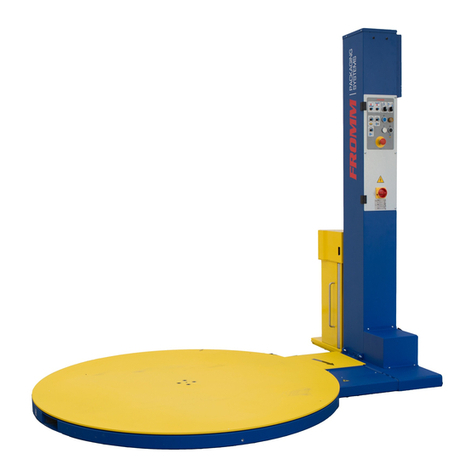

Fromm FSW50 User manual

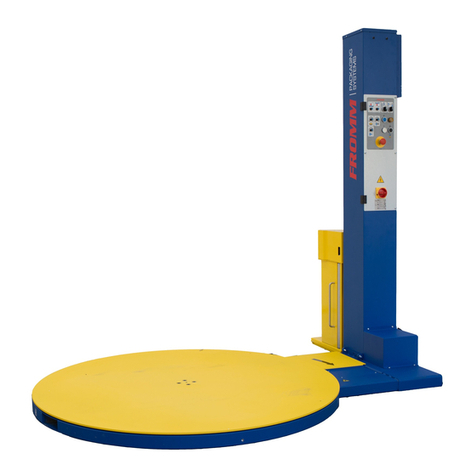

Other Fromm Stretch Wrapping System manuals

Fromm

Fromm FS 401 Series User manual

Fromm

Fromm FR330 User manual

Fromm

Fromm FS 230 Series User manual

Fromm

Fromm FS400 Series User manual

Fromm

Fromm FS360 Series Guide

Fromm

Fromm FR3 Series User manual

Fromm

Fromm FR3 Series User manual

Fromm

Fromm FS 510 Service manual

Fromm

Fromm FR3 Series User manual

Fromm

