Position sensor

SDAT-MHS

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Operating instructions

(Translation of the original instructions)

8080039

2017-11e

[8080041]

Position sensor English...............................................

1 About this document

This document describes the use of the above-mentioned product.

For detailed specifications on the product, a complete description, the software

for the device (IODD) and the declaration of conformity

èwww.festo.com.

For all available product documentation èwww.festo.com/pk

2 Safety

2.1 General safety information

Only use the product in its original condition without unauthorised modifications.

Avoid having magnetic bodies near the position sensor. These could influence

the magnetic field and thereby the behaviour of the sensor.

This product can generate high frequency interference, which may make it ne

cessary to implement interference suppression measures in residential areas.

Installation and commissioning only by qualified personnel and in accordance

with the operating instructions.

2.2 Intended use

The position transmitter SDAT-MHS is intended for contactless detection of

the piston position of magnetic-sensing drives and grippers. It is appropriate

for use with with Festo drives with T-slot (profile slot 8) as well as round cylinders

and tie-rod cylinders with mounting kits.

Use the SDAT-MHS only for the suitable drives and grippers from Festo

èwww.festo.com/catalogue.

2.3 Range of application and certification

The information in this section, in combination with the UL marking on the product,

must be observed in order for there to be compliance with the certification condi

tions of Underwriters Laboratories Inc. (UL) for USA and Canada. Observe the fol

lowing English-language remarks from UL:

UL approval information

Product category code NRKH, NRKH7

File number E232949

Considered standards UL 60947-1 and UL 60947-5-2, C22.2 No. 14-13

UL mark

Product category

Control Number

Ind. Cont. EQ.

(Industrial Control Equipment)

2MD1

Only for connection to an NEC Class 2 supply.

Raccorder Uniquement a un circuit de Classe 2.

This device is intended to be used with a Class 2 power source or Class 2 trans

former in accordance with UL1310 or UL1585.

As an alternative, an LV/C (Limited Voltage/Current) power source with one of

the following properties can be used:

– This device shall be used with a suitable isolating source such that the

maximum open circuit voltage potential available to the product is not more

than 30 V DC and the current is limited to a value not exceeding 8 amperes

measured after 1 minute of operation.

– This device shall be used with a suitable isolating source in conjunction with

a fuse in accordance with UL248. The fuse shall be rated max. 3.3 A and

be installed in the 30 V DC power supply to the device in order to limit

the available current.

Note that, when more than one power supply or isolating device is used,

connection in parallel is not permitted.

Electrical and environmental ratings

Input voltage Max. 30 V DC, Class 2

Input current 160 mA / max. 4.8 W

Analog output 4 … 20 mA

Transistor output max. 30 V DC, 100 mA G.P.

Maximum ambient temperature 70 °C / 158 °F

Enclosure type rating Type 1

3 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

4 Accessories

Accessories èwww.festo.com/catalogue

5 Product overview

5.1 Function

The position transmitter SDAT-MHS records the magnetic field of the piston

magnet and continuously senses the piston movement in the sensing range.

Available output signals include:

– Analogue current signal (4 … 20 mA)

– Programmable switching output (24 V)

