Manual defrost:

- To change from “cooling” to “defrost” or vice-versa, irrespective of the programming, hold < key in

for four seconds, until [def]ou [ref] appears in the display.

To visualize the status and the elapsed time, press >.

[del] Initial delay [ref] Refrigeration [def] Defrosting

6. SIGNALLING

REFRIG - Cooling output on

DEFROST - Performing natural defrost

[Err] - Sensor disconnected or temperature out of the specified range.

7. SELECTION OF THE UNIT (Cº / Fº)

In order to define the unit that the instrument will operate in, enter function “F01” with the access code

“231” and confirm with the @ key. Press the < key and the indication [Uni]will appear. Press

@ to choose between [,=C] or [,=F] and confirm. After selecting the unit the [faC] message

will appear, and the instrument will return to the function “F01”. Every time that the unit is changed, the

parameters should be reconfigured, since they assume the “standard” values.

Ver. 09

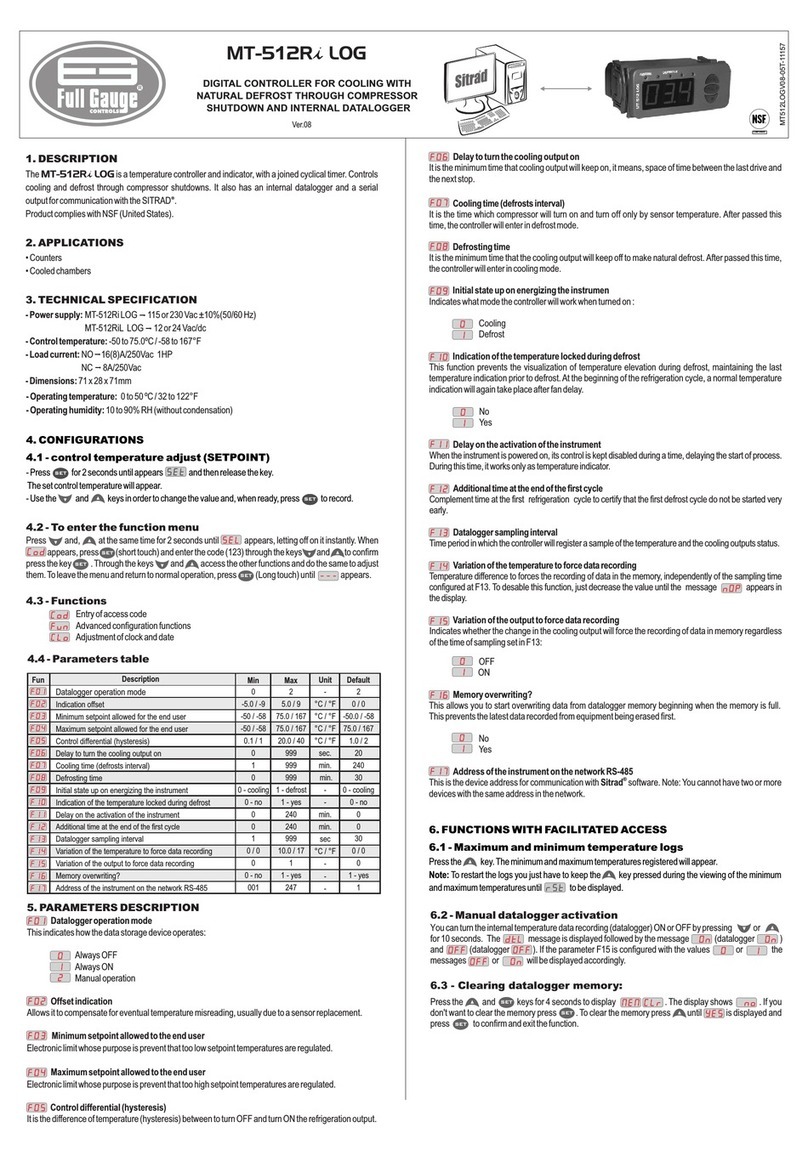

MT-512Ri plus

