MT-516RVTi plus

TEMPERATURE CONTROLLER

WITH CYCLICAL TIMER AND VOLTAGE MONITOR

Ver. 06

MT516RVTI06-02T-10811

UL-Underwriters Laboratories

1.DESCRIPTION

2.APPLICATION

The integrates a heating or cooling thermostat with a cyclical timer and a

TrueRMSvoltagemonitor.ThroughtheF13andF14functionsispossibletodeterminethevoltagelimits

that the thermostat output can be active, this way protecting the compressor. Using True RMS*

technology the controller is capable of measuring the voltages in a variety of different situations in the

electricalgrid,thusprovidinggreaterprecisionintheprotectionofthecomponentsoftheapplication.

ProductcomplieswithULInc.(UnitedStatesandCanada).

•Milkcoolingtanks

•Chambersandcounters

•Heatpumps

MT-516RVTi plus

*TrueRMS:Istherealandeffectivevoltagevaluewhichalsoincludes thevoltagegeneratedbyhighfrequency

noisein thedistributing network(harmonic distortion).This isthe actualvoltage appliedto theconnected load

(example: electric motor, compressor). This method allows the precise voltage measurement for any type of

waveform.Othermeasurementmethodsgivecorrectvalueofappliedvoltageonlyforperfectsinewaveforms.

3.TECHNICALSPECIFICATION

4.CONFIGURATIONS

4.1-Controltemperatureadjust(SETPOINT)

-Electricpowersupply:

-Controltemperature:

-Maximumcurrent:

-Dimensions:

-Operatingtemperature:

-Operatinghumidity:

115or230Vac±10%(50/60Hz)

-50to105°C(decimalresolutionbetween-10and100ºC)

-58to221ºF

8(3)A/250Vac1/4HP(eachoutput)

71x28x71mm

0 to50°C/32to122°F

10to90%RH(withoutcondensation)

-Press fortwosecondsuntil appearsonthedisplay.

Theactualcontroltemperaturewillappear.

-Usethe and keys tochangethevalueandpress whenready.

