Translation of the original instructions

© 2020 all rights reserved to Festo SE & Co. KG

1 About this document

1.1 Purpose of the document

This document describes the use of the above-mentioned product.

The document contains additional information for the use of the product in safety-

oriented systems (safety handbook in accordance with IEC61508).

1.2 Applicable documents

All available documents for the product èwww.festo.com/sp.

Document Contents

Operating conditions EX Information on the use of the product in poten-

tially explosive gas atmospheres

Certification documents Test certificates for machine safety

Tab. 1 Applicable documents

1.3 Target group

The document is targeted towards individuals who install and operate the

product.

The document is additionally targeted towards individuals who are entrusted with

the planning and application of the product in a safety-oriented system.

1.4 Specified standards

Version

IEC61508-1:2010 IEC61508-7:2010

IEC61508-2:2010 IEC61511:2016

IEC61508-4:2010 –

Tab. 2 Specified standards

2 Safety

2.1 General safety instructions

– Only use the product in original status without unauthorised modifications.

– Only use the product if it is in perfect technical condition.

– Take into consideration the legal regulations for the installation location.

– Take into consideration the ambient conditions at the location of use. Corros-

ive environments reduce the service life of the product.

– Observe the specifications on the product labelling.

– Observe labelling on the product.

– Prior to mounting, installation and maintenance work: Switch off compressed

air supply and secure it from being switched back on.

– Exhaust drive prior to assembly, installation and dismounting.

– Product must be regularly tested by a qualified technician, and the test must

be documented è 9 Maintenance.

– Protect the device from pressure fluctuations. Use overpressure valves and

pressure regulators.

Operating medium

– Use compressed air only in accordance with the specifications

è 14 Technical data.

– Use only unlubricated compressed air under normal conditions. Once the

product has been used with lubricated compressed air, it must continue to be

operated with lubricated compressed air only.

Return to Festo

Hazardous substances can endanger the health and safety of personnel and

cause damage to the environment. To prevent hazards, the product should only

be returned upon explicit request by Festo.

– Consult your regional Festo contact.

– Complete the declaration of contamination and attach it to the outside of the

packaging.

– Comply with all legal requirements for the handling of hazardous substances

and the transport of dangerous goods.