DIGITAL CONTROLLER FOR COOLING

WITH NATURAL DEFROST THROUGH

COMPRESSOR SHUTDOWN

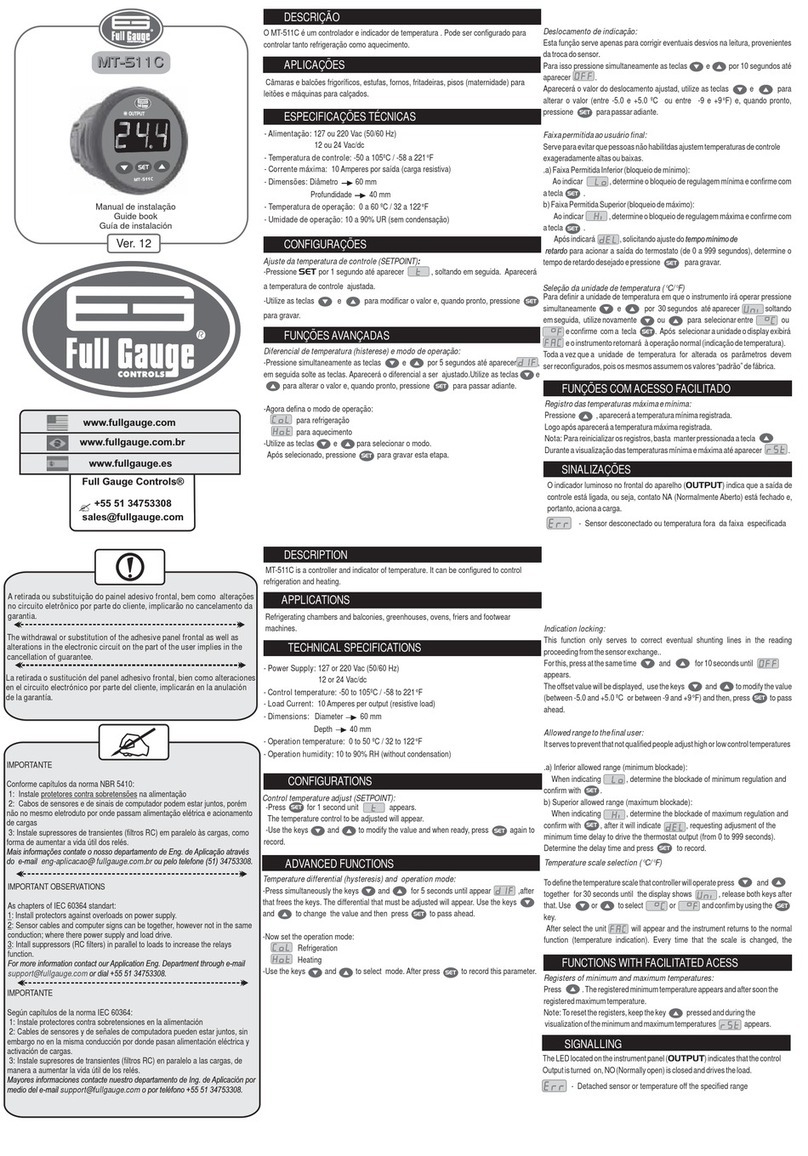

1. DESCRIPTION

The MT-512Ri plus is a temperature controller and indicator, with a joined cyclical timer. Controls

cooling and defrost through compressor shutdowns. It also has a serial output for communication with

the SITRAD .

Product complies with CE (European Union), and UL Inc. (United States and

Canada).

2. APPLICATIONS

• Counters

• Cooled chambers

3. TECHNICAL SPECIFICATION

- Power supply: MT-512Ri plus 115 or 230 Vac 10%(50/60 Hz)

MT-512RiL plus 12 or 24 Vac/dc

- Control temperature: -50 to 75.0ºC / -58 to 167°F

- Load current: NO 16(8)A/250Vac 1HP

NC 8A/250Vac

- Dimensions: 71 x 28 x 71mm

®

NSF (United States)

±

4. CONFIGURATIONS

4.1 - control temperature adjust (SETPOINT)

- Press @ for 2 seconds until appears [SET] and then release the key.

The set control temperature will appear.

- Use the > and < keys in order to change the value and, when ready, press @ to record.