SET

SET

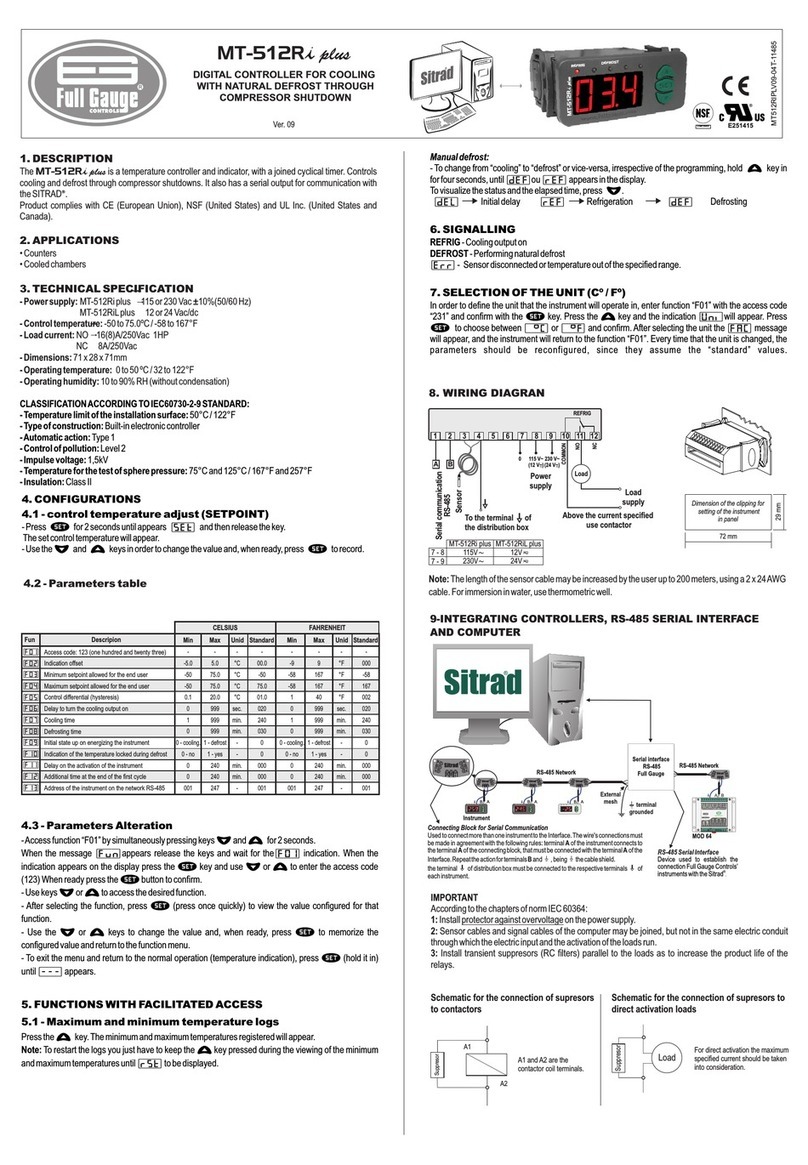

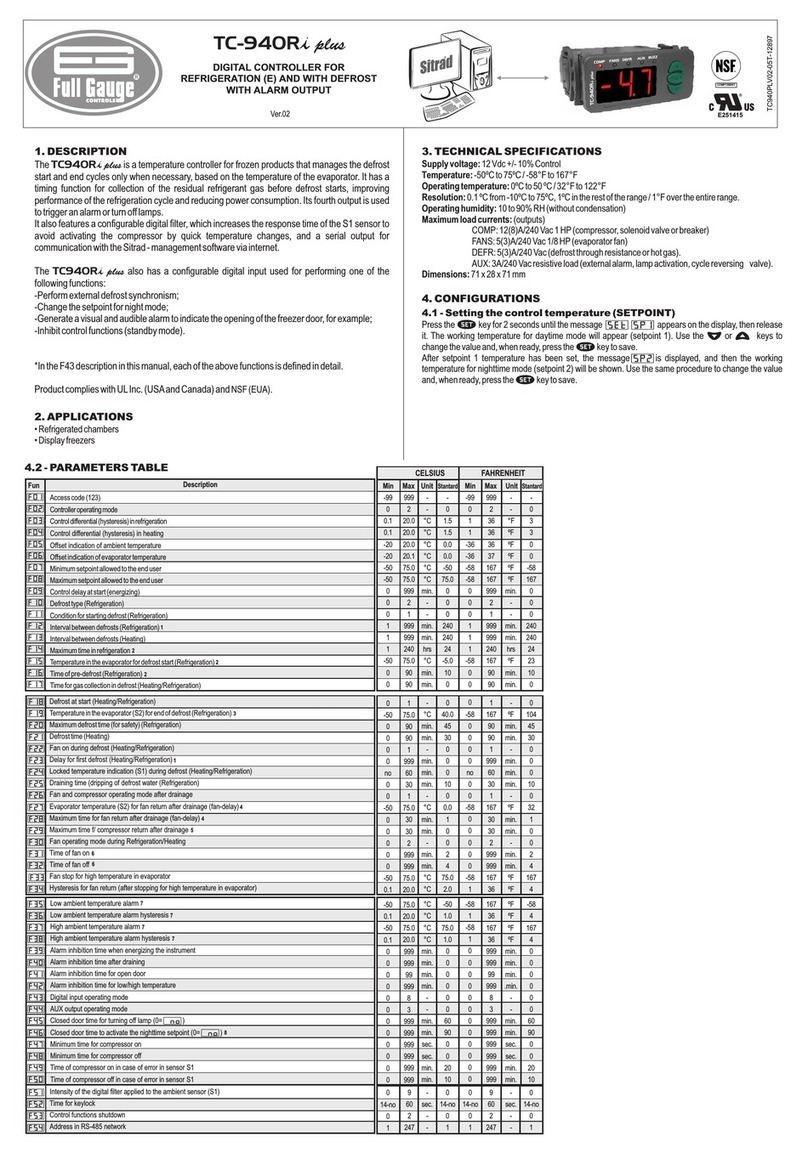

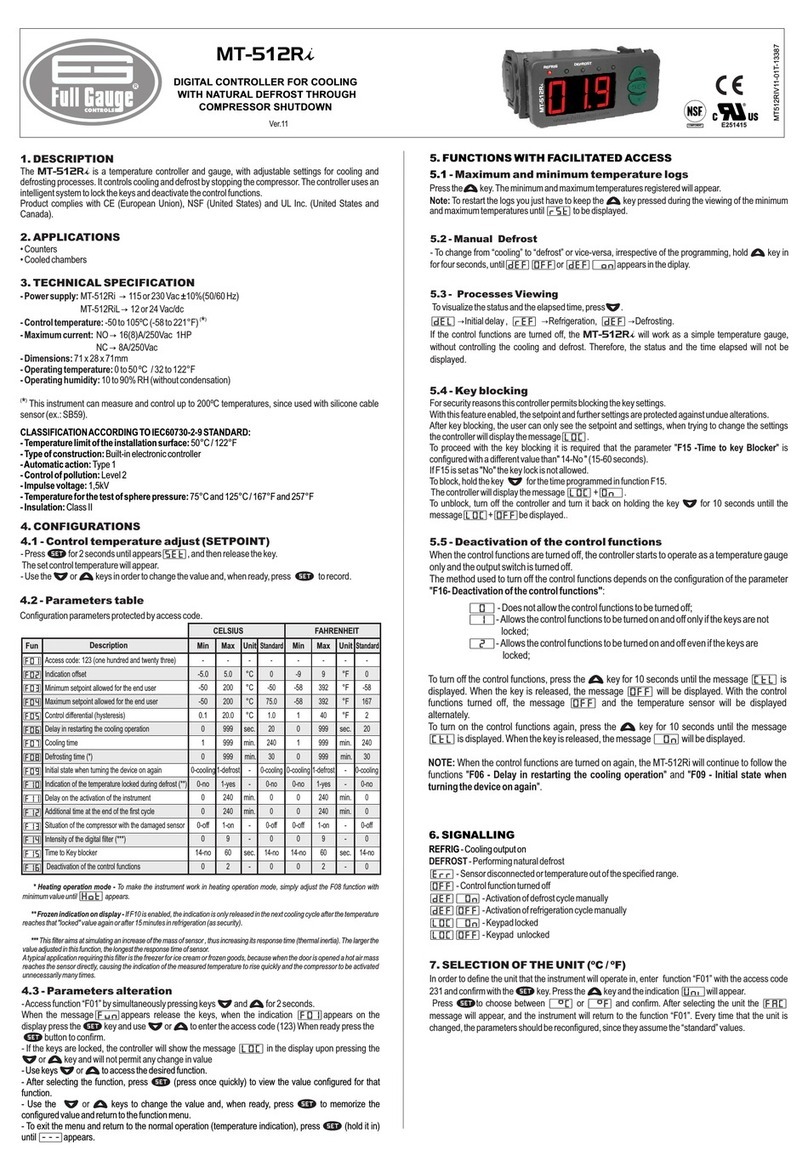

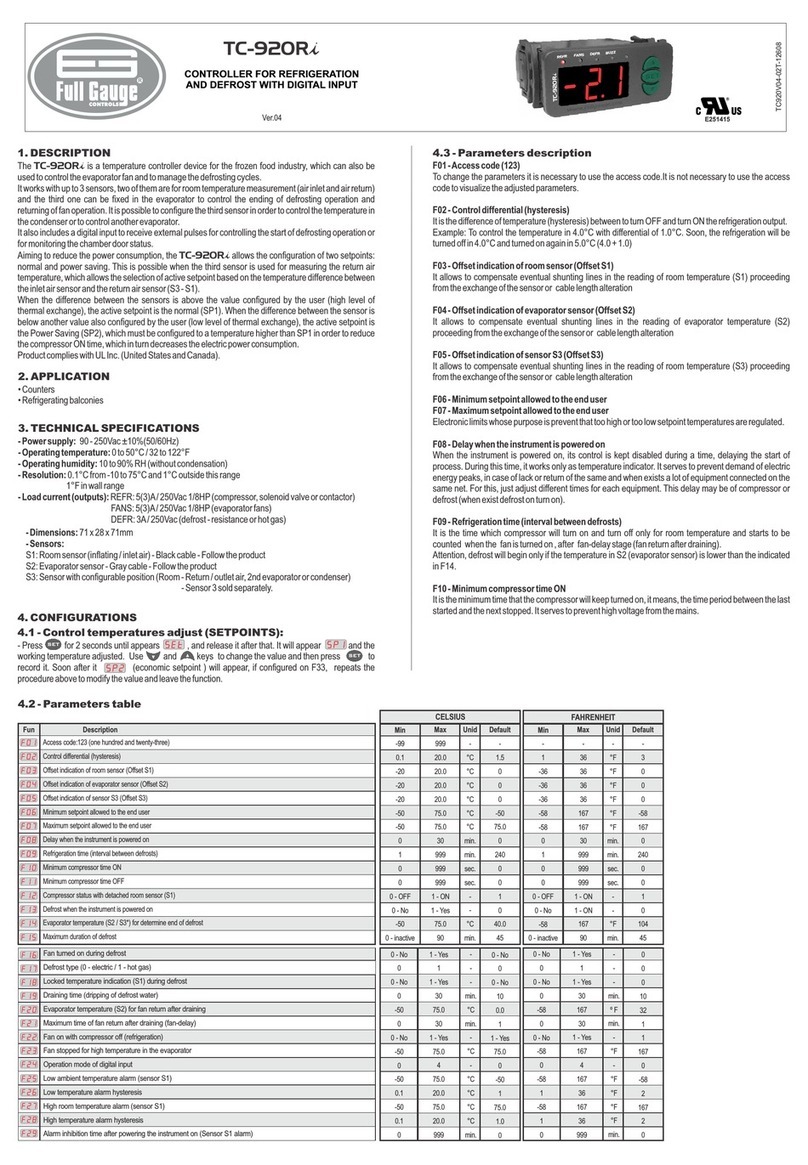

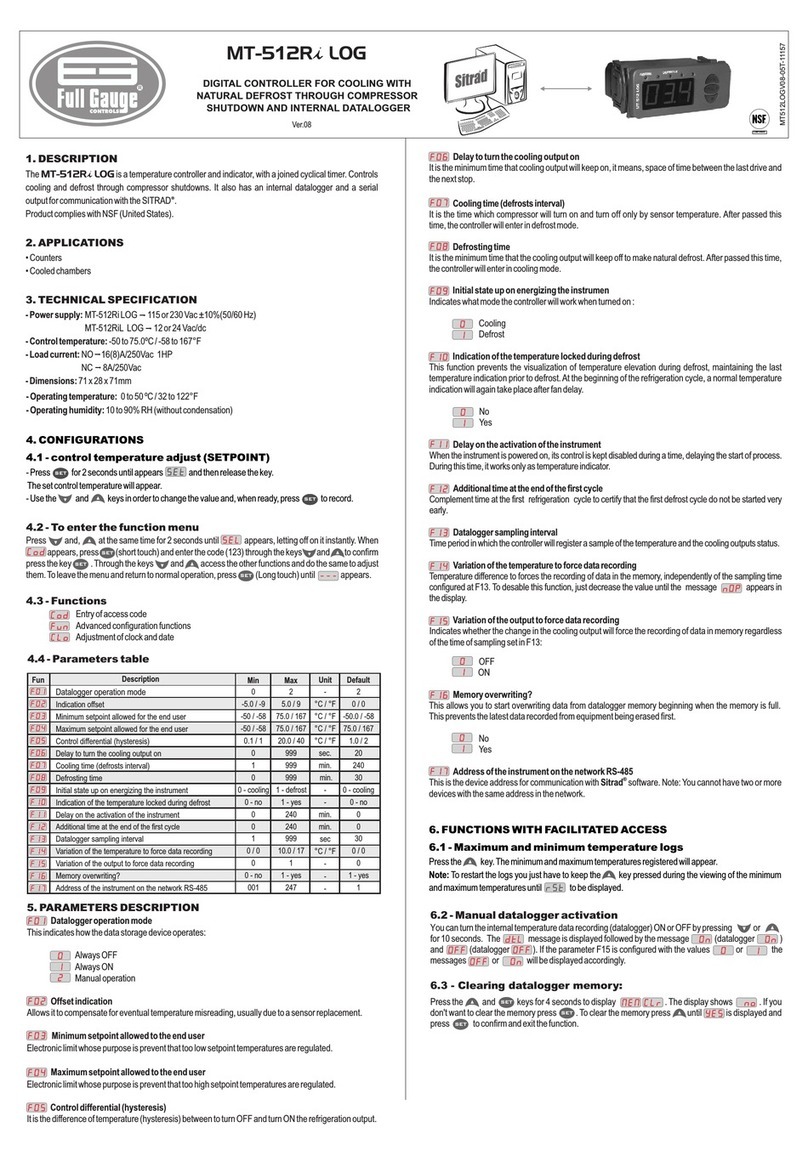

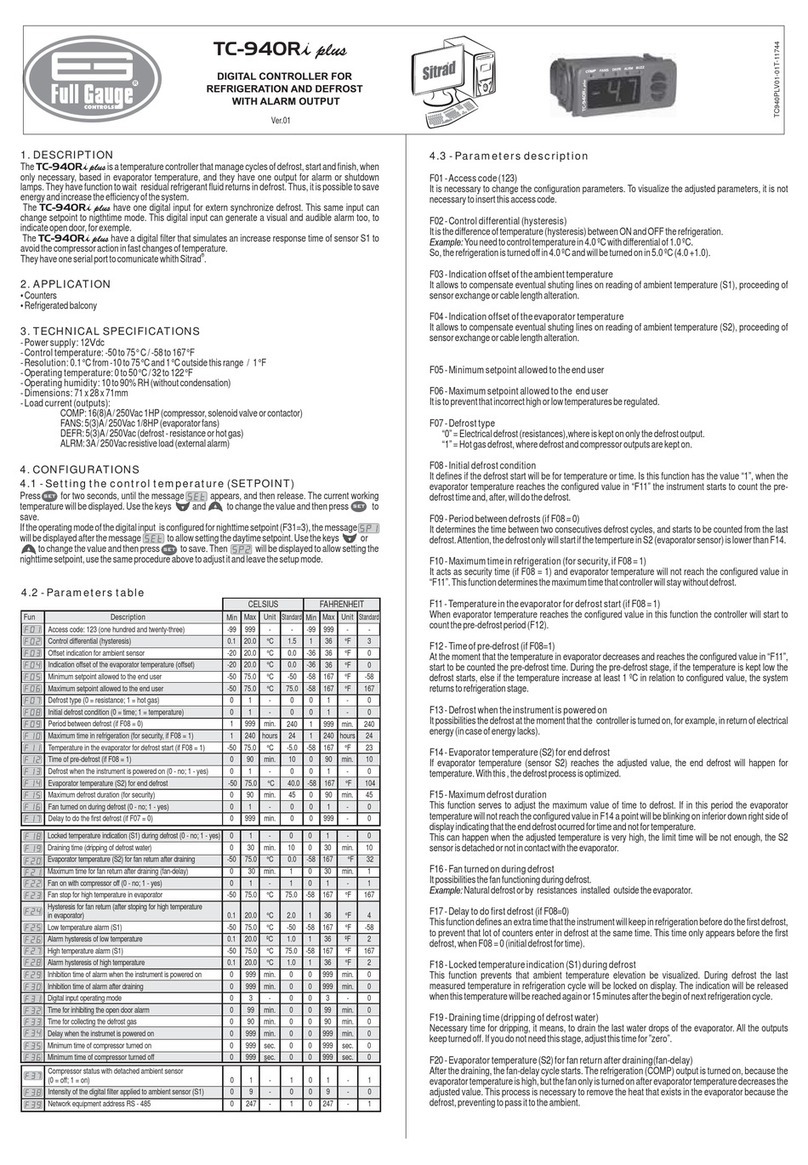

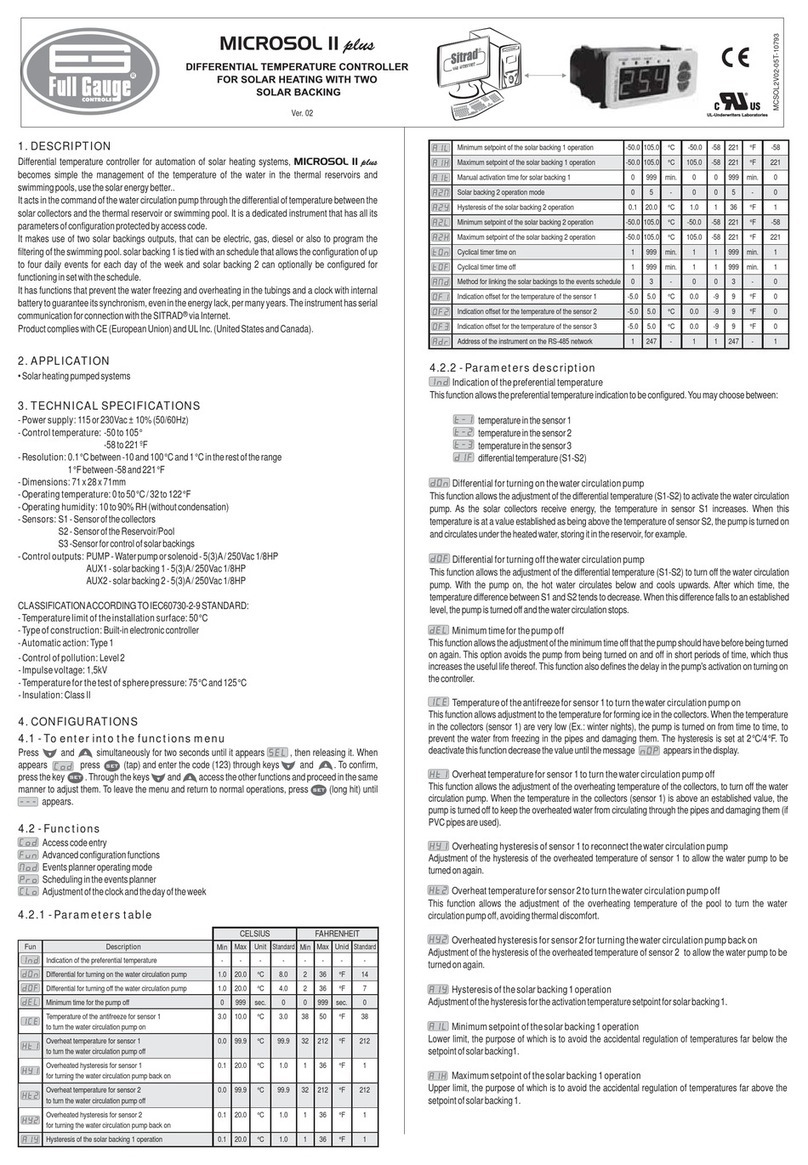

DescriptionFun Access code: 123 (one hundred and twenty three)

Temperature indication offset

Thermostat operating mode

