Ver.01

DIGITAL CONTROLLER FOR

REFRIGERATION AND DEFROST

WITH ALARM OUTPUT

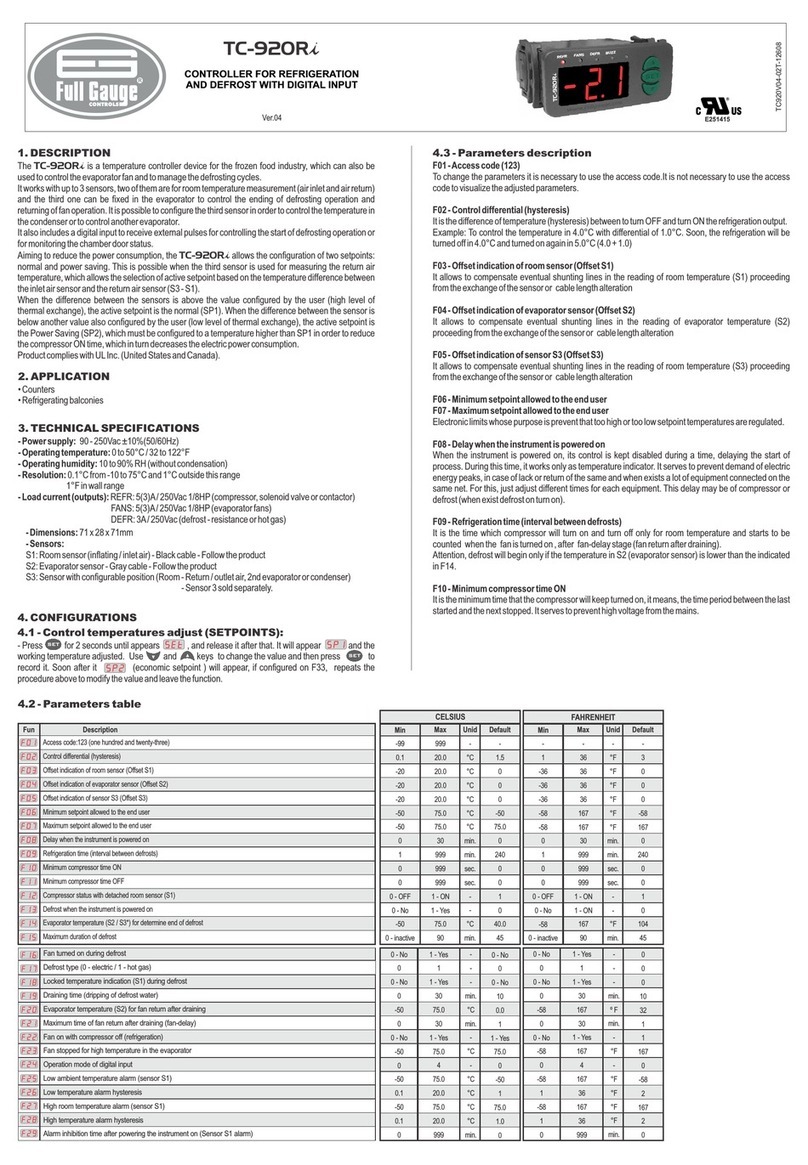

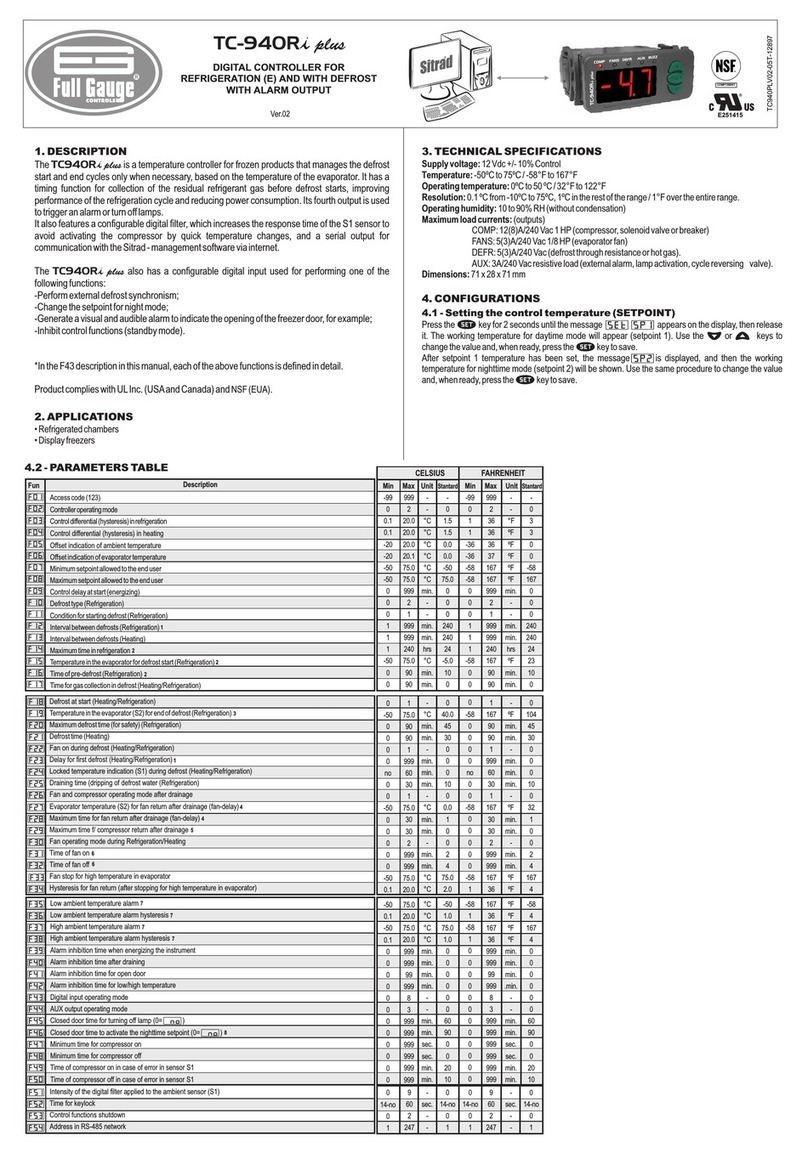

TC-940Ri plus

COMP

1.DESCRIPTION

2.APPLICATION

3.TECHNICAL SPECIFICATIONS

The isatemperaturecontrollerthatmanagecyclesofdefrost,startandfinish,when

only necessary, based in evaporator temperature, and they have one output for alarm or shutdown

lamps.Theyhavefunctiontowait residualrefrigerantfluidreturnsindefrost.Thus,itispossibletosave

energyandincreasetheefficiencyofthesystem.

The have one digital input for extern synchronize defrost. This same input can

change setpoint to nigthtime mode. This digital input can generate a visual and audible alarm too, to

indicateopendoor,forexemple.

The haveadigitalfilterthatsimulatesanincreaseresponsetimeof sensor S1 to

avoidthecompressoractioninfastchangesoftemperature.

TheyhaveoneserialporttocomunicatewhithSitrad .

•Counters

•Refrigeratedbalcony

12 dc-50to75°C/-58to167°F