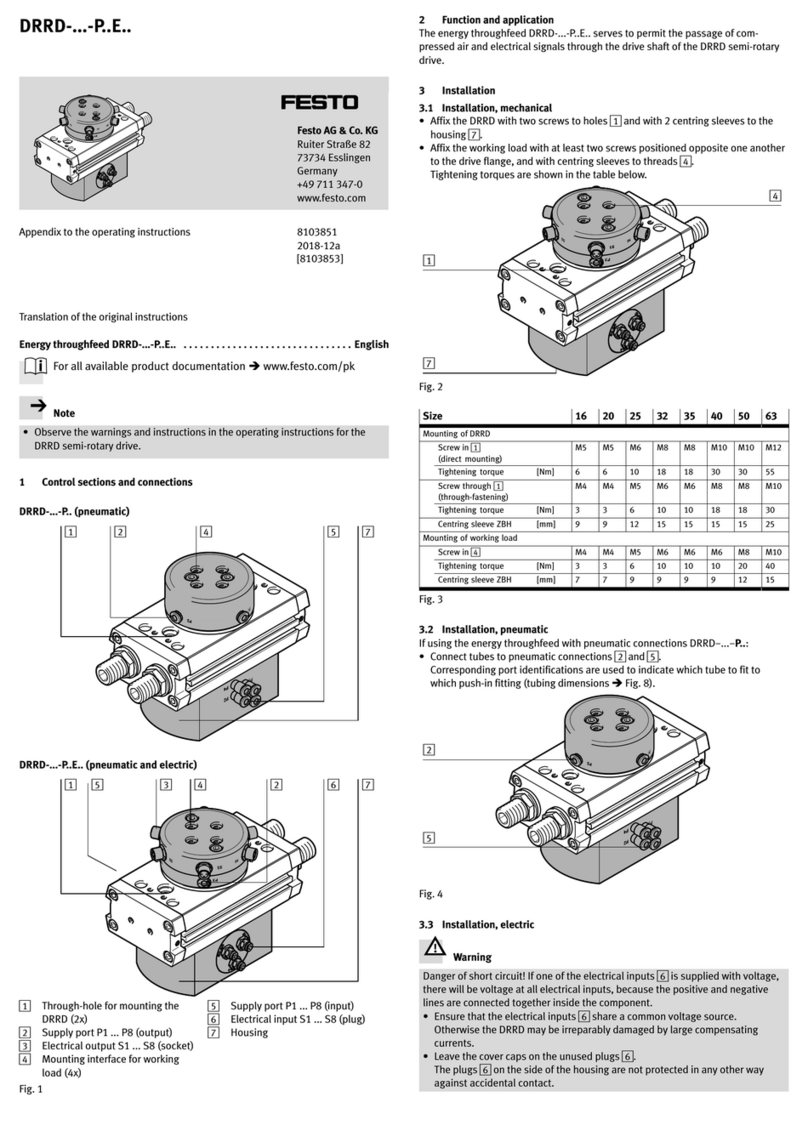

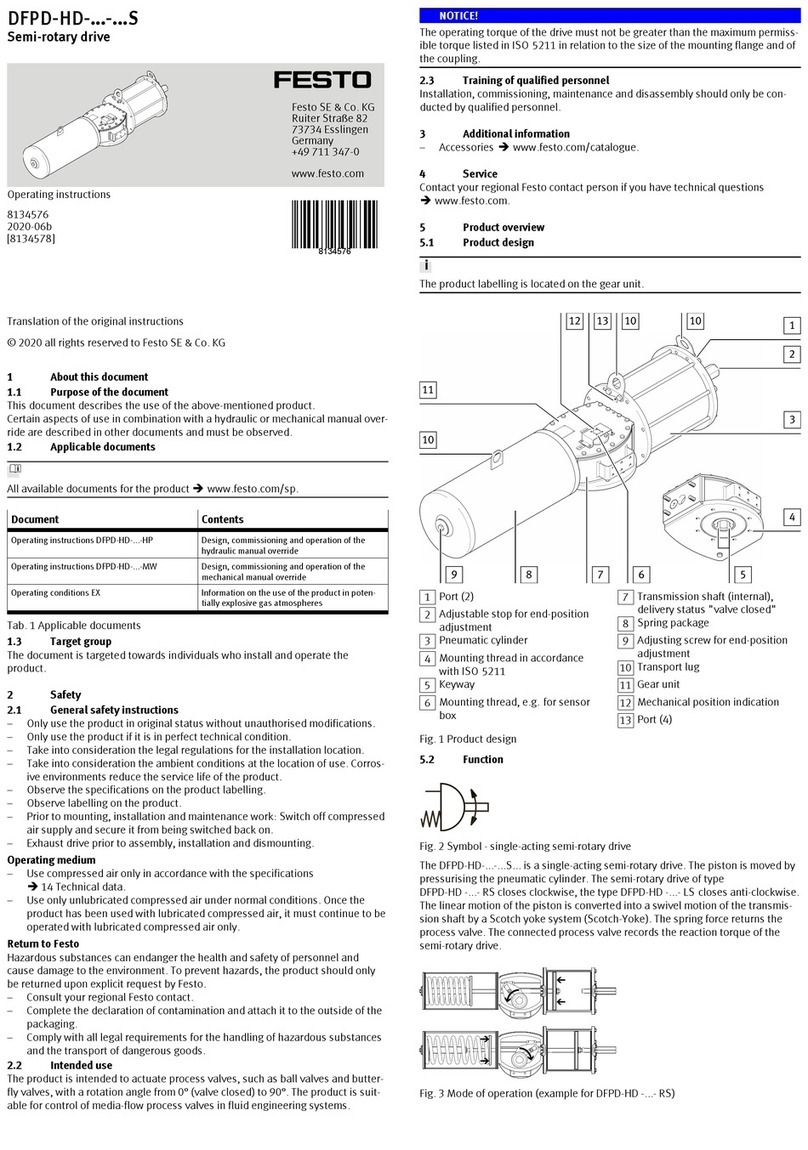

2.2 Intended use

The product is intended to actuate process valves, such as ball valves and butter-