- Operating temperature: 0 to 50 ºC / 32 to 122°F

- Operating humidity: 10 to 90% RH (without condensation)

CLASSIFICATION ACCORDING TO IEC60730-2-9 STANDARD:

- Temperature limit of the installation surface: 50°C / 122°F

- Type of construction: Built-in electronic controller

- Automatic action: Type 1

- Control of pollution: Level 2

- Impulse voltage: 1,5kV

- Temperature for the test of sphere pressure: 75°C and 125°C / 167°F and 257°F

- Insulation: Class II

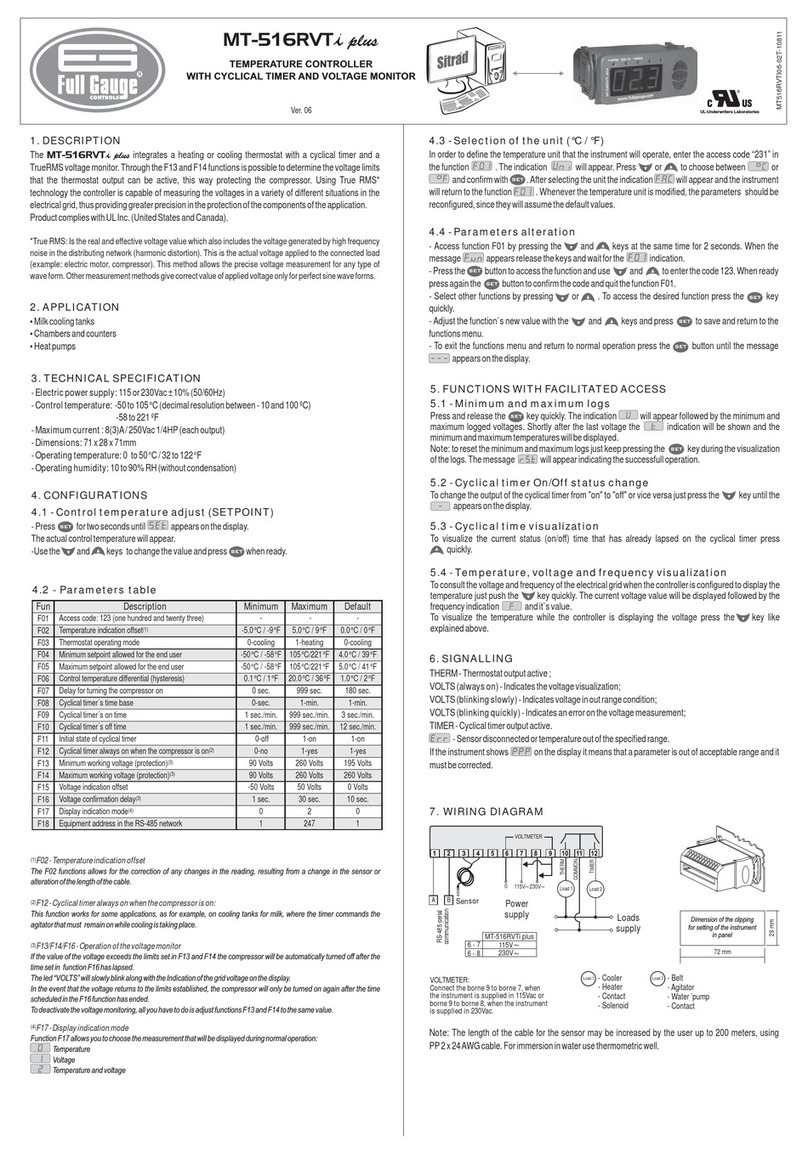

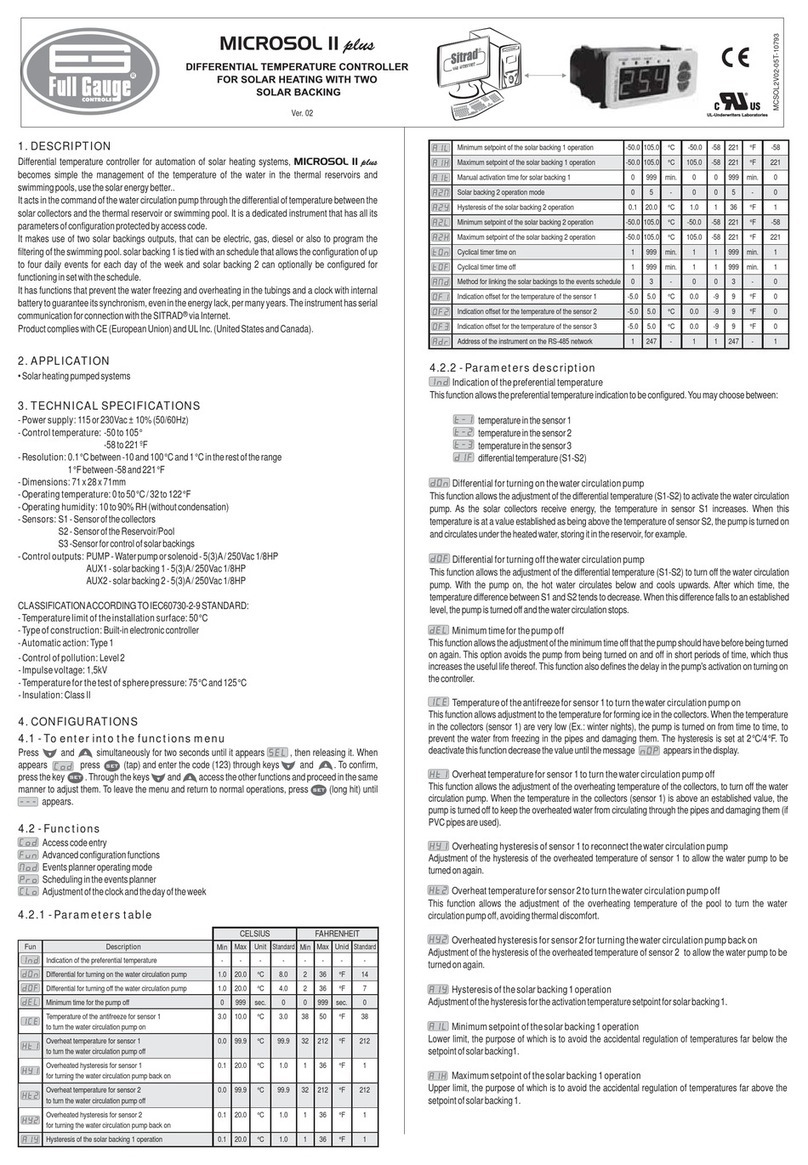

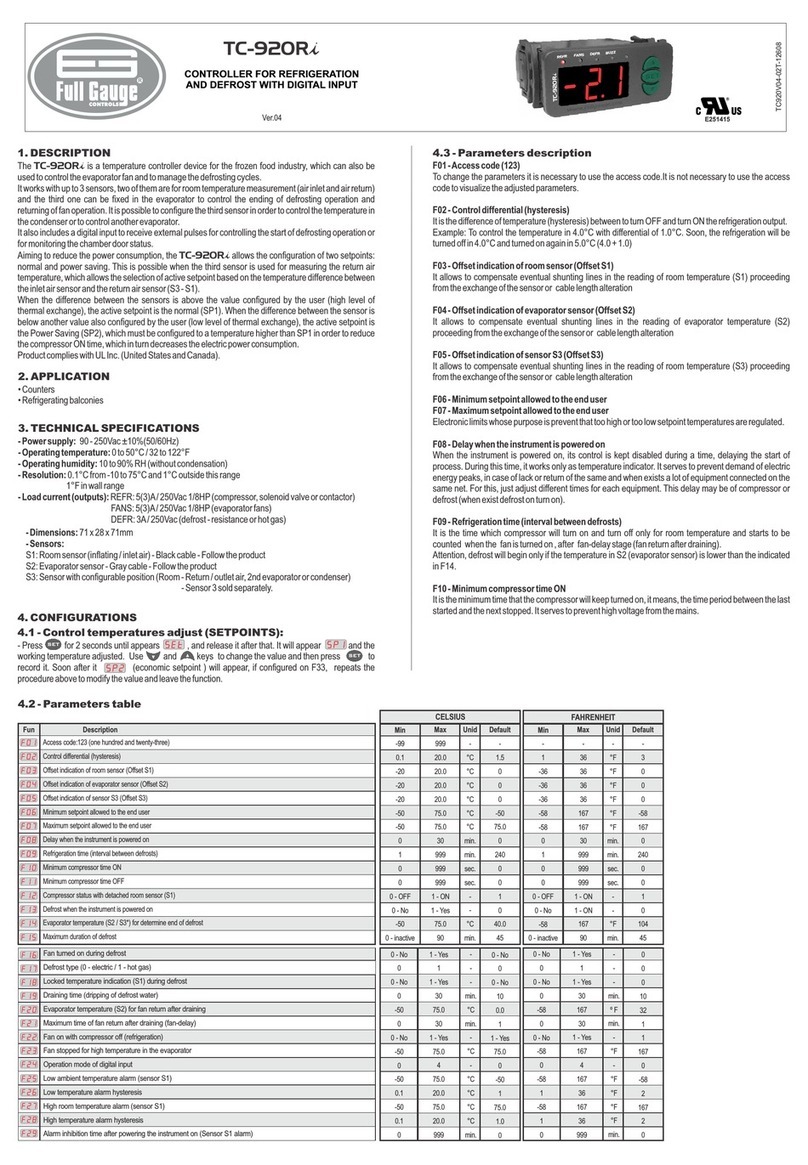

4.2 - Parameters table

4.3 - Parameters Alteration

- Access function “F01” by simultaneously pressing keys > and < for 2 seconds.

When the message [FuN]appears release the keys and wait for the[F01] indication. When the

indication appears on the display press the @ key and use > or < to enter the access code

(123) When ready press the @ button to confirm.

- Use keys > or < to access the desired function.

- After selecting the function, press @ (press once quickly) to view the value configured for that

function.

- Use the > or < keys to change the value and, when ready, press @ to memorize the

configured value and return to the function menu.

- To exit the menu and return to the normal operation (temperature indication), press @ (hold it in)

until [---] appears.

5. FUNCTIONS WITH FACILITATED ACCESS

5.1 - Maximum and minimum temperature logs

Press the < key. The minimum and maximum temperatures registered will appear.

Note: To restart the logs you just have to keep the < key pressed during the viewing of the minimum

and maximum temperatures until [rst] to be displayed.