0.1°Cfrom-10to75°Cand1°Coutsidethisrange / 1°F

0to50°C 32to122°F

10to90%RH(withoutcondensation)

71x28x71mm

COMP:16(8)A/250Vac1HP(compressor,solenoidvalveorcontactor)

FANS:5(3)A/250Vac1/8HP(evaporatorfans)

DEFR:5(3)A/250Vac(defrost-resistanceorhotgas)

ALRM:3A/250Vacresistiveload(externalalarm)

TC-940Ri plus

TC-940Ri plus

TC-940Ri plus

®

-Powersupply:

-Controltemperature:

-Resolution:

-Operatingtemperature: /

-Operatinghumidity:

-Dimensions:

-Loadcurrent(outputs):

V

4.CONFIGURATIONS

4.1-Settingthecontrol temperature (SETPOINT)

Press for two seconds, until the message appears, and then release. The current working

temperaturewillbedisplayed.Usethekeys and tochangethevalueandthenpress to

save.

Iftheoperatingmodeofthedigitalinput isconfiguredfornighttimesetpoint(F31=3),themessage

willbedisplayedafterthemessage toallowsettingthedaytimesetpoint.Usethekeys or

tochangethevalueandthenpress tosave.Then willbedisplayedtoallowsettingthe

nighttimesetpoint,usethesameprocedureabovetoadjustitandleavethesetupmode.

