6.6 Teaching the switching points (TEACH mode)

There is no time-out in the TEACH mode. The sensor changes to the RUN mode

only after the entire teach process is ended.

If the security code is activated, the parameter entry option is blocked: [Lock]

flashes.

• Enter the security code è 6.4.1 Entering the security code.

Requirement:

– The sensor is ready for operation (RUN mode).

Teach-in switching points

1. Establish the switching function in EDIT mode

è 6.4.2 Configuring switching output.

2. Create pressure value 1.

3. Press A pushbutton and Edit pushbutton simultaneously.

ÄThe current pressure value will then be adopted as the first teaching

point (TP1).

[t-IN] flashes.

4. Create pressure value 2.

5. Press A pushbutton and Edit pushbutton.

ÄThe current pressure value is adopted as the second teaching point (TP2).

Switch to the RUN mode.

7 Operation and use

NOTICE!

Property damage due to high temperatures.

Extreme pneumatic conditions (high switching frequency with high pressure amp-

litude) can heat the product above 80°C.

• Select the operating conditions (in particular the ambient temperature, pres-

sure amplitude, switching frequency, current consumption) such that the

product does not heat up above the maximum permitted operating temperat-

ure.

7.1 Restoring Factory Settings (Restore)

By resetting to the factory settings, the current settings are lost. Note down cur-

rent settings before resetting.

1. Switch off operating voltage.

2. Hold down the A and B pushbutton.

3. Switch on the operating voltage.

4. Additionally, press the Edit button.

Ä[RSto PArM] appears. All parameters are reset to the factory settings.

