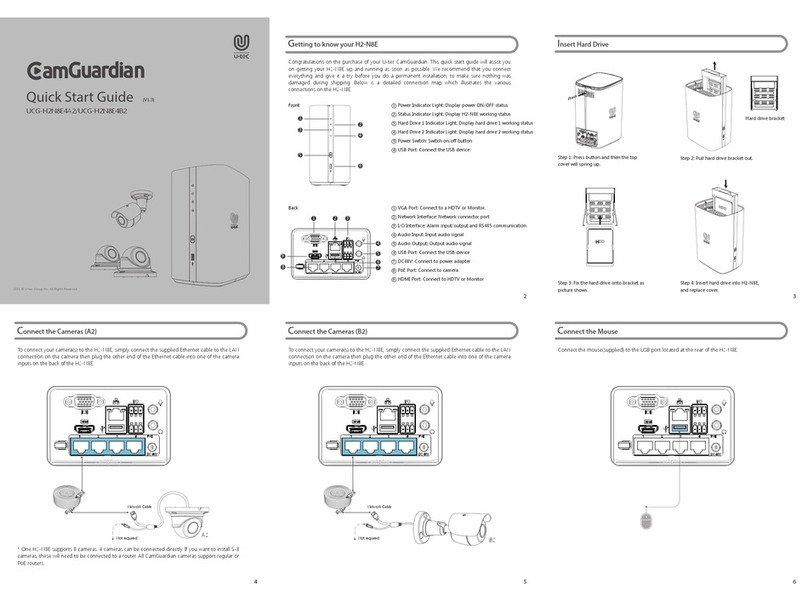

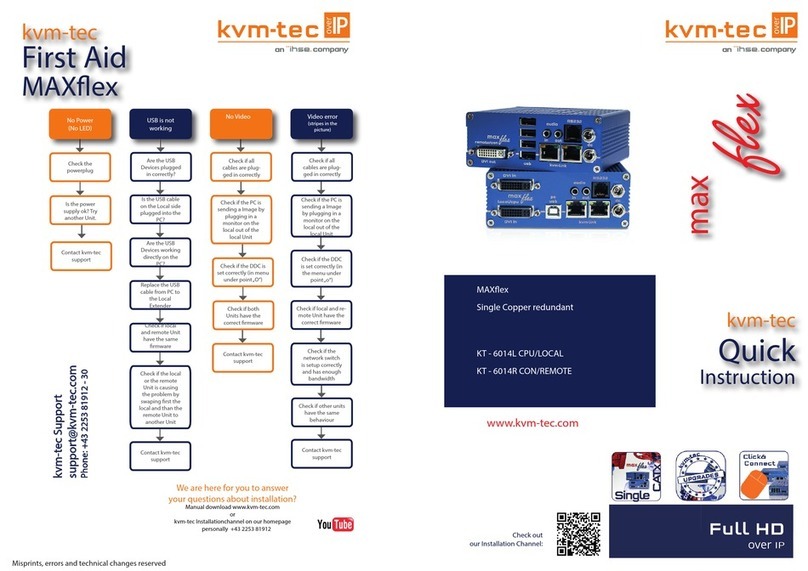

9Preparations for Cable Connectio

Internal cables are the wires and cables t

are usually connected before delivery. In

on site. The items to check include wheth

wires and cables are properly and neatly

whether incorrect insertion or poor inserti

