G

Ga

ag

ge

em

ma

ak

ke

er

r

P

Pi

iv

vo

ot

t

A

Ar

rm

m

G

Ga

ag

ge

e

C

CA

AL

L-

-P

PA

AK

K

F

Fi

ix

xt

tu

ur

re

e

M

Ma

an

nu

ua

al

l

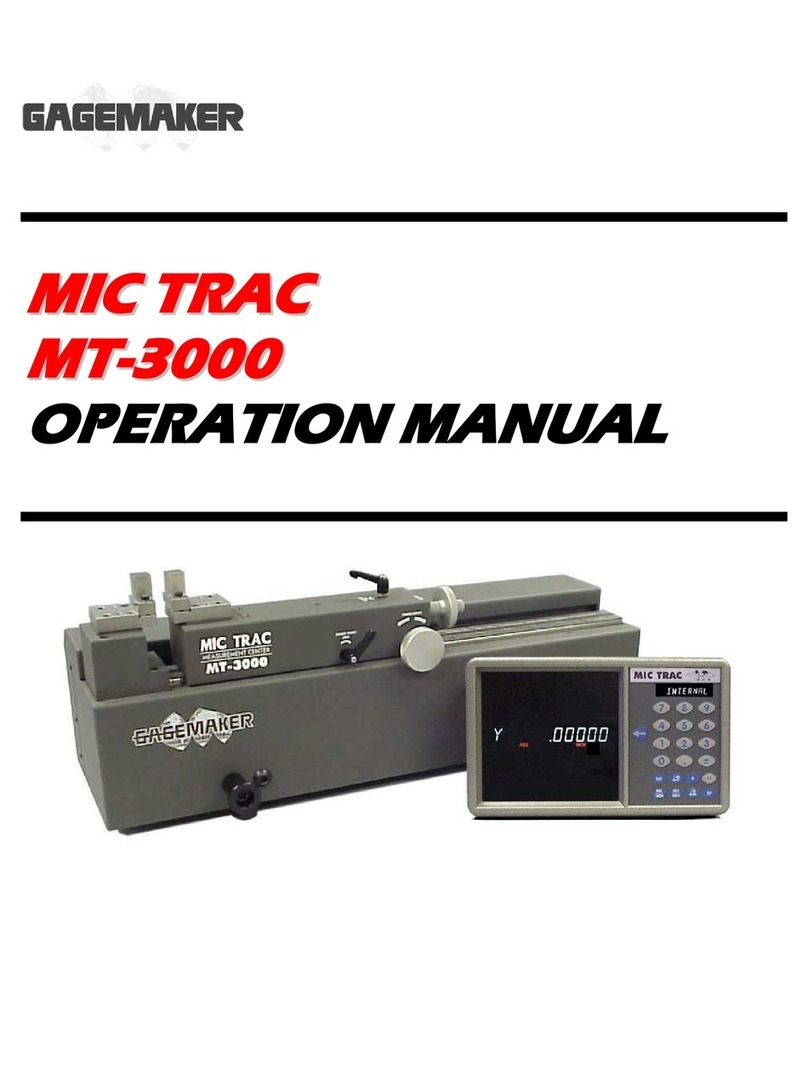

MIC TRAC MT-3000

4 2014 Gagemaker, Inc.

RCGPAMT30007-00

Materials Needed:

•MIC TRAC™ MT-3000 base unit •5/32" hex wrench

•Gagemaker pivot arm gage •30 in/lb torque wrench

•Pivot arm fixture (TF-VB Block) and cap screws •Cloth

•Contact point extension and contact point (certain gage styles) •ZEP I.D. Red cleaner

•Flat face anvil (TF-1F Block) and cap screws

1. Inspect the gage visually as follows:

•Check for damage and excessive wear.

•Check for clear bezel, legible dial face.

•Inspect for proper function of the bezel

adjustment and lock.

•Check for smoothness of travel by

depressing the indicator shaft throughout

the entire travel range. Any indicators with

restricted movement must be repaired prior

to calibration.

2. Clean both of the receiver pads and mounting

surfaces of the flat face anvil using the cloth

and ZEP I.D. Red cleaner.

3. Place the shoulder side of the flat face anvil

against the left receiver pad shoulder.

Inspecting different styles of pivot arm gages