Table of Contents

Read this First ...............................................................................................11

Warning............................................................................................................1

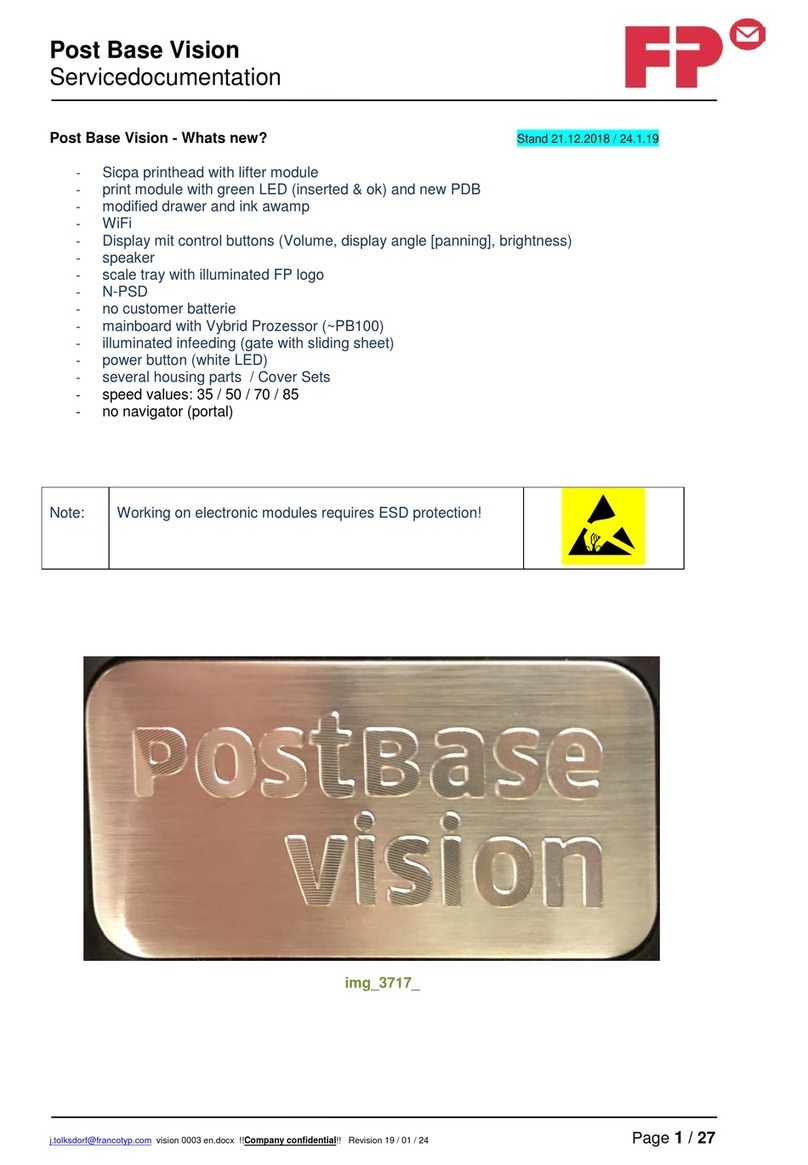

General information..........................................................................................1

Safety...............................................................................................................2

Country Specific Conditions.............................................................................3

End of Life........................................................................................................4

FCC Classification............................................................................................5