– IO-Link communication mode

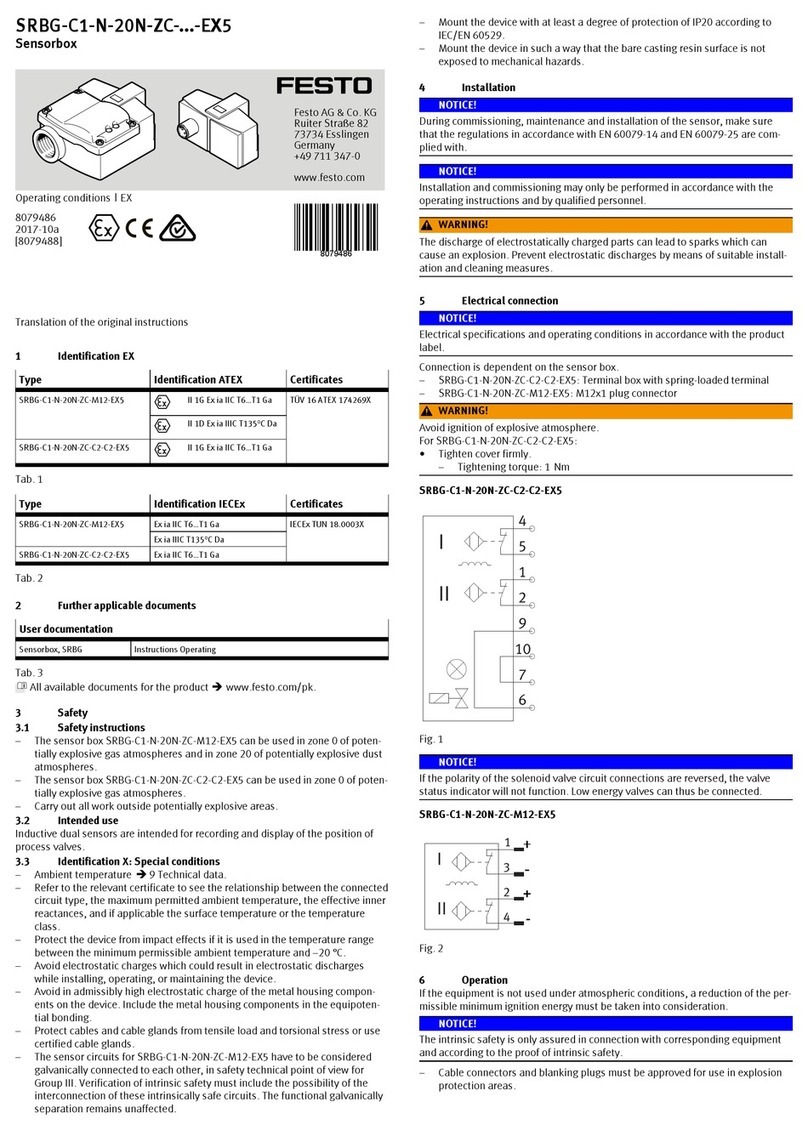

5.2 Configuration

1

2

3

2

4

5

6

7

1Connecting cables

2Mounting screw

3Plug M8, rotatable

4Red LED: status display

5Green LED: ready status display

6Yellow LED: switching status

display

7Operating key

Fig. 1

6 Mounting and installation

Warning

Risk of injury due to electric shock.

Injury caused by electric shock, damage to machine and to system

For the electric power supply, use only PELV circuits that ensure a reliable

electric disconnection from the mains network.

Observe IEC 60204-1/EN 60204-1.

Switched-mode power supplies are permitted, provided that they ensure

reliable separation in accordance with EN 60950/VDE 0805.

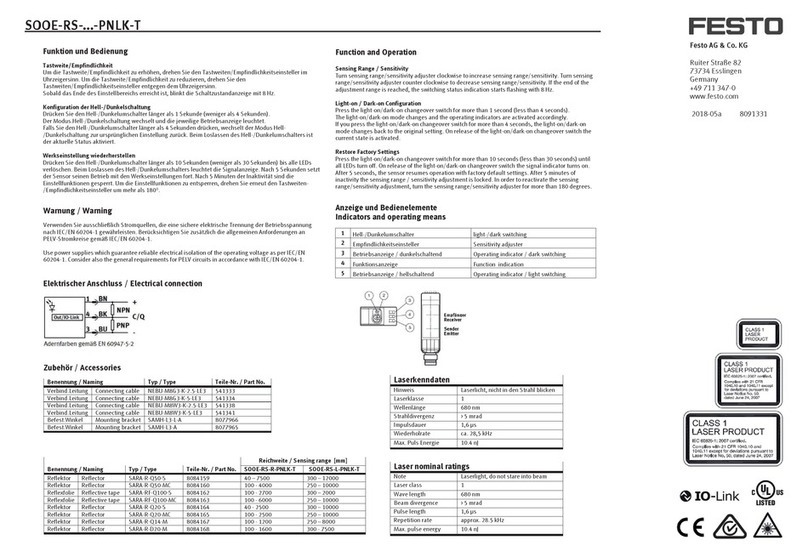

6.1 Circuit diagram and pin allocation

Fig. 2

Pin Allocation

1Operating voltage +24 V DC M8x1, 4-pin

2Switching output 2

30 V

4Switching output 1

Fig. 3