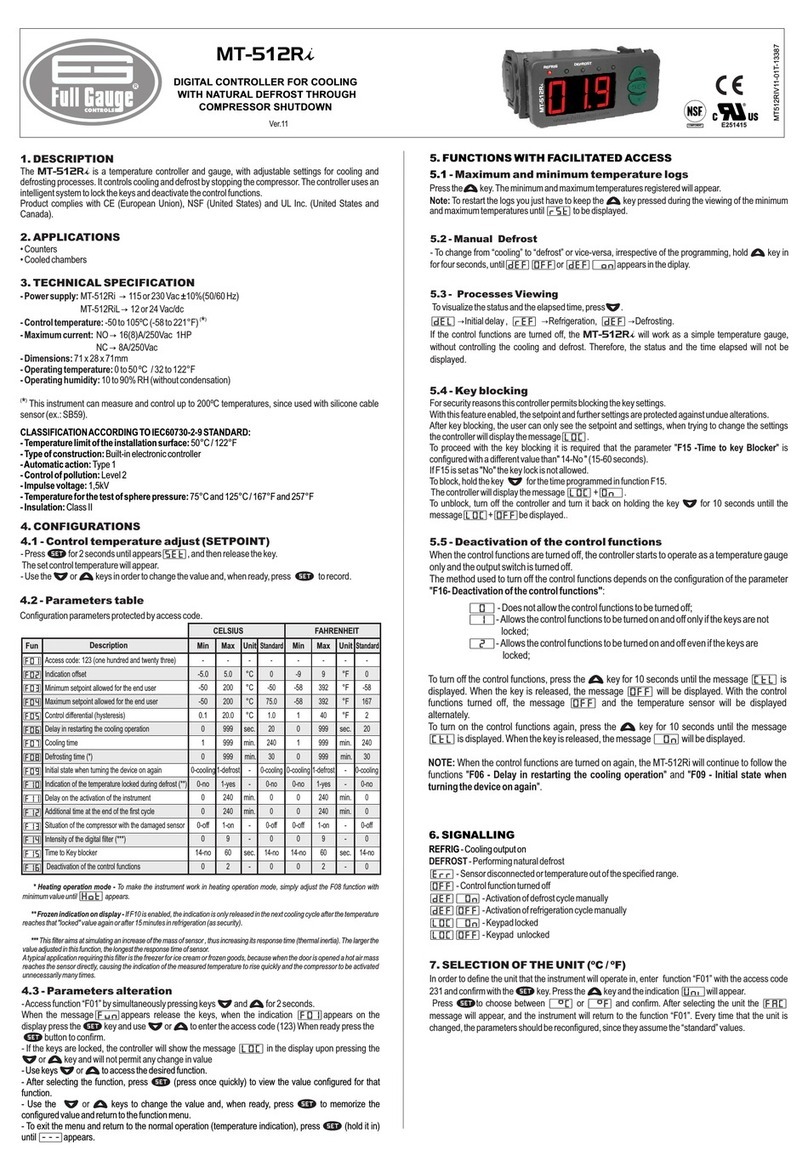

8. WIRING DIAGRAN

Note: The length of the sensor cable may be increased by the user up to 200 meters, using a 2 x 24 AWG

cable. For immersion in water, use thermometric well.

12345678910 11 12

REFRIG

72 mm

29 mm

Dimension of the clipping for

setting of the instrument

in panel

7 - 8

7 - 9

115V

230V

12V

24V

MT-512Ri plus MT-512RiL plus

Power

supply

Load

COMMON

NO

NC

0

Serial communication

RS-485

Load

supply

115 V~

(12 V~)

230 V~

(24 V~)

Sensor

To the terminal of

the distribution box

Above the current specified

use contactor

A

B

9-INTEGRATING CONTROLLERS, RS-485 SERIAL INTERFACE

AND COMPUTER

AA

B B

A B

A

B

OUT 1OUT 2

OUT 3

PCT-400R plus

OUT 4 ALMR

AA

B B

A B

A

B

AA

B B

A B

A

B

AA

B B

A B

AA

B B

A B

PUMP AUX 1

AUX 2

MICROSOL II plus

Connecting Block for Serial Communication

Used to connect more than one instrument to the Interface. The wire's connections must

be made in agreement with the following rules: terminal A of the instrument connects to

the terminal A of the c , that must be connected with the terminal A of the

Interface. Repeat the action for terminals B and , being the cable shield.

onnecting block

the terminal of distribution box must be connected to the respective terminals of

each instrument.

IMPORTANT

According to the chapters of norm IEC 60364:

1: Install protector against overvoltage on the power supply.

2: Sensor cables and signal cables of the computer may be joined, but not in the same electric conduit

through which the electric input and the activation of the loads run.

