DIFFERENTIAL TEMPERATURE CONTROLLER

FOR SOLAR HEATING WITH TWO

SOLAR BACKING

Ver. 02

MICROSOL II plus

MCSOL2V02-05T-10793

UL-Underwriters Laboratories

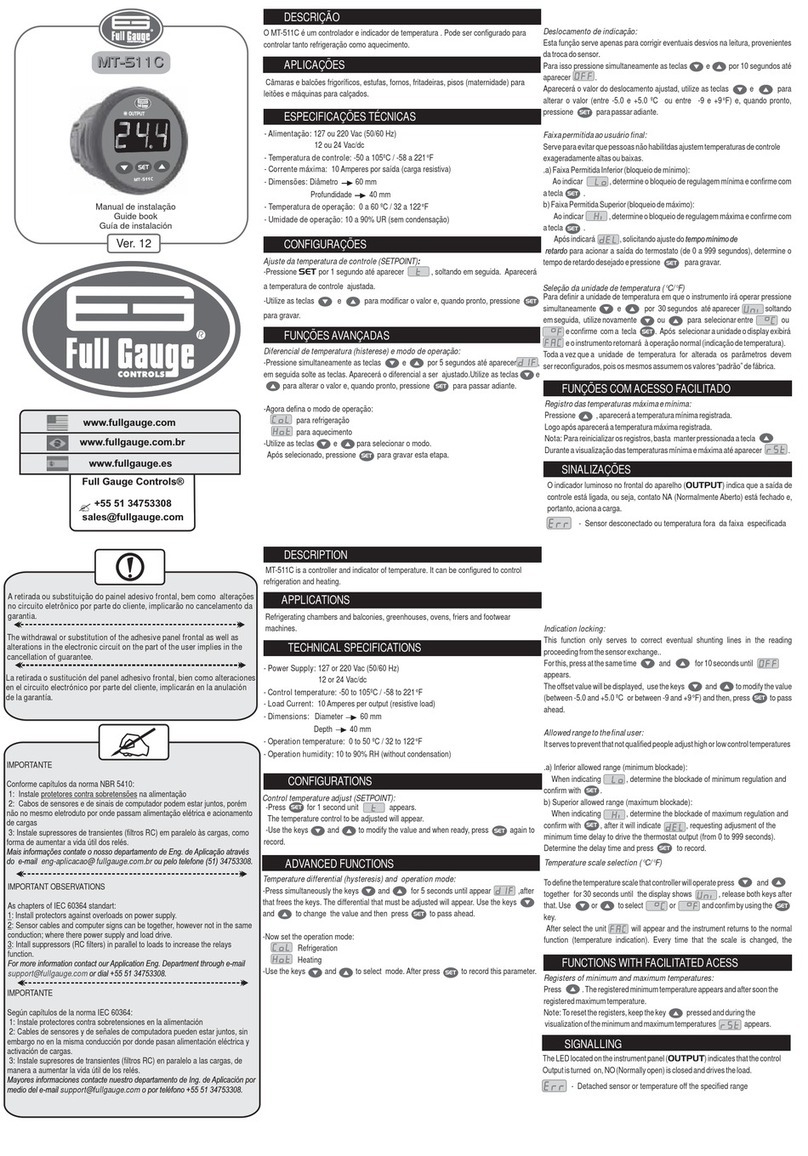

1.DESCRIPTION

Differential temperature controller for automation of solar heating systems,

becomes simple the management of the temperature of the water in the thermal reservoirs and

swimmingpools,usethesolarenergybetter..

Itactsinthecommandofthewatercirculationpumpthroughthedifferentialoftemperaturebetweenthe

solarcollectors andthe thermal reservoiror swimming pool.It is adedicated instrumentthat has allits

parametersofconfigurationprotectedbyaccesscode.

It makes use of two solar backings outputs, that can be electric, gas, diesel or also to program the

filteringoftheswimmingpool.solarbacking1istiedwithanschedulethatallowstheconfigurationofup

to four daily events for each day of the week and solar backing 2 can optionally be configured for

functioninginsetwiththeschedule.