8 Maintenance and Care

1. Switch off the energy sources (operating voltage, compressed air).

2. Clean sensor with non-abrasive cleaning agents.

9 Malfunctions

9.1 Fault clearance

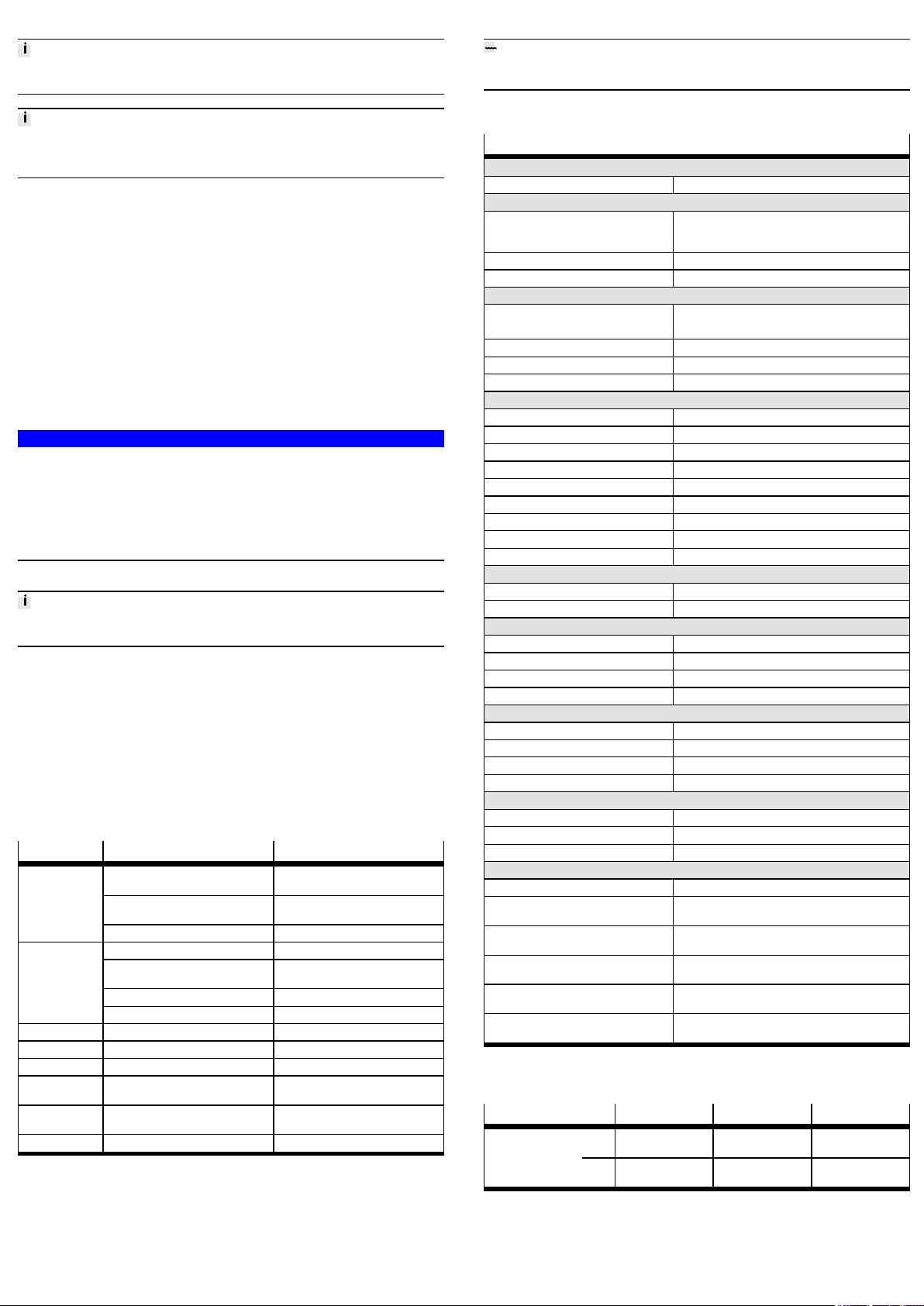

Malfunction Possible cause Remedy

No operating voltage or impermissible

operating voltage

Apply permissible operating voltage

Electrical connections swapped Connect the device in accordance with

the circuit diagram

No display

Device faulty Replace device

Short circuit or overload at the output Eliminate short circuit/overload

Incorrect switching point taught

(e.g.at 0kPa)

Repeat teach-in

Device faulty Replace device

Indicator or

switching output

does not react in

accordance with

the settings

Parameter incorrect Reset to factory settings

[Er01]/[FAIL] 1) Device faulty Replace device

[Err10]/[OVER] Measuring range exceeded Hold measuring range

[Er21]/[SHRt] 2) Short circuit at OutA Eliminate short circuit

[Err]/[BUSY] OutA is switched active Check device settings

è 6.4.4 Replicating parameters.

[Err]/[ID] DeviceID error, replication function

failed

Use sensors with the same type when

replicating (same DeviceID)

[Err]/[COMM] Communication errors Check wiring

1) Display flashes red

2) Display is red

Tab. 9

10 Disassembly

1. Switch off operating voltage and compressed air.

2. Disconnect pneumatic and electrical connections from the device.

3. Loosen mountings and remove device.

11 Disposal

ENVIRONMENT!

Send the packaging and product for environmentally sound recycling in accord-

ance with the current regulations èwww.festo.com/sp.

12 Technical data

SPAN-B-

General information

Approval RCM compliance mark

Input Signal/Measuring Element

Operating medium Compressed air in accordance with ISO 8573-1:2010

[7:4:4]; inert gases, operation with lubricated medium

possible

Temperature of medium [°C] 0…+50

Ambient temperature [°C] 0…+50

Output, general

Accuracy

[%FS] ± 1.5 at room temperature

[%FS] ± 3 over complete temperature range

Repetition accuracy [%FS] ± 0.3, at [Filt] = [OFF]

Temperature coefficient [%FS/K] typ. 0.1

Switching output

Switching output 1x PNP or 1x NPN, switchable

Switching function Threshold value comparator, window comparator

Switch-on/switch-off time [ms] Max.1

Max. output current [mA] 80

Capacitive load maximum DC [nF] 100

Voltage drop [V] max. 2

Pull-down resistor integrated (PNP)

Pull-up resistor not integrated (NPN)

Inductive protective circuit present

Output, additional data

Short circuit current rating yes

Overload protection present

Electronics

Operating voltage range DC [V] 10.8…30 (nominal voltage 12…24)

No-load supply current [mA] max. 30

Ready-state delay [ms] typ. 30

Reverse polarity protection All connections against each other

Mechanics

Housing material PA-reinforced

Inspection window material PC

Keypad material TPE-O

Materials in contact with the medium 1) FPM, NBR, PA reinforced, brass (nickel-plated)

Display/operation

Displayable units 2) bar, kPa, MPa, psi, mmHg, inchHg

Setting range threshold values [%FS] 1…99

Hysteresis setting range [%FS] 0…90

Immissions/emissions

Storage temperature [°C] –20…+80

Max. permissible relative

humidity

[%RH] 85

Degree of protection in accord-

ance with EN 60529

IP40

Protection class in accordance with

DIN VDE 0106-1

III

Shock resistance in accordance with

EN 60068-2

30g acceleration with 11 ms duration (half-sine)

Vibration resistance in accordance with

EN 60068-2

10…60 Hz: 0.35mm/60…150 HZ: 5g

1) depending on the variant

2) depending on the variant

Tab. 10

SPAN-B -B2 -B11 -V1

Pressure measuring

range

[bar]

[MPa]

–1…1

–0.1…0.1

–1…10

–0.1…1

0…–1

0…–0.1

Overload range [bar]

[MPa]

–1…5

–0.1…0.5

–1…15

–0.1…1.5

–1…5

–0.1…0.5

Tab. 11