12 Malfunctions

NOTICE!

Repairs to the product are not permissible. In the event of malfunctions or failure:

Replace the product and let Festo know about the failure. Return defective

products to Festo.

Fault description Cause Remedy

Piston rod does not move in the

desired direction

Displacement encoder cable

incorrectly connected at posi-

tioner or DFPI.

Correct the connection

Piston rod does not move in the

desired direction

Compressed air connections

connected incorrectly

Correct the connection

Tab. 10

13 Disassembly

1. Switch off the power supply (operating medium, electrical power supply).

2. Disconnect electrical and pneumatic connections.

3. Undo the retaining screws of the drive and remove the drive.

14 Disposal

ENVIRONMENT!

Send the packaging and product for environmentally sound recycling in accord-

ance with the current regulations èwww.festo.com/sp.

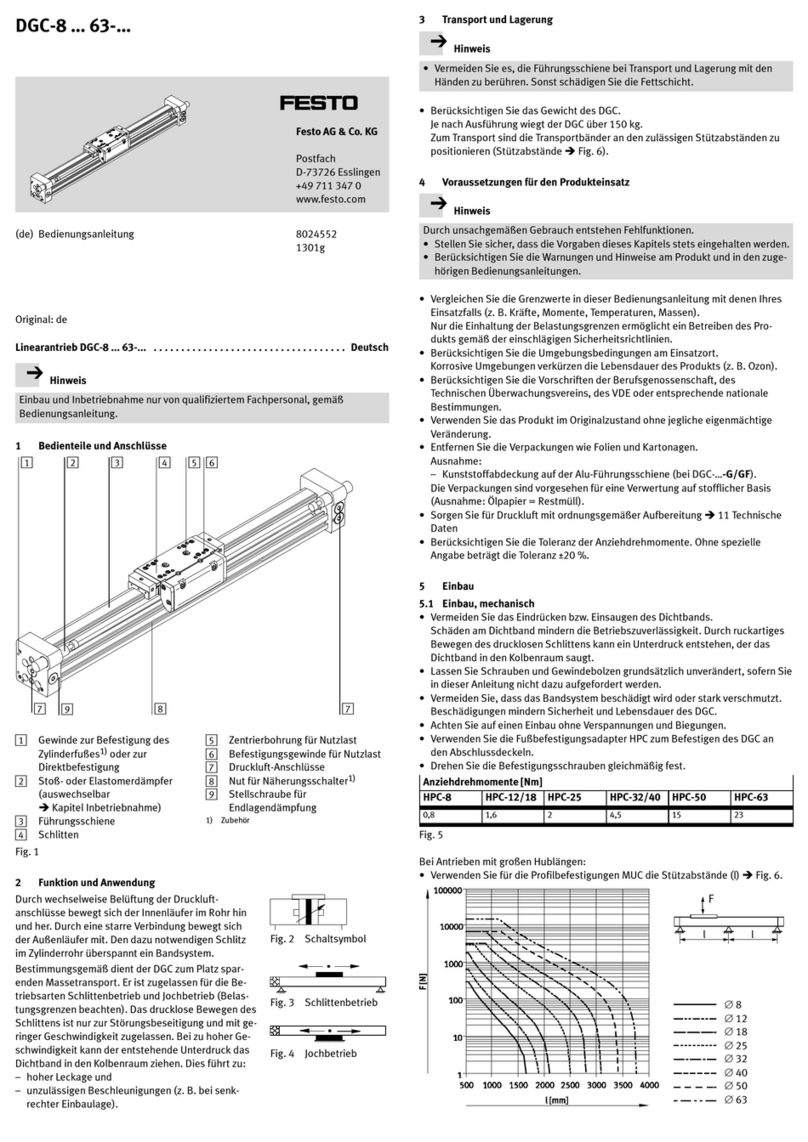

15 Technical data

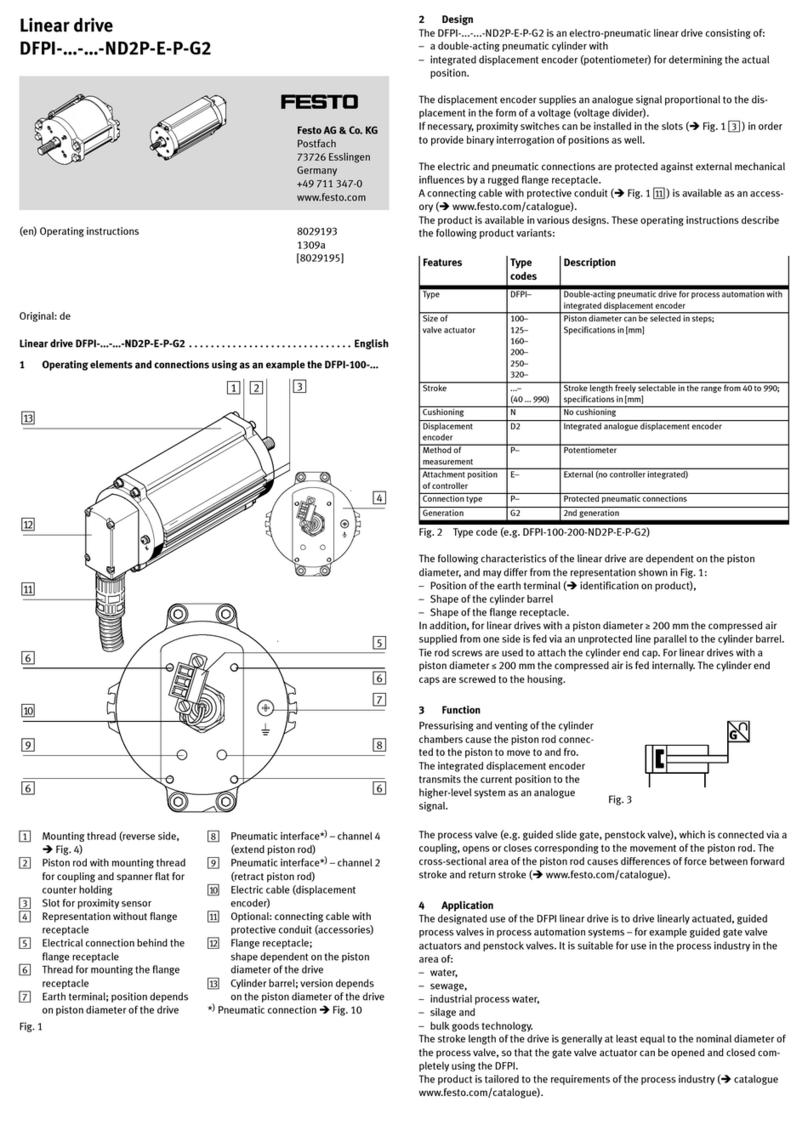

DFPI-... -100 -125 -160 -200 -250 -320

Type of mounting Mounting interface in accordance with ISO 15552

Spanner size on the piston rod 22 27 36 36 46 55

Stroke [mm] 40…990

Min./max. stroke allowance [mm] 0…4

Design Piston rod, cylinder barrel

Cushioning No cushioning

Mounting position any

Mode of operation double-acting