Minimum setpoint allowed for the end user

Maximum setpoint allowed for the end user

Control temperature differential (hysteresis)

Delay for turning the compressor on

Cyclical timer´s time base

Cyclical timer´s on time

Cyclical timer´s off time

Initial state of cyclical timer

Cyclical timer always on when the compressor is on

Minimum working voltage (protection)

Maximum working voltage (protection)

Voltage indication offset

Voltage confirmation delay

Display indication mode

Equipment address in the RS-485 network

(1)

(2)

(3)

(3)

(3)

(4)

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

F13

F14

F15

F16

F17

F18

-

0.0°C / 0°F

0-cooling

4.0°C / 39°F

5.0°C / 41°F

1.0°C / 2°F

180 sec.

1-min.

3 sec./min.

12 sec./min.

1-on

1-yes

195 Volts

260 Volts

0 Volts

10 sec.

0

1

-

-5.0°C / -9°F

0-cooling

-50°C / -58°F

-50°C / -58°F

0.1°C / 1°F

0 sec.

0-sec.

1 sec./min.

1 sec./min.

0-off

0-no

90 Volts

90 Volts

-50 Volts

1 sec.

0

1

-

5.0°C / 9°F

1-heating

105°C/221°F

105°C/221°F

20.0°C / 36°F

999 sec.

1-min.

999 sec./min.

999 sec./min.

1-on

1-yes

260 Volts

260 Volts

50 Volts

30 sec.

2

247

4.2 - Parameters table

Minimum Maximum Default

(1)

(3)

(4)

F02-Temperatureindicationoffset

F12-Cyclicaltimeralwaysonwhenthecompressorison:

F13/F14/F16-Operationofthevoltagemonitor

F17-Displayindicationmode

The F02 functions allows for the correction of any changes in the reading, resulting from a change in the sensor or

alteration of the length of the cable.

This function works for some applications, as for example, on cooling tanks for milk, where the timer commands the

agitator that must remain on while cooling is taking place.