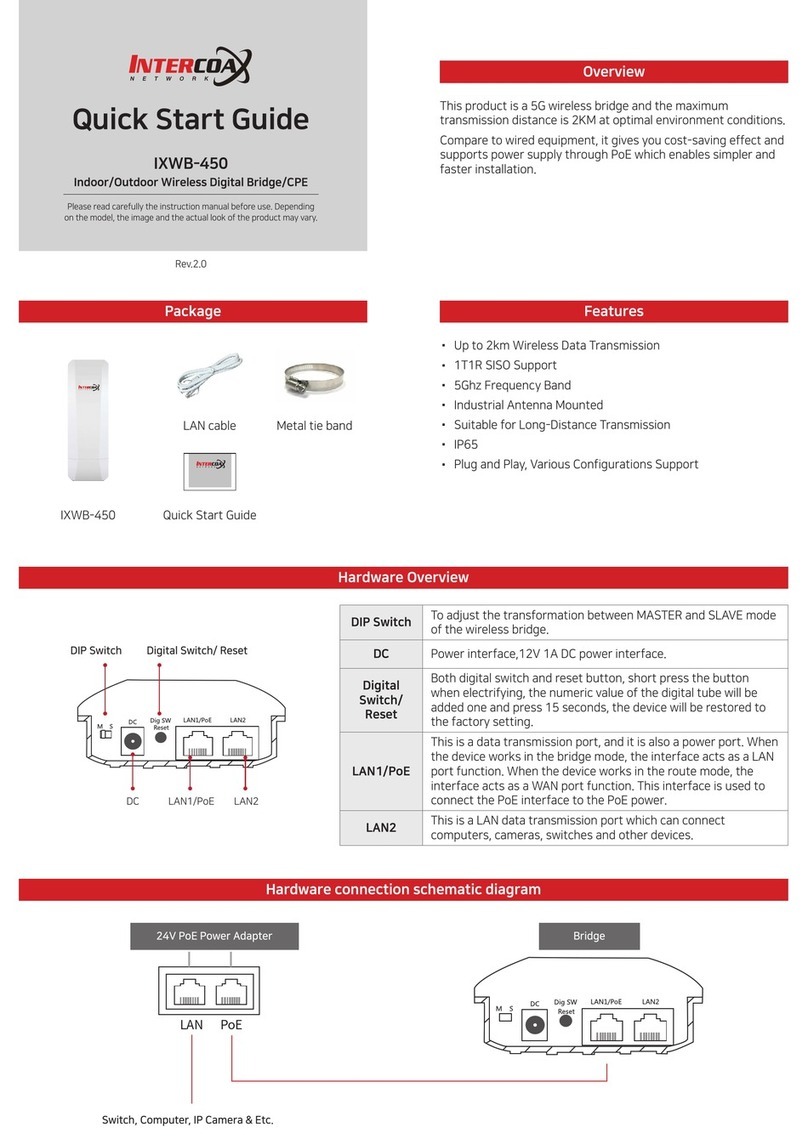

The installers can choose the top access

according to the equipment room and the

access wiring mode as an example for d

Note

Before laying out wires and cables, you n

limited for operations, remove the baffle

After you have completed layout of wires

original places.