Position detection With integrated displacement encoder

Displacement encoder measuring principle – potentiometer (DFPI-...-NB3...)

Operating voltage range [VDC] 0…15

Independent linearity [%FS] _ 0.04

Hysteresis [mm] 0.33

Repetition accuracy [mm] _ 0.12

Resistance value of displacement encoder (at TET) dependent on stroke length1)

≤ 290mm [kΩ] 5

> 290…590mm [kΩ] 10

> 590…990mm [kΩ] 20

Recommended current at the displacement encoder

Recommended slider current [µA] < 0.1

Max. short-time slider current [mA] 10

Displacement encoder measuring principle – potentiometer with integrated transmitter (DFPI-...-

NB3...-T)

Power Supply 2-wire

Analogue output [mA] 4…20

Operating voltage range [VDC] 0…30

Reverse polarity protection Yes

Independent linearity [%FS] _ 0.05

Hysteresis [mm] 0.4

Repetition accuracy [mm] 0.7

Electrical connection

DFPI-...-NB3P

DFPI-...-NB3P9

Straight plug; 3-pin; screw terminal

DFPI-...-NB3M12 Plug M12x1, A-coded

DFPI-...-NB3P-T

DFPI-...-NB3P9-T

Terminal strip; 2-pin

DFPI -...- NB3M12-T Plug M12x1, A-coded

Pneumatic port

DFPI-...-NB3P-... for tubing outside Æ 8mm

DFPI-...-NB3P9/M12-... Air connection Gy

Operating pressure [bar] 3…8

Nominal operating pressure [bar] 6

Operating medium Compressed air in accordance with ISO 8573-1:2010

[7:4:4]

