Note

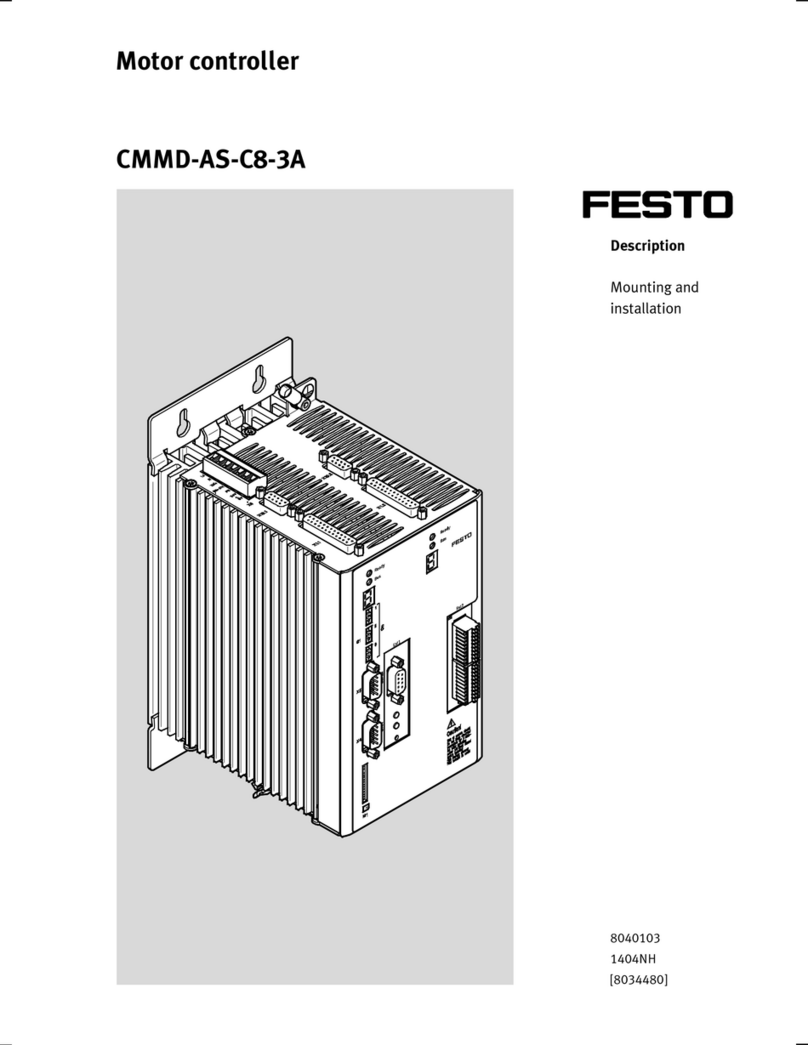

Damage to the motor controller

The motor controller is damaged in case of

– excessive operating voltage

– polarity reversal of the operating voltage connections

– interchange of operating voltage and motor connections

– short circuits in the motor circuit between the motor phases and FU

• Comply with the specified values for the supply voltage.

• Before switching on, check the connections [X9] and [X6].

• Check to ensure there is no FU short in the motor connection circuit.

Before switching on the power supply:

Check the installation of the motor controller:

• Check all connections.

• Connect all FU conductors, even for brief measuring and test purposes.

• Mounted module or cover plate on the card slot [EXT]. Mounted line on [X9]

and [X6].

Checking ready status

1. Make sure that the controller enable is switched off (controller enable: DIN 5

[X1.9] ).

2. Switch on the power supplies of all devices. The READY LED on the front of the

device should now light up.

If the READY LED is not lit, there is a malfunction. If an “E” appears in the 7-seg-

ments display followed by a sequence of numbers, this is an error message and

you must eliminate the cause of the error.

Additional steps for preparation of commissioning can be found in the

Function description GDCP-CMMS-ST-G2-FW- ...

6 Obligations of the operator for the safety function

The operational capability of the safety device is to be checked at adequate intervals. It

is the responsibility of the operator to choose the type of check and time intervals in

the specified time period. The check is to be conducted so the excellent functioning of

the safety device in interaction with all the components can be verified.

Recommendation: Carry out a performance test at least every 24 hours.

7 Diagnostics and fault clearance

No. Message group Cause/measure

01-x Internal error – stack overflow Load approved firmware.

02-x Undervoltage in intermediate

circuit

Check power supply, intermediate circuit voltage,

undervoltage monitoring (threshold value).

03-x Temperature monitoring, motor Check parameterisation (current regulator, limits).