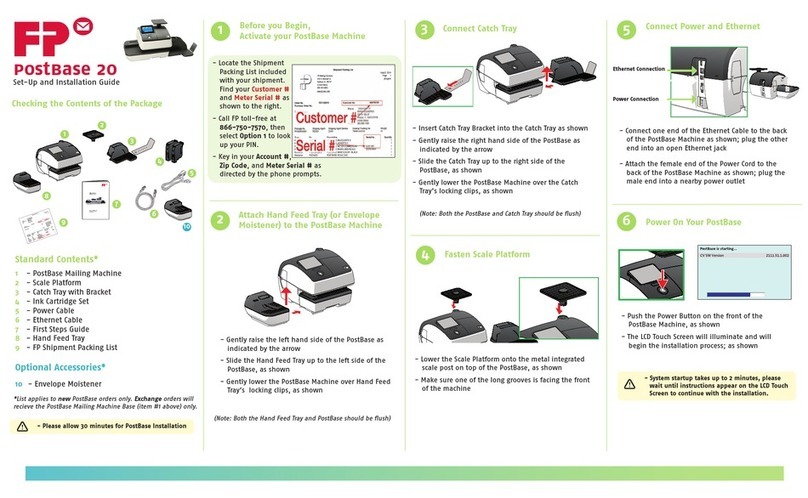

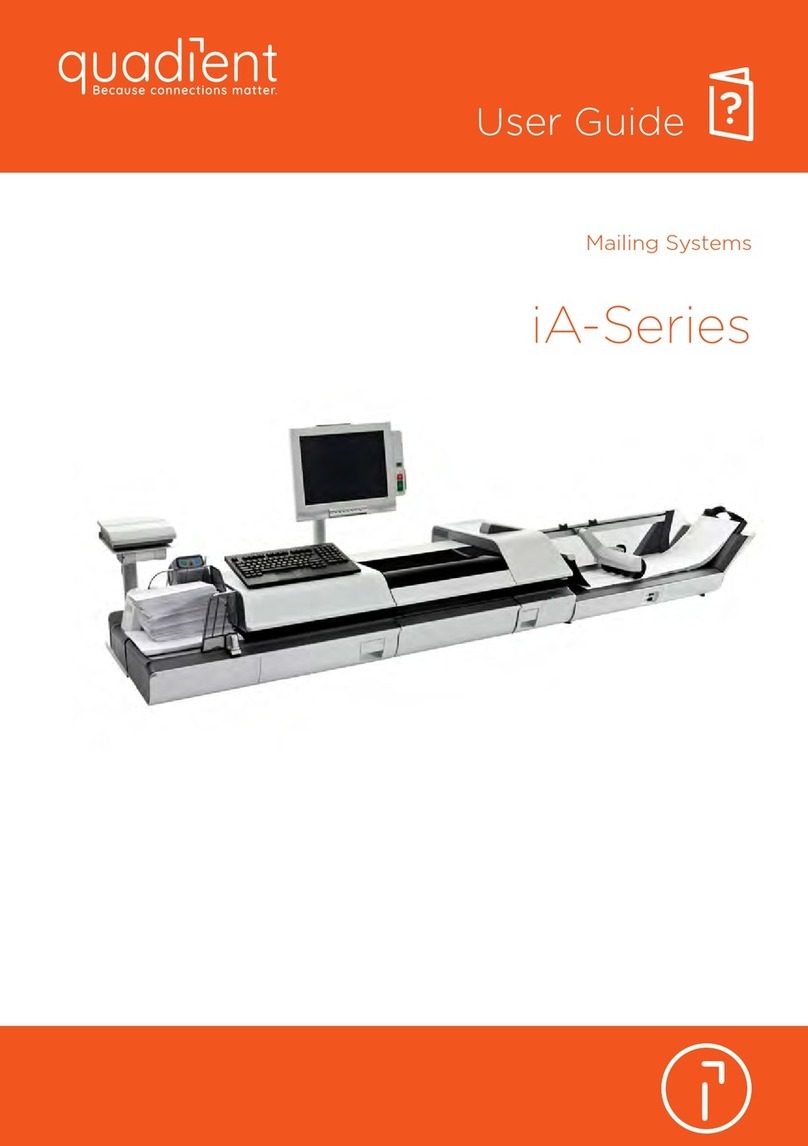

Installation .....................................................................................................62

Prepare the Inserter for Installation..................................................................6

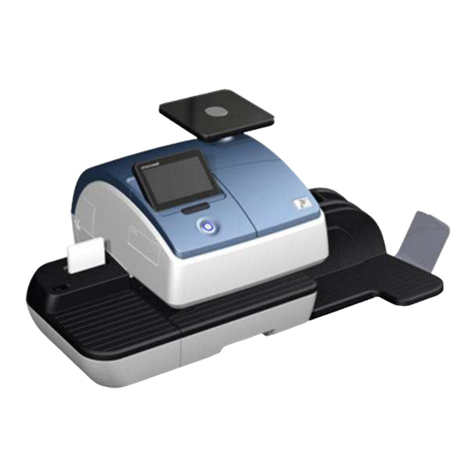

Determine the Best Location for the System....................................................8

Install the Main Modules (with optional VersaFeeder).....................................8

Install the Main Modules (without optional VersaFeeder)..............................10

Install the Document Feed Trays...................................................................11

Install the Power Stacker Support (option).....................................................12

Install the HCDF.............................................................................................12

Install the MaxiFeeder....................................................................................13

Install the High Capacity Conveyor Belt.........................................................14

Install the High Capacity Envelope Hopper....................................................14

Assemble the Catch Tray (option)..................................................................15

Fill the Sealing Liquid Reservoir.....................................................................17

Connect the System to Mains Power Supply and Power Up ..................183

Power Up........................................................................................................18

Set the Service phone number.......................................................................19

Set the Language...........................................................................................20

Connect the System to the Internet ..........................................................214

Options for Connection...................................................................................21

Set up a Wired Connection............................................................................21

| Page 1 | TOC | mrt-03-2014 01:58 |