3: Install transient suppresors (RC filters) parallel to the loads as to increase the product life of the

relays.

Schematic for the connection of supresors

to contactors

Suppresor

A1

A2

A1 and A2 are the

contactor coil terminals.

Schematic for the connection of supresors to

direct activation loads

Load

Suppresor

For direct activation the maximum

specified current should be taken

into consideration.

Padrão Padrão

Access code: 123 (one hundred and twenty three)

Indication offset

Minimum setpoint allowed for the end user

Maximum setpoint allowed for the end user

Control differential (hysteresis)

Delay to turn the cooling output on

Cooling time

Defrosting time

Initial state up on energizing the instrument

Indication of the temperature locked during defrost

Delay on the activation of the instrument

Additional time at the end of the first cycle

Address of the instrument on the network RS-485

DescripionFun Min Max Unid

-

-5.0

-50

-50

0.1

0

1

0

0 - cooling.

0 - no

0

0

001

-

5.0

75.0

75.0

20.0

999

999

999

1 - defrost

1 - yes

240

240

247

-

°C

°C

°C

°C

sec.

min.

min.

-

-

min.

min.

-

CELSIUS

-

-9

-58

-58

1

0

1

0

0 - cooling.

0 - no

0

0

001

-

9

167

167

40

999

999

999

1 - defrost

1 - yes

240

240

247

-

°F

°F

°F

°F

sec.

min.

min.

-

-

min.

min.

-

FAHRENHEIT

Min Max Unid

[F01]

[F02]

[F03]

[F04]

[F05]

[F06]

[F07]

[F08]

[F09]

[F10]

[F11]

[F12]

[F13]

-

00.0

-50

75.0

01.0

020

240

030

0

0

000

000

001

-

000

-58

167

002

020

240

030

0

0

000

000

001

Standard Standard

MT512RIPLV09-04T-11485

REFRIG

MT-512Ri plus

DEFROST

E251415

COMPONENT