Note on the operating medium lubricated operation possible

(required in further operation)

DFPI-... -100 -125 -160 -200 -250 -320

Degree of protection in mounted

state

IP65, IP67, IP69K, NEMA 4

Ambient temperature [°C] –20…+80

Product weight

Basic weight at 0mm stroke [g] 4900 7500 12800 18100 31100 57700

Additional weight per 10mm

stroke

[g] 90 134 200 238 358 582

Moving mass at 0mm stroke [g] 1060 1900 3700 4800 9300 16500

Additional moving mass per

10mm stroke

[g] 28 53 89 89 134 227

Information on materials

Cylinder barrel Anodised wrought aluminium alloy

Cover (end cap) Coated wrought aluminium alloy

Bottom cover (bearing cap) Coated die-cast aluminium

Tie rods high-alloy stainless steel

Piston rod high-alloy stainless steel

Flange screws/nuts Coated steel

Screws – Coated steel

– high-alloy stainless steel

Rod bearing Sintered bronze

Piston rod seal PUR NBR

Static seal NBR

Note on materials – DFPI -...- NB3P: PWIS-free, RoHS-compliant

– DFPI-...-NB3P9/M12: contains PWIS, RoHS-com-

pliant

Vibration resistance in accordance

with DIN/IEC 68 Part 2-6

0.35mm path at 0…60 Hz;

