DRVS

Semi-rotary drive

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Operating instructions

8158337

2021-10

[8158339]

Translation of the original instructions

© 2021 all rights reserved to Festo SE & Co. KG

1Applicable Documents

All available documents for the product è www.festo.com/sp.

2 Safety

2.1 Safety instructions

–Only use the product in its original condition without unauthorised modifica-

tions.

–Take into account the ambient conditions at the location of use.

–Only use the product if it is in perfect technical condition.

–Store the product in a cool, dry environment protected from UV and corrosion.

Keep storage times short.

–Before working on the product, switch off the compressed air supply and lock it

to prevent it from being switched on again.

2.2 Intended use

The product is intended to swivel payloads that must execute a defined angular

movement.

2.3 Foreseeable misuse

Do not exceed the maximum permissible transverse loads è 11 Technical data.

2.4 Training of qualified personnel

Work on the product may only be carried out by qualified personnel who can

evaluate the work and detect dangers. The qualified personnel have skills and

experience in dealing with pneumatic (open-loop) control technology.

3 Additional information

–Contact the regional Festo contact if you have technical problems

è www.festo.com.

–Accessories è www.festo.com/catalogue.

4 Function

The pneumatic ports [4] are pressurised alternately, causing the inner sash in the

housing to swivel back and forth. The swivel motion is transmitted to the drive

shaft [1]. The drive shaft serves as an interface and connecting element for the

extension elements push-on flange FWSR and push-on flange DARF. The square

[2] serves as a connecting element for the extension elements sensors SRBS, stop

kit KSM and stop kit DADP.