-

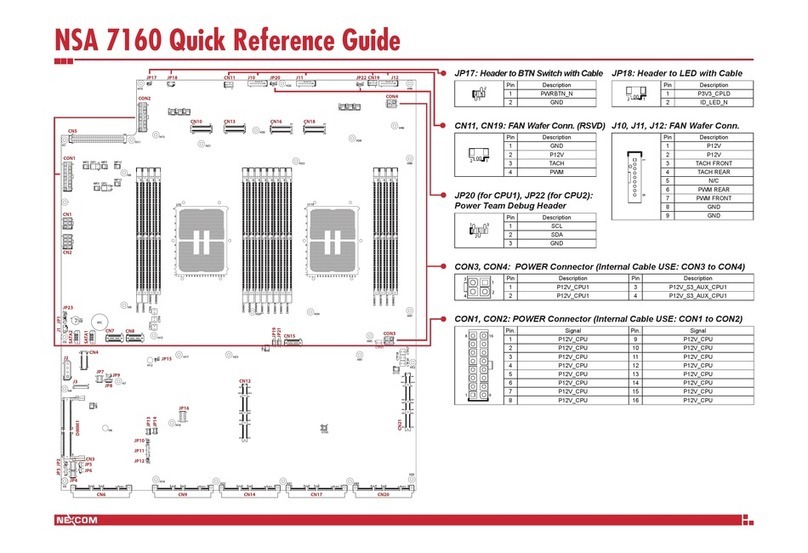

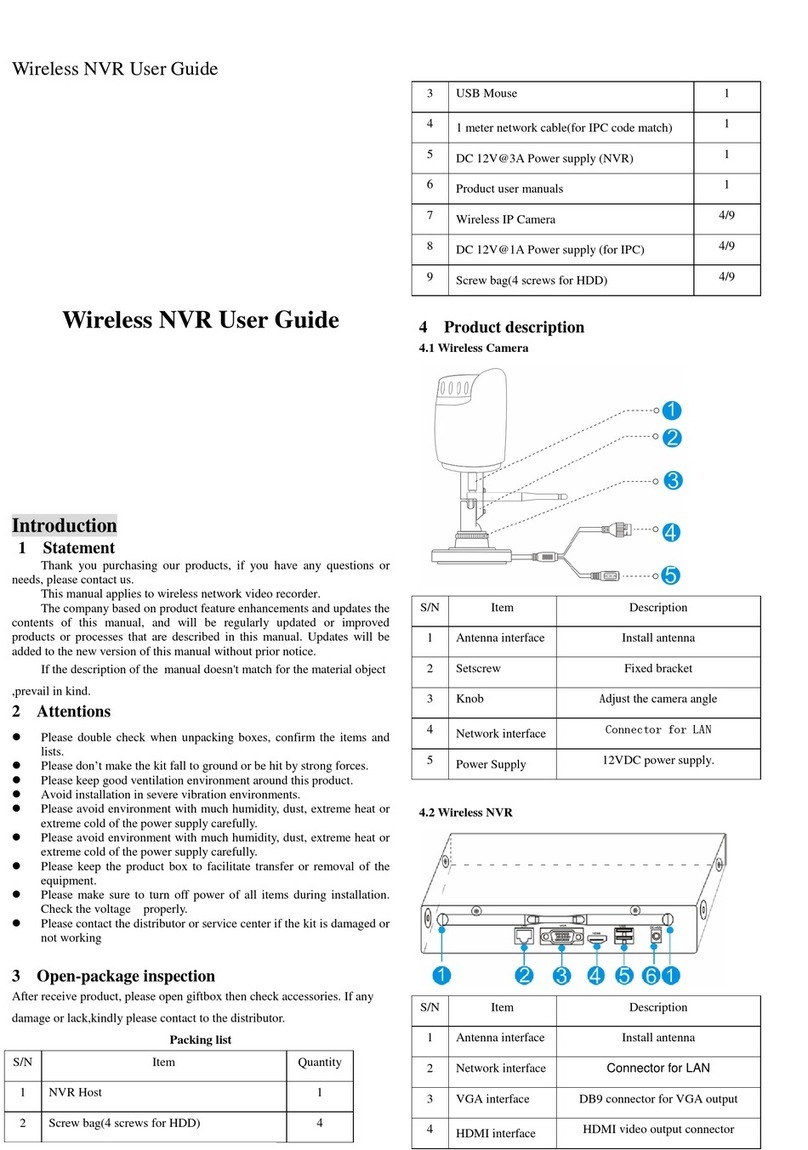

specifications and pin definitions of the P

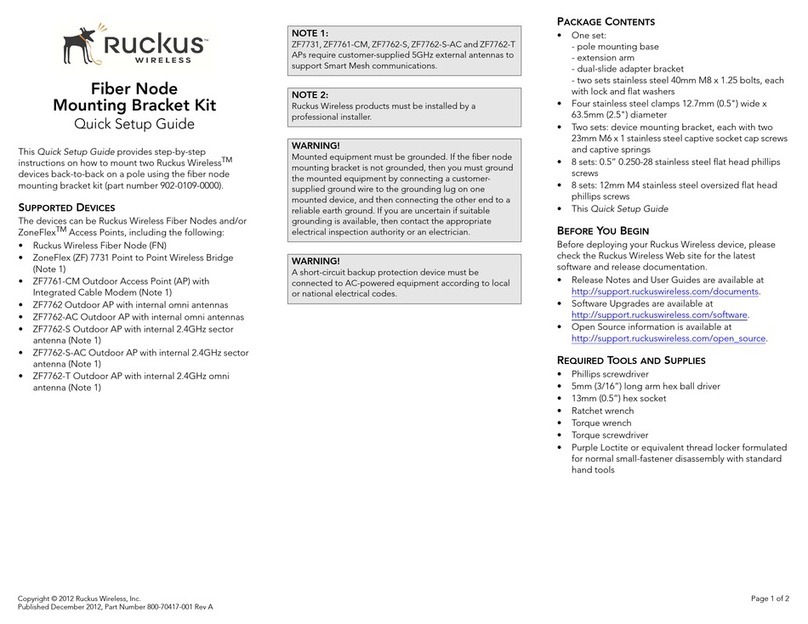

For a cabinet equipped with mouseproof

on the top fasten the mouseproof hop

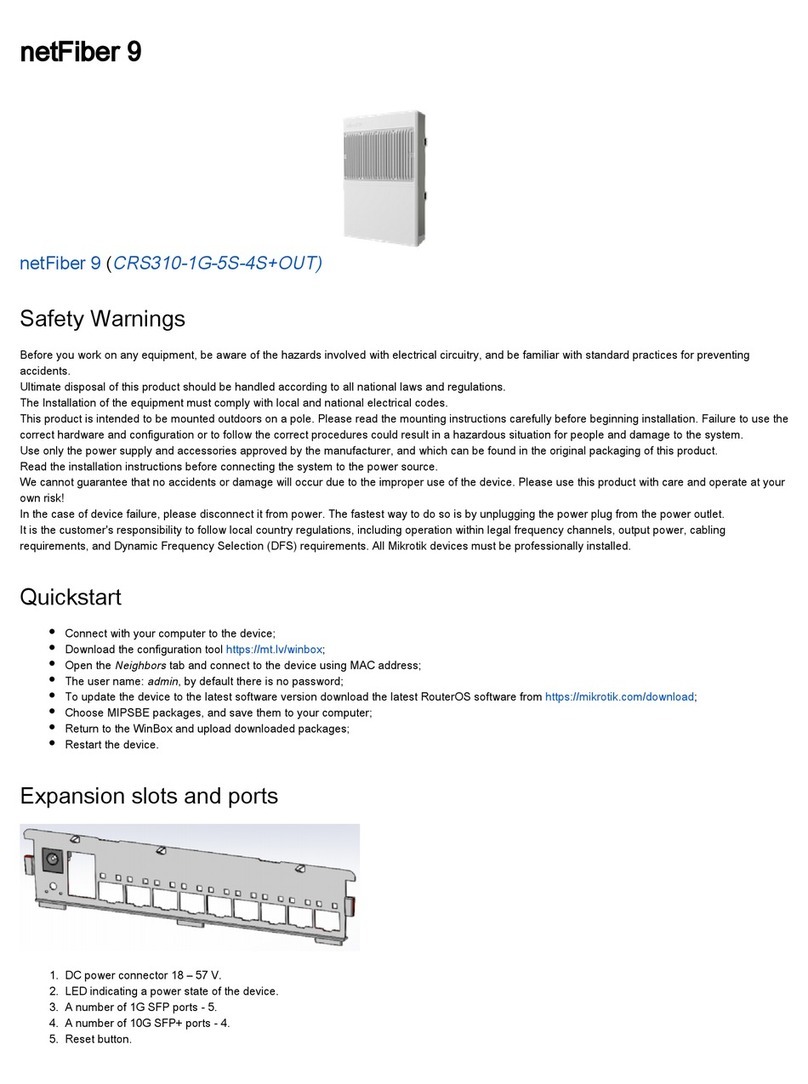

Preparing Wiring Holes on the Cabinet

Tip

Note

,

-

external wires and cables are led into the

well arranged.

For a cabinet equipped with cover plate o

or bottom of the cabinet, determine the p

and number of wiring holes according to t

plan. Pierce the cover plate with diagonal

holes. The following introduces how to m

Recommended areas and

sequence for making wiring holes

Caution

Prepare the holes from near to far in seq

Polish the raw edges of holes so that the

LMR

1

1

at are connected inside the cabinet. These cables

tallers should check the connection of internal cables

er the cable distribution is reasonable, whether the

rranged, whether the plugs are connected firmly,

n exists, and whether any part is missing.

wiring mode or the floor access wiring mode

installation site conditions (This guide uses the top

scription).

Fastening the mouseproof hop-

pockets on the top of cabinet

ed to remove the front panel of the PDP. If space is

t the bottom of the PDP.

and cables, restore the front panel and baffle to their

.

P.

op-pockets

cabinet and

n the top

sition, size

he wiring

pliers at desired positions to make wiring

ke wiring holes on the top of the cabinet.

Making a wiring hole

ence.

will not cut hands or cables.

Pierce the cover plate

with diagonal pliers

along the edges desired

for making a wiring hole

3