SET

SET

SET

4.3-Parameters description

F01-Accesscode(123)

F02-Controldifferential(hysteresis)

F03- ambient

F05-Minimumsetpointallowedtotheenduser

F06-Maximumsetpointallowedtothe enduser

F07-Defrosttype

F08-Initialdefrostcondition

F09-Periodbetweendefrosts(ifF08=0)

F10-Maximumtimeinrefrigeration(forsecurity,ifF08=1)

F11-Temperatureintheevaporatorfordefroststart(ifF08=1)

F12-Timeofpre-defrost(ifF08=1)

F13-Defrostwhentheinstrumentispoweredon

F14-Evaporatortemperature(S2)forenddefrost

F15-Maximumdefrostduration

F16-Fanturnedonduringdefrost

F17-Delaytodofirstdefrost(ifF08=0

F18-Lockedtemperatureindication(S1)duringdefrost

F19-Drainingtime(drippingofdefrostwater)

F20-Evaporatortemperature(S2)forfanreturnafterdraining(fan-delay)

It is necessary to change the configuration parameters. To visualize the adjusted parameters, it is not

necessarytoinsertthisaccesscode.

Itisthedifferenceoftemperature(hysteresis)betweenONandOFFtherefrigeration.

Youneedtocontroltemperaturein4.0ºCwithdifferentialof1.0ºC.

So,therefrigerationisturnedoffin4.0ºCandwillbeturnedonin5.0ºC(4.0+1.0).

Itallowstocompensateeventualshutinglineson reading of ambient temperature (S1), proceedingof

sensorexchangeorcablelengthalteration.

Itallowstocompensateeventualshutinglineson reading of ambient temperature (S2), proceedingof

sensorexchangeorcablelengthalteration.

Itistopreventthatincorrecthighorlowtemperaturesberegulated.

“0”=Electricaldefrost(resistances),whereiskeptononlythedefrostoutput.

“1”=Hotgasdefrost,wheredefrostandcompressoroutputsarekepton.

Itdefinesifthedefroststartwillbefortemperature or time. Is this function has the value“1”,whenthe

evaporator temperature reaches the configured value in “F11” the instrument starts to count the pre-

defrosttimeand,after,willdothedefrost.

Itdeterminesthetime betweentwoconsecutivesdefrost cycles,andstartsto becountedfromthe last

defrost.Attention,thedefrostonlywillstartifthetempertureinS2(evaporatorsensor)islowerthanF14.

It acts as security time (if F08 = 1) and evaporator temperature will not reach the configured value in

“F11”.Thisfunctiondeterminesthemaximumtimethatcontrollerwillstaywithoutdefrost.

When evaporator temperature reaches the configured value in this function the controller will start to

countthepre-defrostperiod(F12).

Atthemoment thatthetemperature inevaporatordecreasesandreachestheconfigured valuein“F11”,

start to be counted the pre-defrost time. During the pre-defrost stage, if the temperature is kept low the

defrost starts, else if the temperature increase at least 1 ºC in relation to configured value, the system

returnstorefrigerationstage.

Itpossibilitiesthedefrostatthemomentthatthe controlleristurnedon,forexample,inreturnofelectrical

energy(incaseofenergylacks).

If evaporator temperature (sensor S2) reaches the adjusted value, the end defrost will happen for

temperature.Withthis,thedefrostprocessisoptimized.

This function serves to adjust the maximum value of time to defrost. If in this period the evaporator

temperaturewillnotreachtheconfiguredvalueinF14apointwillbeblinkingoninferiordownrightsideof

displayindicatingthattheenddefrostocurredfortimeandnotfortemperature.

This can happen when the adjusted temperature is very high, the limit time will be not enough, the S2

sensorisdetachedornotincontactwiththeevaporator.

Itpossibilitiesthefanfunctioningduringdefrost.

)

Thisfunctiondefinesanextratimethattheinstrumentwillkeepinrefrigerationbeforedothefirstdefrost,

topreventthatlotofcountersenterindefrost at the same time. Thistimeonlyappearsbeforethefirst

defrost,whenF08=0(initialdefrostfortime).

This function prevents that ambient temperature elevation be visualized. During defrost the last

measured temperature in refrigeration cycle will be locked on display. The indication will be released

whenthistemperaturewillbereachedagainor15minutesafterthebeginofnextrefrigerationcycle.

Necessary time for dripping, it means, to drain the last water drops of the evaporator.All the outputs

keepturnedoff.Ifyoudonotneedthisstage,adjustthistimefor”zero”.