5 Product design

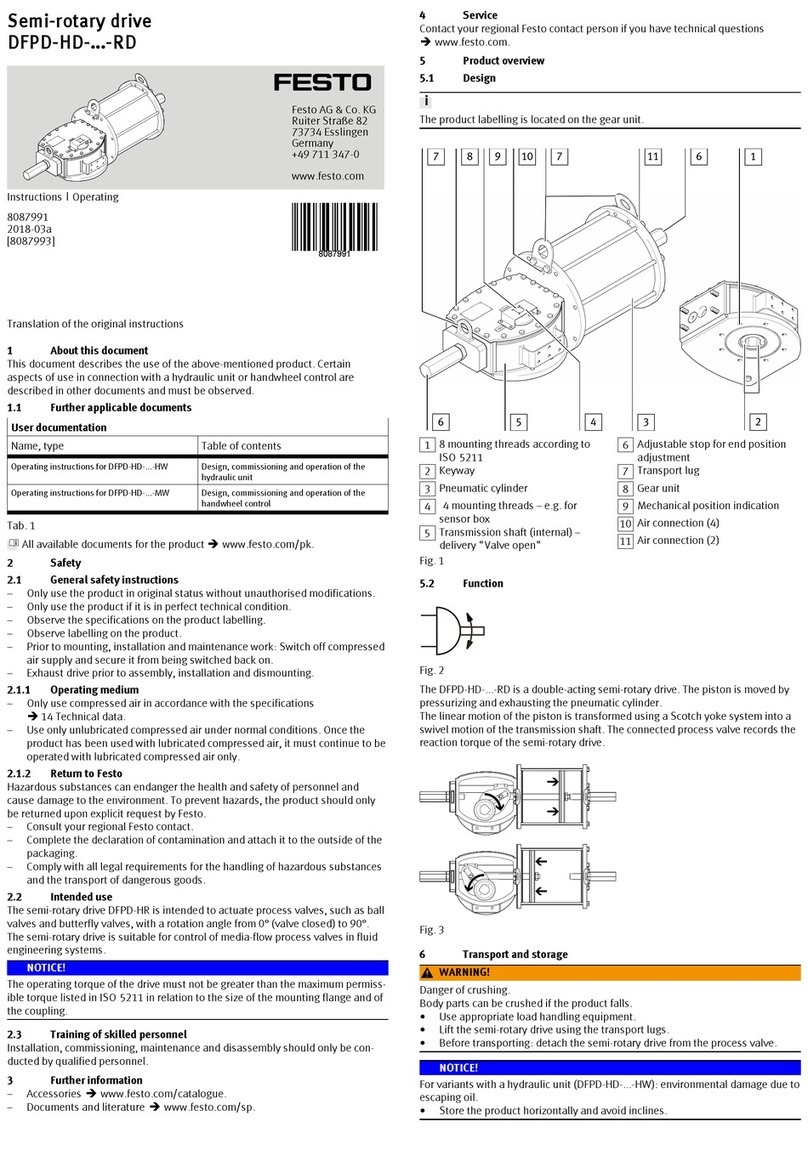

Fig. 1: Product design

Output shaft

Square

Thread

depending on size (3x, 4x)

Pneumatic port (2x)

6 Assembly

1. Mount the product on the threads [3].

2. Push the payload onto the drive shaft and fasten it.

7 Installation

Use one-way flow control valves to set the swivel speed.

•Screw the one-way flow control valves into the pneumatic ports [4].

8 Commissioning

For use with reduced particle emission:

Clean the product with a clean, soft cloth and non-abrasive cleaning agents.

1. Close the one-way flow control valves completely.

2. Unscrew the one-way flow control valves one turn.

3. Pressurise the product slowly.

4. Start a test run.

5. Take the following into account in the test run:

–The swivel range

–The swivel speed

6. Make changes only when stationary.

7. Unscrew the one-way flow control valves until the required swivel speed

is reached. Do not fall below the minimum permissible swivel time

è www.festo.com/catalogue.

NOTICE

Dynamic characteristic values that are too high can lead to the destruction of

the product, e.g. internal vanes.

• Observe the mass moment of inertia and the maximum permissible swivel

frequency.

8. Terminate the test run.

9 Cleaning

Clean the product with a clean, soft cloth and non-abrasive cleaning agents.

For use with reduced particle emission:

–Remove abraded particles and soil from the product:

–Prior to initial commissioning

–Regularly during operation

10 Fault clearance

Fault description Cause Remedy

Uneven movement The flow control valves are

incorrectly adjusted.

Check the exhaust air flow con-

trol

Hard impacts at the end posi-

tion

Excessive residual energy –Select a lower rotational

speed.

–Use external shock

absorbers.

–Only drive against the

residual air cushion on the

exhaust air side.

–Select a smaller payload

mass.

The output shaft does not

remain in the end position.

Tab. 1: Fault clearance

11 Technical data

DRVS -6 -8 -12 -16

Pneumatic port M3 M5

Mounting position any

Design Rotary cylinder with rotary vane

Cushioning Elastic cushioning, at both ends

Ambient temperature [°C] 0 … 60

Storage temperature [°C] 0 … 20

Operating medium Compressed air to ISO 8573-1:2010 [7:4:4]

Information on operating

medium

lubricated operation possible, in which case lubricated

operation will always be required

Operating pressure [MPa] 0.35 … 0.8 0.25 … 0.8

[bar] 3.5 … 8 2.5 … 8

[psi] 50.75 … 116 36.25 … 116

Forces

Permissible impact force Fmax [N] 15 30 90 160

Theoretical torque at 0.6 MPa

(6 bar, 87 psi)

[N] 0.15 0.35 1 2

Max. permissible forces on the drive shaft

Axial force Fx[N] 10 20 25

Radial force Fz[N] 15 20 25 30

Mass moment of inertia at 0.6 MPa (6 bar, 87 psi)

unthrottled 10-4 kgm20.05 0.1 0.3 0.6

throttled 10-4 kgm26.5 13 50 100

Max. permissible swivel frequency

DRVS-...-90 [Hz] 3

DRVS-...-180 [Hz] 3

DRVS-...-270 [Hz] – – 2

Tab. 2: Technical data DRVS-6 … -16