Ithas functionsthat preventthewater freezingand overheatingin thetubings anda clockwith internal

batterytoguaranteeitssynchronism,evenintheenergylack,permanyyears.Theinstrumenthasserial

communicationforconnectionwiththeSITRAD viaInternet.

ProductcomplieswithCE(EuropeanUnion)andULInc.(UnitedStatesandCanada).

•Solarheatingpumpedsystems

MICROSOL II plus

®

2.APPLICATION

3.TECHNICALSPECIFICATIONS

-Powersupply:

-Controltemperature:

-Resolution:

-Dimensions:

-Operatingtemperature:

-Operatinghumidity:

-Sensors:

-Controloutputs:

CLASSIFICATIONACCORDINGTOIEC60730-2-9STANDARD:

-Temperaturelimitoftheinstallationsurface:

-Typeofconstruction:

-Automaticaction:

115or230Vac±10%(50/60Hz)

-50to105°

-58to221ºF

0.1°Cbetween-10and100°Cand1°Cintherestoftherange

1°Fbetween-58and221°F

71x28x71mm

0to50°C/32to122°F

10to90%RH(withoutcondensation)

S1-Sensorofthecollectors

S2-SensoroftheReservoir/Pool

S3-Sensorforcontrolofsolarbackings

PUMP-Waterpumporsolenoid-5(3)A/250Vac1/8HP

AUX1-solarbacking1-5(3)A/250Vac1/8HP

AUX2-solarbacking2-5(3)A/250Vac1/8HP

50°C

Built-inelectroniccontroller

Type1

-Controlofpollution:

-Impulsevoltage:

-Temperatureforthetestofspherepressure:

-Insulation:

Level2

1,5kV 75°Cand125°C

ClassII

Press and simultaneously for two seconds until it appears , then releasing it. When

appears press (tap) and enter the code (123) through keys and . To confirm,

pressthekey .Throughthekeys and accesstheotherfunctionsandproceedinthesame

manner to adjust them. To leave the menu and return to normal operations, press (long hit) until

appears.

Accesscodeentry

Advancedconfigurationfunctions

Eventsplanneroperatingmode

Schedulingintheeventsplanner

Adjustmentoftheclockandthedayoftheweek

4.CONFIGURATIONS

4.1-Toenterintothefunctionsmenu

4.2-Functions

SET

SET

SET

4.2.1-Parameters table

Description Min Max Unit

CELSIUS

Fun

Standard Standard

Min Max Unid

FAHRENHEIT

-

1.0

1.0

0

3.0

0.0

0.1

0.0

0.1

0.1

-

20.0

20.0

999

10.0

99.9

20.0

99.9

20.0

20.0

-

°C

°C

sec.

°C

°C

°C

°C

°C

°C

-

8.0

4.0

0

3.0

99.9

99.9

1.0

1.0

1.0

-

°F

°F

sec.

°F

°F

°F

°F

°F

°F

-

36

36

999

50

212

36

212

36

36

-

2

2

0

38

32

32

1

1

1

-

14

7

0

38

212

212

1

1

1

Indication of the preferential temperature

Differential for turning on the water circulation pump

Differential for turning off the water circulation pump

Minimum time for the pump off

Temperature of the antifreeze for sensor 1

to turn the water circulation pump on

Overheat temperature for sensor 1

to turn the water circulation pump off

Overheated hysteresis for sensor 1

for turning the water circulation pump back on

Overheat temperature for sensor 2

to turn the water circulation pump off

Overheated hysteresis for sensor 2

for turning the water circulation pump back on

Hysteresis of the solar backing 1 operation

Minimum setpoint of the solar backing 1 operation

Maximum setpoint of the solar backing 1 operation

Manual activation time for solar backing 1

Solar backing 2 operation mode

Hysteresis of the solar backing 2 operation

Minimum setpoint of the solar backing 2 operation

Maximum setpoint of the solar backing 2 operation

Cyclical timer time on

Cyclical timer time off

Method for linking the solar backings to the events schedule

Indication offset for the temperature of the sensor 1

Indication offset for the temperature of the sensor 2

Indication offset for the temperature of the sensor 3

Address of the instrument on the RS-485 network

-50.0

-50.0

0

0

0.1

-50.0

-50.0

1

1

0

-5.0

-5.0

-5.0

1

105.0

105.0

999

5

20.0

105.0

105.0

999

999

3

5.0

5.0

5.0

247

°C

°C

min.