Fromm FR330 Service manual

Fromm

Fromm FS4 Series Operation instructions

Fromm

Fromm FS 271 Series User manual

Fromm

Fromm FS35 Series User manual

Fromm

Fromm P328S User manual

Fromm

Fromm FS 540 User manual

Fromm

Fromm FS390 Series Operation instructions

Fromm

Fromm FS3 Series Installation guide

Fromm

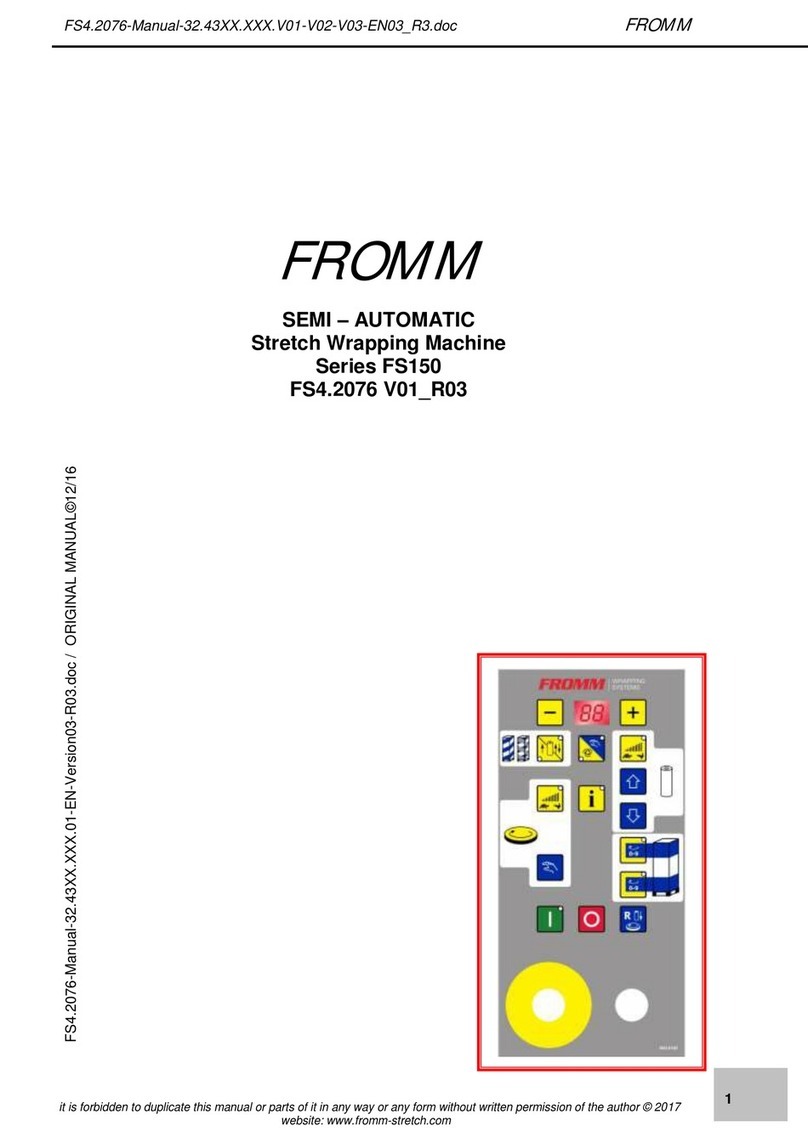

Fromm FS150 Series User manual

Fromm

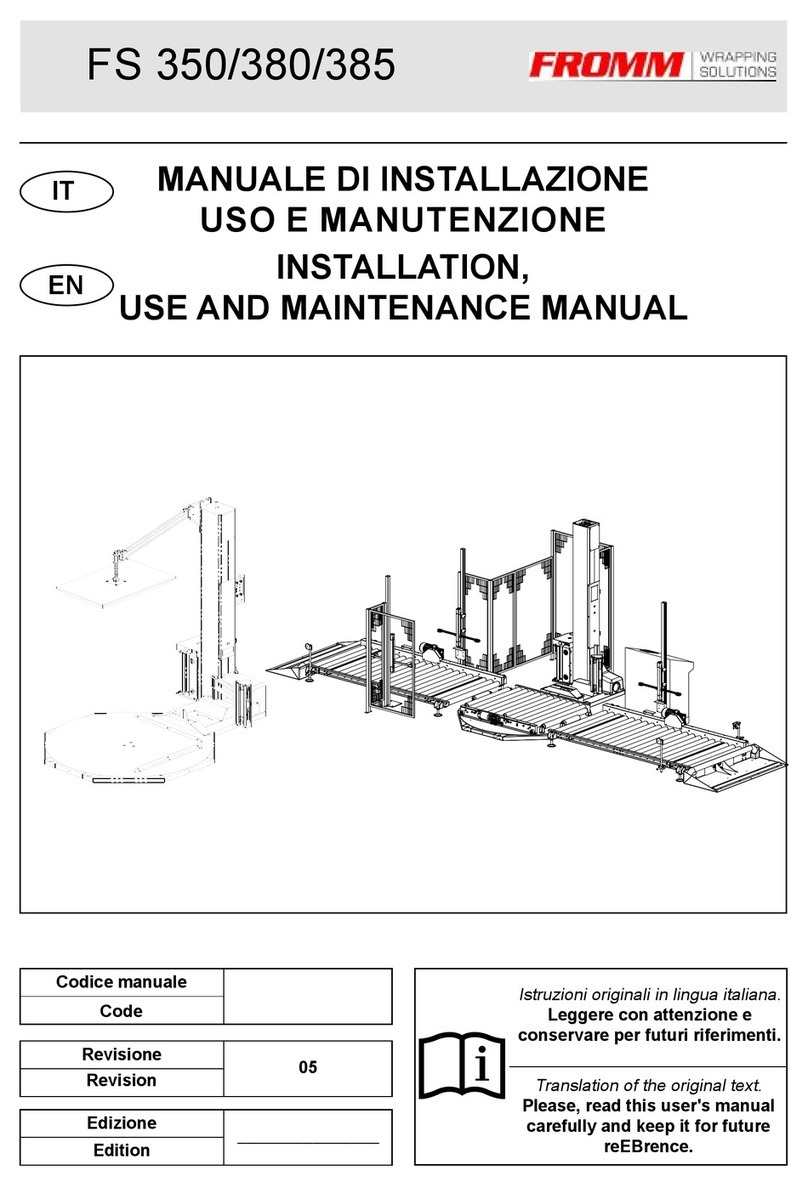

Fromm FS350 Service manual

Fromm

Fromm FS380 Service manual