Table of Contents

1. Prior to Starting...........................................................................................................................1

1-1. Welcome ............................................................................................................................1

1-2. Features.............................................................................................................................1

1-3. About This Manual..............................................................................................................1

2. Panel Descriptions .....................................................................................................................2

2-1. Front Panel.........................................................................................................................2

2-2. Rear Panel .........................................................................................................................3

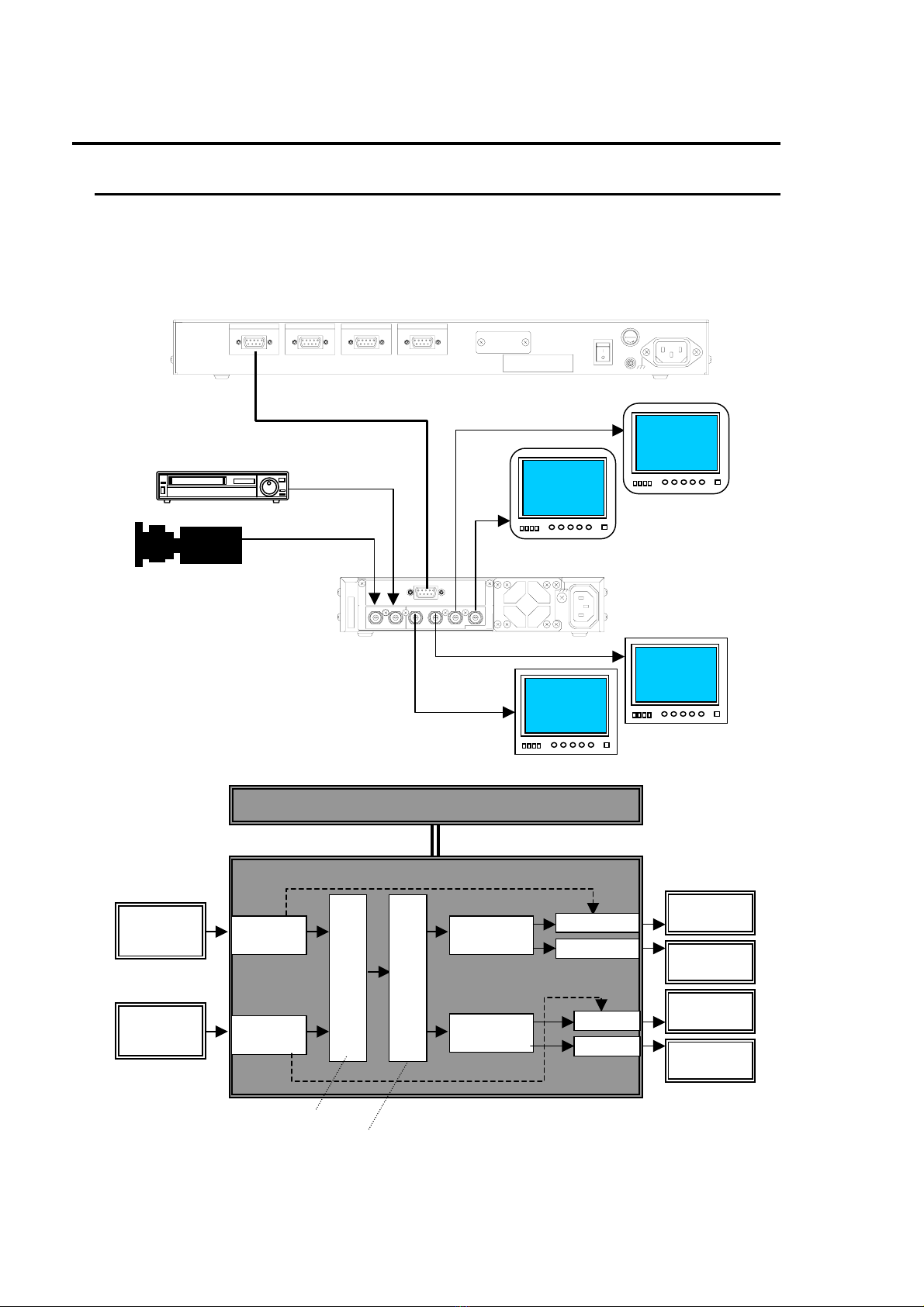

3. Connection.................................................................................................................................4

3-1. Connection Example 1.......................................................................................................4

3-2. Connection Example 2.......................................................................................................5

4. Operation ...................................................................................................................................6

4-1. Power On...........................................................................................................................6

4-2. Front Panel Operations......................................................................................................6

4-2-1. INPUT SELECT..........................................................................................................6

4-2-2. SPLIT.........................................................................................................................7

4-3. Remote Control..................................................................................................................8

4-3-1. REMOTE Connector ..................................................................................................8

5. Internal Setting...........................................................................................................................9

5-1. Dipswitch Settings..............................................................................................................9

5-1-1. SW1 ...........................................................................................................................9

5-1-2. SW2 ......................................................................................................................... 11

5-1-3. SW3 (SETUP Setting)..............................................................................................13

5-2. Jumper Settings ...............................................................................................................14

5-2-1. COMPOSITE OUT 2 / GENLOCK IN Switching.......................................................14

6. If Problems Occur.....................................................................................................................15

7. Specifications & Dimensions....................................................................................................16

7-1. Unit Specifications............................................................................................................16

7-2. External Dimensions ........................................................................................................18

7-2-1. Single Unit................................................................................................................18

7-2-2. Rack Mounting Examples......................................................................................... 19