fly valves with a rotation angle from 0° (valve closed) to 180° (depending on the

version).

NOTICE!

The operating torque of the drive must not be greater than the maximum permiss-

ible torque listed in ISO5211 in relation to the size of the mounting flange and of

the coupling.

2.2.1 Information on functional safety

2.2.1.1 Achievable safety classification

The product is suitable for use as an element in a safety-oriented system in

accordance with IEC61511.

– in Low Demand Mode up to SIL2

– in High Demand Mode up to SIL1

Considering the necessary minimum hardware fault tolerance of HFT=1, the

product can also be used up to SIL3 in a redundant execution of the entire sys-

tem.

NOTICE!

The suitability for certain applications can only be determined in connection with

the assessment of further components of the subsystem. These must achieve the

same safety level.

2.2.1.2 Safety function

Single-acting semi-rotary drives DFPD-...-RS/DFPD-...-LS

The element safety function consists of the control valve moving to the switching

position when the compressed air is switched off. It is returned by spring force.

Double-acting semi-rotary drives DFPD-...-RD/DFPD-...-LD

The element safety function consists in the execution of a complete working

stroke (opening or closing the process valve) within a defined time.

2.2.1.3 Operating conditions

– General information on safe operation è 2.1 General safety instructions.

– Periodic tests (function test) è 9 Maintenance.

– Ambient conditions and additional technical specifications

è 14 Technical data.

2.2.1.4 Limitations of use

If used in a safety-oriented system, the service life is limited to 8years subject to

compliance with the operating conditions.

– Recommended interval for a complete function test: 1year

– Maximum permissible interval for a complete function test: 3years

If function tests are negative, maintenance work must be performed immediately.

2.2.1.5 Characteristic values

Safety characteristic (in accordance with

IEC61508)

Value

Probability of dangerous failure on demand

(Probability of Dangerous Failure on Demand)

PFDspec 8.89·10-4

Assumed test interval (Assumed Test Interval) Ti1 a

Confidence level (Confidence Level) 1-á95%

Hardware fault tolerance (Hardware Fault Tolerance) HFT 0

Diagnostic coverage (Diagnostic Coverage) DC 0

Type of subsystem (Type of Sub System) Type A

Mode of operation (Mode of Operation) Low Demand and

High Demand

Degree of detection of dangerous errors by the proof test

(Proof Test Coverage)

PTC 99%

Assumed demands per year (Low Demand Mode)

(Assumed Demands per Year)

nop 1/a

Failure rate for dangerous errors not detected

(Lambda Dangerous Undetected)

ëDU 1.01·10-7/h

Mean time to failure (dangerous)

(Mean Time to Failure dangerous)

MTTFD1.126 a

Low Demand Mode (double-acting)

Failure rate for dangerous errors not detected

(Lambda Dangerous Failure Rate)

ëD3.24·10-7/h

Mean probability of dangerous failure on demand

(Average Probability of Failure on Demand) 1oo1

PFDavg (TI = 1 a) 1.42·10-3

Mean probability of dangerous failure on demand

(Average Probability of Failure on Demand) 1oo2

PFDavg (TI = 1 a) 1.44·10-4

Low Demand Mode (single-acting)

Failure rate for dangerous errors not detected

(Lambda Dangerous Failure Rate)

ëD1.78·10-7/h

8147709

DFPD-...

Semi-rotary drive

8147709

2020-11d

[8147711]

Operating instructions

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com