If the value of the voltage exceeds the limits set in F13 and F14 the compressor will be automatically turned off after the

time set in function F16 has lapsed.

The led “VOLTS” will slowly blink along with the Indication of the grid voltage on the display.

In the event that the voltage returns to the limits established, the compressor will only be turned on again after the time

scheduled in the F16 function has ended.

To deactivate the voltage monitoring, all you have to do is adjust functions F13 and F14 to the same value.

Function F17 allows you to choose the measurement that will be displayed during normal operation:

Temperature

Voltage

Temperature and voltage

(2)

4.3-Selectionof theunit (°C/ °F)

4.4-Parametersalteration

In order to define the temperature unit that the instrument will operate, enter the access code “231” in

thefunction .Theindication willappear.Press or tochoosebetween or

andconfirmwith .Afterselectingtheunittheindication willappearandtheinstrument

willreturntothefunction .Wheneverthetemperatureunitismodified,theparameters shouldbe

reconfigured,sincetheywillassumethedefaultvalues.

- Access function F01 by pressing the and keys at the same time for 2 seconds. When the

message appearsreleasethekeysandwaitforthe indication.

-Pressthe buttontoaccessthefunctionanduse and toenterthecode123.Whenready

pressagainthe buttontoconfirmthecodeandquitthefunctionF01.

- Select other functions by pressing or . To access the desired function press the key

quickly.

-Adjustthe function`snewvaluewiththe and keysandpress tosaveandreturnto the

functionsmenu.

- To exit the functions menu and return to normal operation press the button until the message

appearsonthedisplay.

SET

SET

SET

SET

SET

SET

5.FUNCTIONSWITHFACILITATED ACCESS

5.1-Minimumandmaximum logs

5.2-CyclicaltimerOn/Off statuschange

5.3-Cyclicaltimevisualization

5.4-Temperature,voltageandfrequencyvisualization

Pressand releasethe key quickly.The indication will appearfollowedbytheminimumand

maximum logged voltages. Shortly after the last voltage the indication will be shown and the

minimumandmaximumtemperatureswillbedisplayed.

toresettheminimumandmaximumlogsjustkeeppressingthe keyduringthevisualization

ofthelogs.Themessage willappearindicatingthesuccessfulloperation.

Tochangetheoutputofthecyclicaltimerfrom"on"to"off"orviceversajustpressthe keyuntilthe

appearsonthedisplay.

To visualize the current status (on/off) time that has already lapsed on the cyclical timer press

quickly.

Toconsultthevoltageandfrequencyoftheelectricalgridwhenthecontrollerisconfiguredtodisplaythe

temperaturejustpush the keyquickly.The current voltagevalue will bedisplayed followed bythe

frequencyindication andit`svalue.

To visualize the temperature while the controller is displaying the voltage press the key like

explainedabove.

Note:

SET

SET

6.SIGNALLING

Iftheinstrumentshows onthedisplayitmeansthataparameterisoutofacceptablerangeandit

mustbecorrected.

THERM-

VOLTS(alwayson)-

VOLTS(blinkingslowly)-

VOLTS(blinkingquickly)-

TIMER-

Thermostatoutputactive;

Indicatesthevoltagevisualization;

Indicatesvoltageinoutrangecondition;

Indicatesanerroronthevoltagemeasurement;

Cyclicaltimeroutputactive.

-Sensordisconnectedortemperatureoutofthespecifiedrange.

72 mm

29 mm

7. WIRING DIAGRAM

Note: The length of the cable for the sensor may be increased by the user up to 200 meters, using

PP2x24AWGcable.Forimmersioninwaterusethermometricwell.

1245678910 11 12

3

THERM

TIMER

AB

VOLTMETER

COMMON

Load 1 Load 2

0115V 230V

RS-485 serial

communication

Sensor

6-7

6-8 115V

230V

MT-516RVTi plus

- Belt

-Agitator

- Water ’pump

- Contact

Load 1 Load 2

Power

supply Loads

supply

VOLTMETER:

Connect the borne 9 to borne 7, when

the instrument is supplied in 115Vac or

borne 9 to borne 8, when the instrument

is in 230Vac.supplied

- Cooler

- Heater

- Contact

- Solenoid

Dimension of the clipping

for setting of the instrument

in panel