Fisher Scientific FB-705 User manual

Other Fisher Scientific Laboratory Equipment manuals

Fisher Scientific

Fisher Scientific Isotemp 05FFEEFSA Specification sheet

Fisher Scientific

Fisher Scientific Isotemp 148 User manual

Fisher Scientific

Fisher Scientific Fisherbrand GT2 User manual

Fisher Scientific

Fisher Scientific Finnpipette II User manual

Fisher Scientific

Fisher Scientific 15-460-2Q User manual

Fisher Scientific

Fisher Scientific Fisherbrand 88861027 User manual

Fisher Scientific

Fisher Scientific 280A User manual

Fisher Scientific

Fisher Scientific Isotemp 600 Series User manual

Fisher Scientific

Fisher Scientific 282A User manual

Fisher Scientific

Fisher Scientific Fisherbrand Isotemp FBG Series Owner's manual

Fisher Scientific

Fisher Scientific 150 Homogenizer User manual

Fisher Scientific

Fisher Scientific accuSpin 3 User manual

Fisher Scientific

Fisher Scientific accumet BASIC AB 15 User manual

Fisher Scientific

Fisher Scientific HPS RT2 Basic User manual

Fisher Scientific

Fisher Scientific 15212985 User manual

Fisher Scientific

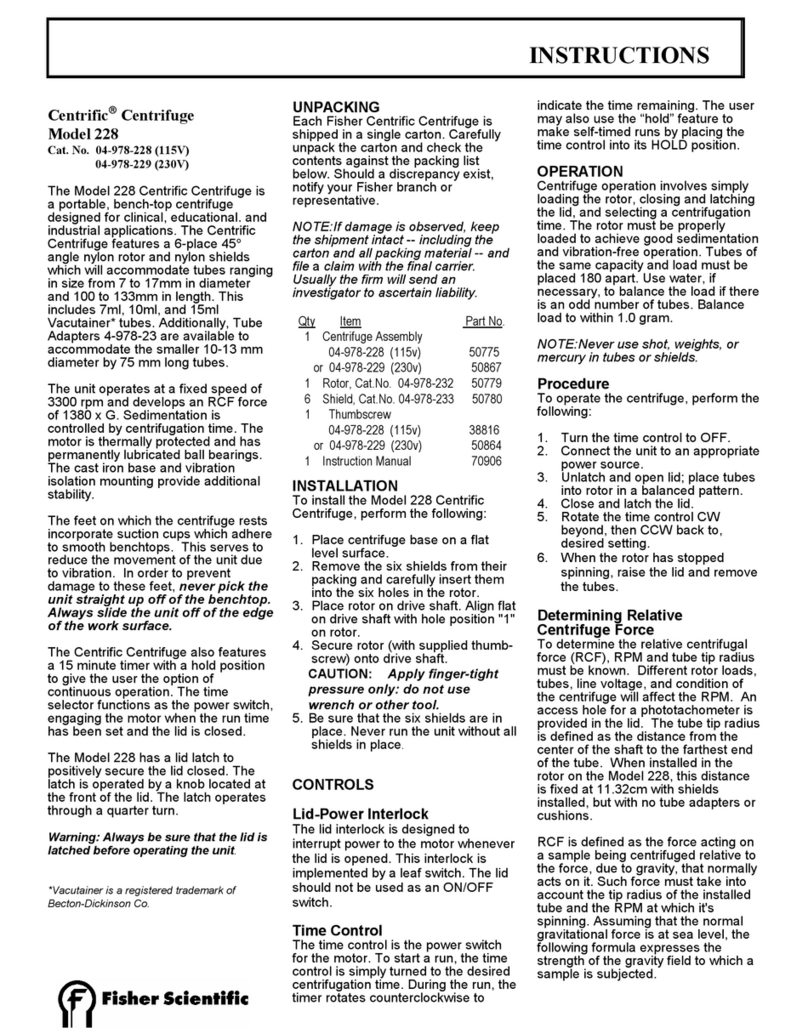

Fisher Scientific 04-978-229 User manual

Fisher Scientific

Fisher Scientific 88861023 User manual

Fisher Scientific

Fisher Scientific Isotemp 642 User manual

Fisher Scientific

Fisher Scientific Isotemp Plus 13-986-120 User manual

Fisher Scientific

Fisher Scientific Isotemp 11-800-49S/.57A User manual

Popular Laboratory Equipment manuals by other brands

Integra

Integra DOSE IT operating instructions

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

REITEL

REITEL SANDUBLAST 3 operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

Labnet

Labnet Rocker 35 EZ instruction manual

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use