-

°C

°C

°C

min.

min.

-

°C

°C

°C

-

-58

-58

0

0

1

-58

-58

1

1

0

-9

-9

-9

1

221

221

999

5

36

221

221

999

999

3

9

9

9

247

°F

°F

min.

-

°F

°F

°F

min.

min.

-

°F

°F

°F

-

-58

1

0

0

0

0

1

221

0

0

1

-58

221

1

-50.0

1

0

0.0

0.0

0.0

1

105.0

0

0

1.0

-50.0

105.0

1

4.2.2 - Parameters description

Thisfunctionallowsthepreferentialtemperatureindicationtobeconfigured.Youmaychoosebetween:

temperatureinthesensor1

temperatureinthesensor2

temperatureinthesensor3

differentialtemperature(S1-S2)

Thisfunctionallowstheadjustmentofthedifferentialtemperature(S1-S2)toactivatethewatercirculation

pump. As the solar collectors receive energy, the temperature in sensor S1 increases. When this

temperatureisatavalueestablishedasbeingabovethetemperatureofsensorS2,thepumpisturnedon

andcirculatesundertheheatedwater,storingitinthereservoir,forexample.

Thisfunction allowsthe adjustmentof the differentialtemperature(S1-S2) toturnoffthe watercirculation

pump. With the pump on, the hot water circulates below and cools upwards. After which time, the

temperaturedifferencebetweenS1andS2tendstodecrease.Whenthisdifferencefallstoanestablished

level,thepumpisturnedoffandthewatercirculationstops.

Indicationofthepreferentialtemperature

Differentialforturningonthewatercirculationpump

Differentialforturningoffthewatercirculationpump

Thisfunctionallowstheadjustmentoftheminimumtimeoffthatthepumpshouldhavebeforebeingturned

on again. This option avoids the pump from being turned on and off in short periods of time, which thus

increasestheusefullifethereof.Thisfunctionalsodefinesthedelayinthepump'sactivationonturningon

thecontroller.

Thisfunctionallowsadjustmenttothetemperatureforformingiceinthecollectors.Whenthetemperature

in the collectors (sensor 1) are very low (Ex.: winter nights), the pump is turned on from time to time, to

prevent the water from freezing in the pipes and damaging them. The hysteresis is set at 2°C/4°F. To

deactivatethisfunctiondecreasethevalueuntilthemessage appearsinthedisplay.

This function allows the adjustment of the overheating temperature of the collectors, to turn off the water

circulation pump. When the temperature in the collectors (sensor 1) is above an established value, the

pumpisturnedofftokeeptheoverheatedwater fromcirculatingthroughthe pipesanddamagingthem (if

PVCpipesareused).

Adjustment of the hysteresis of the overheated temperature of sensor 1 to allow the water pump to be

turnedonagain.

Minimumtimeforthepumpoff

Temperatureoftheantifreezeforsensor1toturnthewatercirculationpumpon

Overheattemperatureforsensor1toturnthewatercirculationpumpoff

Overheatinghysteresisofsensor1toreconnectthewatercirculationpump

Overheattemperatureforsensor2toturnthewatercirculationpumpoff

Overheatedhysteresisforsensor2forturningthewatercirculationpumpbackon

Hysteresisofthesolarbacking1operation

Minimumsetpointofthesolarbacking1operation

Maximumsetpointofthesolarbacking1operation

This function allows the adjustment of the overheating temperature of the pool to turn the water

circulationpumpoff,avoidingthermaldiscomfort.

Adjustmentofthe hysteresisofthe overheatedtemperatureofsensor2 toallowthe waterpumpto be

turnedonagain.

Adjustmentofthehysteresisfortheactivationtemperaturesetpointforsolarbacking1.

Lower limit, the purpose of which is to avoid the accidental regulation of temperatures far below the

setpointofsolarbacking1.

Upper limit, the purpose of which is to avoid the accidental regulation of temperatures far above the

setpointofsolarbacking1.