04-x Temperature monitoring,

electronics

Check installation conditions and cylinder sizing.

05-x Internal power supply Check 24 V logic supply. If error is present without

connected peripheral equipment Repair.

06-x Intermediate circuit

(over-current)

Check motor, cable and motor controller.

07-x Intermediate circuit

(overvoltage)

Check design and connection of the braking resistor.

08-x Angle encoder Check encoder and encoder signals.

11-x Homing Check homing, switch arrangement.

12-x CAN Re-start CAN controller. Check CAN configuration in the

controller. Check wiring.

14-x Motor identification Check intermediate circuit voltage, encoder cable.

Motor blocked, e.g. holding brake does not release?

16-x Initialization Load firmware again. Hardware defective?

17-x Following error monitoring Increase error window. Parameterise acceleration to

be less. Motor overloaded?

18-x Temperature monitoring Check installation conditions.

19-x I²t monitoring Motor/mechanics blocked or sluggish?

21-x Current measurement If the error occurs repeatedly Hardware defective.

22-x PROFIBUS Check slave address, bus termination, cabling.

25-x Firmware Update the firmware.

26-x Data flash Load factory setting. Hardware defective?

29-x SD card Check SD card.

31-x I²t monitoring Check motor and mechanical system.

32-x Intermediate circuit Check mains voltage/power supply, braking resistor.

35-x Fast stop Check parameterisation.

40-x Software limit Check target data and positioning range.

41-x Path program Check parameterisation.

42-x Positioning Parameterisation/sequence control, homing?

43-x Limit switch error Check parametrisation, wiring and limit switches.

45-x STO error Check activation; the error must not recur.

64-x DeviceNet error Check configuration and network.

65-x DeviceNet error Check configuration and network.

70-x Operating mode error Check factor group and impermissible change.

79-x RS232 error Check wiring and transferred data.

8 Repair and disposal

Repair or maintenance of the motor controller is not permissible. If re-

quired, replace the motor controller.

Observe the local regulations for environmentally friendly disposal of elec-

tronic components.

9Technicaldata

The complete technical data on CMMS-ST-...-G2 Mounting and installa-

tion description GDCP-CMMS-ST-G2-HW-....

When using the safety function, observe the special technical data and

restrictions on environmental conditions in dependence on required out-

put nominal power in the description STO GDCP-CMMS-ST-G2-S1-...

Safety reference data and safety specifications

Safety function STO STO, Safe Torque Off

Category 3Grading in categories in accordance with EN ISO 13849-1

Performance Level PL d Performance level in accordance with EN ISO 13849-1

T[Years] 20 Proof test interval

Duration of use in accordance with EN ISO 13849-1

MTTF

d

[Years] 2521 Mean time to dangerous failure.

Due to the service life of the internal switching relay, the safety data for the STO function apply

for an annual actuation rate of nop = 500,000 / a (CMMS-ST-...-G2 from Rev. 02).

Type t est The functional safety engineering of the product has been

certified by an independent testing authority (certificate

www.festo.com/sp).

Reliable component yes, for the STO safety function

General technical data

Product conformity and certifications

CE marking (declaration of conformity

www.festo.com/sp)

in accordance with EU Machinery Directive 2006/42/EC

In accordance with EU EMC Directive 2004/108/EC

The device is intended for use in an industrial environment. Measures for interference suppression

may need to be implemented in residential areas.

Operating and environmental conditions

Permissible setup altitude above sea level

with nominal power [m] 1000

with power reduction [m] 1000 … 3000

Air humidity [%] 0 … 90 (non-condensing)

Degree of protection IP20

Degree of contamination 2

Ambient temperature

with nominal power [°C] 0…+40

with power reduction [°C] +40 … +50

Storage temperature [°C] –25 … +70

Vibration and resistance to shocks

Operation in accordance with EN 61800-5-1, section 5.2.6.4

Conveying in accordance with EN 61800-2, section 4.3.3

Power supply/braking resistor [X9]

Load voltage

Nominal voltage, load voltage supply [V DC] 48

Alternative load voltage supply (parameterisable) [V DC] 24, 48

Voltage range [V DC] 12 … 58

Nominal current [A] 8 (with nominal motor current)

PWM switching frequency (permanently set) [kHz] 50

Logic supply

Nominal voltage [V DC] 24 ± 20 %

Nominal current (outputs unloaded, without holding

brake)

[A] 0.2

Maximum current (incl. holding brake) [A] 1.5

Integrated braking resistor

Braking resistor [Ω] 17

Pulse power (for 50 ms) [W] 500

Nominal power [W] 10

Rated trigger level [V DC] Adjustable in FCT up to 58