Afterthedraining,thefan-delaycyclestarts.Therefrigeration(COMP)outputisturnedon,becausethe

evaporatortemperatureishigh,butthefanonlyisturnedonafterevaporatortemperaturedecreasesthe

adjustedvalue.Thisprocessisnecessarytoremovetheheatthatexistsintheevaporatorbecausethe

defrost,preventingtopassittotheambient.

Example:

Indicationoffsetofthe temperature

F04-Indicationoffsetoftheevaporatortemperature

Example: Naturaldefrostorby resistances installed outsidetheevaporator.

TC940PLV01-01T-11744

Access code: 123 (one hundred and twenty-three)

Control differential (hysteresis)

Offset indication for ambient sensor

Indication offset of the evaporator temperature (offset)

Minimum setpoint allowed to the end user

Maximum setpoint allowed to the end user

Defrost type (0 = resistance; 1 = hot gas)

Initial defrost condition (0 = time; 1 = temperature)

Period between defrost (if F08 = 0)

Maximum time in refrigeration (for security, if F08 = 1)

Temperature in the evaporator for defrost start (if F08 = 1)

Time of pre-defrost (if F08 = 1)

Defrost when the instrument is powered on (0 - no;1-yes)

Evaporator temperature (S2) for end defrost

Maximum defrost duration (for security)

Fan turned on during defrost (0 - no;1-yes)

Delay to do the first defrost (if F07 = 0)

4.2-Parameters table CELSIUS

Fun FAHRENHEIT

0

0

0

1

9

247

-

-

-

1

0

1

0

0

0

1

9

247

-

-

-

1

0

1

Compressor status with detached ambient sensor

(0=off;1=on)

Intensity of the digital filter applied to ambient sensor (S1)

Network equipment address RS - 485

Locked temperature indication (S1) during defrost (0 - no;1-yes)

Draining time (dripping of defrost water)

Evaporator temperature (S2) for fan return after draining

Maximum time for fan return after draining (fan-delay)

Fanonwithcompressoroff(0-no;1-yes)

Fan stop for high temperature in evaporator

Hysteresis for fan return (after stoping for high temperature

in evaporator)

Low temperature alarm (S1)

Alarm hysteresis of low temperature

High temperature alarm (S1)

Alarm hysteresis of high temperature

Inhibition time of alarm when the instrument is powered on

Inhibition time of alarm after draining

Digital input operating mode

Time for inhibiting the open door alarm

Time for collecting the defrost gas

Delay when the instrumet is powered on

Minimum time of compressor turned on

Minimum time of compressor turned off

Description Min Max Unit

Standard

Min Max Unit

Standard

-99

0.1

-20

-20

-50

-50

0

0

1

1

-50

0

0

-50

0

0

0

999

20.0

20.0

20.0

75.0

75.0

1

1

999

240

75.0

90

1

75.0

90

1

999

-

°C

°C

°C

°C

°C

-

-

min.

hours

°C

min.

-

°C

min.

-

min.

-

1.5

0.0

0.0

-50

75.0

0

0

240

24

-5.0

10

0

40.0

45

0

0

-99

1

-36

-36

-58

-58

0

0

1

1

-58

0

0

-58

0

0

0

999

36

36

36

167

167

1

1

999

240

167

90

1

167

90

1

999

-

°F

°F

°F

°F

°F

-

-

min.

hours

°F

min.

-

°F

min.

-

-

-

3

0

0

-58

167

0

0

240

24

23

10

0

104

45

0

0

0

0

-50

0

0

-50

0.1

-50

0.1

-50

0.1

0

0

0

0

0

0

0

0

1

30

75.0

30

1

75.0

20.0

75.0

20.0

75.0

20.0

999

999

3

99

90

999

999

999

-

min.

°C

min.

-

°C

°C

°C

ºC

°C

°C

min.

min.

-

min.

min.

min.

sec.

ec.s

0

10

0.0

1

1

75.0

2.0

-50

1.0

75.0

1.0

0

0

0

0

0

0

0

0

0

0

-58

0

0

-58

1

-58

1

-58

1

0

0

0

0

0

0

0

0

1

30

167

30

1

167

36

167

36

167

36

999

999

3

99

90

999

999

999

-

min.

°F

min.

-

°F

°F

°F

ºF

°F

°F

min.

min.

-

min.

min.

min.

sec.

sec.

0

10

32

1

1

167

4

-58

2

167

2

0

0

0

0

0

0

0

0