5g acceleration at 0…150 Hz

Continuous shock resistance as

per DIN/IEC68 Part 2-82

_ 15g at 6ms duration; 1000 shocks per direction

1) TET = theoretical electrical travel

Tab. 11 Technical data

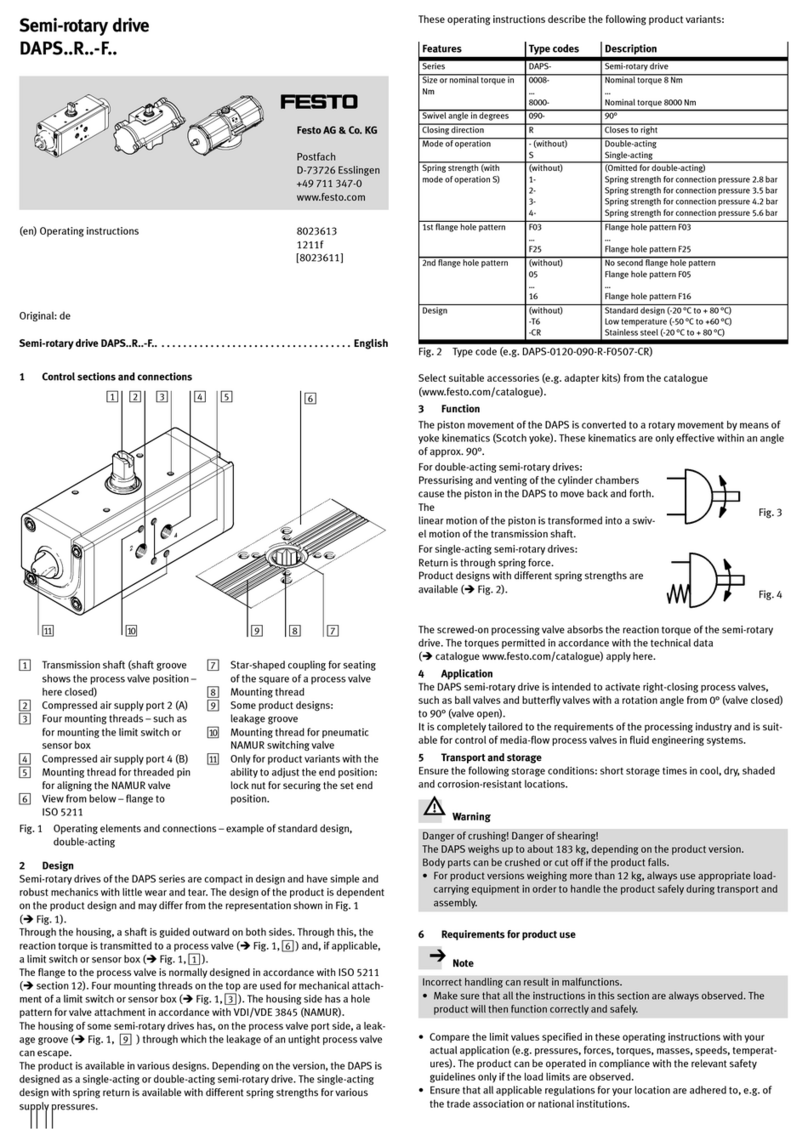

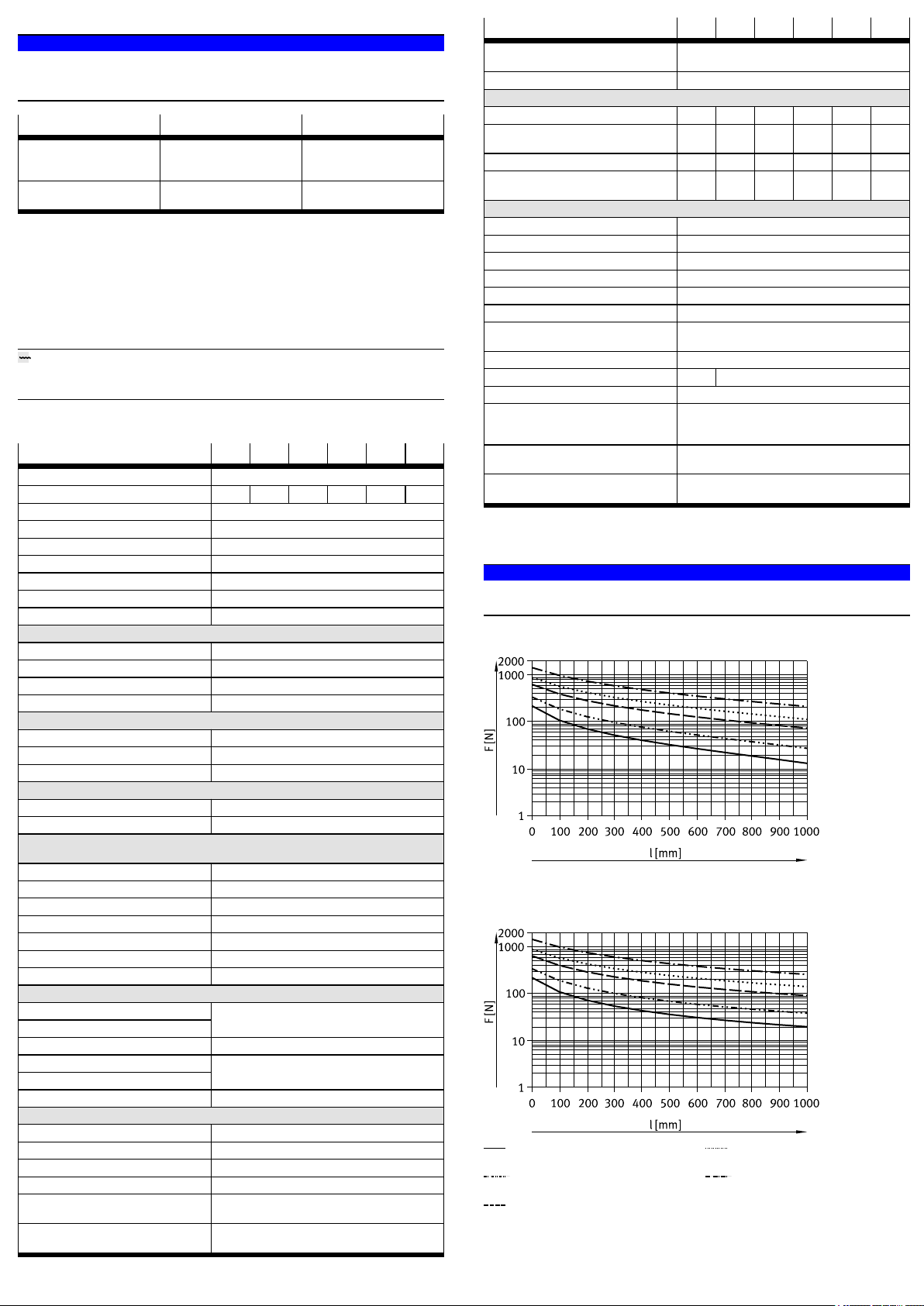

15.1 Max. permissible lateral forces for static applications

NOTICE!

In controlled operation, it may be necessary to adjust the max. lateral force to the

type of control.

Horizontal installation

Fig. 8

Vertical installation

Æ 100

Æ 125

Æ 160/200

Æ 250

Æ 320

Fig. 9