range

incorrectly defined

Define the end points again using

the teaching procedure

Noisy or slow measuring signal

due to incorrect filter setting in

the PLC/IPC

Correct the filter setting in PLC/IPC

Fig.15

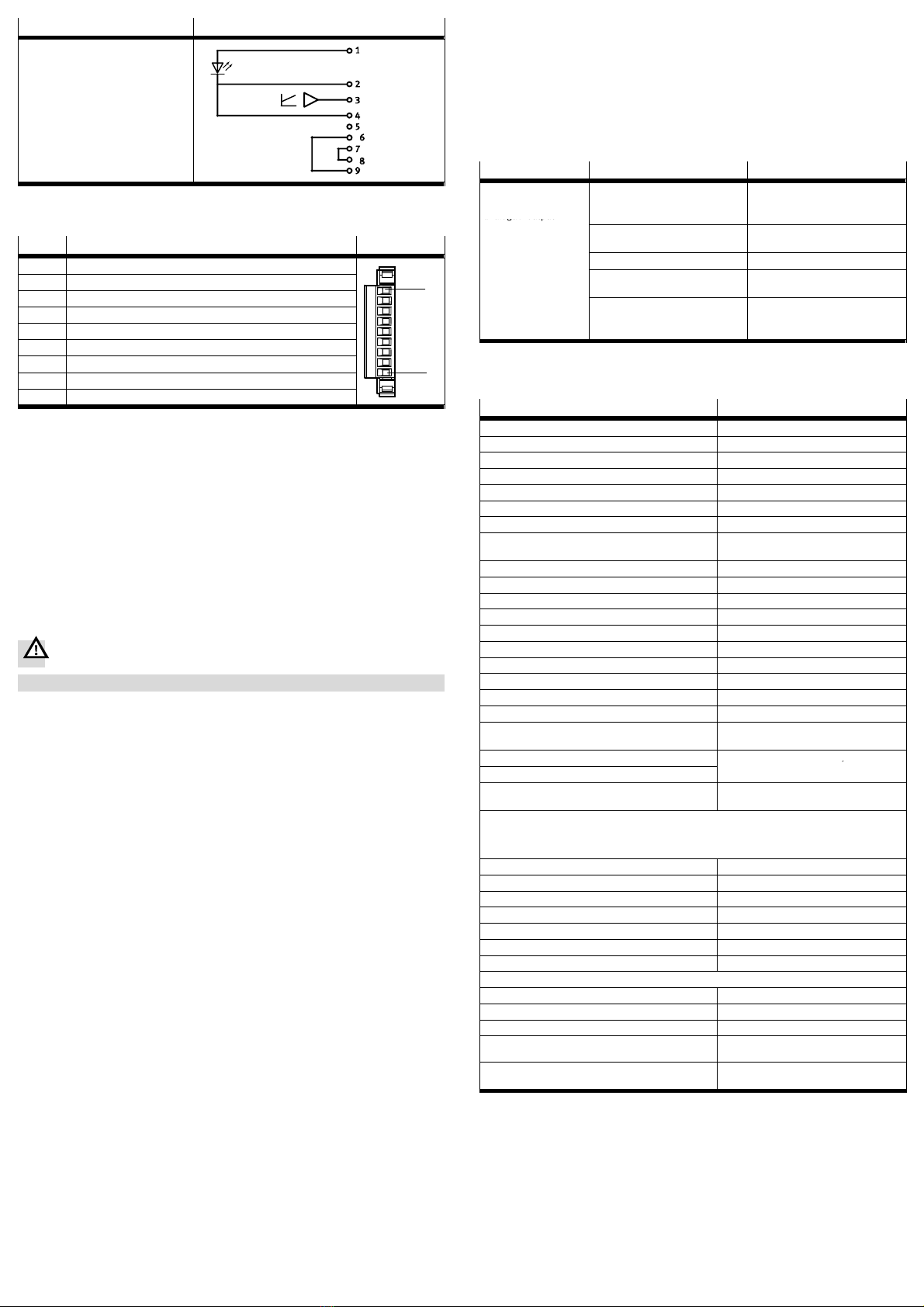

13 Technical data

SRAP−...−...

Based on standard VDI/VDE 3845 (NAMUR)

Mounting position Any

Protection against short circuit Yes

Measured variable Rotation angle

Measuring principle Magnetic Hall

Reverse polarity protection All electrical terminals

Setting range, angle sensing [°] 0 ... 270

Sensing range tolerance at the end posi

tions

[°] Min. 5/max. +5

Operating principle Non−contacting semiconductor output

Analogue output [mA] 4 ... 20 1)

Operating voltage range DC [V DC] 15 ... 30

Overload protection Yes

Idle current [mA] < 40

Max. load resistance at current output [] 300 (up to 500 in case of overload)

Linearity [°] ±5

Hysteresis [°] ±2

Repetition accuracy of analogue value [°] ±1

Temperature coefficient [°/K] < 0.15

Position hysteresis (buffer on the teach

points)

[°] 7.2

Interference immunity See declaration of conformity

Interference emission

èwww.festo.com

CE mark (see declaration of conformity

èwww.festo.com)

In accordance with EU EMC Directive 2)

Continuous shock resistance to DIN/IEC 68, part 2−82

Shock resistance to DIN/IEC 68, part 2−27

Vibration resistance to DIN/IEC 68, part 2−6

When directly mounted on DFPB−... Severity level 2

When mounted with mounting bracket Severity level 1

Protection class IP 65

Ambient temperature [°C] 20 ... +80

Surge capacity [kV] 0.8

Insulation voltage [V] 50

Degree of contamination 3

Materials information 3)

Housing, shaft Wrought aluminium alloy

Cover of position indicator Polycarbonate

Seal Nitrile rubber, fluoro elastomer

Mounting screws, toothed disc, retaining

washer Stainless steel (A2−70)

Sensor system, position indicator

(internal) Polyacetate

1) At positions outside the defined measuring range (out of range): 2 mA

2) In residential areas, measures for radio interference suppression may be necessary.

3) For information on the resistance of materials to aggressive media èwww.festo.com.

Fig.16